Patents

Literature

35results about How to "High degree of aging resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Porcine reproductive and respiratory syndrome live vaccine heat-resistant freeze-drying protective agent and preparation method thereof

ActiveCN102166362AReduce loss rateHigh degree of aging resistanceViral antigen ingredientsInorganic non-active ingredientsLoss rateFreeze-drying

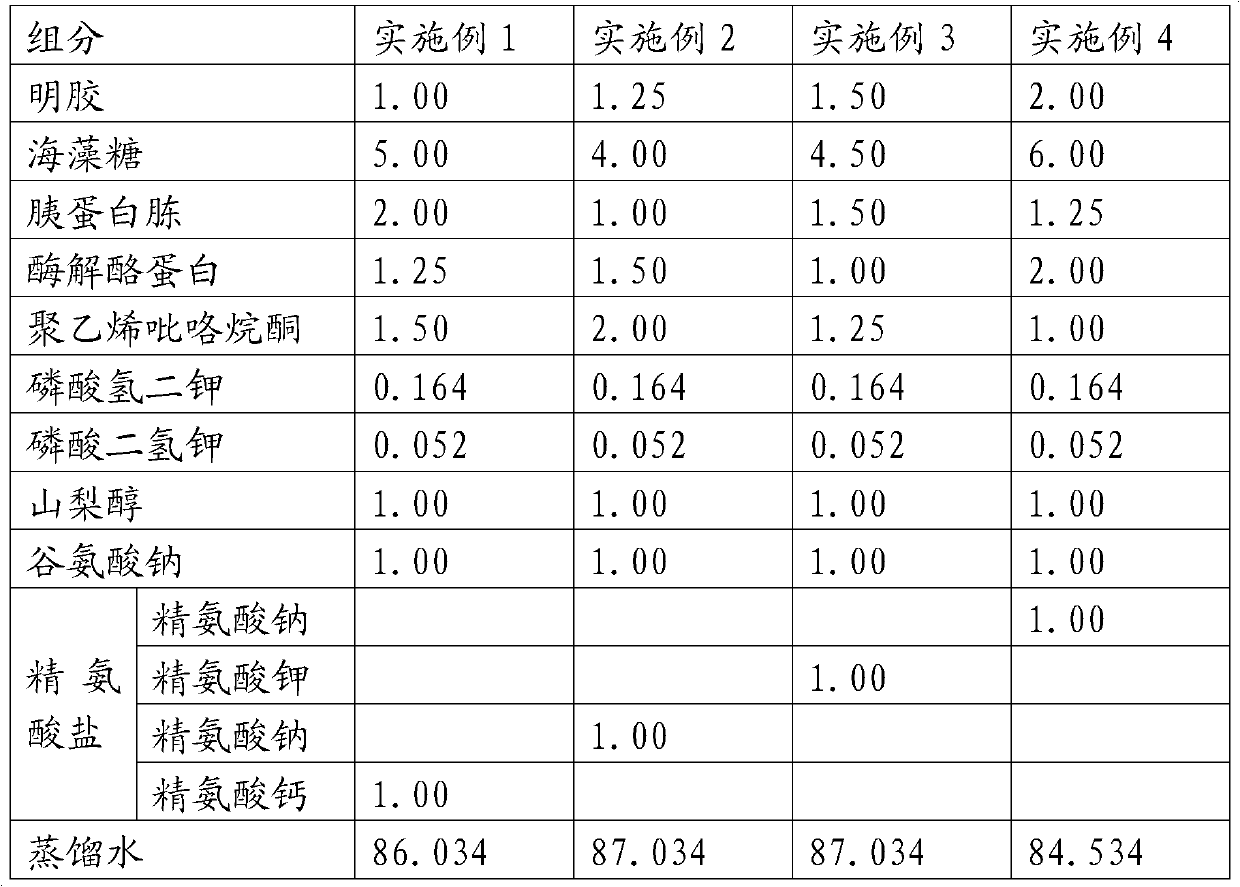

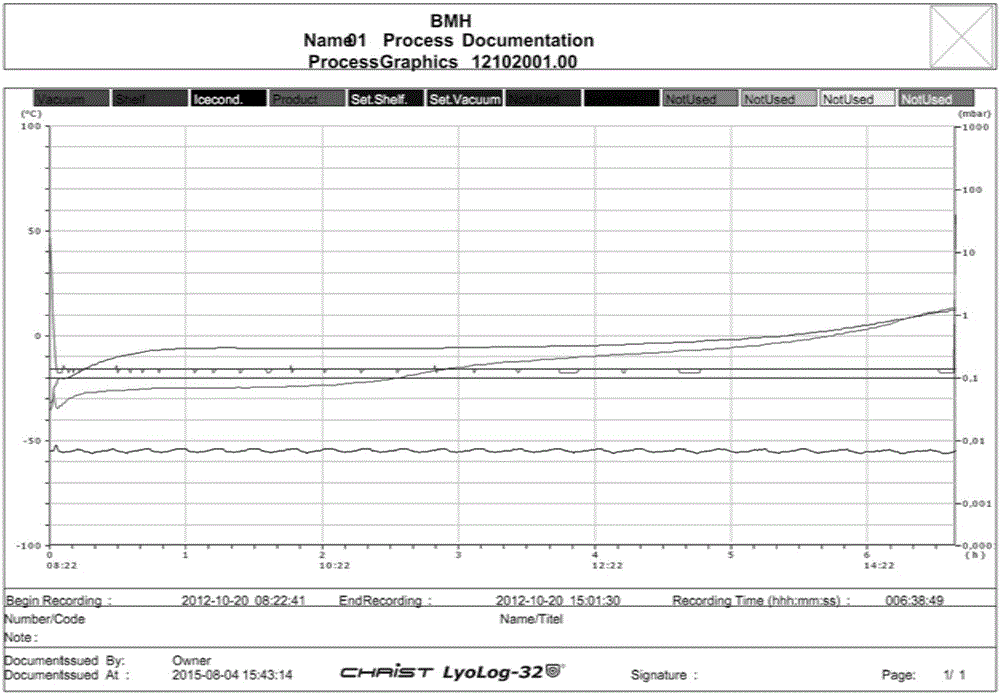

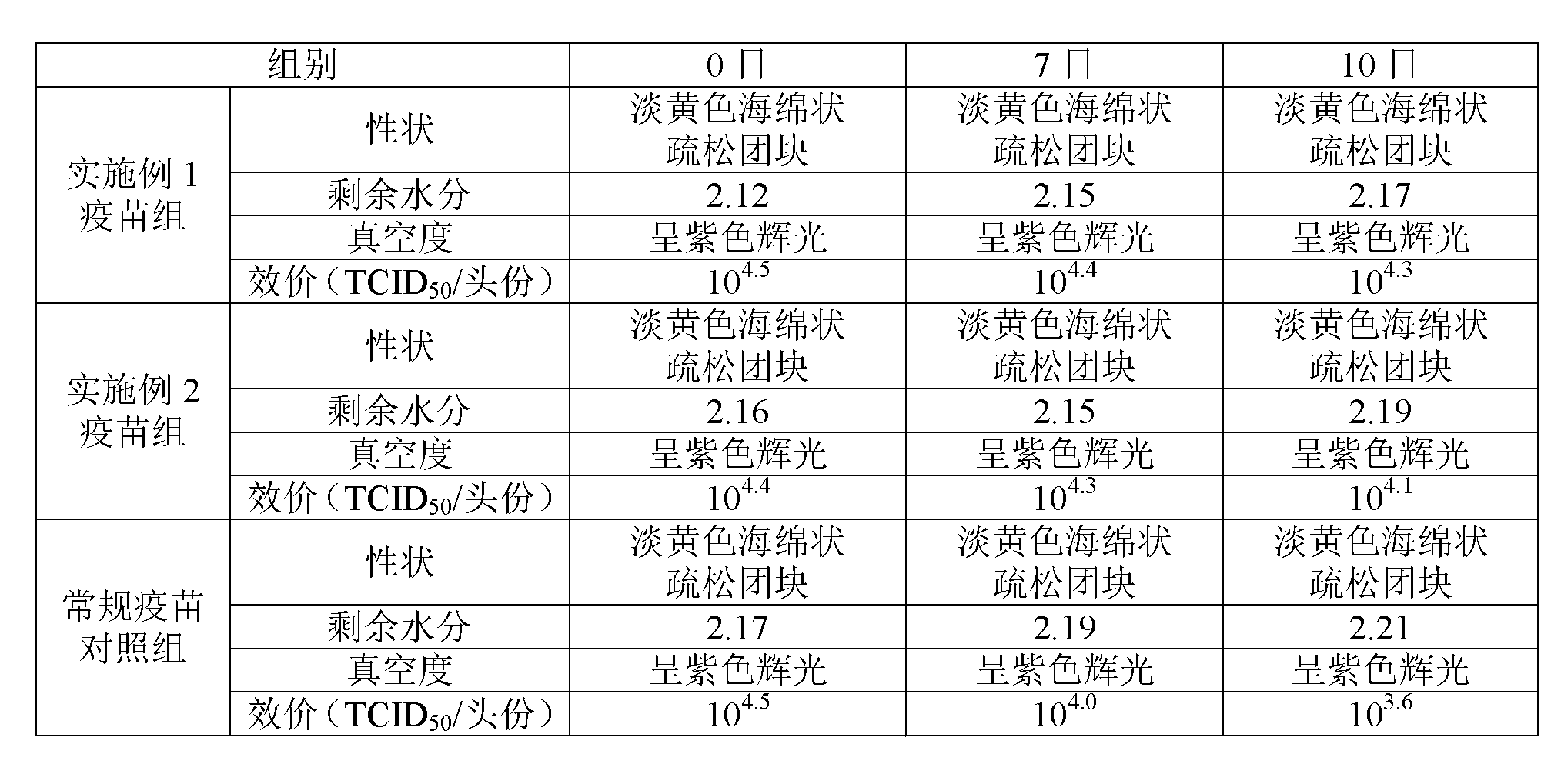

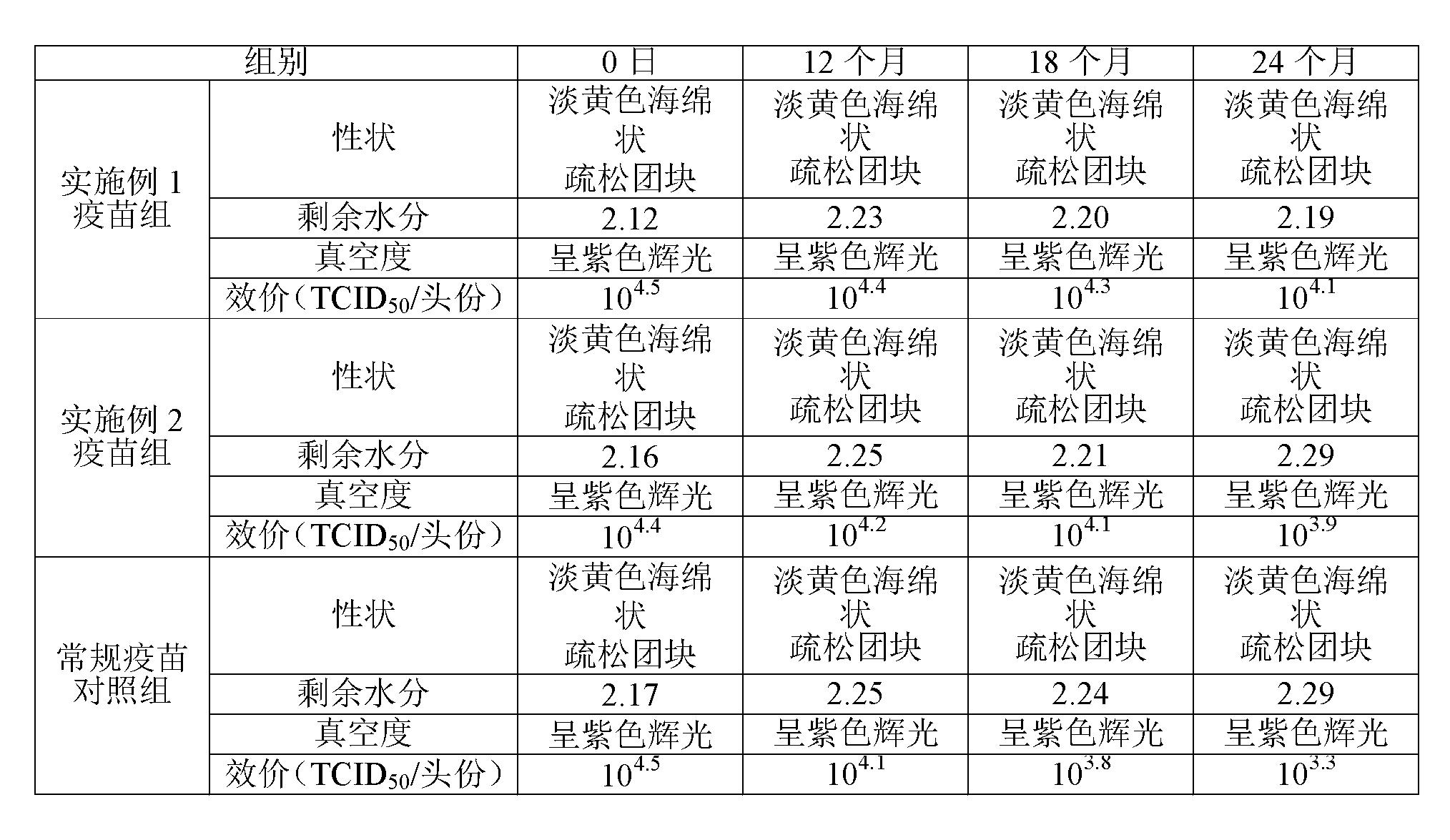

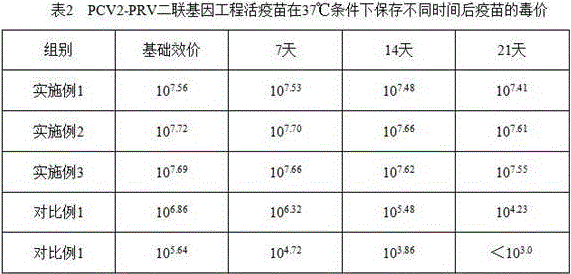

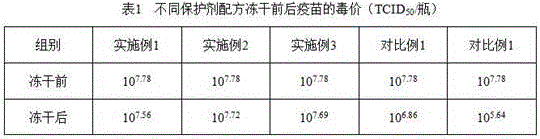

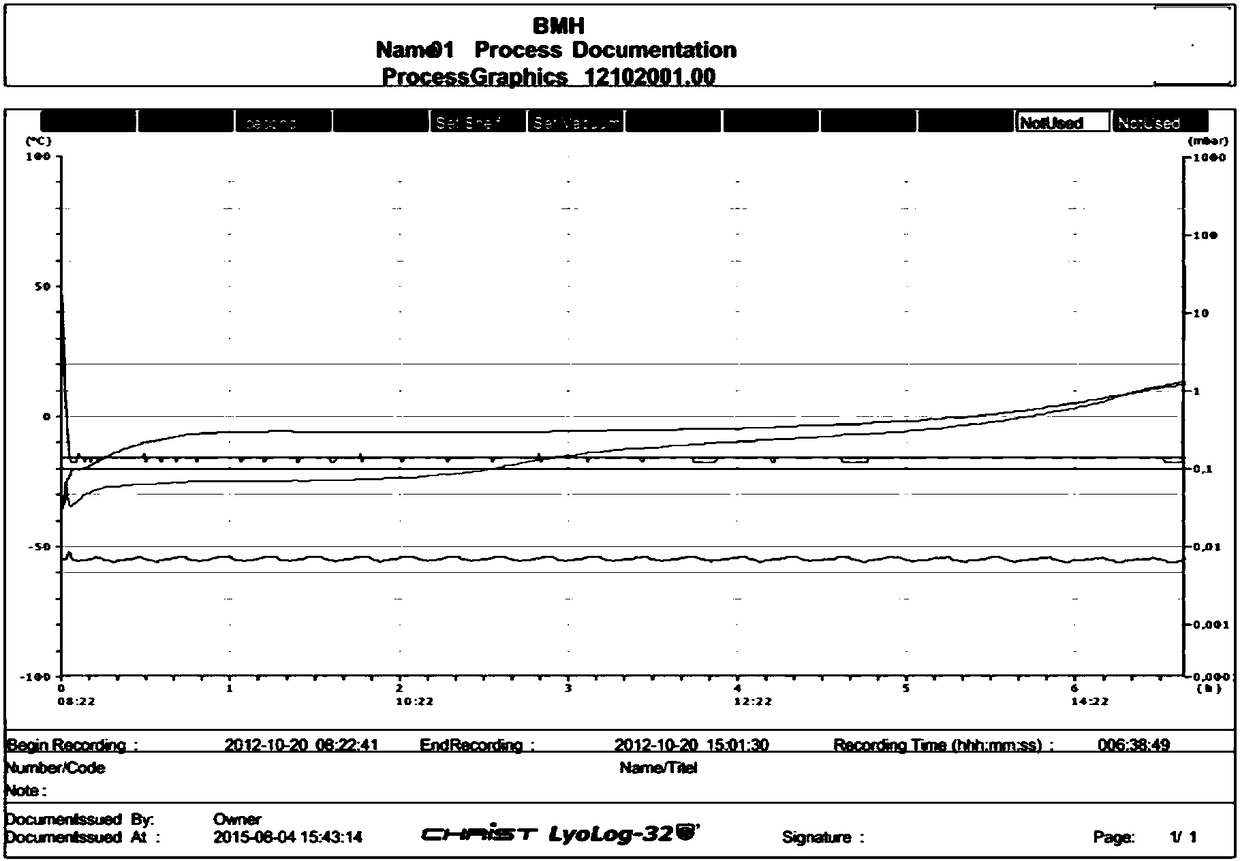

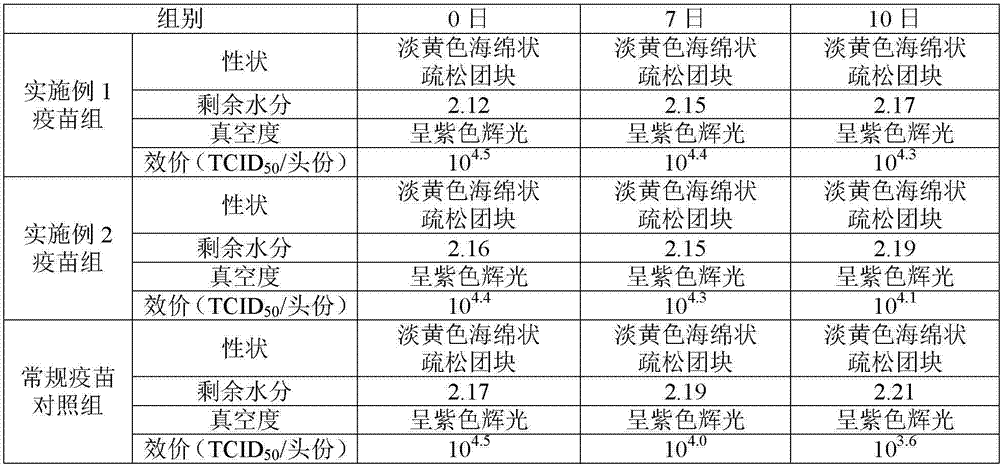

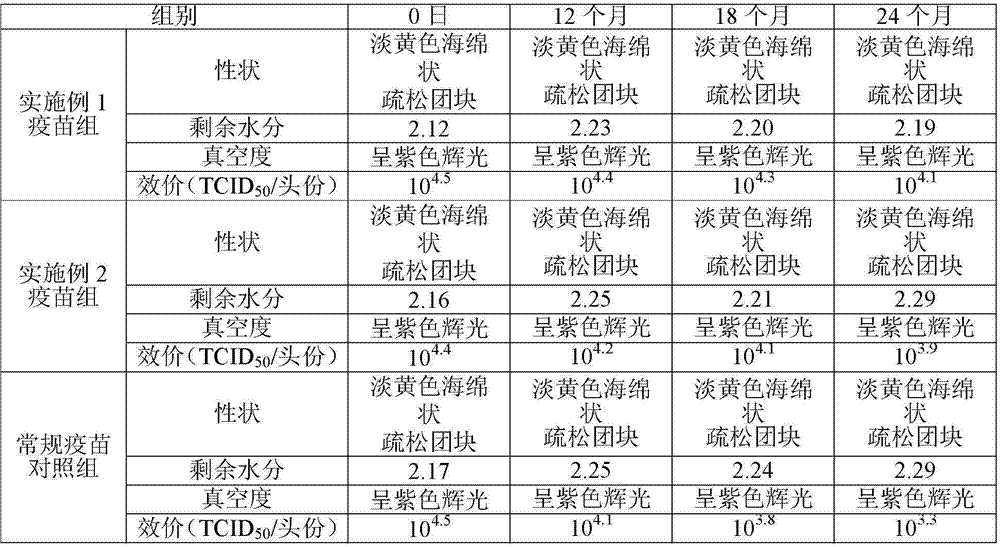

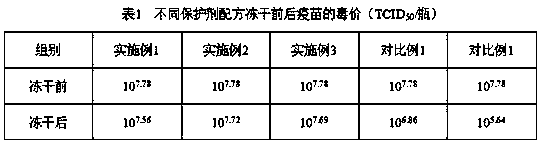

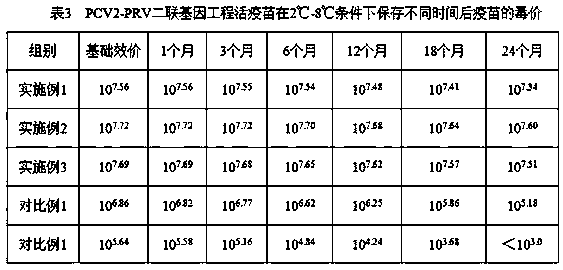

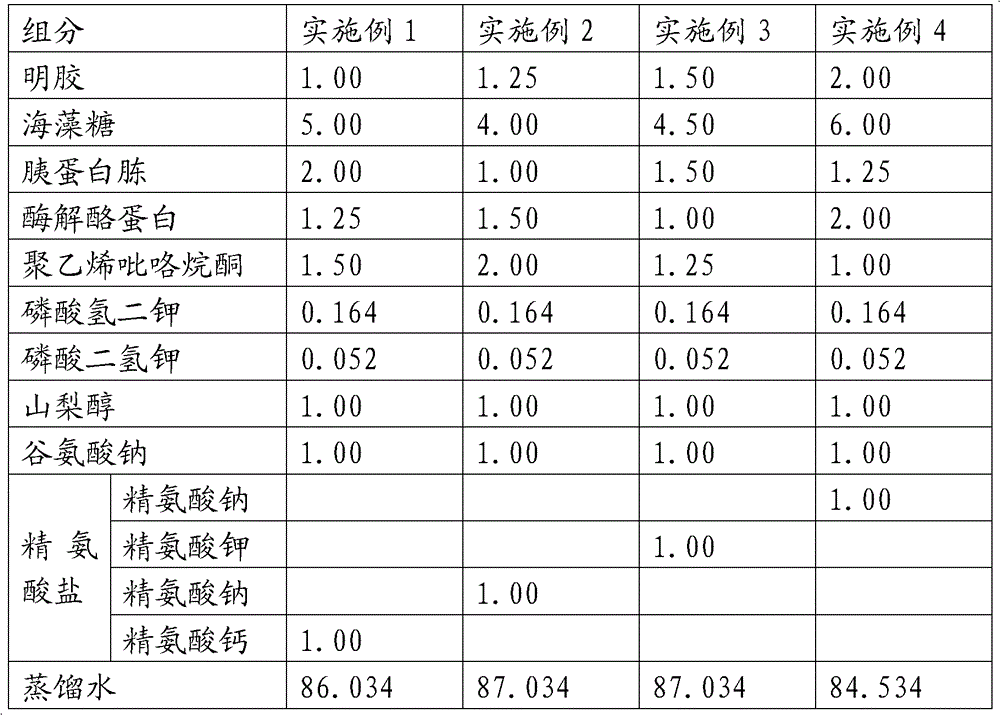

The invention relates to a porcine reproductive and respiratory syndrome live vaccine heat-resistant freeze-drying protective agent and a preparation method thereof. The heat-resistant freeze-drying protective agent is mixed by the raw materials based on weight percentage: 1-2% of gelatin, 4-6% of trehalose, 1-2% of tryptone, 1-2% of trypticase, 1-2% of polyvinylpyrrolidone, 0.164% of dipotassium phosphate, 0.052% of monopotassium phosphate, 1% of sorbic alcohol, 1% of sodium glutamate, 1% of arginine salt and the balance of water. The preparation method comprises the steps of: preparing the materials into two mixed solution, respectively preparing in a mixing way by means of degerming to prepare a heat-resistant freeze-drying protective agent, mixing according to the proportion of the protective agent to the virus-resistant raw material as 1:1, performing split charging, and drying in a freezing way. Before drying in a freezing way, the virus loss rate is low, a freeze-drying product is high in ageing-resistant degree, and the virus is invariable in content after the freeze-drying product is preserved at the temperature of 2-8 DGE C for 24 months. After the invention is used, the technical neck bottle that the porcine reproductive and respiratory syndrome live vaccine can be preserved and transported under the condition of -15 DEG C is solved.

Owner:WUHAN CHOPPER BIOLOGY

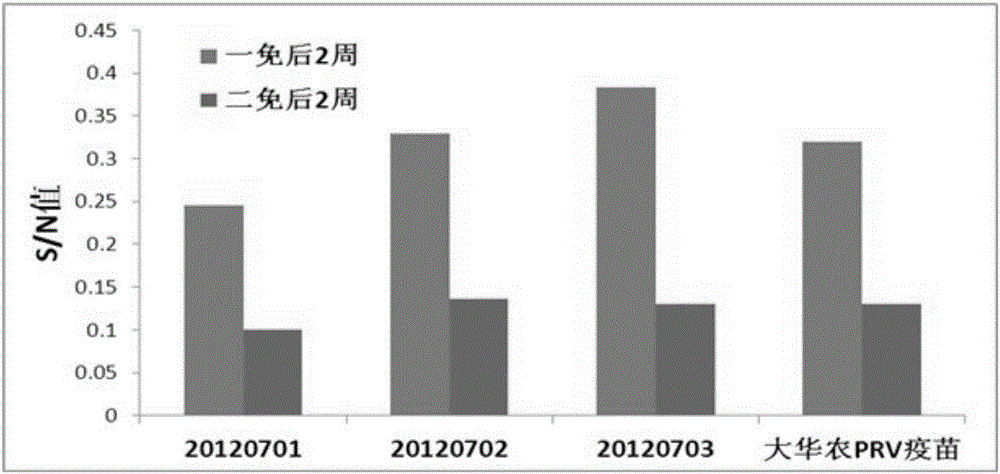

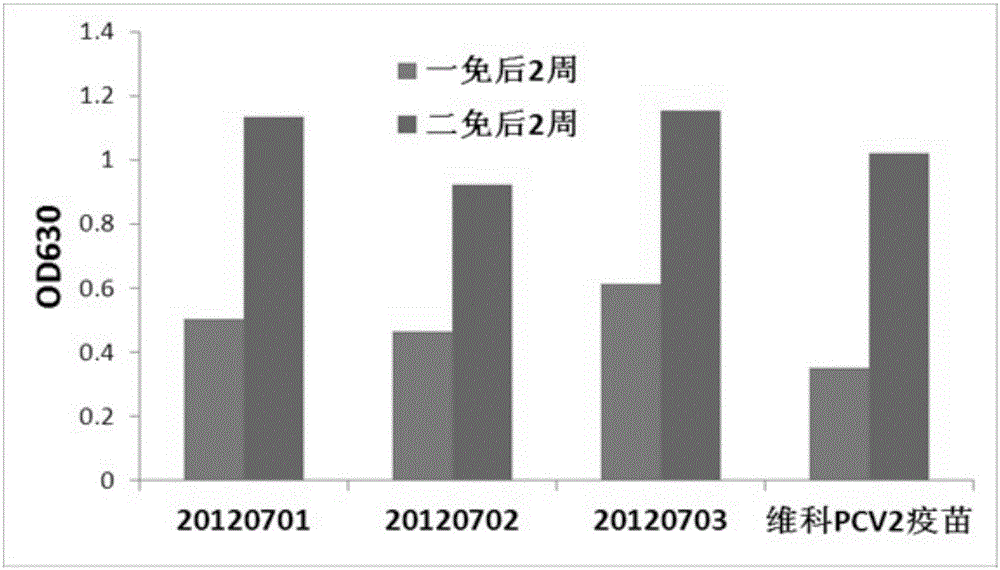

Heat-resisting lyophilized protector for recombinant pseudorabies virus vaccine and preparation method of heat-resisting lyophilized protector

ActiveCN105012963AImprove protectionGood lookingMacromolecular non-active ingredientsGlycineAstragalus polysaccharide

The invention relates to a heat-resisting lyophilized protector for a recombinant pseudorabies virus vaccine. The heat-resisting lyophilized protector comprises the following ingredients by weight: 2 to 3 percent of gelatin, 1 to 2 percent of polyvinylpyrrolidone K-30, 0 to 4 percent of trehalose, 2 to 5 percent of saccharose, 0.1 to 0.5 percent of mannitol, 0 to 0.5 percent of astragalus polysaccharide, 1 to 1.5 percent of glycine, 0 to 1 percent of arginine, 0 to 1 percent of bovine serum albumin and the balance of water for injection. The invention further provides a preparation method of the heat-resisting lyophilized protector. The heat-resisting lyophilized protector has the advantage that the preservation period of the vaccine in a relatively-high-temperature environment can be prolonged; the preparation method is simple; the production and the application are convenient.

