Air electrode and preparation method thereof

An air electrode and mixture technology, applied in the field of electrochemistry, can solve the problems of shortening the battery cycle life, separating the waterproof layer from the catalytic layer, reducing the effective discharge area and reducing the battery discharge capacity and capacity, etc., so as to improve the service life and not easy to separate , the effect of solid connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

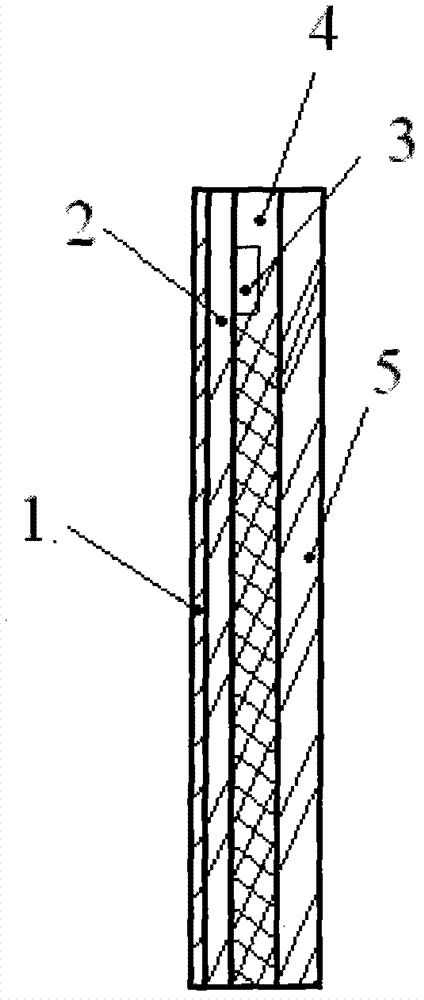

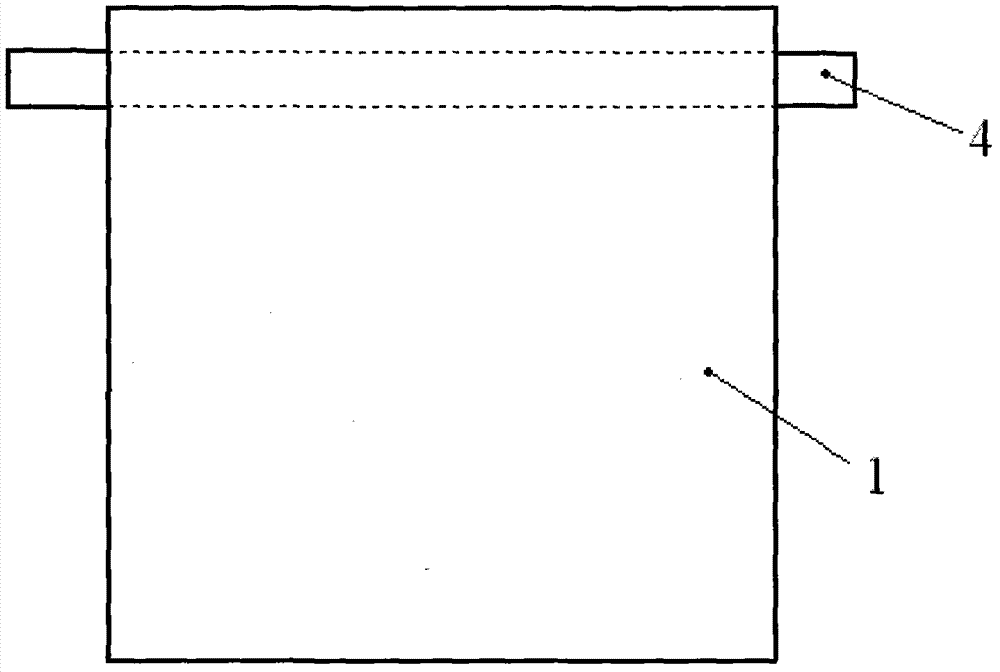

[0035] like figure 1 , figure 2 As shown, the air electrode of this embodiment includes a catalytic layer 1, a first waterproof carbon powder layer 2, a current collector layer 4 and a second waterproof carbon powder layer 5 that are sequentially bonded by thermocompression, and the current collector layer 4 is provided with One lead out the tab 3 .

[0036] The preparation method of the air electrode in this embodiment is as follows:

[0037] a. Preparation of waterproof carbon powder

[0038] 11) Mix acetylene black (Jiaozuo Hexing Chemical Industry Co., Ltd., model: 50% compression acetylene black) with high-density low-pressure polyethylene (the Second Auxiliary Factory of Beijing Dongfang Petrochemical Co., Ltd., model: LD0020 (30 mesh)) Mix with kerosene in a ratio of 7:1:15 by weight;

[0039] 12) Heat the mixture obtained in step 11) to 100°C with a heater, and keep stirring the mixture, stop heating after 1 hour, continue stirring for 20 minutes, and then cool to...

Embodiment 2

[0051] The air electrode of this embodiment includes a catalytic layer 1, a first waterproof carbon powder layer 2, a current collector layer 4 and a second waterproof carbon powder layer 5 that are hot-pressed and bonded in sequence, and the current collector layer 4 is provided with two Lead out the tab 3.

[0052] The preparation method of the air electrode in this embodiment is as follows:

[0053] a. Preparation of waterproof carbon powder

[0054] 11) Mix acetylene black (Jiaozuo Hexing Chemical Industry Co., Ltd., model: 50% compression acetylene black) with high-density low-pressure polyethylene (the Second Auxiliary Factory of Beijing Dongfang Petrochemical Co., Ltd., model: LD0020 (30 mesh)) Mix with kerosene in a ratio of 6:1:20 by weight;

[0055] 12) Heat the mixture obtained in step 11) to 90°C with a heater, and keep stirring the mixture, stop heating after 1 hour, continue stirring for 20 minutes, and then cool to ambient temperature at room temperature;

[...

Embodiment 3

[0067] The air electrode of this embodiment includes a catalytic layer 1, a first waterproof carbon powder layer 2, a current collector layer 4 and a second waterproof carbon powder layer 5 that are hot-pressed and bonded in sequence, and the current collector layer 4 is provided with two Lead out the tab 3.

[0068] The preparation method of the air electrode in this embodiment is as follows:

[0069] a. Preparation of waterproof carbon powder

[0070] 11) Mix acetylene black (Jiaozuo Hexing Chemical Industry Co., Ltd., model: 50% compression acetylene black) with high-density low-pressure polyethylene (the Second Auxiliary Factory of Beijing Dongfang Petrochemical Co., Ltd., model: LD0020 (30 mesh)) Mix with kerosene in a ratio of 8:1:10 by weight;

[0071] 12) Heat the mixture obtained in step 11) to 145°C with a heater, keep stirring the mixture, stop heating after 1 hour, continue stirring for 20 minutes, and then cool to ambient temperature at room temperature;

[007...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com