Low-cost on-line reinforcement method of aluminosilicate glass

An aluminosilicate glass, low-cost technology, applied in the direction of glass tempering, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of low production cost, achieve the effect of low working temperature, reduce investment cost and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

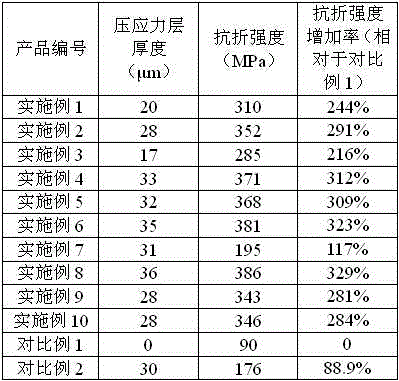

Examples

Embodiment 1

[0037] Prepare raw materials according to the following composition ratio: SiO 2 65%, Al 2 o 3 13%, CaO 1%, MgO 4%, Na 2 O 15%, K 2 O 1.6%, Sb 2 o 3 0.4%.

[0038] The glass raw materials enter the annealing kiln after mixing, melting and forming. The temperature system of the annealing kiln is: the inlet temperature of the pre-annealing zone is 660°C, the inlet temperature of the annealing zone is 610°C, the inlet temperature of the slow cooling zone is 510°C, and the inlet temperature of the forced cooling zone The temperature is 360°C, and the inlet temperature of the natural cooling zone is 260°C. In this embodiment, a pair of high-temperature spraying devices are installed in the area of 480°C in the slow cooling zone, and the high-temperature spraying device is equipped with 480°C KNO 3 Molten salt, high temperature spraying device will KNO 3 The molten salt is atomized and evenly sprayed on both sides of the glass. During the spraying process, the temperat...

Embodiment 2

[0040] Prepare raw materials according to the following composition ratio: SiO 2 65%, Al 2 o 3 13%, CaO 1%, MgO 4%, Na 2 O 15%, K 2 O 1.6%, Sb 2 o 3 0.4%.

[0041] The glass raw materials enter the annealing kiln after mixing, melting and forming. The temperature system of the annealing kiln is: the inlet temperature of the pre-annealing zone is 660°C, the inlet temperature of the annealing zone is 610°C, the inlet temperature of the slow cooling zone is 510°C, and the inlet temperature of the forced cooling zone The temperature is 360°C, and the inlet temperature of the natural cooling zone is 260°C. In this embodiment, a pair of high-temperature spraying devices are installed in the area of 435°C in the slow cooling zone, and KNO at 435°C is installed in the high-temperature spraying device. 3 Molten salt, high temperature spraying device will KNO 3 The molten salt is atomized and evenly sprayed on both sides of the glass. During the spraying process, the tempera...

Embodiment 3

[0043] Prepare raw materials according to the following composition ratio: SiO 2 65%, Al 2 o 3 13%, CaO 1%, MgO 4%, Na 2 O 15%, K 2 O 1.6%, Sb 2 o 3 0.4%.

[0044] The glass raw materials enter the annealing kiln after mixing, melting and forming. The temperature system of the annealing kiln is: the inlet temperature of the pre-annealing zone is 660°C, the inlet temperature of the annealing zone is 610°C, the inlet temperature of the slow cooling zone is 510°C, and the inlet temperature of the forced cooling zone The temperature is 360°C, and the inlet temperature of the natural cooling zone is 260°C. In this embodiment, a pair of high-temperature spraying devices are installed in the area of 390°C in the slow cooling zone, and the high-temperature spraying device is equipped with 390°C KNO 3 Molten salt, high temperature spraying device will KNO 3 The molten salt is atomized and evenly sprayed on both sides of the glass. During the spraying process, the temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com