Diaphragm for lithium-ion battery and lithium-ion battery containing diaphragm

A lithium-ion battery and diaphragm technology, applied in secondary batteries, battery pack components, circuits, etc., can solve problems such as blockage of the separator, affecting battery performance, and plugging holes, and achieve the effect of solving deformation and improving battery performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Preparation of positive electrode sheet:

[0034] Lithium cobaltate, conductive carbon, and binder polyvinylidene fluoride were mixed uniformly in N-methylpyrrolidone (NMP) solvent at a mass ratio of 97:1.2:1.8 to make positive electrode slurry, which was then coated on aluminum foil and placed on After drying at 110°C, cold pressing, slitting, trimming, and tab welding are carried out to make positive plates.

[0035] Preparation of negative electrode sheet:

[0036] Mix graphite, conductive carbon, thickener sodium carboxymethyl cellulose, and binder styrene-butadiene rubber in deionized water at a mass ratio of 96:2.0:1.0:1.0 to make negative electrode slurry, and then coat it on copper foil After being dried at 85°C, cold pressing, slitting, trimming, and tab welding are carried out to make negative electrodes.

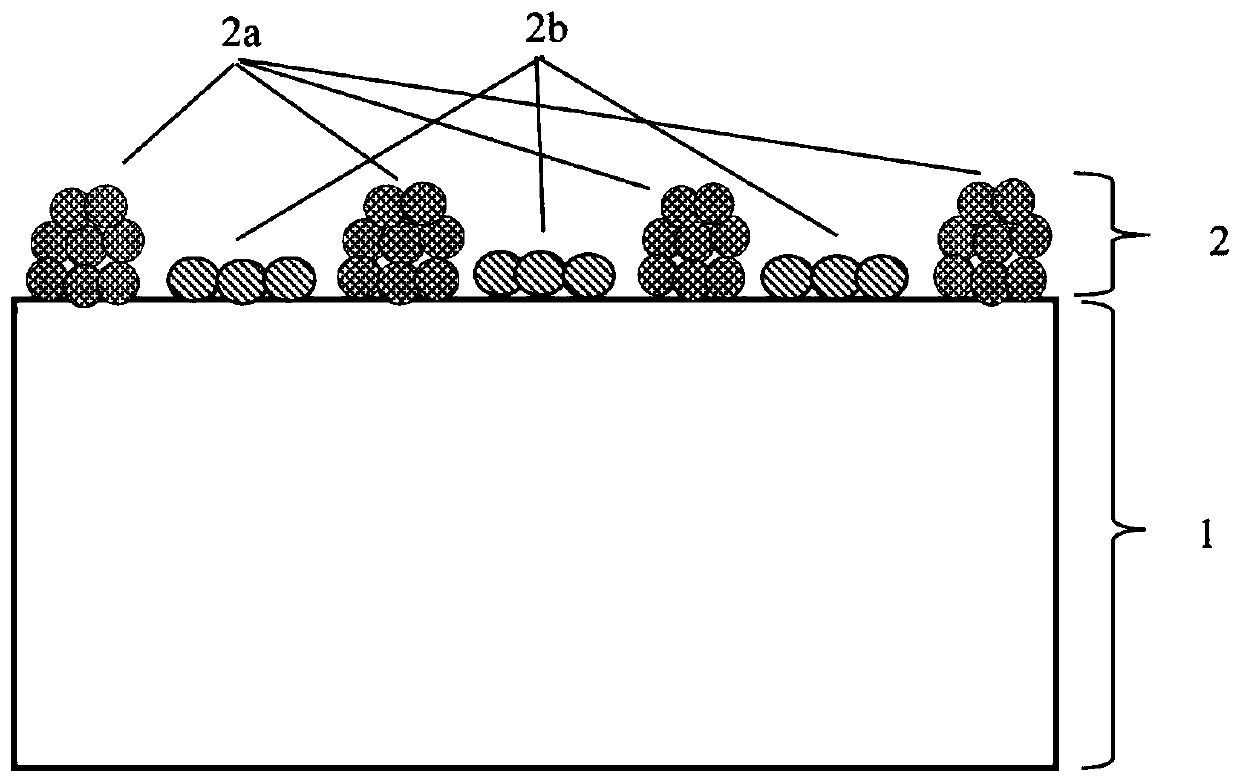

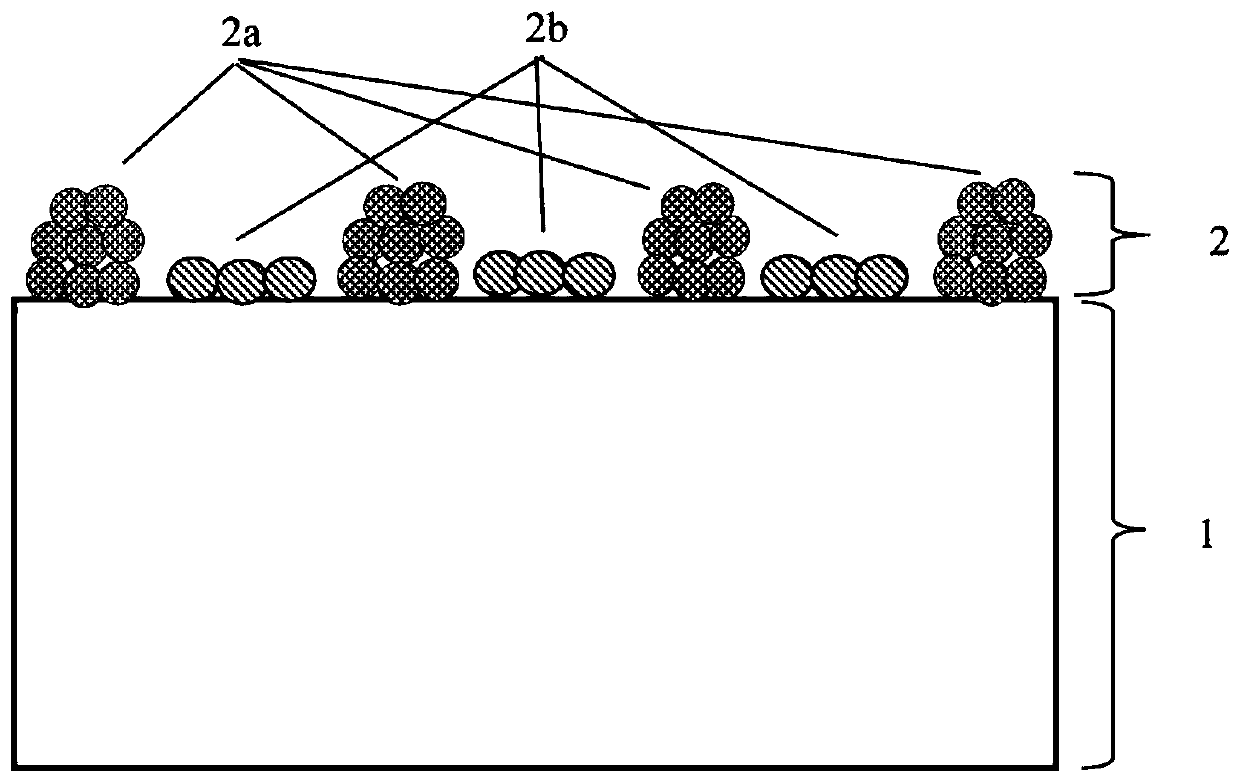

[0037] Preparation of diaphragm:

[0038] 1) Take a polypropylene microporous film with a thickness of 16 μm as the diaphragm body;

[0039] 2) Stir po...

