Porcine Japanese encephalitis live vaccine heat-resistant lyophilized protective agent as well as preparation method and application thereof

A porcine Japanese encephalitis, heat-resistant freeze-drying technology, applied in the directions of freeze-drying delivery, antiviral agents, pharmaceutical formulations, etc. The formula ingredients and preparation method are simple, solve the problem of refrigerated transportation, and have good heat resistance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

[0024] Example 1-3 Heat-resistant freeze-dried protective agent for porcine Japanese encephalitis live vaccine and its preparation

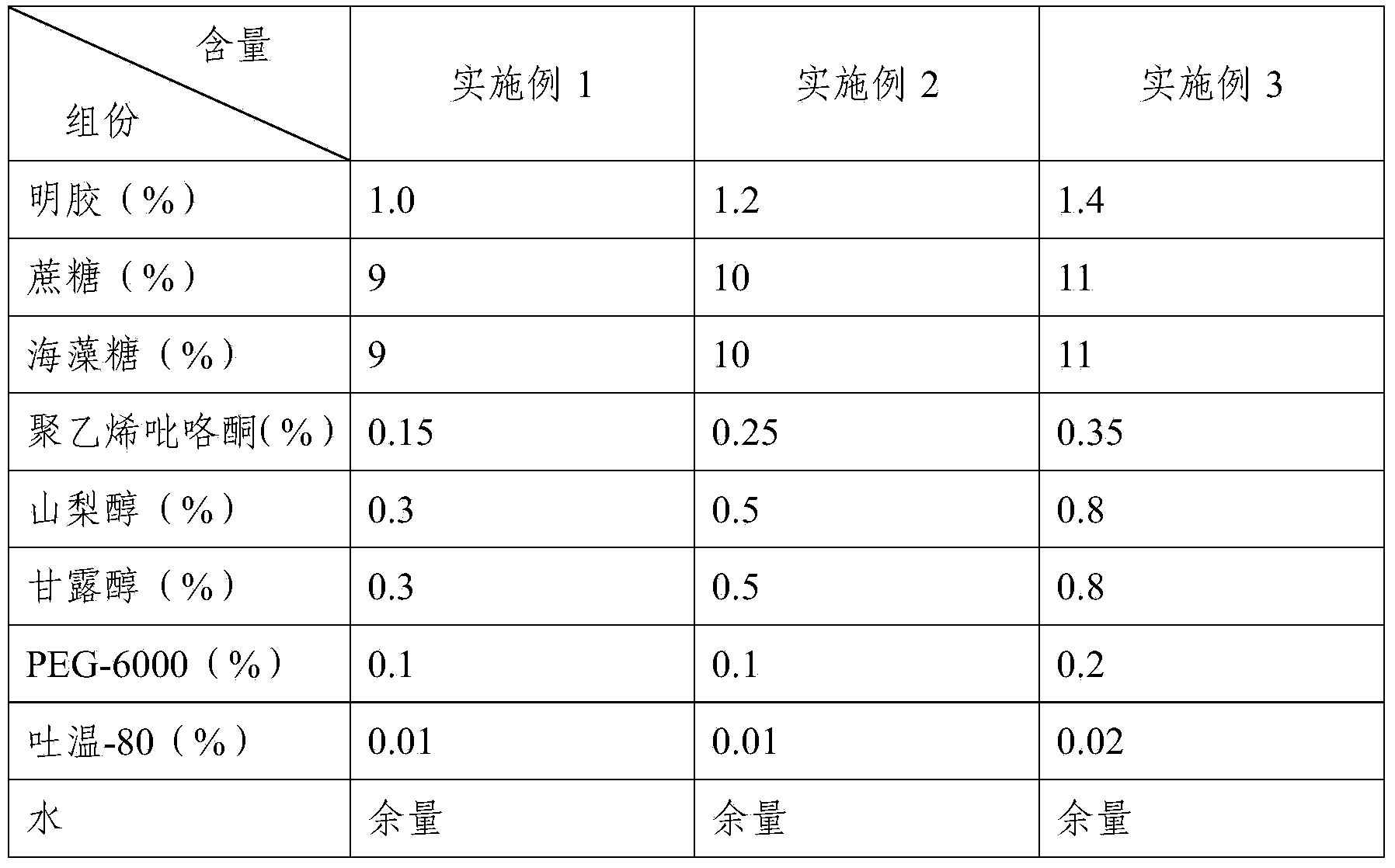

[0025] (1) Formula of freeze-dried protective agent

[0026] The formulation of the freeze-dried protective agent is shown in Table 1, and the pH value is 7.5, prepared with water.