Owner:ZHAOQING DAHUANONG BIOLOGIC PHARMA +1

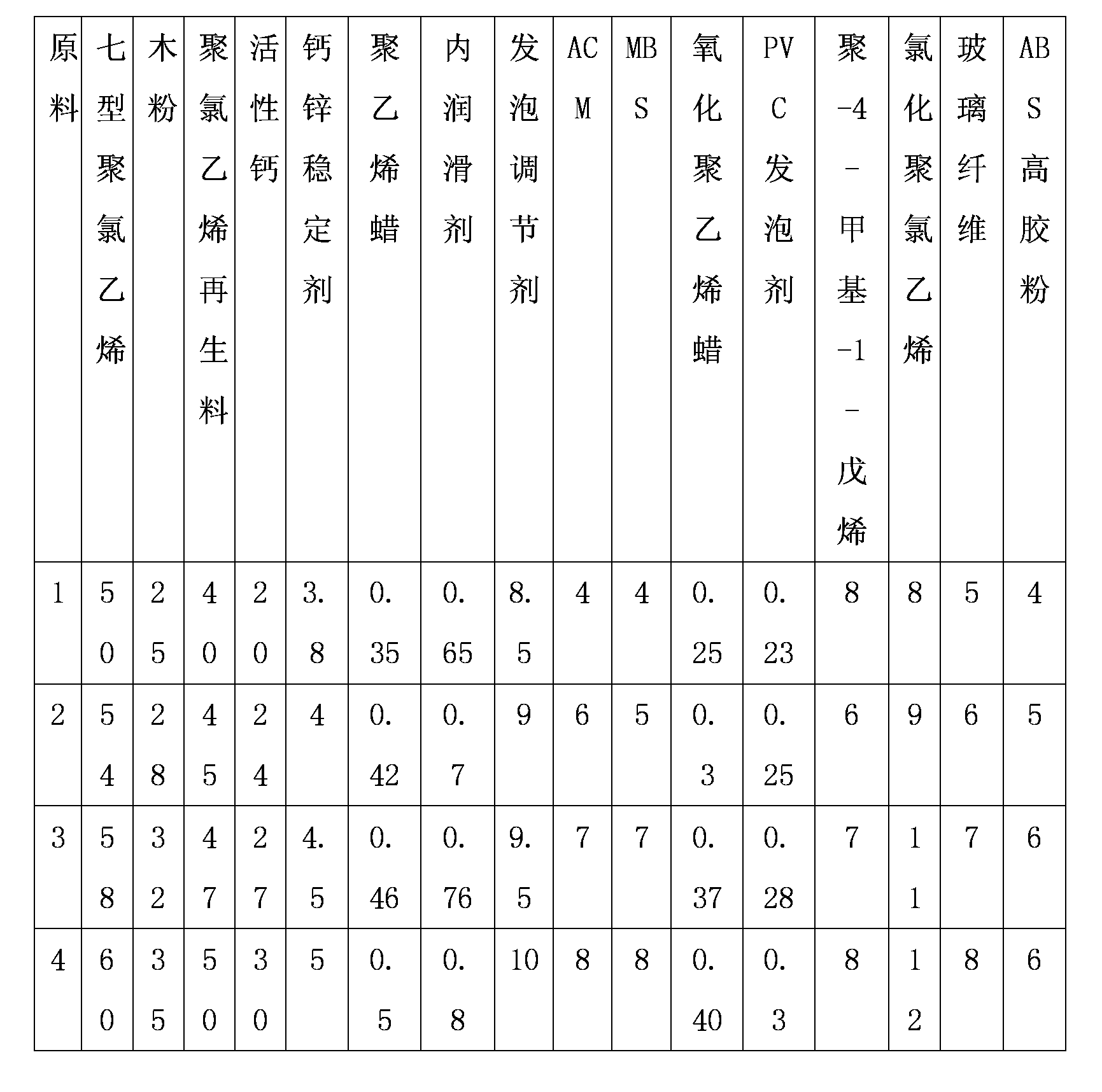

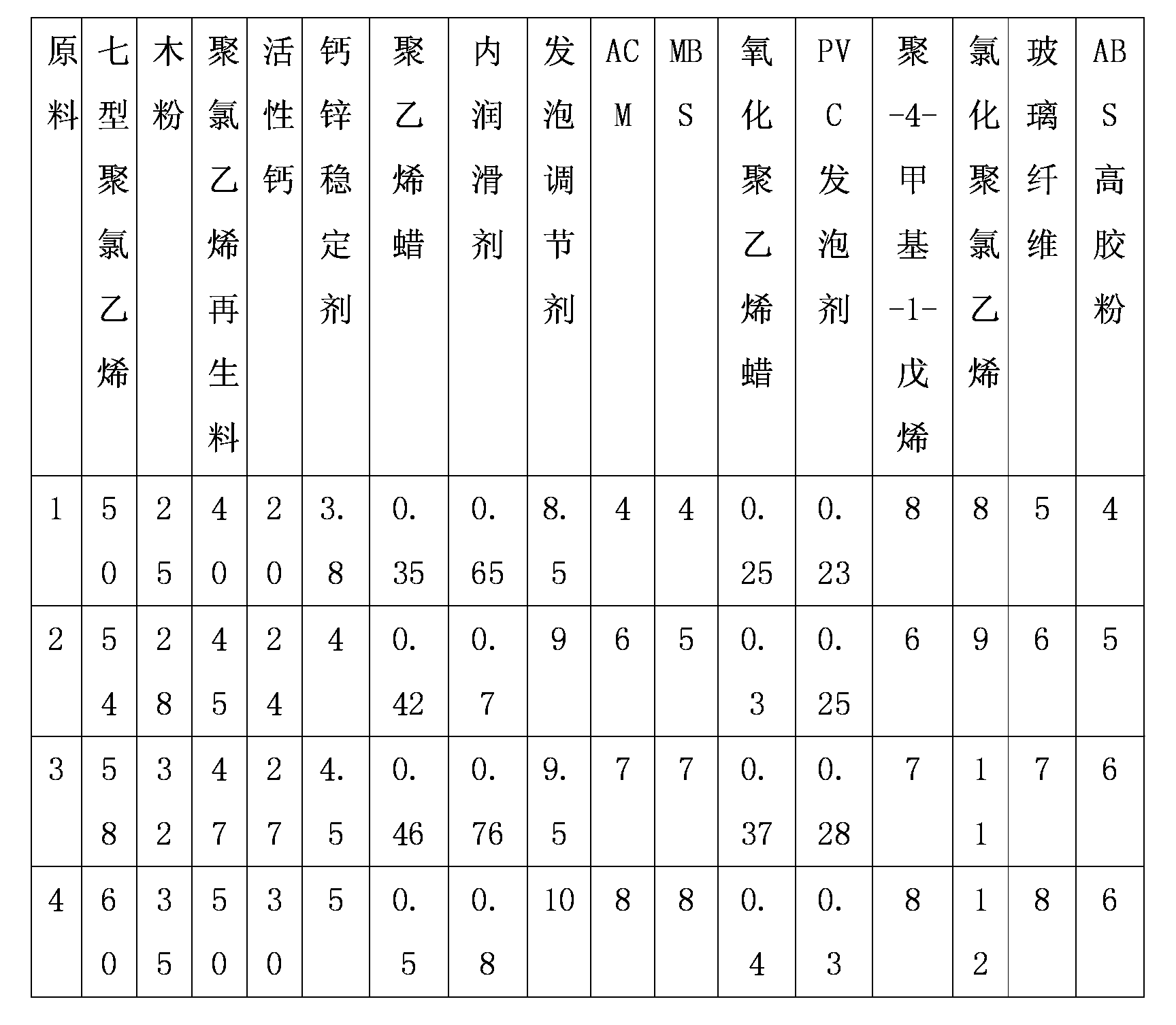

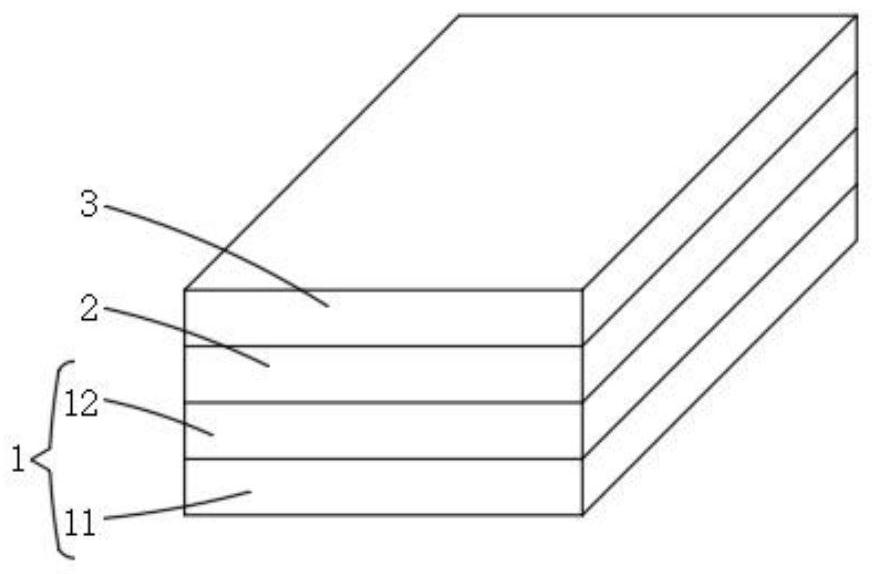

Novel durable plastic-wooden composite sheet material

The invention discloses a novel durable plastic-wooden composite sheet material, which comprises the following raw materials: VII PVC, wood powder, a polyvinyl chloride reworked material, active calcium, a calcium-zinc stabilizer, polyethylene wax, an internal lubricant, a foam adjusting agent, ACM, MBS, oxidized polyethylene wax, a polyvinyl chloride (PVC) foaming agent, poly-4-methyl-1-pentene, chlorinated polyvinyl chloride, glass fiber and ABS high glue powder. Compared with a traditional plastic-wooden composite sheet material, the novel durable plastic-wooden composite sheet material adds the ABS high glue powder, a MBS impact modifier, glass fiber and the like, thereby the product can reach the usage function, and has toughness, rigidity and elasticity, and the flexural modulus of the product can reach 2000MPA. The novel durable plastic-wooden composite sheet material can fully embody the advanced concepts of sustainable economic development such as circular economy, resource utilization, healthy and environment protection, conservation and substitution and the like, the problem of white pollution caused by waste plastic without treatment, recovery and utilization can be effectively solved, and the novel durable plastic-wooden composite sheet material enables comprehensive utilization of resources and a function of the environment protection.

Owner:SHUCHENG ANTAI PLASTIC PROD

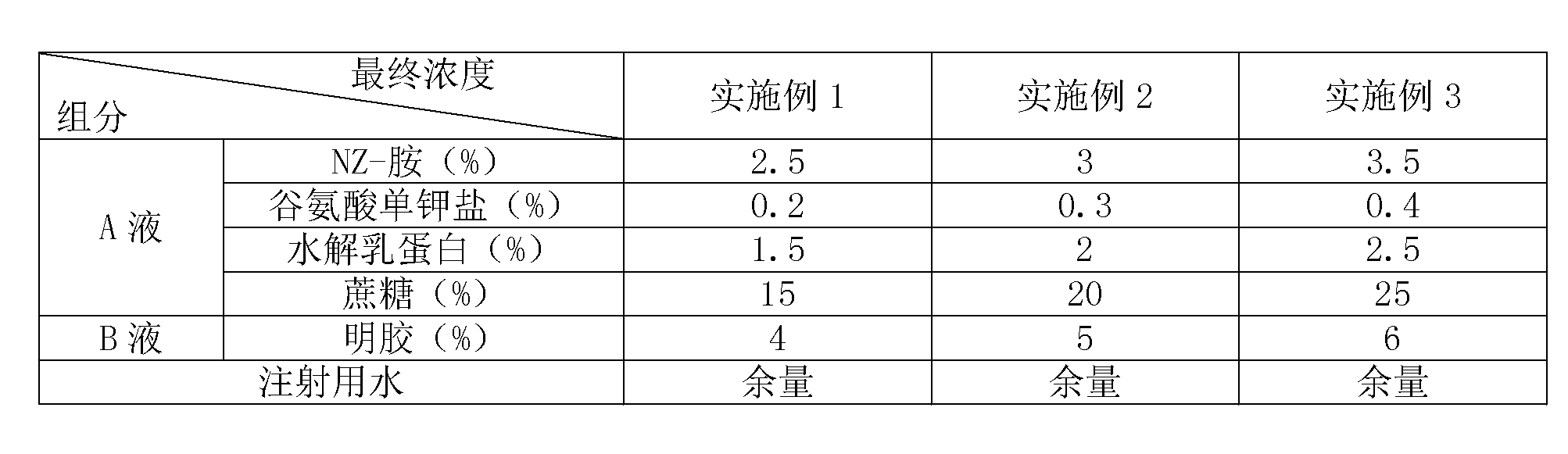

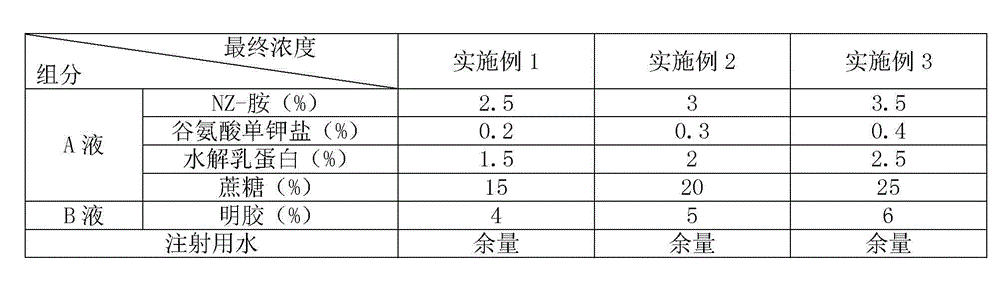

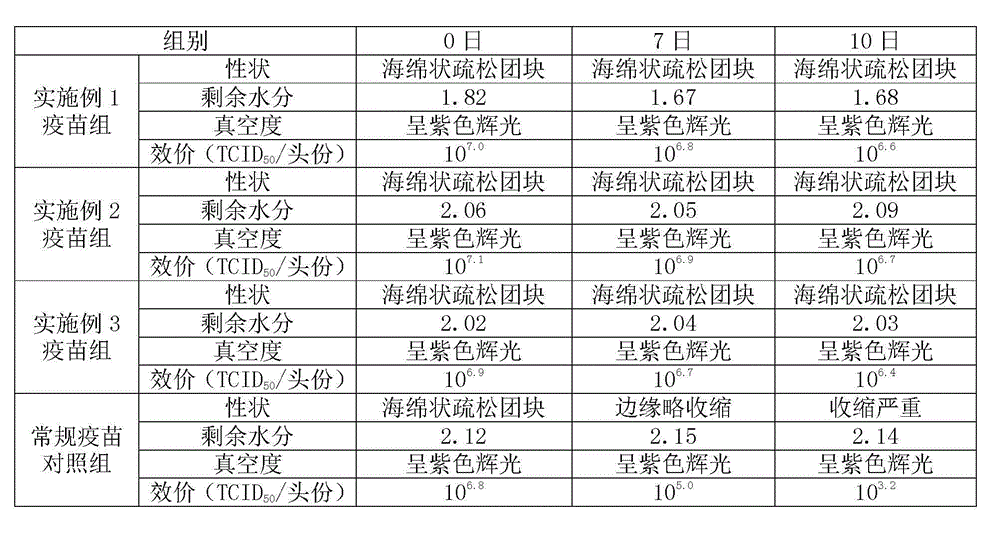

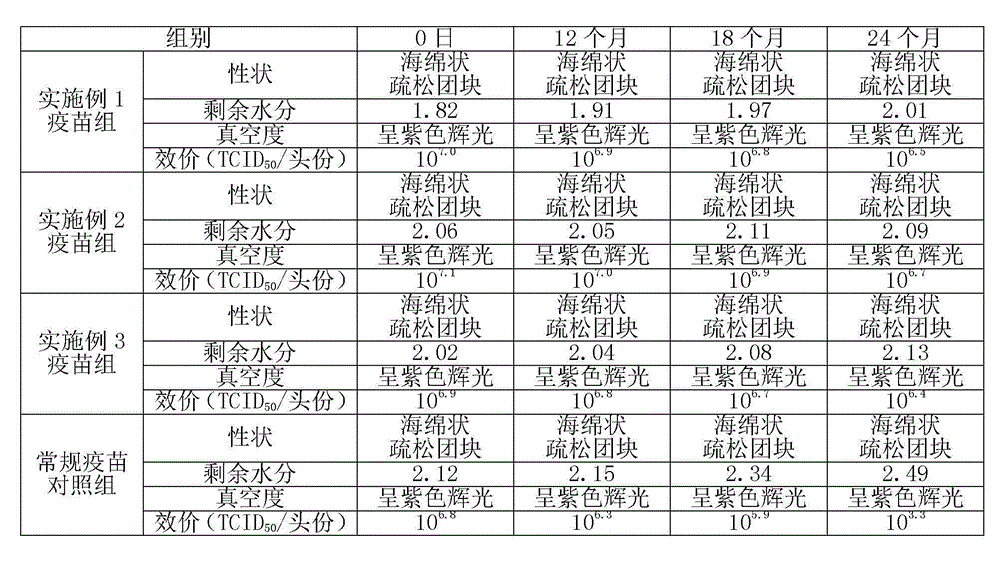

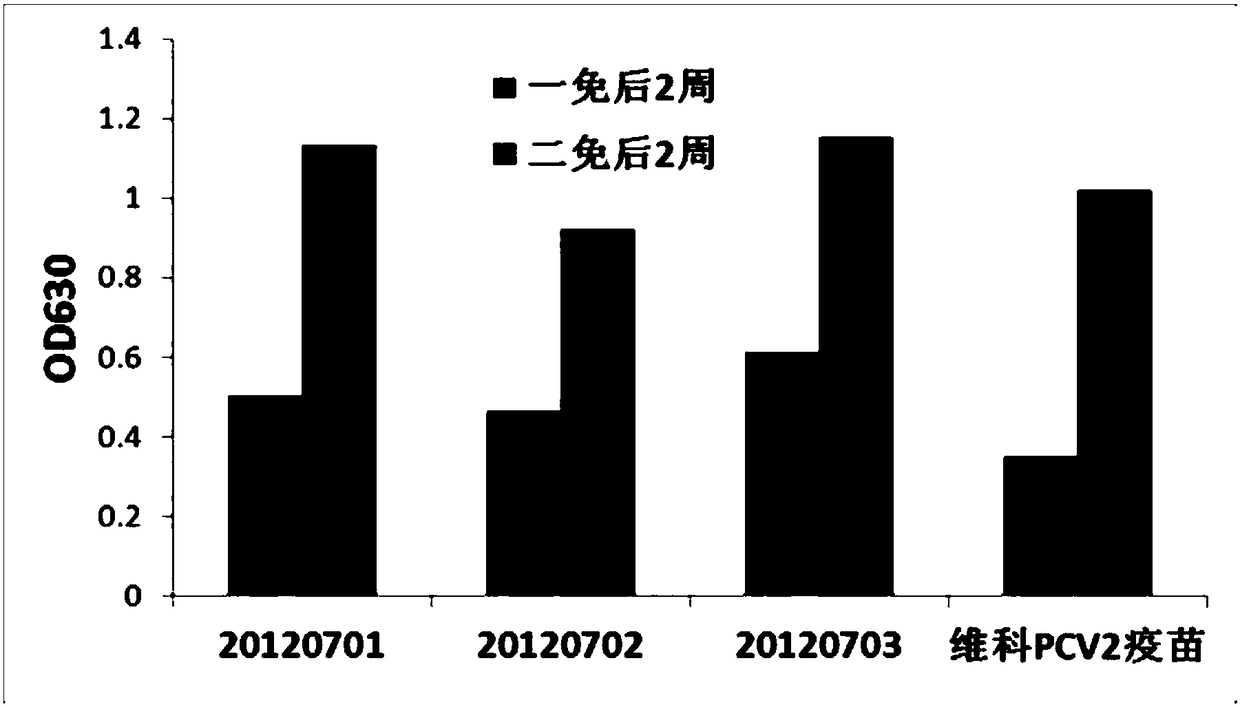

Lyophilized vaccine for swine encephalitis B and preparation method thereof

ActiveCN103301452AAvoid damageReduce titer lossViral antigen ingredientsAntiviralsProtective antigenAntigen

