Manufacturing method of all-printed electronic carbon dioxide thin-film SAW (Surface Acoustic Wave) sensor

A carbon dioxide, gas thin film technology, applied in the direction of using material absorption and weighing, can solve the problems of complex process and high cost of gas thin film SAW sensor, and achieve the effect of material saving, accurate sensing function and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The specific implementation steps are as follows:

[0030] 1. Selection of piezoelectric substrate: ST-cut quartz with a temperature coefficient of zero is selected as the piezoelectric substrate in the present invention.

[0031] The ST-cut quartz substrate with zero temperature coefficient prevents the influence of temperature on the measurement. Its wave velocity is 3159m / s; the electromechanical coupling coefficient is 0.16%. In order to reduce unnecessary loss during SAW transmission, it is necessary to grind, clean and polish the surface of the substrate.

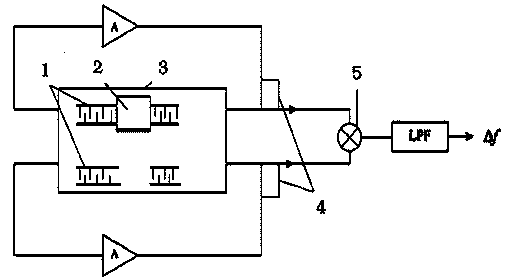

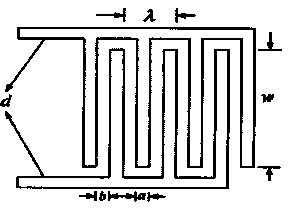

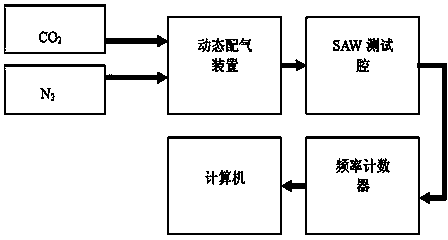

[0032] 2. Electrode design and printing: The present invention uses a dual-channel delay line structure and a uniform interdigitated electrode structure. In the dual-channel structure, the SAW propagation path of one channel is not processed for reference and comparison; while in the other A sensitive film is printed on the channel to detect gas, and finally the two signals are output through the mixer. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electromechanical coupling coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com