[0027] Table 1 The formula of the heat-resistant freeze-dried protective agent of the porcine Japanese encephalitis vaccine

[0028]

[0029] (2) Preparation method

[0030] The above components are weighed in proportion, dissolved in water, adjusted to pH 7.5 with hydrochloric acid solution, and sterilized at 110°C for 30 minutes to obtain a heat-resistant lyophilized protective agent for porcine Japanese encephalitis live vaccine.

Embodiment 4

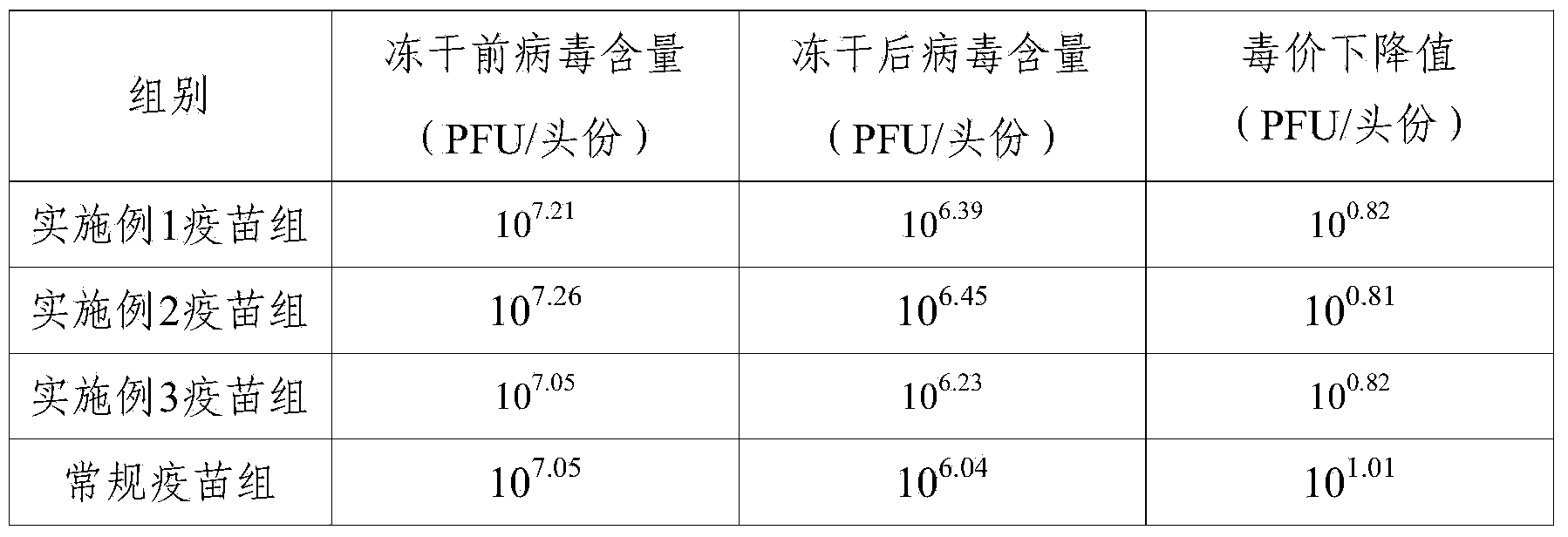

[0031] Example 4 Application of the heat-resistant freeze-dried protective agent of porcine Japanese encephalitis live vaccine in preparing porcine Japanese encephalitis live vaccine

[0032] Three batches of the heat-resistant freeze-dried protective agent prepared in Example 1-3 and the virus antigen (SA14-14-2) that have passed the test were shaken thoroughly at a volume ratio of 1:1, and then immediately after the quantitative aliquot Freeze dry. At the same time, 0.5% gelatin and 2.5% sucrose protectant vaccine were set as the control group. The freeze-drying method is as follows:

[0033] Put the aliquoted vaccine into a freeze-dried cabinet. The minimum temperature of the vaccine in the pre-freezing stage is +40°C, and it is maintained for 2 hours after reaching the lowest temperature; the final temperature of the vaccine in the sublimation drying stage is -20°C, and the time to reach the final temperature is 17 hours. The vacuum control pressure of the freeze-drying box i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com