Good-heat-resistance rubber for hot water bag and preparation method of good-heat-resistance rubber

A hot water bottle and heat resistance technology, applied in the rubber field, can solve the problem of low heat resistance, achieve good heat resistance and aging resistance, improve corrosion resistance, and improve high temperature and low temperature performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

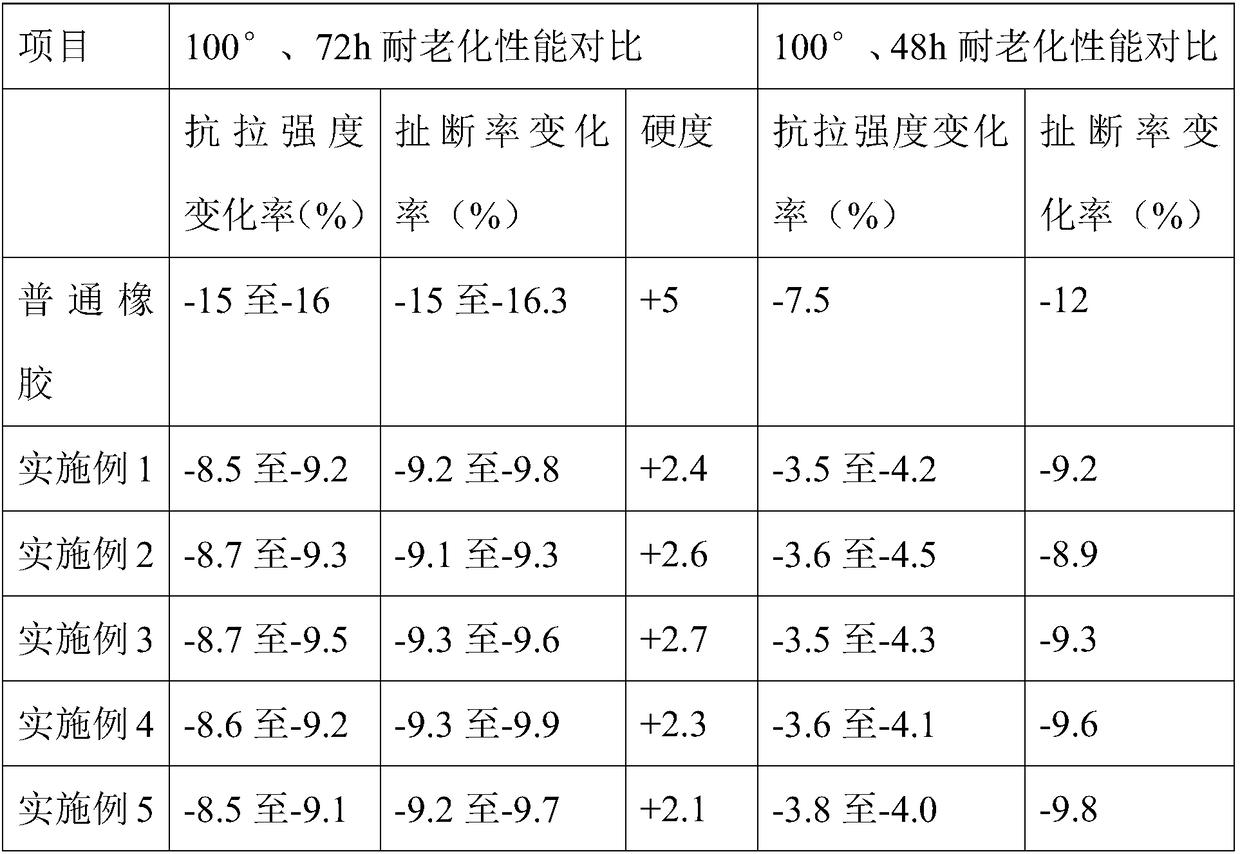

Examples

Embodiment 1

[0016] A kind of rubber with good heat resistance for a hot water bag, its raw materials include by weight: 40 parts of EPDM rubber, 15 parts of hydrogenated nitrile rubber, 2 parts of urethane vulcanizing agent, 1.8 parts of sulfur, and 2 parts of accelerator TMTD 30 parts of modified silica, 9 parts of cashew nut shell oil, 7 parts of boron powder, 14 parts of fly ash microbeads, 15 parts of calcined clay, 10 parts of zinc oxide, 5 parts of quartz powder, 5 parts of antioxidant MB, 4 parts of light calcium carbonate, 5 parts of barium stearate, 7 parts of palm wax, 2 parts of zinc diethyldithiocarbamate, 2.5 parts of dicumyl peroxide.

[0017] The method for preparing rubber for a hot water bag with good heat resistance comprises the following steps: weighing each raw material according to the weight portion, mixing and stirring for 35 minutes to form raw rubber, putting the raw rubber into a blast furnace for melting, and the melting temperature is 270°C, After smelting, it...

Embodiment 2

[0019] A kind of rubber with good heat resistance for a hot water bag, its raw materials include by weight: 45 parts of EPDM rubber, 10 parts of hydrogenated nitrile rubber, 3 parts of urethane vulcanizing agent, 1.2 parts of sulfur, and 4 parts of accelerator TMTD 20 parts of modified silica, 11 parts of cashew nut shell oil, 5 parts of boron powder, 15 parts of fly ash microbeads, 14 parts of calcined clay, 12 parts of zinc oxide, 3 parts of quartz powder, 7 parts of antioxidant MB, 2 parts of light calcium carbonate, 8 parts of barium stearate, 5 parts of palm wax, 4 parts of zinc diethyldithiocarbamate, 1.5 parts of dicumyl peroxide;

[0020] Wherein, the modified white carbon black is prepared according to the following process: place the white carbon black in an appropriate amount of 30wt% ethanol solution for ultrasonic dispersion for 40 minutes, add nano-silica under high-speed stirring, and then use hydrochloric acid to adjust the pH value of the system to maintain At...

Embodiment 3

[0023] A kind of rubber with good heat resistance for a hot water bag, its raw materials include by weight: 42 parts of EPDM rubber, 13 parts of hydrogenated nitrile rubber, 2.5 parts of urethane vulcanizing agent, 1.5 parts of sulfur, and 3 parts of accelerator TMTD 25 parts of modified silica, 10 parts of cashew nut shell oil, 6 parts of boron powder, 14.5 parts of fly ash microbeads, 14.5 parts of calcined clay, 11 parts of zinc oxide, 4 parts of quartz powder, 6 parts of antioxidant MB, 3 parts of light calcium carbonate, 6.5 parts of barium stearate, 6 parts of palm wax, 3 parts of zinc diethyldithiocarbamate, 2 parts of dicumyl peroxide;

[0024] Wherein, the modified silica is prepared according to the following process: place the silica in an appropriate amount of 50wt% ethanol solution for ultrasonic dispersion for 30 minutes, add nano-silica under high-speed stirring, and then use hydrochloric acid to adjust the pH value of the system to maintain At 3.5, the holding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com