The invention relates to a lyophilized vaccine for swine encephalitis B. The lyophilized vaccine consists of Japanese encephalitis virus serving as an antigen, and a protective agent, wherein the protective agent is prepared from the following substances in percentage by mass: 2.4-4% of NZ-amine, 0.3-0.5% of mono-potassium glutamate, 16-20% of sucrose, 6-20% of lactoalbumin hydrolysate, 1-1.6% of gelatin and the balance of water. According to the vaccine disclosed by the invention, the used lyophilized protective agent is made from raw materials which are low in cost, and the operation is simple, so that the vaccine can be produced in a large scale. After the vaccine prepared from the protective agent is stored for 24 months at the temperature of 2-8 DEG C, the potency of the vaccine is not smaller than 10<5.7>TCID50 / head (Chinese Standard), so that the storage life of the vaccine is prolonged effectively.

Owner:YEBIO BIOENG OF QINGDAO

Porcine Japanese encephalitis live vaccine heat-resistant lyophilized protective agent as well as preparation method and application thereof

ActiveCN103656661AAvoid damageReduce loss ratePowder deliveryViral antigen ingredientsProtective antigenSucrose

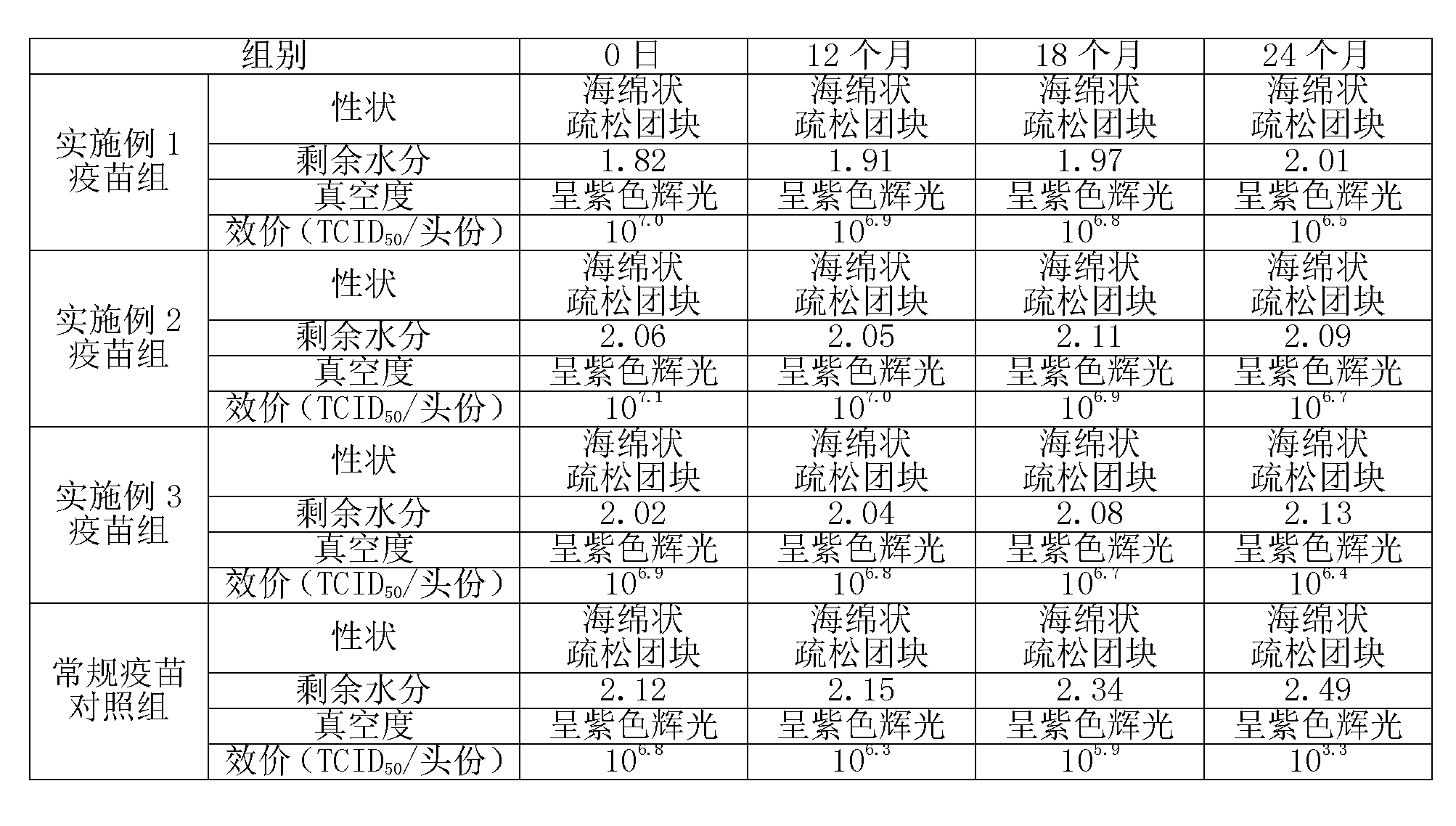

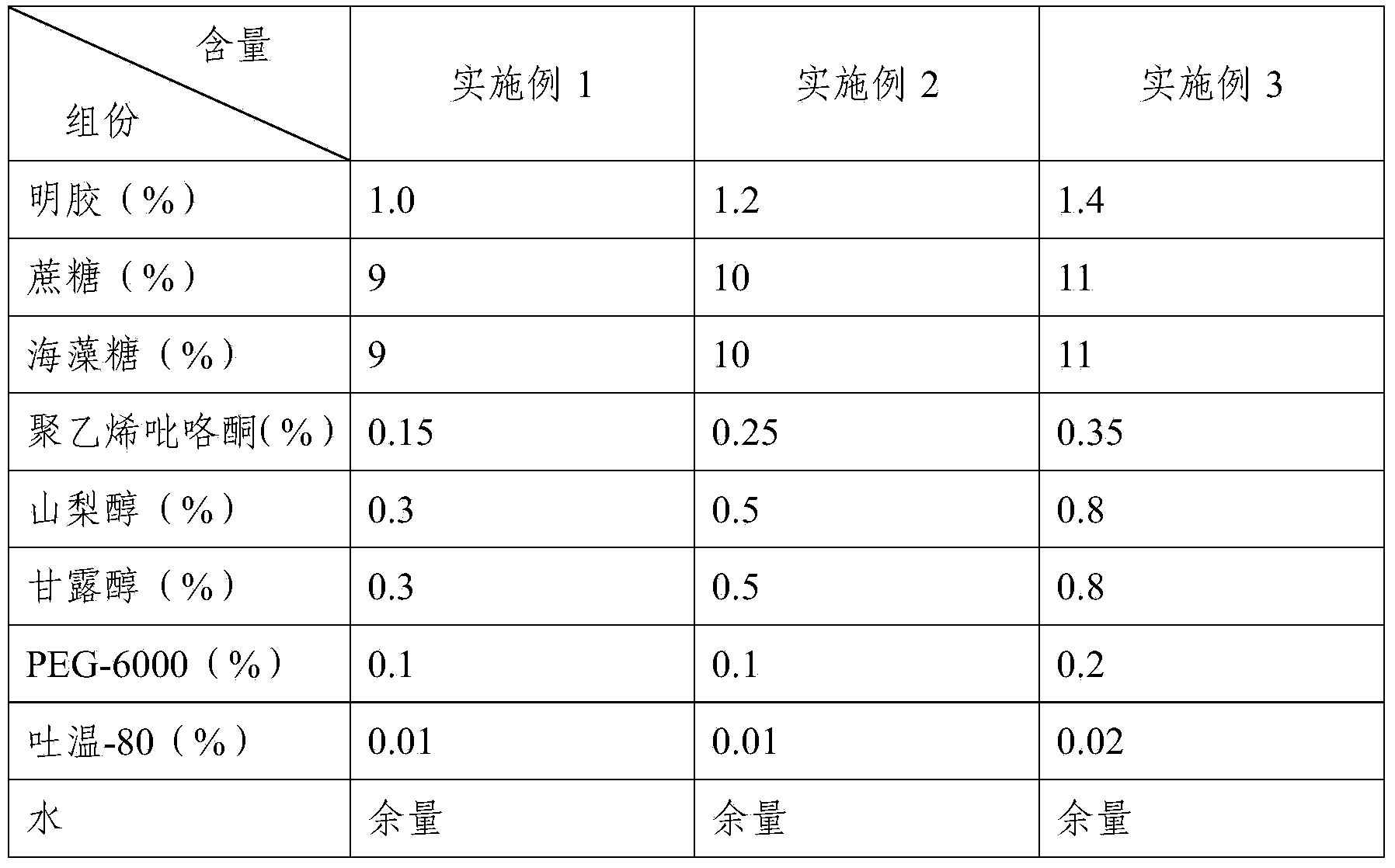

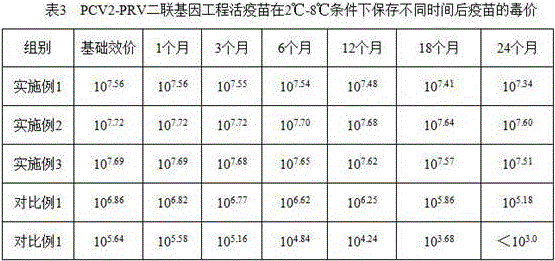

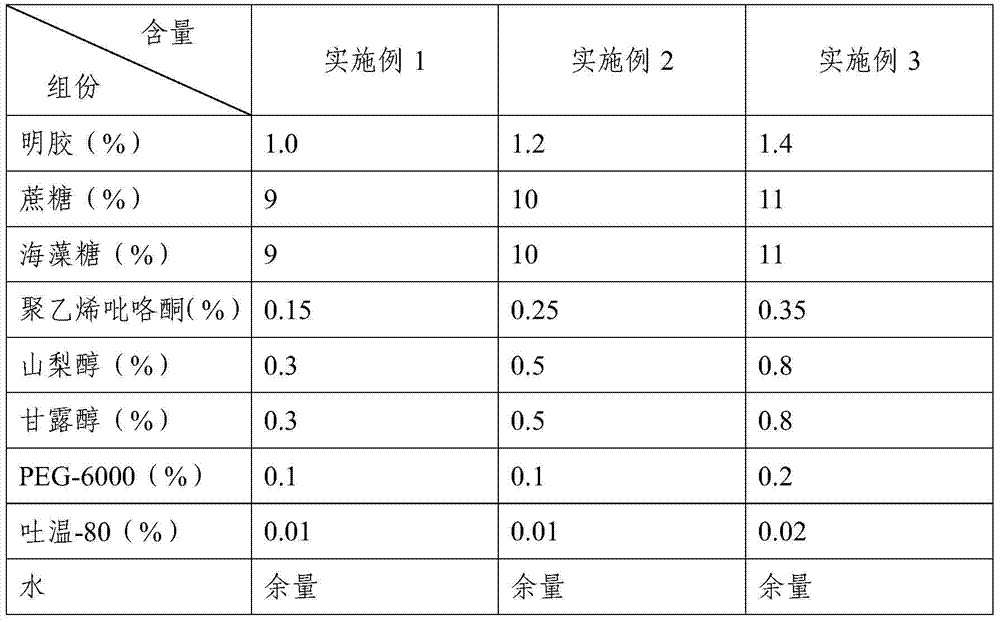

The invention provides a porcine Japanese encephalitis live vaccine heat-resistant lyophilized protective agent. The protective agent comprises the following components in percentage by weight: 1.0-1.4% of gelatin, 9-11% of sucrose, 9-11% of trehalose, 0.15-0.35% of polyvinylpyrrolidone, 0 .3-0.8% of sorbitol, 0.3-0.8% of mannitol, 0.1-0.2% of PEG-6000, and 0.01-0.02% of tween-80, the pH value of the protective agent is 7.5, and the components are added with water to be dissolved and sterilized at high temperature to obtain the protective agent.The lyophilized protective agent disclosed by the invention is mixed with a porcine Japanese encephalitis live vaccine virus solution, and freeze-drying is carried out to obtain a lyophilized vaccine. The heat-resistant lyophilized protective agent disclosed by invention is simple in formulation, easy in preparation, suitable for large-scale production, has good protection efficacy for vaccines, and can ensure that the vaccines can be preserved for 10 days effectively at the normal temperature, even at the temperature of 37 DEG C, and preserved for 24 months at the temperature of 2-8 DEG C.

