Parts and component made from Nano plastic alloy for watering apparatus, and preparing method

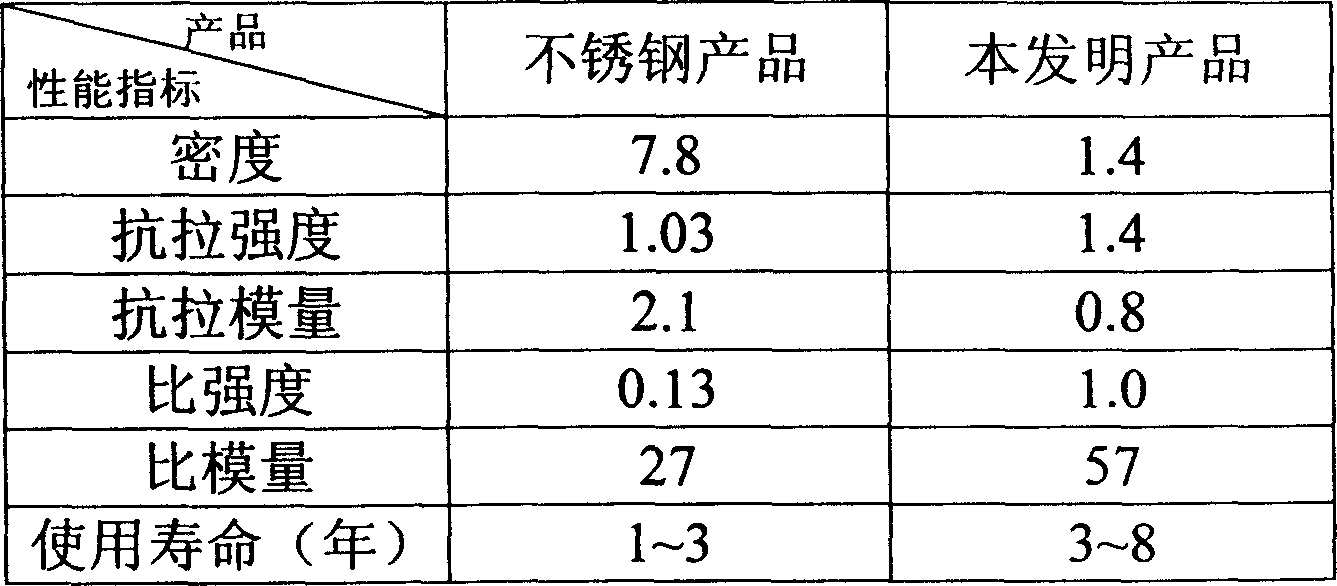

A technology of nano-plastics and parts, applied in the field of water-machine nano-plastic alloy parts and their preparation, can solve the problem of low bonding strength between soft coating and base material, difficulty in exerting anti-wear, anti-cavitation, and base material of parts and components. Problems such as poor combination, to achieve the effect of strong machinability, low weight, and improved cavitation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1 Preparation of a water turbine bottom ring wear plate with a diameter of 1400 mm and a thickness of 30 mm

[0033] Specific steps are as follows:

[0034] (1). The total weight of the sample is 100 kg, and it is accurately weighed according to the following weight ratio: 25 kg of carbon steel skeleton, 10 kg of aramid mesh fabric reinforcement, 12 kg of aramid staple fiber, and 8 kg of nano-silica , 10 kilograms of nylon 6 powder, 5 kilograms of polytetrafluoroethylene powder, 30 kilograms of epoxy resin slurry, epoxy resin slurry consists of epoxy resin E-44, curing agent methyltetrahydrophthalic anhydride, The diluent (butyl glycidyl ether) is mixed and prepared according to the weight ratio of 1:2:1, that is, 10 kg of epoxy resin E-44, 20 kg of methyl tetrahydrophthalic anhydride, and 10 kg of butyl glycidyl ether , Only 30 kg of the prepared epoxy resin slurry is used.

[0035] (2). Dry the aramid staple fiber in an oven at 90°C for 3 hours and set it as...

Embodiment 2

[0044] Preparation of runner chamber wear sleeves with a diameter of 1248 mm

[0045] Specific steps are as follows:

[0046] (1). The total weight of the sample is 70 kg, and it is accurately weighed according to the following weight ratio: 17.5 kg of carbon steel skeleton, 7 kg of aramid mesh fabric reinforcement, 7 kg of aramid staple fiber, and nano-silica powder 3.5 kg, 5.6 kg of nylon 66 powder, 5.6 kg of polytetrafluoroethylene powder, 23.8 kg of epoxy resin slurry, epoxy resin slurry consists of epoxy resin E-44, curing agent methyltetrahydrophthalo Acid anhydride and diluent (phenyl glycidyl ether) are mixed and prepared according to the weight ratio of 1:1:1, that is, 449 kg of epoxy resin E-449 kg, 9 kg of methyl tetrahydrophthalic anhydride, and phenyl glycidyl ether 9 kilograms, while only 23.8 kilograms are used when the prepared epoxy resin slurry is used.

[0047](2). Dry the aramid staple fiber in an oven at 120°C for 3 hours;

[0048] (3). Put the nano-pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com