Embodiment 2

[0043] The difference between this embodiment and Example 1 is the preparation of diaphragm:

[0044] 1) Take a polypropylene microporous film with a thickness of 16 μm as the diaphragm body;

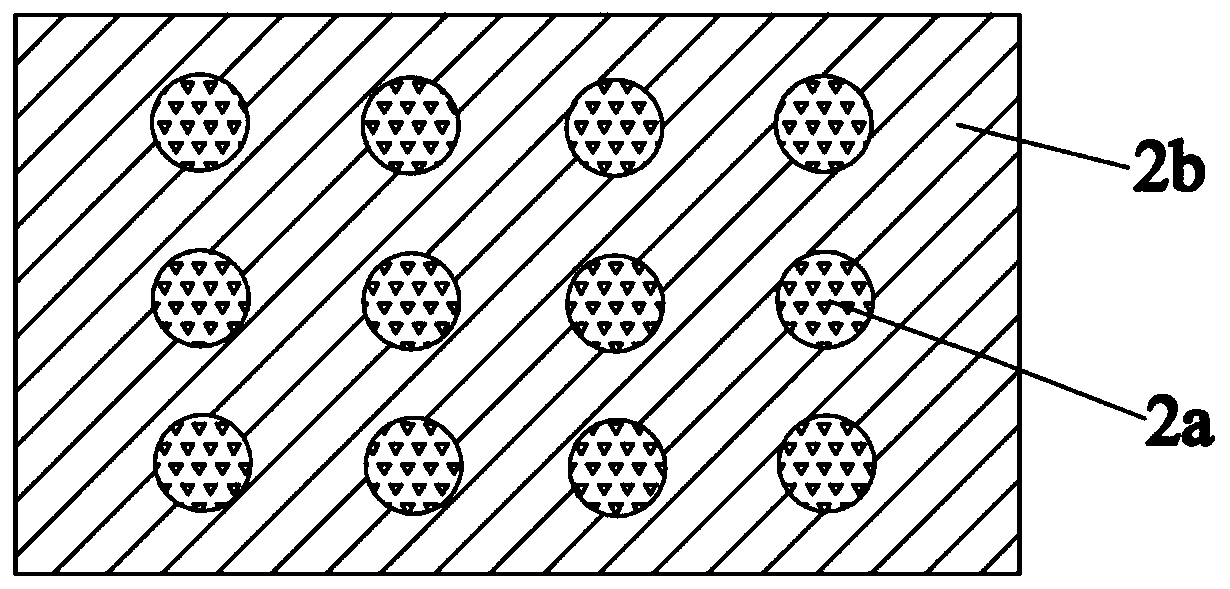

[0045] 2) Stir polyvinylidene fluoride-hexafluoropropylene (with a particle size distribution range of 1.0-5.0 μm) and polyacrylonitrile (with a particle size distribution range of 0.1-0.4 μm) in a polyacrylic acid solution in deionized water, and polyvinylidene fluoride The weight ratio of vinyl fluoride-hexafluoropropylene: polyacrylonitrile: polyacrylic acid is 10:80:10, and the slurry prepared after stirring for 4 hours has a solid content of 20%, and then the prepared slurry is uniformly prepared by gravure coating The coating forms a functional coating on one side of the diaphragm body, and finally cuts it into pieces. Among them, the thickness of the functional coating is 4 μm, the forward projection area of the functional coating accounts for 80% of the forward projection are...

Embodiment 3

[0048] The difference between this embodiment and Example 1 is the preparation of diaphragm:

[0049] 1) Take a polypropylene microporous film with a thickness of 16 μm as the diaphragm body;

[0050] 2) Stir polyacrylonitrile (particle size distribution range of 6.0-10.0 μm) and polyoxyethylene (particle size distribution range of 0.2-0.5 μm) in polyvinylidene fluoride solution in deionized water, polyacrylonitrile: poly The weight ratio of oxyethylene: polyvinylidene fluoride is 15:75:10, and the slurry prepared after stirring for 4 hours has a solid content of 20%, and then the prepared slurry is evenly coated on the diaphragm body by gravure coating A functional coating is formed on one side, and finally cut into pieces. Among them, the thickness of the functional coating is 8 μm, the forward projection area of the functional coating accounts for 75% of the forward projection area of the diaphragm body, and the area distribution ratio of the support area and the bondi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size distribution range | aaaaa | aaaaa |

| Particle size distribution range | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com