Owner:CHINA ANIMAL HUSBANDRY IND

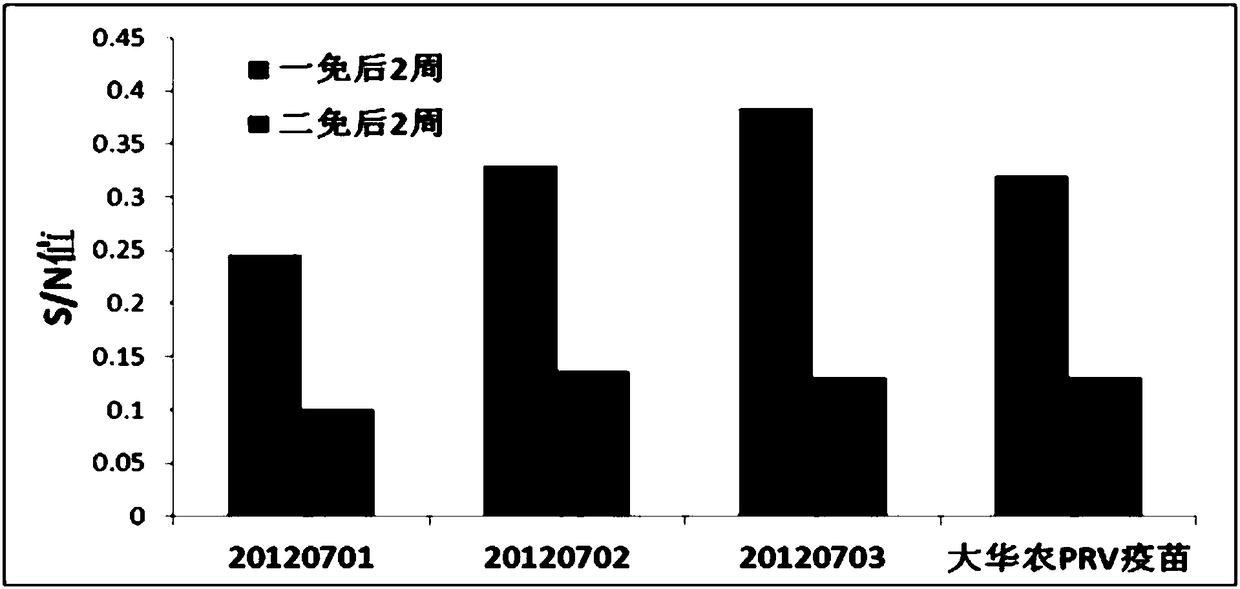

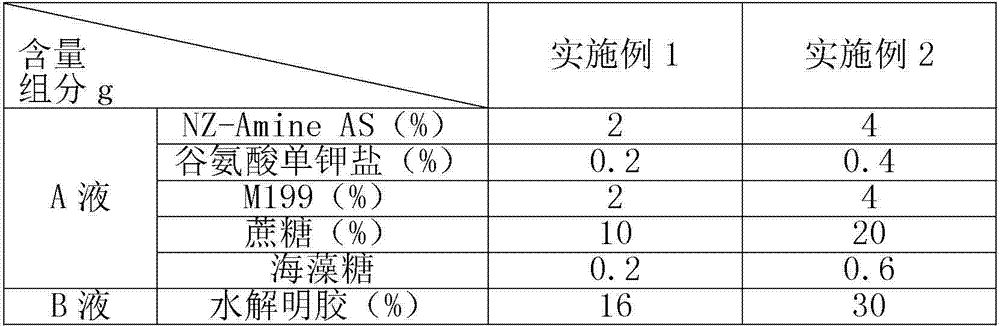

Pseudorabies live vaccine and preparation method thereof

ActiveCN103316355AAvoid damageReduce titer lossPowder deliveryAntiviralsMonosodium glutamateSaccharum

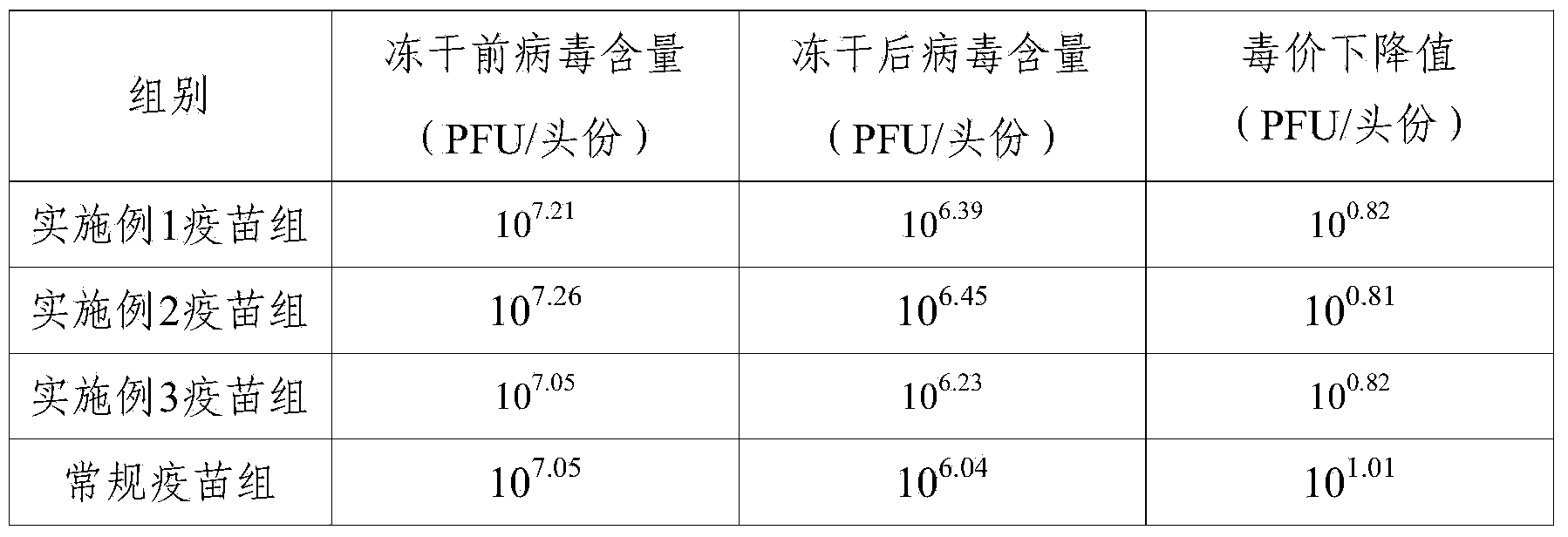

The invention relates to a freeze-drying protective additive which is composed of 1 to 2% of NZ-Amine AS, 0.1 to 0.2% of monosodium glutamate, 5 to 10% of saccharose, 1 to 2% of M199, 0.1 to 0.3% of trehalose, 8 to 15% of hydrolyzed gelatin, and the balance of water. The freeze-drying protective additive is used for preparing a freeze-dried pseudorabies vaccine. A heat-resisting protective agent can minimize the damage of various physical and chemical factors of a product to virus activity during sub-packaging and freezing-drying processes, greatly reduces the titer loss of the virus before and after freezing and drying and keeps the loss of being not greater than 0.2 titer. A heat-resisting protective agent live vaccine is high in degree of resistance to aging, the loss ratio of the virus kept for 10 days under a condition of 37 DEG C is not greater than 0.5 titer; the heat-resisting protective agent live vaccine can be stored for 24 months at 2 to 8 DEG C, the titer of the vaccine is reduced a little, so that the problem that the vaccine in general transporting and storing needs strict cold chain condition, which leads to energy waste and inconvenient storage, can be solved effectively.

Owner:YEBIO BIOENG OF QINGDAO

Heatproof freeze-drying protecting agent for recombined pseudorabies virus vaccines and preparation method of heatproof freeze-drying protecting agent

ActiveCN105561317AImprove protectionImprove securityViral antigen ingredientsAntiviralsVaccine StabilitySaccharum

The invention relates to a heatproof freeze-drying protecting agent for recombined pseudorabies virus vaccines. The heatproof freeze-drying protecting agent comprises, by weight, 4-8% of trehalose, 0-3% of cane sugar, 0.2-0.8% of sorbitol, 1-3% of polyvinylpyrrolidone K-30, 4-7% of soybean protein isolate, 0.5-1% of wheat proteolysis product and the balance injection water. The invention further provides a preparation method of the heatproof freeze-drying protecting agent for the recombined pseudorabies virus vaccines. The heatproof freeze-drying protecting agent is simple in formula, easy to prepare and suitable for mass production, has the advantages of high vaccine stability, prolonged vaccine shelf life and the like, and does not contain gelatin and animal source ingredients. Safety of the vaccines is high when the protecting agent is applied to the vaccines.

Owner:ZHAOQING DAHUANONG BIOLOGIC PHARMA

Heat-resistant freeze-drying protectant for porcine Japanese encephalitis live vaccine, preparation method and application thereof

ActiveCN103656661BAvoid damageReduce loss ratePowder deliveryViral antigen ingredientsJapanese encephalitisSucrose

Owner:CHINA ANIMAL HUSBANDRY IND

Newcastle disease and avian infectious bronchitis bigeminal live vaccine heat-resisting freeze-drying protective agent and preparation method

InactiveCN102671207ALow virus lossHigh degree of aging resistanceViral antigen ingredientsAntiviralsXyloseSodium carboxymethylcellulose

The invention relates to a newcastle disease and avian infectious bronchitis bigeminal live vaccine heat-resisting freeze-drying protective agent and a preparation method. The newcastle disease and avian infectious bronchitis bigeminal live vaccine heat-resisting freeze-drying protective agent provided by the invention comprises the following components: 1-2% of sodium carboxymethylcellulose, 2-8% of xylo-oligosaccharide, 1-3% of sorbitol, 0.5-0.8% of sodium glutamate, 0.1-0.5% of sodium selenite and the balance of water for injection. The heat-resisting freeze-drying protective agent provided by the invention solves the problem that the newcastle disease and avian infectious bronchitis bigeminal live vaccine can not be stored for a long time and transported at 2-8 DEG C.

Owner:QINGDAO AGRI UNIV

Heat-resisting freeze-dried protective agent for live vaccine for chicken infectious bursal diseases and preparation method for heat-resisting freeze-dried protective agent

InactiveCN102671208ALow virus lossHigh degree of aging resistanceViral antigen ingredientsAntiviralsXyloseSodium carboxymethylcellulose

The invention relates to a heat-resisting freeze-dried protective agent for a live vaccine for chicken infectious bursal diseases and a preparation method for the heat-resisting freeze-dried protective agent. The heat-resisting freeze-dried protective agent for the live vaccine for chicken infectious bursal diseases is prepared from the following components in percentage by weight: 2 to 3 percentof sodium carboxy methyl cellulose, 3 to 6 percent of xylo-oligosaccharide, 2 to 3 percent of polyvinylpyrrolidone, 0.5 to 0.8 percent of glutamine, 0.1 to 0.5 percent of sodium selenite, 0.01 to 0.05 percent of potassium chloride and the balance of water for injection. By the heat-resisting freeze-dried protective agent, the technical problem that the live vaccine for chicken infectious bursal diseases cannot be stored and transported for long time at the temperature of between 2 and 8 DEG C is solved, production process is simplified, and production cost is reduced.

Owner:QINGDAO AGRI UNIV

Macromolecular composite material decorative plate and manufacturing process

InactiveCN103146167AExcellent non-combustible heat resistanceStay away from fire accidentsUnsaturated polyesterPeroxide

The invention relates to a macromolecular composite material decorative plate and belongs to the technical field of production of macromolecular composite materials. Raw materials of the macromolecular composite material decorative plate are adequately mixed to form a ball-shaped prepreg based on glass fiber and unsaturated resin as a base material and various additives as supplement, and the prepreg is stirred and compressed at high temperature to generate products in different colors, wherein the raw materials comprise the components in percentage by weight as follows: 88-90% of unsaturated polyester resin, 1.5-2.5% of formyl peroxide, 1.0-1.8% of magnesium oxide, 3.0-3.5% of calcium carbonate, 1-2% of inorganic silver, 1.5-2% of release agent and 1-1.5% of coloring agent; and the proportion of glass fiber and the mixed material mainly based on unsaturated polyester resin is 50-60:40-50 in parts by weight. The specific manufacturing process of the decorative plate comprises the following steps of: preparation of the mixed material, glass fiber processing, manufacture of decorative plate ball-shaped material, high-temperature mould pressing and moulding and putting into a warehouse. According to the decorative plate provided by the invention, no combustible materials are added from manufacture to installation, so that fire accidents are completely avoided; and the formula proportion and the preparation process of the raw materials are improved, so that the strength and hardness of the product are enhanced, and the anti-aging degree of the product is increased.

Owner:德州悦缘复合材料科技有限公司

Heat-resistant freeze-drying protective agent for newcastle disease live vaccines and preparation method

InactiveCN102671209AHigh degree of aging resistanceReduce loss rateViral antigen ingredientsAntiviralsCellulosePyrrolidinones

The invention relates to a heat-resistant freeze-drying protective agent for newcastle disease live vaccines and a preparation method. The heat-resistant freeze-drying protective agent for the newcastle disease live vaccines specifically comprises the following components in percentage by weight: 1-2% of sodium carboxymethylcellulose, 2-8% of xylo-oligosaccharide, 1-3% of sorbitol, 1-3 %of polyvinylpyrrolidone, 0.5-0.8% of glutamine, 0.1-0.5% of sodium selenite and the balance of water for injection. The technical problem that the newcastle disease live vaccines cannot be stored and transported for a long time at the temperature of 2 DEG C to 8 DEG C is solved by the protective agent provided by the invnetion.

Owner:QINGDAO AGRI UNIV

Freeze-dried vaccine for porcine reproductive and respiratory syndrome and preparation method thereof

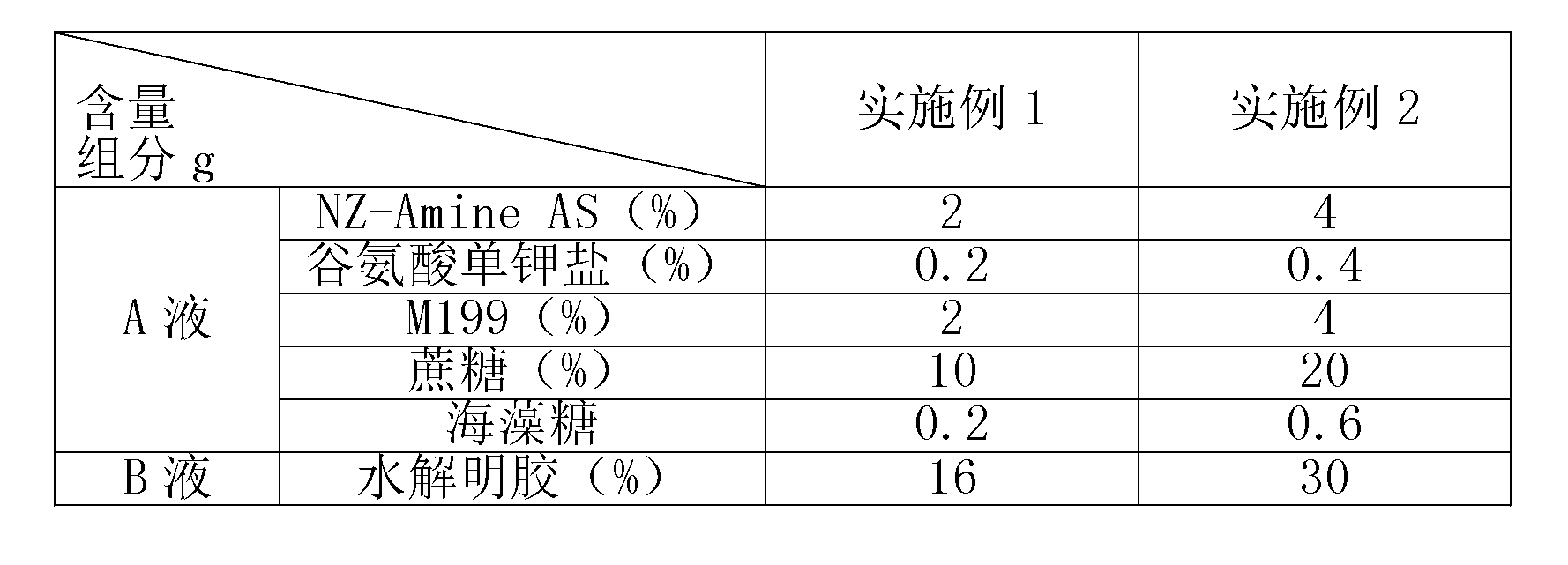

InactiveCN103301453AAvoid damageReduce titer lossPowder deliveryViral antigen ingredientsVitamin CSucrose

