Traceable adhesive tape and preparation method thereof

A tape and glue technology, which is applied in the direction of adhesives, adhesive types, film/sheet adhesives, etc., can solve the problems that cannot meet the needs of lithium batteries, the identification rate is not high, and the product identification rate is not high. Convenient for large-scale production, high identification success rate, and the effect of lithium battery electrolyte resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

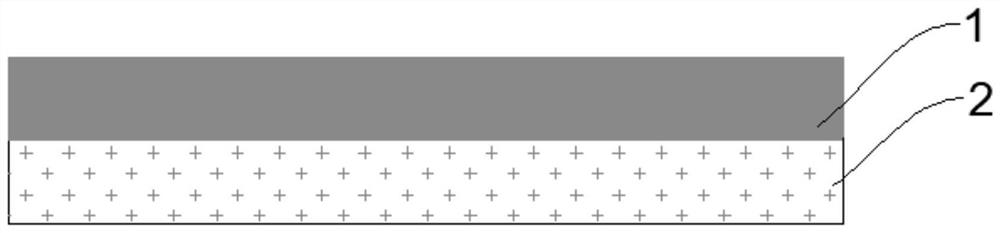

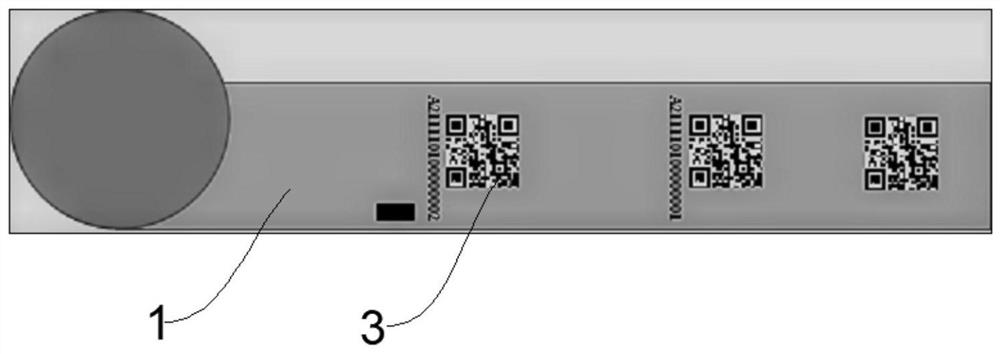

[0037] This embodiment provides a kind of traceable adhesive tape, the specific structure is as follows figure 1 and figure 2 As shown, it includes a light-permeable substrate 1 and an adhesive layer 2 arranged in sequence. A two-dimensional code 3 is arranged on the corona surface of the light-permeable substrate 1 .

[0038] The light-permeable substrate 1 is a PET film with a thickness of 16 μm. The PET film is a single-sided corona surface, and a two-dimensional code 3 is arranged on the corona surface. The adhesive layer 2 is composited with the adhesive tape along the longitudinal direction, and is arranged on the two-dimensional code 3. The thickness of the adhesive layer 3 is 10 μm. The light transmittance of the light-transmitting substrate is 90%

[0039] The formula for preparing the adhesive layer 3 is: calculated in parts by weight, including 100 parts of polyurethane glue, 100 parts of acrylate glue, 4 parts of isocyanate curing agent, and 50 parts of organic...

Embodiment 2

[0045] This embodiment provides a kind of traceable adhesive tape, the specific structure is as follows figure 1 and figure 2 As shown, it includes a light-permeable substrate 1 and an adhesive layer 2 arranged in sequence. A two-dimensional code 3 is arranged on the corona surface of the light-permeable substrate 1 .

[0046] The light-transmissible substrate 1 is a PC film with a thickness of 6 μm. The PC film is a single-sided corona surface, and a two-dimensional code 3 is arranged on the corona surface. The adhesive layer 2 is composited with the tape along the longitudinal direction, and is arranged on the two-dimensional code 3. The thickness of the adhesive layer 2 is 50 μm.

[0047] The formula for preparing the adhesive layer is: calculated in parts by weight, including 100 parts of polyurethane glue, 120 parts of acrylate glue, 5 parts of aziridine curing agent, and 80 parts of inorganic pigment.

[0048] The preparation process of the traceable adhesive tape pr...

Embodiment 3

[0053] This embodiment provides a kind of traceable adhesive tape, the specific structure is as follows figure 1 and figure 2 As shown, it includes a light-permeable substrate 1 and an adhesive layer 2 arranged in sequence. A two-dimensional code 3 is arranged on the corona surface of the light-permeable substrate 1 .

[0054] The light-transmitting substrate 1 is a PPS film with a thickness of 100 μm. The PPS film is a single-sided corona surface, and a two-dimensional code 3 is arranged on the corona surface. The adhesive layer 2 is composited with the tape along the longitudinal direction, and is arranged on the two-dimensional code 3. The thickness of the adhesive layer 2 is 2 μm.

[0055] The formula for preparing the adhesive layer is: calculated in parts by weight, including 110 parts of polyurethane glue: 100 parts of acrylate glue, 4.5 parts of isocyanate curing agent, and 60 parts of organic pigment.

[0056] The preparation process of the traceable adhesive tape...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com