Lithium lanthanum zirconium oxide solid electrolyte, preparation method thereof and lithium ion battery

A solid electrolyte, lithium lanthanum zirconium oxide technology, applied in secondary batteries, circuits, electrical components and other directions, can solve the problems of complex preparation methods, high cost, inability to have both electrochemical properties and mechanical properties, and achieve easy availability of raw materials. , low cost, the effect of optimizing interface compatibility and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The lithium lanthanum zirconium oxide solid electrolyte is composed of: 63.56wt% polymer, 10.24wt% lithium salt and 26.20wt% lithium lanthanum zirconium oxide three-dimensional porous inorganic network.

[0036] S1. Preparation of lithium lanthanum zirconium oxygen precursor solution: dissolve 0.9526g lithium nitrate, 2.598g lanthanum nitrate hexahydrate, 0.924g zirconyl nitrate, 0.18g aluminum nitrate nonahydrate in 25mL deionized water, stir at room temperature for 3 hours, get Li 6.28 La 3 Zr 2 al 0.24 o 12 The precursor solution;

[0037] S2, the area is 400cm 2 Dust-free paper cut into 5×5cm 2After that, completely immerse in the lithium lanthanum zirconium oxide precursor solution for 6 hours, and dry the template at 70°C after soaking;

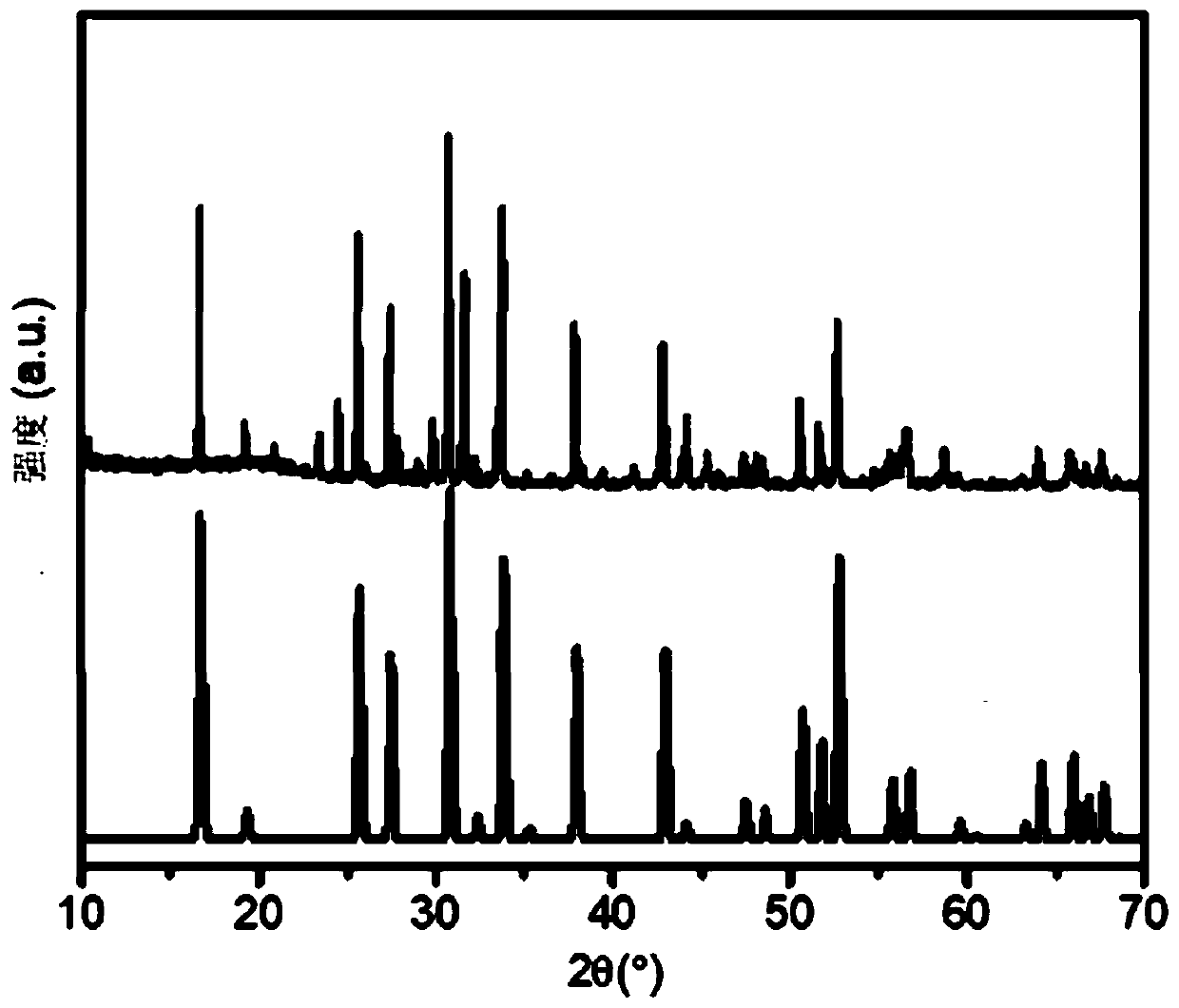

[0038] S3, the dried 5 × 5cm 2 The dust-free paper was heat-treated in a muffle furnace at 850°C for 2 hours, and the heating rate was 5°C / min to obtain a three-dimensional porous inorganic network of lithium lanthanum zi...

Embodiment 2

[0048] The lithium lanthanum zirconium oxygen solid electrolyte is composed of: 75wt% polymer, 10wt% lithium salt and 15wt% lithium lanthanum zirconium oxide three-dimensional porous inorganic network.

[0049] The lithium lanthanum zirconium oxygen solid electrolyte was prepared according to the following steps:

[0050] S1. Preparation of lithium lanthanum zirconium oxygen precursor solution: dissolve 0.834g lithium nitrate, 2.598g lanthanum nitrate hexahydrate, 1.289g octahydrate zirconium oxychloride, 0.176g gallium trichloride in 25mL deionized water, stir at room temperature 3 hours, get Li 5.5 La 3 Zr 2 Ga 0.5 o 12 The precursor solution; the concentration of lithium nitrate is 33.36g / L; the concentration of lanthanum nitrate hexahydrate is 103.92g / L; the concentration of zirconium oxychloride octahydrate is 51.56g / L; the concentration of gallium trichloride is 7.04g / L;

[0051] S2, the area is 400cm 2 Lens cleaning paper cut into 5×5cm 2 After that, completely i...

Embodiment 3

[0058] The lithium lanthanum zirconium oxygen solid electrolyte is composed of: 60wt% polymer, 10wt% lithium salt and 30wt% lithium lanthanum zirconium oxide three-dimensional porous inorganic network.

[0059] The lithium lanthanum zirconium oxygen solid electrolyte was prepared according to the following steps:

[0060] S1. Preparation of lithium lanthanum zirconium oxygen precursor solution: 0.944g lithium acetate, 1.896g lanthanum acetate, 0.982g zirconium acetate, 0.358g tantalum pentachloride were dissolved in 25mL deionized water, and stirred at room temperature for 3 hours to obtain Li 6.5 La 3 Zr 1.5 Ta 0.5 o 12 The precursor solution; lithium acetate concentration is 37.76g / L; lanthanum acetate concentration is 75.84g / L; zirconium acetate concentration is 39.28g / L; tantalum pentachloride concentration is 14.32g / L;

[0061] S2, the area is 400cm 2 Filter paper cut into 5×5cm 2 Afterwards, completely immerse in the lithium lanthanum zirconium oxide precursor solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com