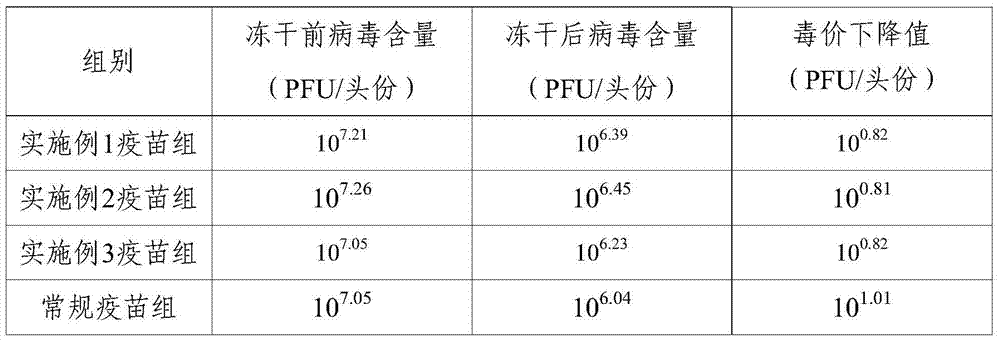

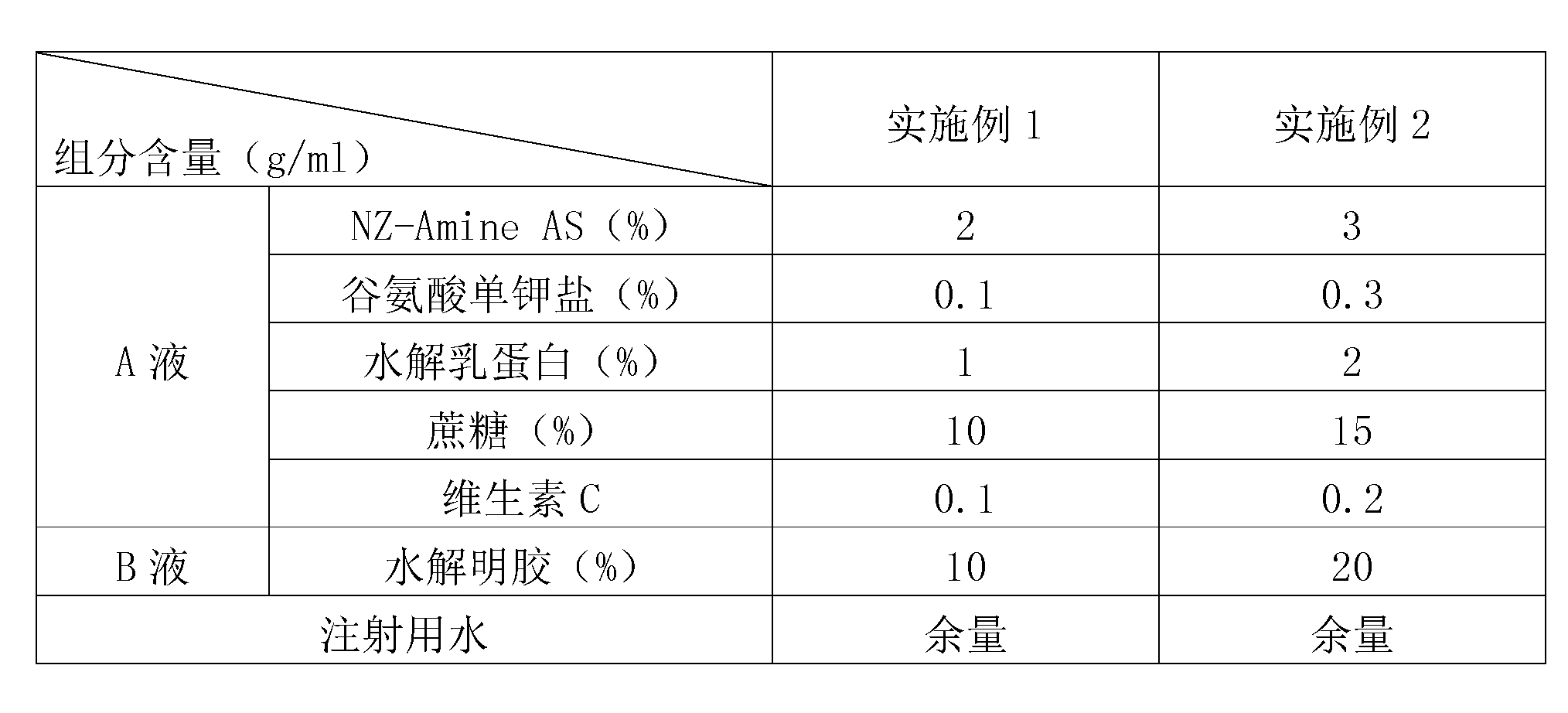

The invention relates to a freeze-dried vaccine for porcine reproductive and respiratory syndrome and a preparation method thereof. The freeze-dried vaccine is prepared from a porcine reproductive and respiratory syndrome viral antigen and a protective agent, wherein the protective agent is prepared from the following substances by weight percent: 2-3% of NZ-Amine AS, 0.1-0.3% of glutamic acid mono potassium salt, 10-15% of cane sugar, 1-2% of lactoalbumin hydrolysate, 10-20% of hydrolyzed gelatin, 0.1-0.2% of vitamin C and the balance of water for injection. The heat-resisting protective agent is capable of minimizing injuries caused by various physical and chemical factors to virus activity during processes of sub-packaging and freeze-drying products, so that the titer loss of a virus before and after freeze-drying is reduced to be not more than 0.2 titer; and the live vaccine of the heat-resisting protective agent is high in anti-aging degree, the loss ratio of the virus does not exceed 0.5 titer after the vaccine is preserved for 10 days at the temperature of 37 DEG C, the titer reduction of the vaccine is little after the vaccine is preserved for 24 months at the temperature of 2-8 DEG C, and therefore, the problems of energy waste and preservation inconvenience caused by a strict cold chain condition required in transportation and preservation of conventional vaccines are effectively solved.

