A kind of warp-knitted polyester glass fiber three-dimensional slope-fixing soil grid and its preparation method

A technology of polyester glass fiber three and polyester fiber, applied in warp knitting, chemical instruments and methods, excavation, etc., can solve the problems of high production cost, low production efficiency, difficult construction, etc., and achieve a high degree of aging resistance , Simple production and good slope consolidation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

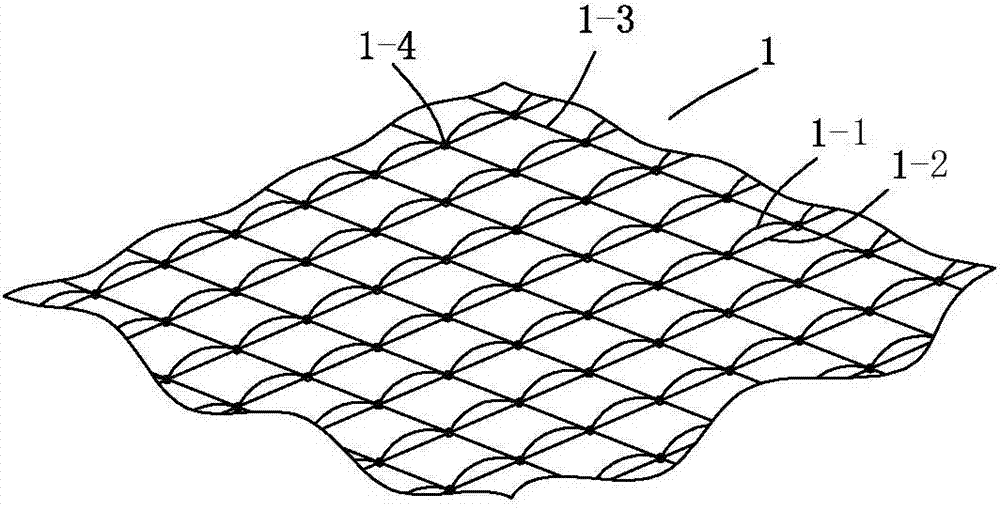

[0024] A kind of warp-knitted polyester glass fiber three-dimensional slope-fixing soil grid, see figure 1 , the three-maintenance slope consolidation soil grid is a multi-square grid 1 composed of polyester fiber yarn and glass fiber yarn weaving, and the horizontal grid of the grid is made of glass fiber yarn 1-1 and polyester fiber yarn 1-2 arrangement, the longitudinal grid 1-3 of the grid is made of glass fiber yarn, and the intersection nodes 1-4 of the horizontal grid and the longitudinal grid of the grid are bound and fixed with polyester wire; wherein, the grid is After heat treatment, the glass fiber yarns of the grid horizontal grid are bent upward from the binding points on both sides to form a three-dimensional state of the grid, and the surface of the grid has a cured layer formed by a waterproof adhesive emulsion; in the embodiment The transverse direction refers to the direction coaxial with the transverse direction of the ramp when the grid is laid on the ramp...

Embodiment 2

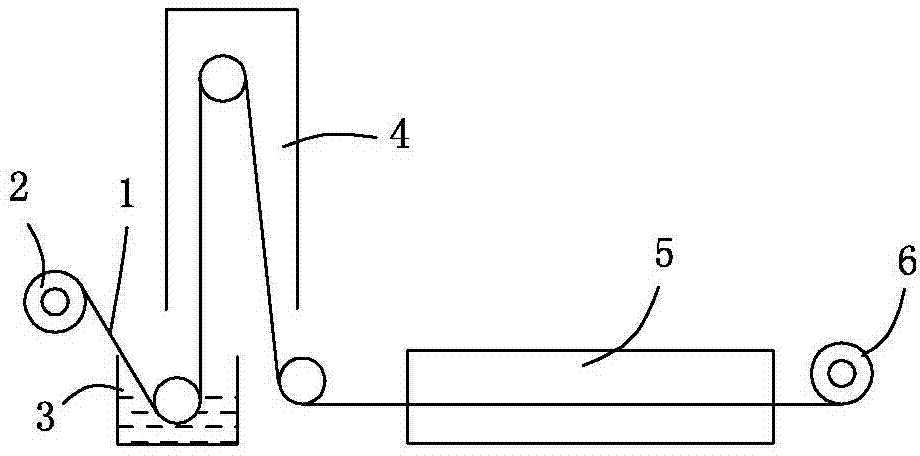

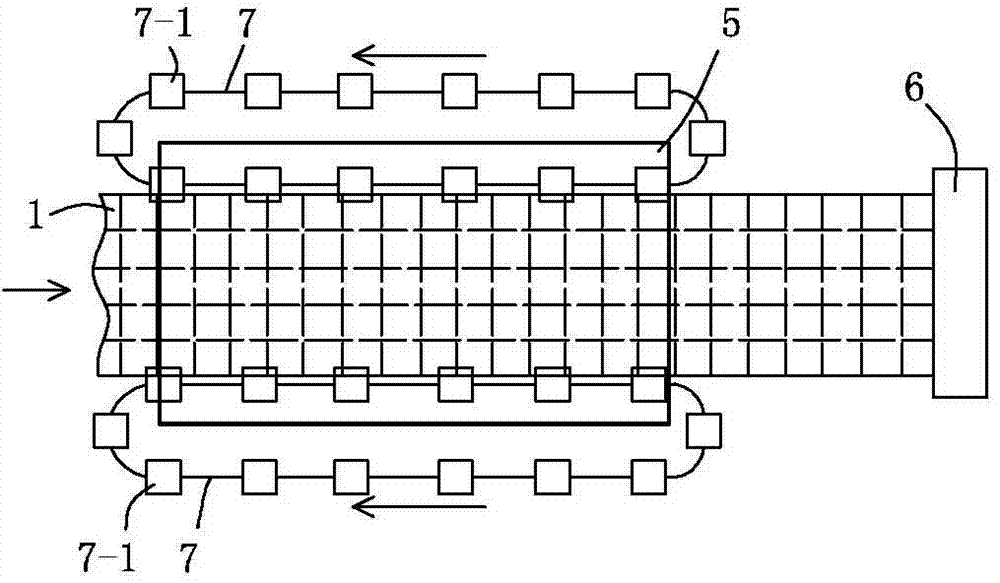

[0037] A kind of preparation method of warp-knitted polyester glass fiber three-dimensional slope-fixing soil grid, see figure 1 , figure 2 with image 3 , the method is: firstly, polyester fiber yarn and glass fiber yarn are woven into a multi-grid grid by a knitting machine, and the horizontal grid of the grid is composed of glass fiber yarn and polyester fiber yarn arrangement. The longitudinal grid of the grid is made of glass fiber yarn, and the intersection points of the horizontal grid and the longitudinal grid of the square grid are bound and fixed with polyester filaments; Roll 2 is unrolled, first sent to the waterproof adhesive emulsion tank 3 for waterproof adhesive emulsion coating, and the grid coated with waterproof adhesive emulsion is sent to the vertical oven 4 for preheating and drying. When the polyester fiber yarn of the grid is heated to shrink by 70% to 75%, the grid is sent into the horizontal oven 5 for heat-shrinking treatment; the grid coming out ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com