Bonding method of powder metallurgy iron-based friction material layer and steel backing and bonding material

A friction material and powder metallurgy technology, applied in the field of materials, can solve the problem of inability to achieve high-strength connection between iron-based powder metallurgy materials and steel backs, and achieve the effects of promoting bonding, improving shear strength and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

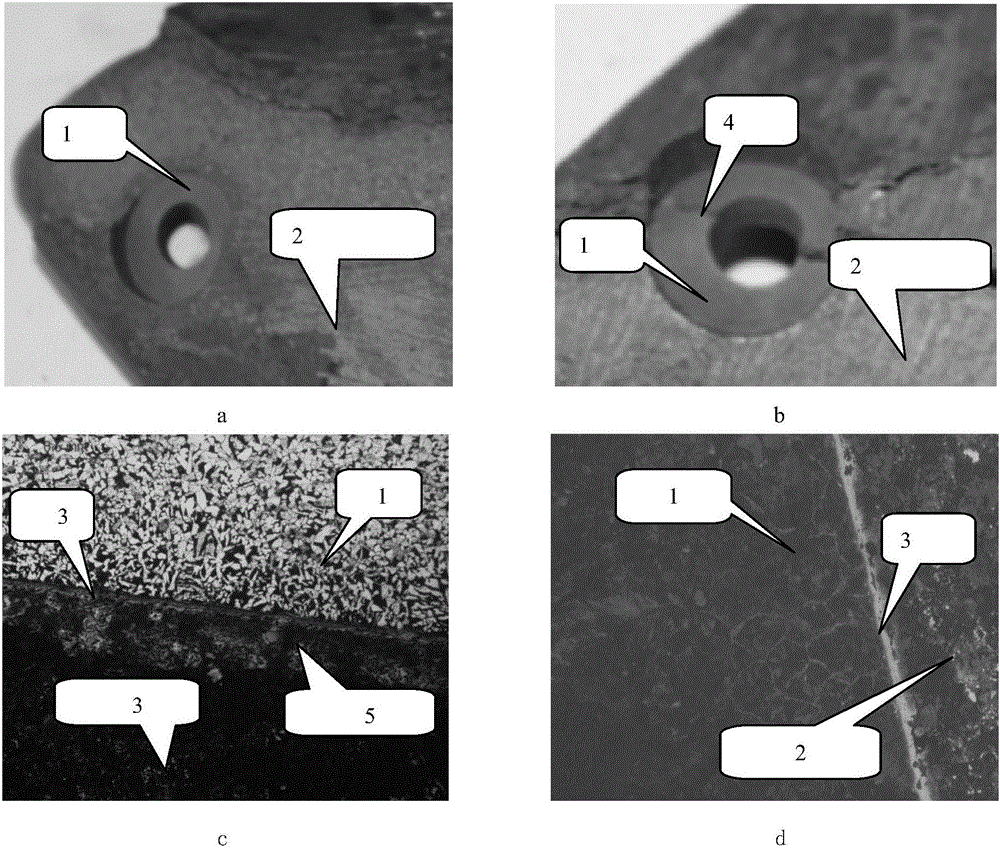

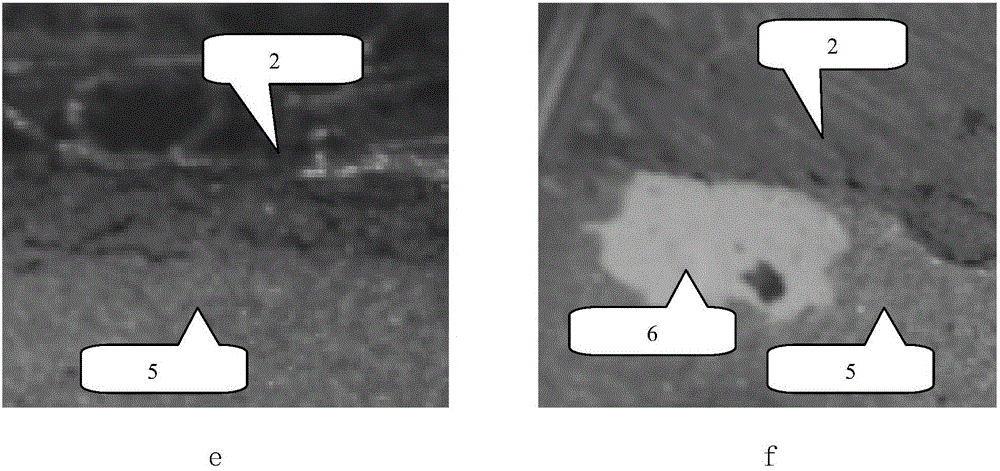

[0051] The invention relates to a bonding material for bonding a powder metallurgy iron-based friction material layer and a steel back.

[0052] The present invention specifically describes the implementation process of the present invention through 8 embodiments.

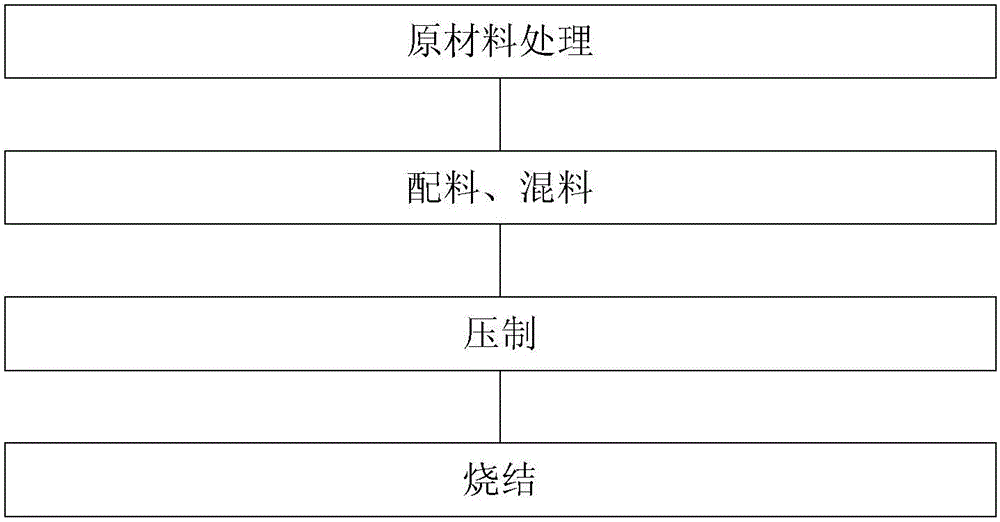

[0053] The specific process of bonding the powder metallurgy iron-based friction material layer and the steel back proposed by the present invention is:

[0054] Step 1. Raw material processing:

[0055] (1) Reduction: Reduce the iron powder and copper powder under the protection of hydrogen atmosphere to eliminate the oxygen content and work hardening phenomenon in the metal powder. The reduction temperature of the iron powder is 600-700°C, and the reduction temperature of the copper powder is 350-450°C. The heat preservation time in the reduction is 2 to 3 hours.

[0056] (2) Ball milling: put the reduced iron powder and copper powder into a ball mill for ball milling; the iron powder ball milling time is 0.5-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com