Owner:YEBIO BIOENG OF QINGDAO

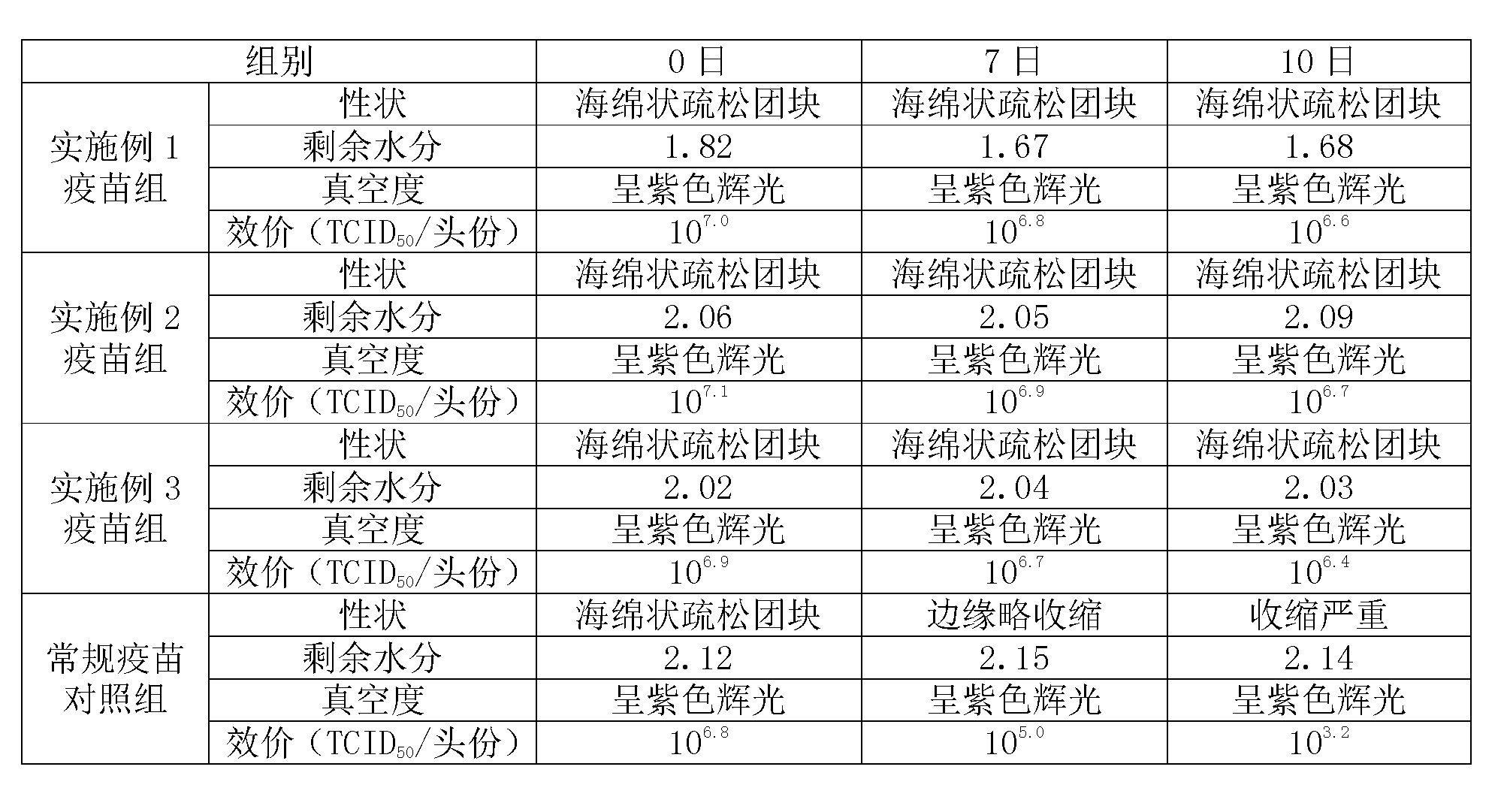

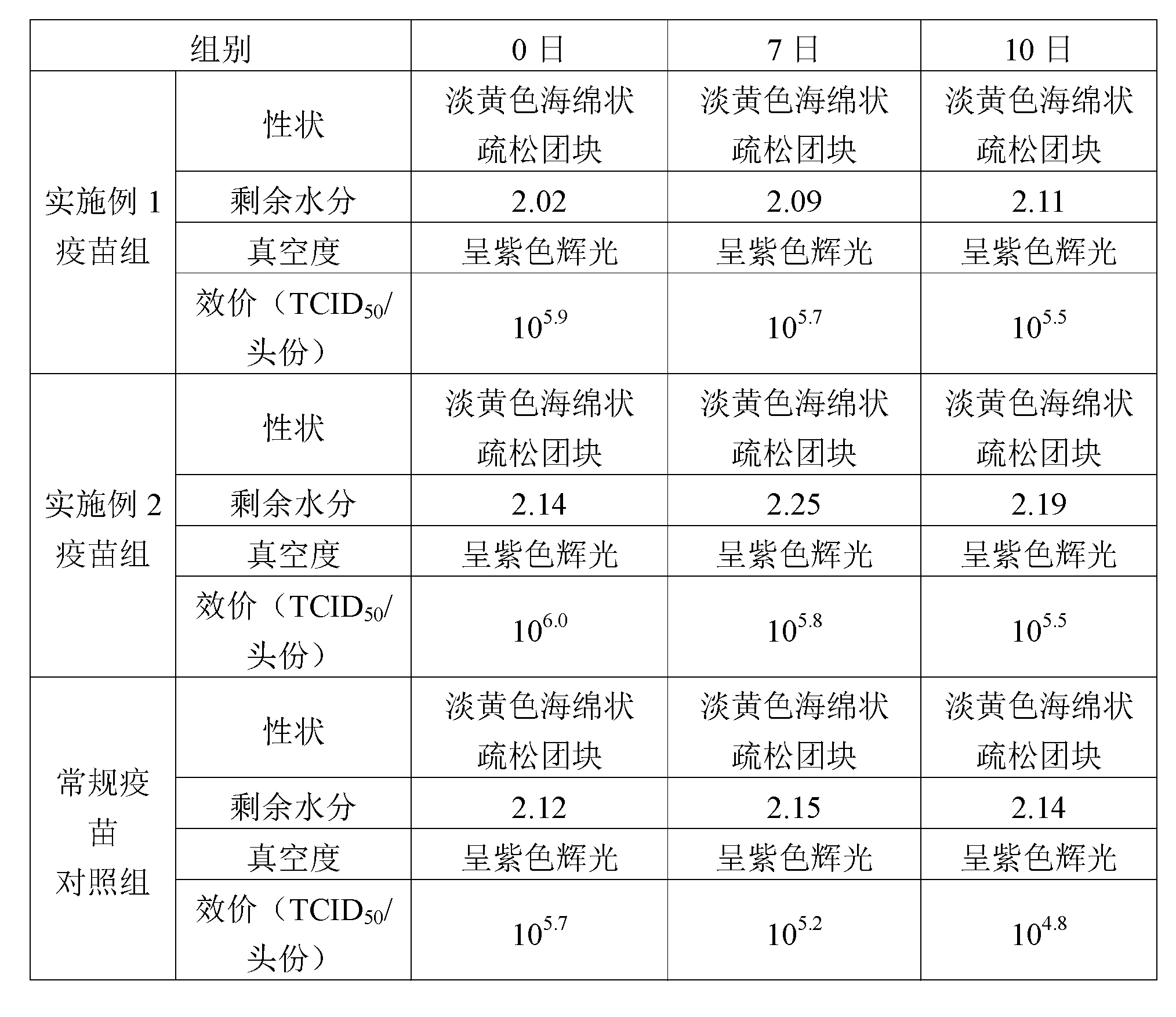

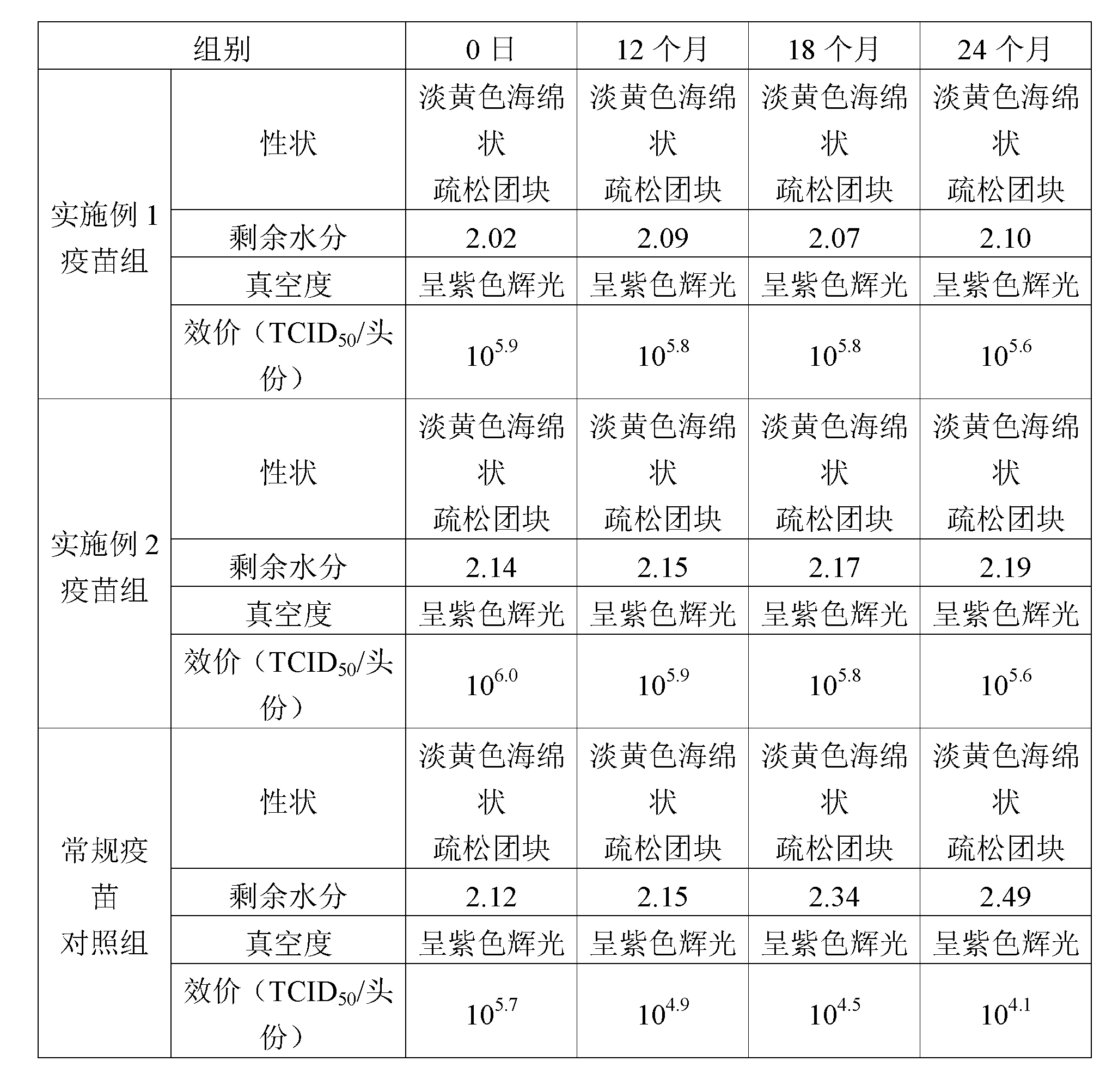

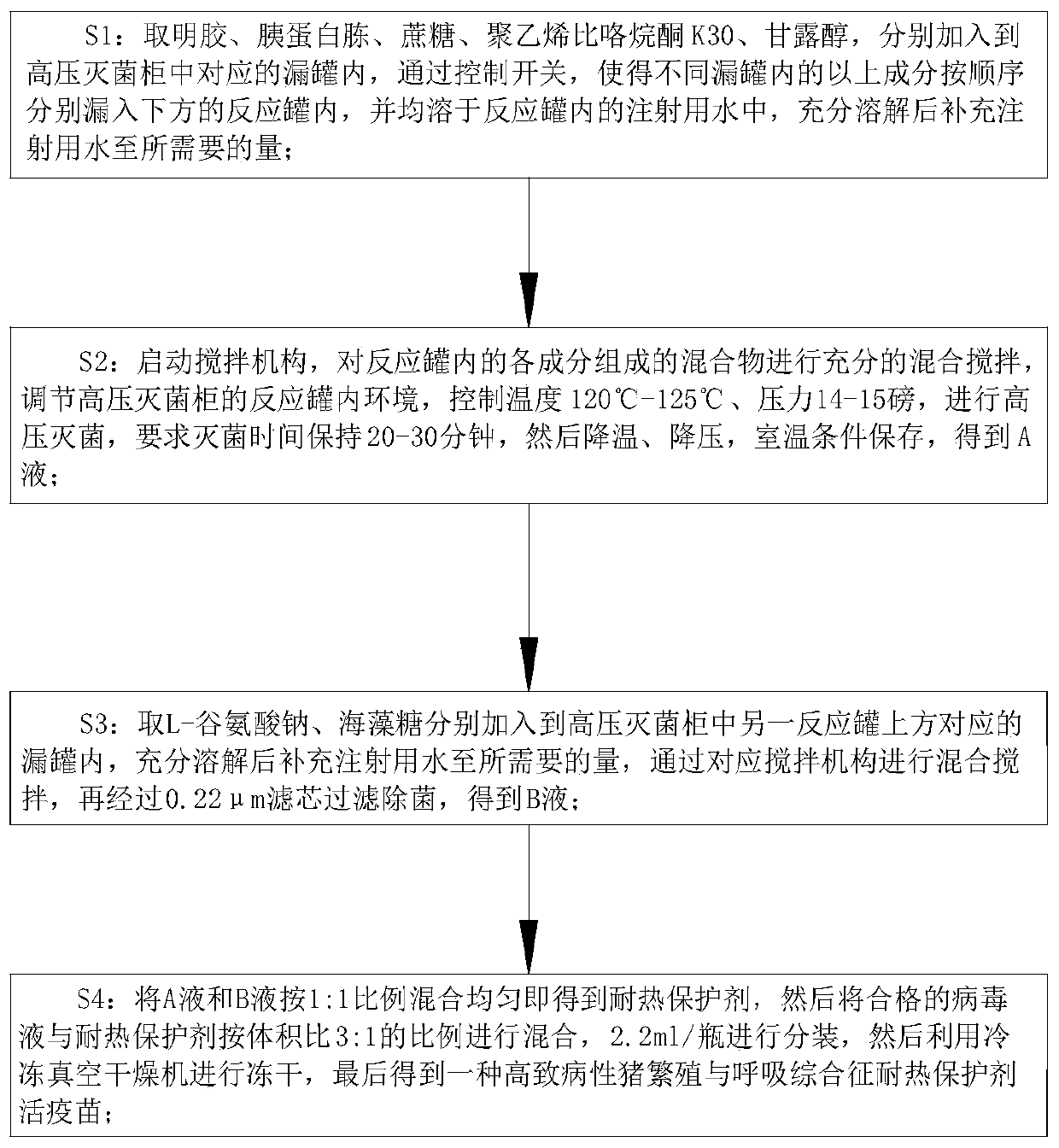

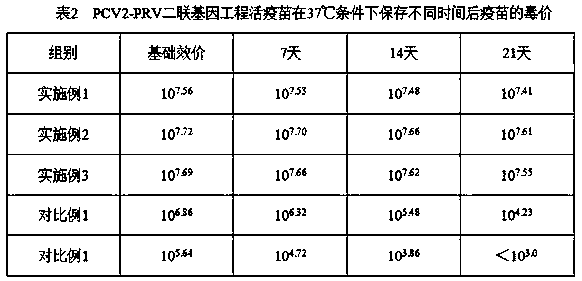

High-pathogenicity porcine reproductive and respiratory syndrome heat-resistant protective agent live vaccine and preparation method thereof

ActiveCN111588845AHigh degree of aging resistanceLower titerSsRNA viruses positive-senseViral antigen ingredientsBiotechnologyPathogenicity

Owner:哈尔滨元亨生物药业有限公司

Lyophilized vaccine for swine encephalitis B and preparation method thereof

ActiveCN103301452BAvoid damageReduce titer lossViral antigen ingredientsAntiviralsProtective antigenAntigen

The invention relates to a lyophilized vaccine for swine encephalitis B. The lyophilized vaccine consists of Japanese encephalitis virus serving as an antigen, and a protective agent, wherein the protective agent is prepared from the following substances in percentage by mass: 2.4-4% of NZ-amine, 0.3-0.5% of mono-potassium glutamate, 16-20% of sucrose, 6-20% of lactoalbumin hydrolysate, 1-1.6% of gelatin and the balance of water. According to the vaccine disclosed by the invention, the used lyophilized protective agent is made from raw materials which are low in cost, and the operation is simple, so that the vaccine can be produced in a large scale. After the vaccine prepared from the protective agent is stored for 24 months at the temperature of 2-8 DEG C, the potency of the vaccine is not smaller than 10<5.7>TCID50 / head (Chinese Standard), so that the storage life of the vaccine is prolonged effectively.

Owner:YEBIO BIOENG OF QINGDAO

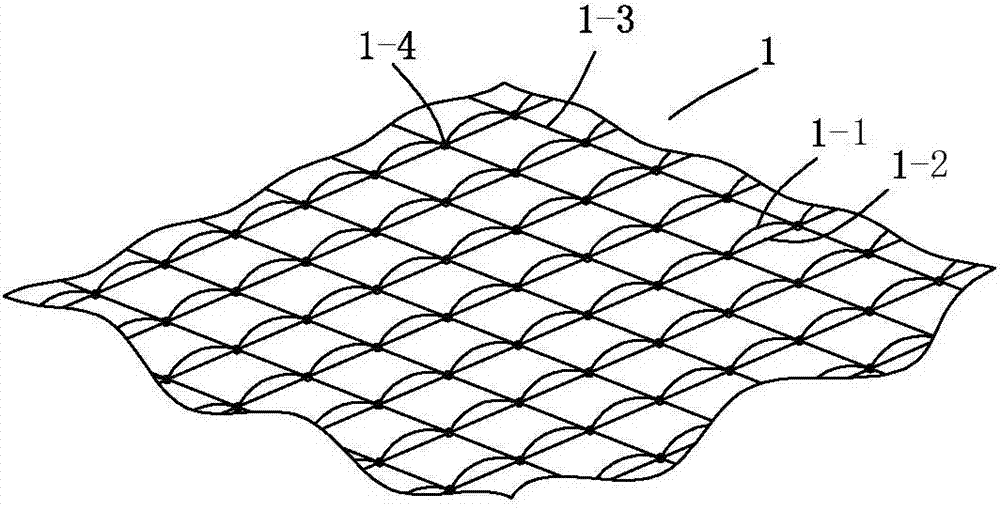

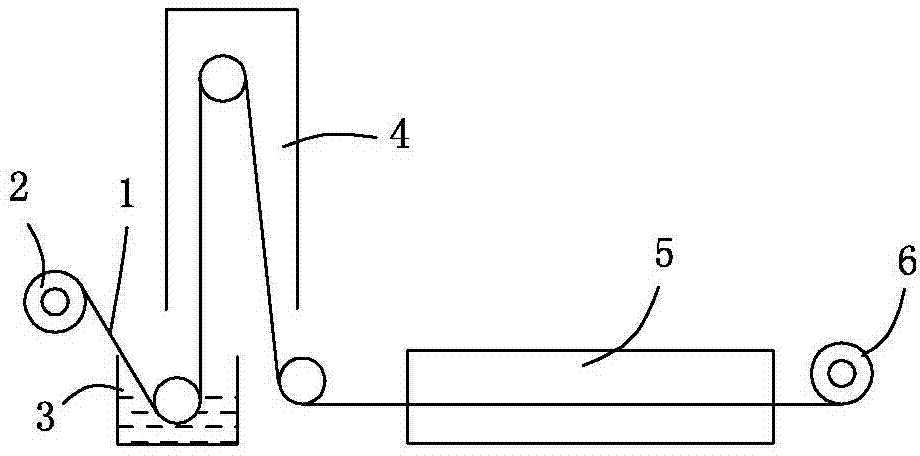

