High-wear-resistance rubber for toy balls

A high-abrasion-resistance, ball-bearing technology, applied in the field of high-abrasion-resistance rubber, can solve the problem of low abrasion resistance, and achieve the effects of improving elasticity and tensile strength, improving mechanical properties, and improving elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

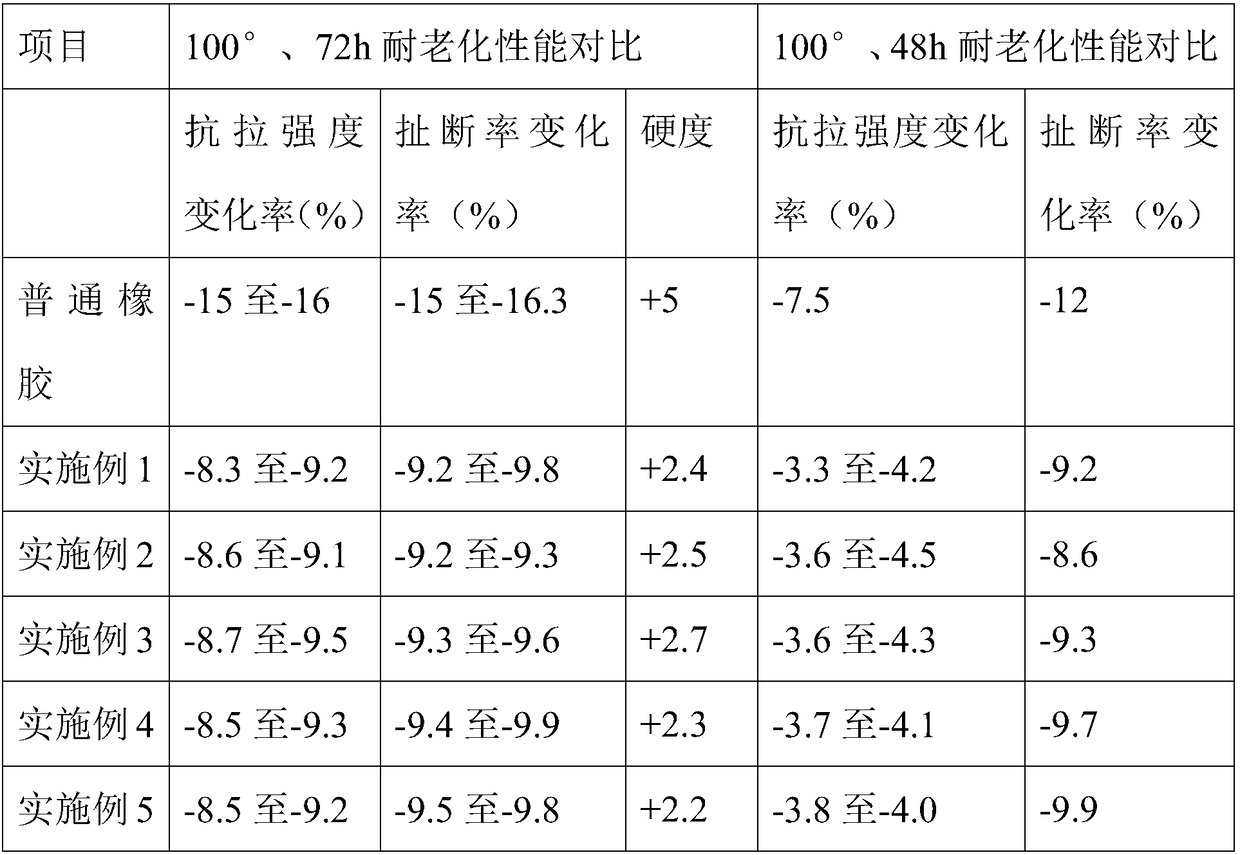

Examples

Embodiment 1

[0013] A kind of high wear-resistant rubber used for toy balls, its raw materials include by weight: 50 parts of butadiene rubber, 20 parts of nitrile rubber, 30 parts of light calcium, 9 parts of wear-resistant agent, 7 parts of zinc carbonate, vulcanizing agent 14 parts, 2 parts of dioctyl phthalate, 1.8 parts of spray carbon black, 2 parts of coumarone, 15 parts of xylene resin, 10 parts of antioxidant RD, 5 parts of asphalt, 5 parts of accelerator CZ, 4 parts of softener .

Embodiment 2

[0015] A kind of high wear-resistant rubber used for toy balls, its raw materials include by weight: 25 parts of butadiene rubber, 9 parts of nitrile rubber, 20 parts of light calcium, 11 parts of wear-resistant agent, 5 parts of zinc carbonate, vulcanizing agent 15 parts, 3 parts of dioctyl phthalate, 1.2 parts of spray carbon black, 4 parts of coumarone, 14 parts of xylene resin, 12 parts of antioxidant RD, 3 parts of asphalt, 7 parts of accelerator CZ, 2 parts of softener ;

[0016] Wherein, the preparation method of the wear-resistant agent is as follows: after the diatomite is pulverized, add lemongrass oil, grind for 35 minutes, add camphor wood powder, continue grinding for 25 minutes, add ethylenediamine solution, heat up to 50°C, and stir to react After 50 minutes, filter under reduced pressure and dry to obtain the anti-wear agent.

Embodiment 3

[0018] A kind of high wear-resistant rubber used for toy balls, its raw materials include by weight: 30 parts of butadiene rubber, 12 parts of nitrile rubber, 25 parts of light calcium, 10 parts of wear-resistant agent, 6 parts of zinc carbonate, vulcanizing agent 14.5 parts, 2.5 parts of dioctyl phthalate, 1.5 parts of spray carbon black, 3 parts of coumarone, 14.5 parts of xylene resin, 11 parts of antioxidant RD, 4 parts of asphalt, 6 parts of accelerator CZ, 3 parts of softener share;

[0019] Wherein, the preparation method of the wear-resistant agent is as follows: after the diatomite is pulverized, add lemongrass oil, grind for 55 minutes, add camphor wood powder, continue grinding for 10 minutes, add ethylenediamine solution, heat up to 75°C, and stir to react 30min, filter under reduced pressure, and dry to obtain the anti-wear agent;

[0020] The mass fraction of the ethylenediamine solution is 45wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com