Method for preparing hydrogen-containing diamond-like carbon film

A technology of diamond-like carbon film and hydrogen gas is applied in the field of preparation of hydrogen-containing diamond-like carbon film, which can solve the problems of difficulty in practical application and low growth rate, and achieve the effect of an effective preparation method and increasing growth rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 1) Substrate pretreatment: standard cleaning is carried out on the quartz wafers used for the preparation of hydrogen-containing diamond-like films. Ultrasonic cleaning for 10 minutes with a numerically controlled ultrasonic cleaner, followed by rinsing the quartz slices with hot and cold deionized water for 10 minutes, and drying the quartz slices with a nitrogen gun. Then, the dried quartz slices were soaked in chromic acid solution for more than 12h. After taking out the quartz plate from the chromic acid, rinse it with hot and cold deionized water for 15 minutes respectively, and dry it with a nitrogen gun. Finally, the cleaned quartz wafer substrate was baked in a vacuum oven at 120° C. for 30 minutes, and then used.

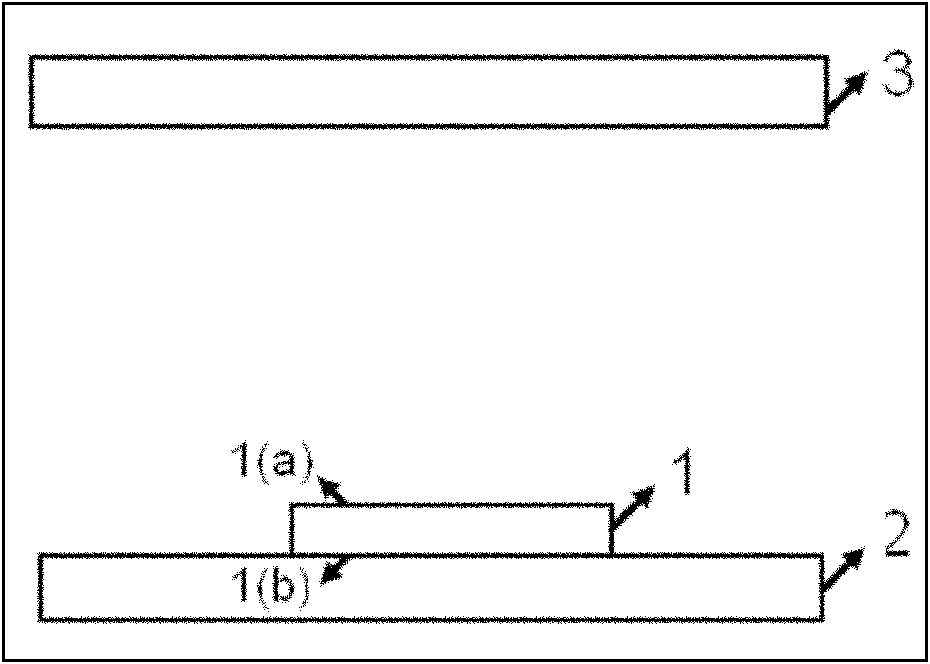

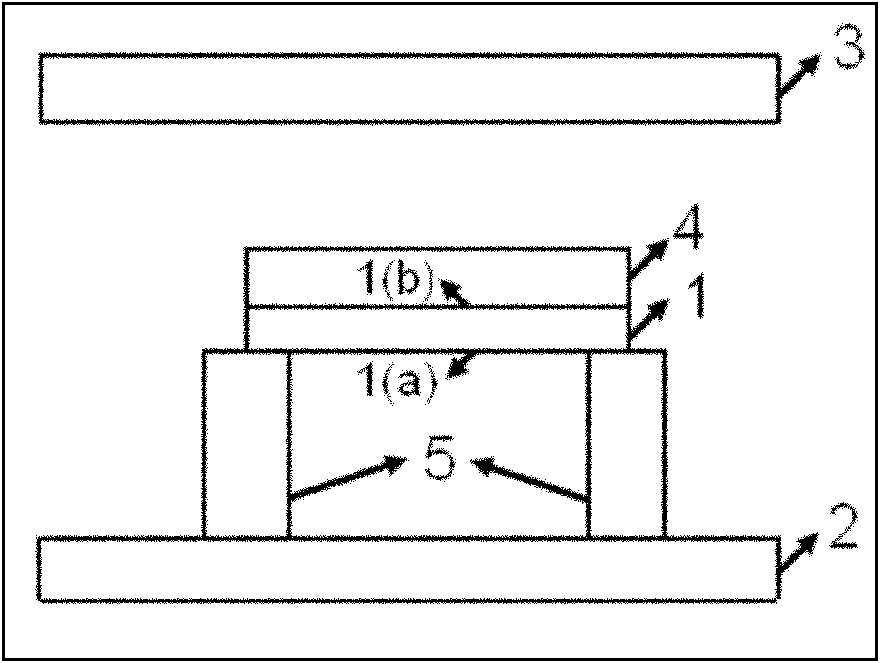

[0038] 2) Substrate antiparallel placement: In the plasma-enhanced chemical vapor deposition growth chamber, put a quartz sample holder with a height of 1.0 cm, and then place the cleaned quartz wafer substrate on the glass sample stage in reverse ...

Embodiment 2

[0047] 1) Substrate pretreatment: the treatment process is the same as in Example 1;

[0048] 2) The substrate is placed in reverse: in the plasma-enhanced chemical vapor deposition growth chamber, a quartz sample holder with a height of 1.5 cm is placed, and then the cleaned quartz wafer substrate is placed on the glass sample stage in reverse, And an insulating masking sheet is covered on the back of the substrate, so that the front of the substrate used for growing the hydrogen-containing diamond-like film faces the source electrode.

[0049] 3) Use plasma sputtering to clean the growth chamber and the surface of the substrate: the oxygen flow rate of 60 sccm is passed into the plasma-enhanced chemical vapor deposition growth chamber, and plasma gas is formed after glow discharge, which is beneficial to the plasma-enhanced chemical vapor deposition. The chemical vapor deposition growth chamber and the surface of the substrate are cleaned by sputtering. During the cleaning ...

Embodiment 3

[0054] 1) Substrate pretreatment: Bottom pretreatment: The treatment process is the same as that in Embodiment 1.

[0055] 2) The substrate is placed in reverse: in the plasma-enhanced chemical vapor deposition growth chamber, a quartz sample holder with a height of 2.5 cm is placed, and then the cleaned quartz wafer substrate is placed on the glass sample stage in reverse, And an insulating masking sheet is covered on the back of the substrate, so that the front of the substrate used for growing the hydrogen-containing diamond-like film faces the source electrode.

[0056] 3) Use plasma sputtering to clean the growth chamber and the surface of the substrate: the flow rate of 80sccm oxygen is passed into the plasma-enhanced chemical vapor deposition growth chamber, and plasma gas is formed after glow discharge, which is beneficial to the plasma-enhanced chemical vapor deposition. The chemical vapor deposition growth chamber and the surface of the substrate are cleaned by sputt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com