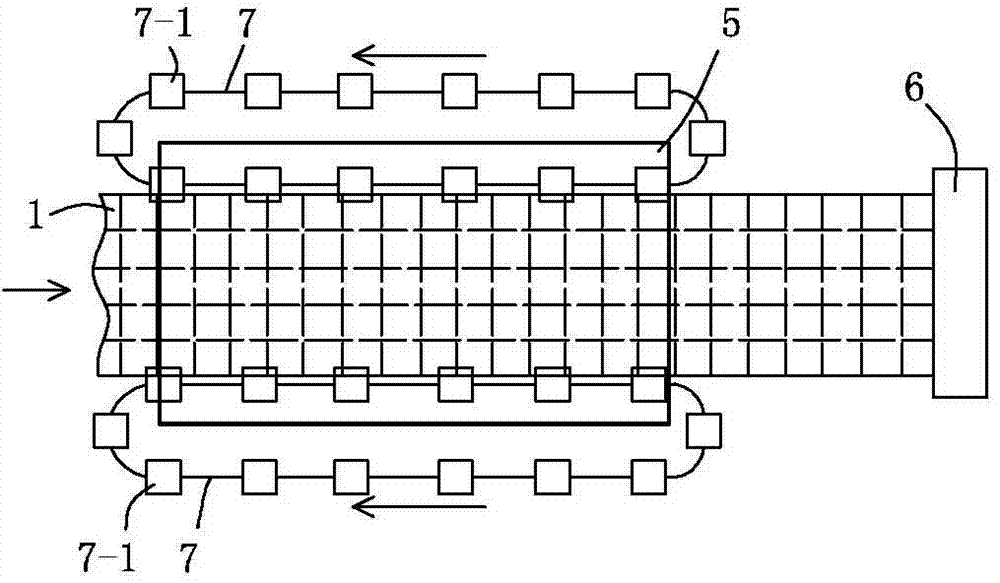

A kind of warp-knitted polyester glass fiber three-dimensional slope-fixing soil grid and its preparation method

The invention relates to a warp-knitted polyester glass fiber three-dimensional slope protection soil fixation grating and a preparation method thereof, and in particular relates to a multi-grid grating formed by weaving polyester fiber yarns and glass fiber yarns and a preparation method thereof. Transverse gratings of the grating are formed by arranging glass fiber yarns and polyester fiber yarns; longitudinal gratings of the grating are glass fiber yarns; joints of transverse gratings and longitudinal gratings of grids are bound by polyester wires; after the grating is heated, the glass fiber yarns of the transverse gratings of the grids are upwards bent and protruded from binding points on two sides to form a three-dimensional state of the grating; and a solidification layer formed by waterproof adhesive emulsion is arranged on the surface of the grating. The grating in the preparation method is easy in production and manufacture and high in efficiency; in a construction paving process, the stability of the length and the width of the grating is good; a large area of gratings are paved; the construction difficulty is low; the warp-knitted polyester glass fiber three-dimensional slope protection soil fixation grating is used on the surface of a slope body, and a slope fixing effect is good; and even if the grating is corroded by rainwater for a long time and is immersed in water, the grating still has enough strength.

Owner:泰安三英新材料股份有限公司

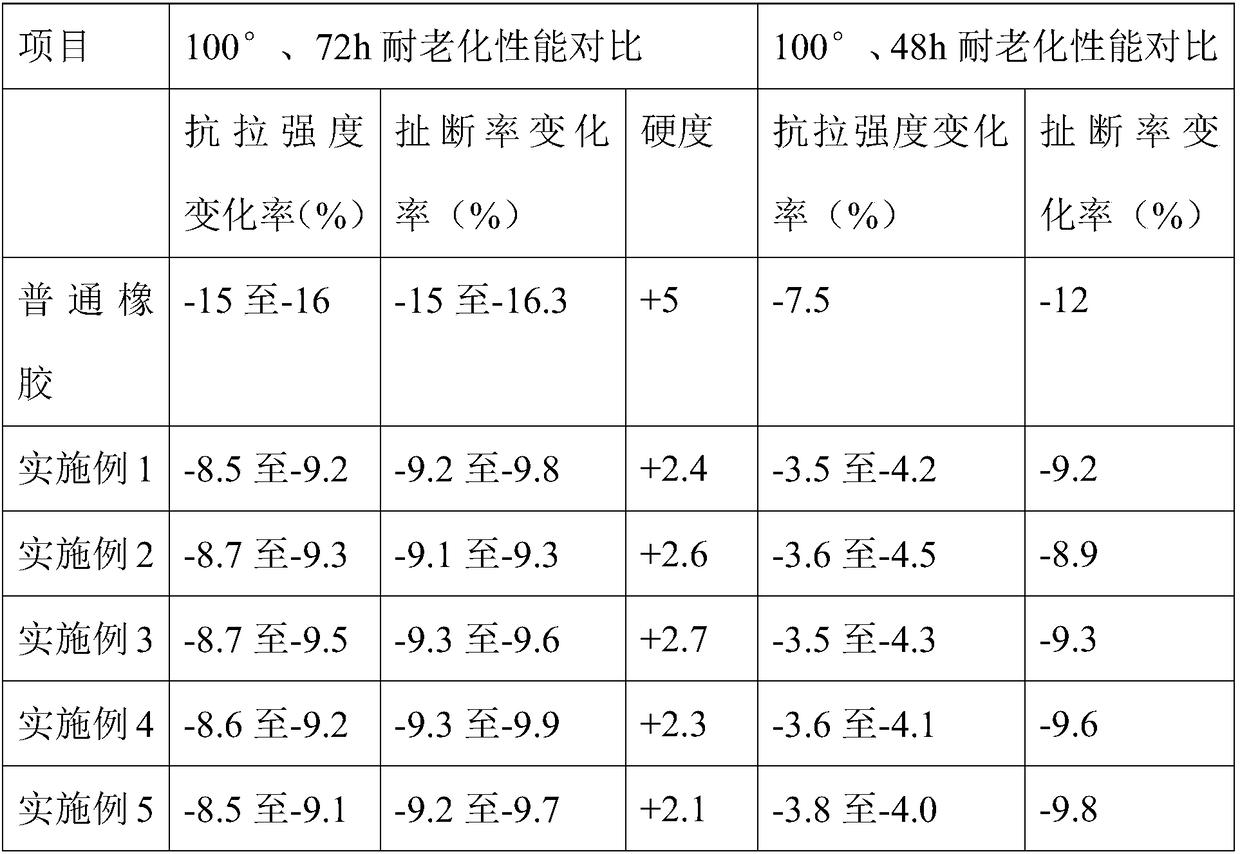

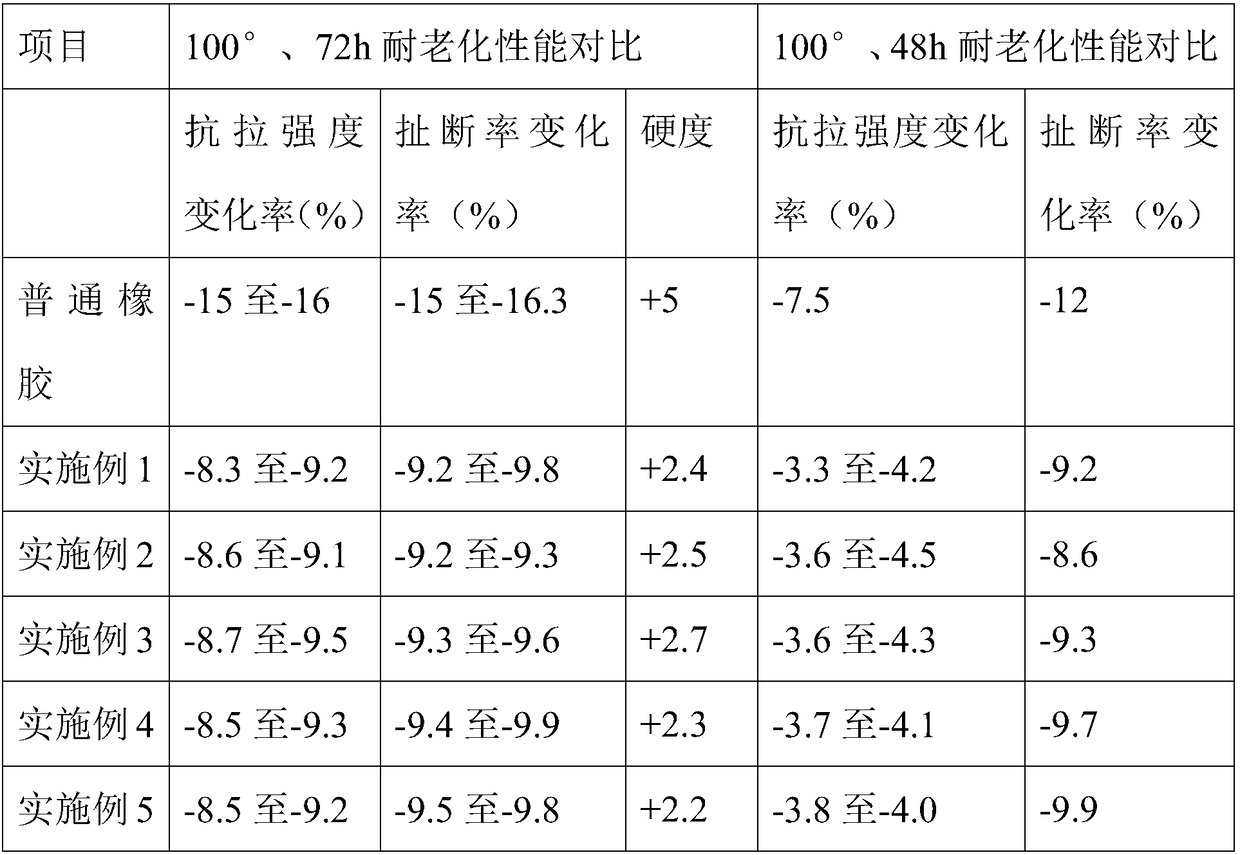

Good-heat-resistance rubber for hot water bag and preparation method of good-heat-resistance rubber

The invention discloses a good-heat-resistance rubber for a hot water bag. The good-heat-resistance rubber comprises the raw materials in parts by weight: 40-45 parts of ethylene-propylene-diene rubber, 10-15 parts of hydrogenated butadiene-acrylonitrile rubber, 2-3 parts of carbamate vulcanizing agent, 1.2-1.8 parts of sulfur, 2-4 parts of accelerant TMTD, 20-30 parts of modified white carbon black, 9-11 parts of cashew nut shell oil, 5-7 parts of boron powder, 14-15 parts of fly ash cenospheres, 14-15 parts of calcined clay, 10-12 parts of zinc oxide, 3-5 parts of quartz powder, 5-7 parts ofanti-aging agent MB, 2-4 parts of light calcium carbonate, 5-8 parts of barium stearate, 5-7 parts of palm wax, 2-4 parts of zinc diethyl dithiocarbamate and 1.5-2.5 parts of dicumyl peroxide. The invention further discloses a preparation method of the good-heat-resistance rubber for the hot water bag. The preparation method is safe, environment-friendly, simple and suitable for industrial production; and the prepared rubber has excellent heat resistance, wear resistance, anti-aging properties and elasticity and good mechanical properties.

Owner:赵建志

A heat-resistant freeze-drying protectant for recombinant pseudorabies virus vaccine and its preparation method

ActiveCN105012963BImprove protectionGood lookingMacromolecular non-active ingredientsArginineFreeze-drying

The invention relates to a heat-resistant freeze-drying protective agent for a recombinant pseudorabies virus vaccine, which is made of the following components in terms of weight percentage: 2-3% gelatin, 1-2% polyvinylpyrrolidone K-301-2%, and 0-0 trehalose 4%, sucrose 2-5%, mannitol 0.1-0.5%, astragalus polysaccharide 0-0.5%, glycine 1-1.5%, arginine 0-1%, bovine serum albumin 0-1%, and the balance is injection use water. The invention also provides a preparation method of the recombinant pseudorabies virus vaccine heat-resistant freeze-drying protectant. The heat-resistant freeze-drying protective agent for recombinant pseudorabies virus vaccine of the invention can prolong the storage time of the vaccine in a relatively high temperature environment, and its preparation method is simple, which is convenient for production and application.

Owner:ZHAOQING DAHUANONG BIOLOGIC PHARMA +1

Heat-resistant freeze-drying protective agent for newcastle disease live vaccines and preparation method

InactiveCN102671209BHigh degree of aging resistanceReduce loss rateViral antigen ingredientsAntiviralsCellulosePyrrolidinones

Owner:QINGDAO AGRI UNIV

Live pseudorabies vaccine and preparation method thereof

ActiveCN103316355BAvoid damageReduce titer lossPowder deliveryAntiviralsMonosodium glutamateCold chain

The invention relates to a freeze-drying protective additive which is composed of 1 to 2% of NZ-Amine AS, 0.1 to 0.2% of monosodium glutamate, 5 to 10% of saccharose, 1 to 2% of M199, 0.1 to 0.3% of trehalose, 8 to 15% of hydrolyzed gelatin, and the balance of water. The freeze-drying protective additive is used for preparing a freeze-dried pseudorabies vaccine. A heat-resisting protective agent can minimize the damage of various physical and chemical factors of a product to virus activity during sub-packaging and freezing-drying processes, greatly reduces the titer loss of the virus before and after freezing and drying and keeps the loss of being not greater than 0.2 titer. A heat-resisting protective agent live vaccine is high in degree of resistance to aging, the loss ratio of the virus kept for 10 days under a condition of 37 DEG C is not greater than 0.5 titer; the heat-resisting protective agent live vaccine can be stored for 24 months at 2 to 8 DEG C, the titer of the vaccine is reduced a little, so that the problem that the vaccine in general transporting and storing needs strict cold chain condition, which leads to energy waste and inconvenient storage, can be solved effectively.

Owner:YEBIO BIOENG OF QINGDAO

High-wear-resistance rubber for toy balls

InactiveCN108659280AEvenly dispersedImprove high temperatureBuilding insulationsWear resistantPhthalate

The invention discloses high-wear-resistance rubber for toy balls. The high-wear-resistance rubber comprises, by weight, 25-50 parts of butadiene rubber, 9-20 parts of nitrile rubber, 20-30 parts of light calcium, 9-11 parts of wear-resistant agent, 5-7 parts of zinc carbonate, 14-15 parts of vulcanizing agent, 2-3 parts of dioctyl phthalate, 1.2-1.8 parts of spray carbon black, 2-4 parts of coumarone, 14-15 parts of xylene resin, 10-12 parts of antiager RD, 3-5 parts of asphalt, 5-7 parts of promoter CZ and 2-4 parts of softener. The rubber has excellent heat resistance, wear resistance, aging resistance and elasticity and good mechanical performance.

Owner:赵建志

Recombinant pseudorabies virus vaccine heat-resistant freeze-drying protectant and preparation method thereof

ActiveCN105561317BImprove protectionImprove securityViral antigen ingredientsAntiviralsVaccine StabilityFreeze-drying

The invention relates to a heatproof freeze-drying protecting agent for recombined pseudorabies virus vaccines. The heatproof freeze-drying protecting agent comprises, by weight, 4-8% of trehalose, 0-3% of cane sugar, 0.2-0.8% of sorbitol, 1-3% of polyvinylpyrrolidone K-30, 4-7% of soybean protein isolate, 0.5-1% of wheat proteolysis product and the balance injection water. The invention further provides a preparation method of the heatproof freeze-drying protecting agent for the recombined pseudorabies virus vaccines. The heatproof freeze-drying protecting agent is simple in formula, easy to prepare and suitable for mass production, has the advantages of high vaccine stability, prolonged vaccine shelf life and the like, and does not contain gelatin and animal source ingredients. Safety of the vaccines is high when the protecting agent is applied to the vaccines.

Owner:ZHAOQING DAHUANONG BIOLOGIC PHARMA

Porcine reproductive and respiratory syndrome live vaccine heat-resistant freeze-drying protective agent and preparation method thereof

ActiveCN102166362BReduce loss rateHigh degree of aging resistanceViral antigen ingredientsInorganic non-active ingredientsFreeze-dryingArginine

The invention relates to a porcine reproductive and respiratory syndrome live vaccine heat-resistant freeze-drying protective agent and a preparation method thereof. The heat-resistant freeze-drying protective agent is mixed by the raw materials based on weight percentage: 1-2% of gelatin, 4-6% of trehalose, 1-2% of tryptone, 1-2% of trypticase, 1-2% of polyvinylpyrrolidone, 0.164% of dipotassiumphosphate, 0.052% of monopotassium phosphate, 1% of sorbic alcohol, 1% of sodium glutamate, 1% of arginine salt and the balance of water. The preparation method comprises the steps of: preparing the materials into two mixed solution, respectively preparing in a mixing way by means of degerming to prepare a heat-resistant freeze-drying protective agent, mixing according to the proportion of the protective agent to the virus-resistant raw material as 1:1, performing split charging, and drying in a freezing way. Before drying in a freezing way, the virus loss rate is low, a freeze-drying productis high in ageing-resistant degree, and the virus is invariable in content after the freeze-drying product is preserved at the temperature of 2-8 DGE C for 24 months. After the invention is used, thetechnical neck bottle that the porcine reproductive and respiratory syndrome live vaccine can be preserved and transported under the condition of -15 DEG C is solved.

Owner:WUHAN CHOPPER BIOLOGY

Heat-resisting freeze-dried protective agent for live vaccine for chicken infectious bursal diseases and preparation method for heat-resisting freeze-dried protective agent

InactiveCN102671208BHigh degree of aging resistanceReduce loss rateViral antigen ingredientsAntiviralsBiotechnologyCellulose

Owner:QINGDAO AGRI UNIV

Imitation stone thermal insulating decoration board and making process thereof

InactiveCN101824883BExcellent non-combustible heat resistanceThe ratio is scientific and reasonableCovering/liningsSolid waste managementMelamine formaldehyde resinBuilding construction

Owner:山东中南集团有限公司

Polymeric composite material decoration plate and production method thereof

The invention belongs to the technical field of decoration materials, and provides a polymeric composite material decoration plate and a production method thereof. Raw materials of the polymeric composite material decoration plate comprise ethylene acrylate, inorganic fibers, benzoyl peroxide, calcium oxide, magnesium carbonate, inorganic silver, a mold release agent and a colorant. All above rawmaterials are specifically proportioned to form a unique formula, and the polymeric composite material decoration plate by the production method has increased strength and hardness and enhanced agingresistance. The polymeric composite material decoration plat has a low thermal conductivity, also has energy saving and environmental protection properties, and has good antibacterial property and good corrosion resistance due to the addition of the inorganic silver.

Owner:桐城市景瑞建筑装饰工程有限公司

Newcastle disease and avian infectious bronchitis bigeminal live vaccine heat-resisting freeze-drying protective agent and preparation method

InactiveCN102671207BHigh degree of aging resistanceReduce loss rateViral antigen ingredientsAntiviralsCelluloseOligosaccharide

Owner:QINGDAO AGRI UNIV

LED light strip material with excellent heat resistance and preparation method thereof

The invention discloses an LED light strip material with excellent heat resistance and a preparation method thereof. The LED light strip material with excellent heat resistance is prepared from the following ingredients: 35-45 parts of PTT, 20-30 parts of epoxy resin, 15-25 parts of a plasticizer, 12-18 parts of organophosphorus ester, 0.3-0.8 part of a lubricant, 20-28 parts of calcium carbonate,10-16 parts of polyether amine, 0.5-2 parts of maleic anhydride, 3-8 parts of polyethylene glycol, 0.5-1.5 parts of azodiisobutyronitrile, 18-25 parts of TPU and 0.8-1.8 parts of a light absorber. The LED light strip material has the characteristics of high strength and aging resistance.

Owner:何明俊

Anti-aging plastic product containing polyethylene wax

The invention discloses an anti-aging plastic product containing polyethylene wax. The anti-aging plastic product is prepared from the following raw material in parts by weight: 60 to 80 parts of main material, 2 to 8 parts of silane coupling agent KH-550, 4 to 8 parts of modified polyethylene wax, 40 to 50 parts of filling material, 2 to 4 parts of dicumyl peroxide, 1 to 2 parts of diphenylamine, 1 to 2 parts of polycaprolactone, 1 to 2 parts of phenol formaldehyde resin and 1 to 2 parts of 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate. The modified polyethylene wax is prepared by the following steps: adding polyethylene wax into a citric acid sodium solution; heating and stirring; adding agarose; performing ultrasonic treatment; performing microwave treatment; adding a product into liquid paraffin; stirring in an ice water bath to obtain modified polyethylene wax.

Owner:无为华兴高分子材料有限公司

Decorative composite board and production process thereof

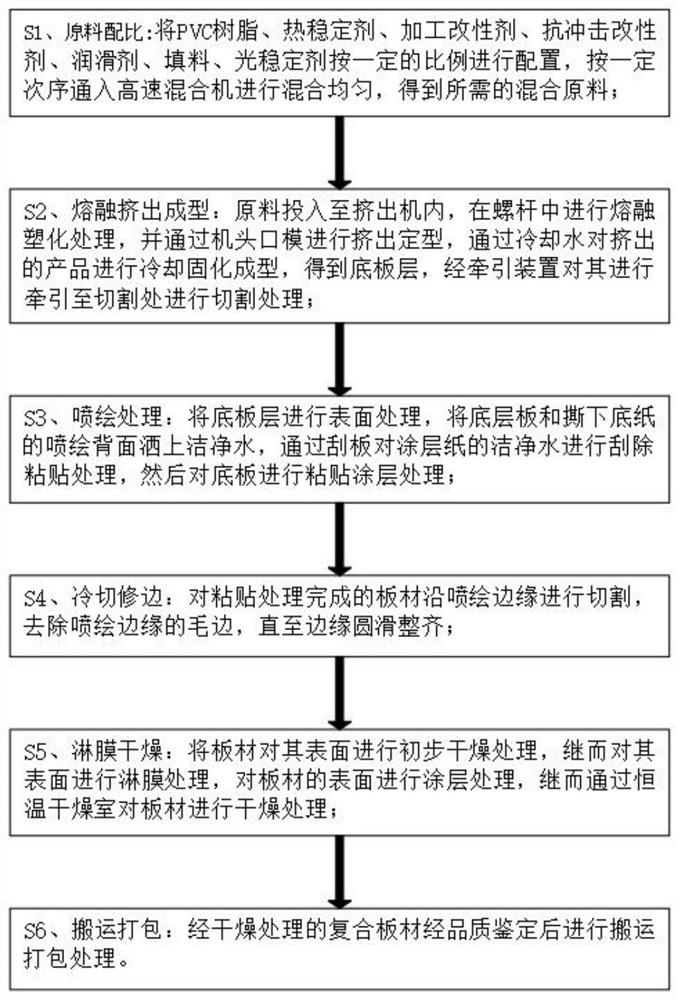

The invention belongs to the technical field of PVC board processing, and particularly relates to a decorative composite board and a production process thereof. Aiming at the problems of poor stability and processability of a PVC board during processing, the decorative composite board comprises a bottom board layer, a spray painting coating and a curing coating, the bottom plate layer comprises a high-density PVC plate solid section and a middle section which are formed by an extrusion process, the spray-painted coating is adhered to the upper surface of the middle section of the bottom plate layer, and the cured coating is pressed and adhered to the outer surface of the spray painting coating; and the PVC board is subjected to extrusion molding processing treatment through an extruder, the separability of a mouth mold is improved, and the heat stabilizer, the processing modifier, the impact modifier, the lubricant, the filler and the light stabilizer are added according to a certain proportion during PVC resin processing, so that the stability and processability of the PVC composite board during processing are improved, the processing mechanical load is reduced, the product is smooth, the plasticizing quality of the composite board is improved, the appearance of the composite board is changed, and the rigidity effect of the composite board is improved.

Owner:龙里县粤盛型材有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com