Preparation process of wool-like fabric

A preparation technology and fabric technology, which is applied in the field of wool-like fabric preparation technology, can solve problems such as stuffy wearing, achieve the effects of improving softness, ensuring width stability, and improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

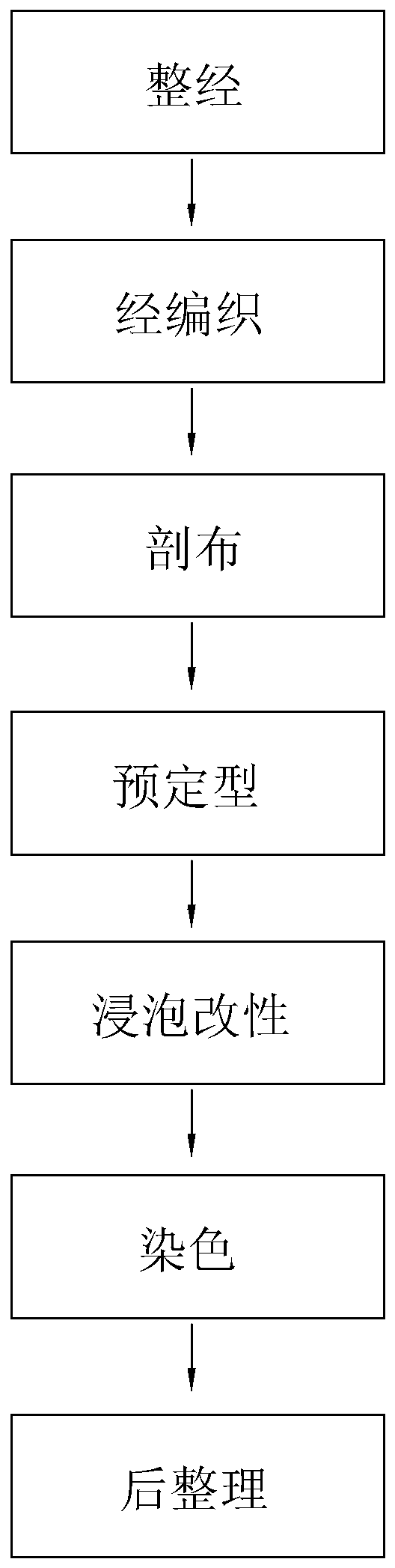

[0054] A kind of preparation technology of wool-like fabric, such as figure 1 shown, including the following steps:

[0055] S1, warping: Warping FDY polyester and DTY polyester respectively;

[0056] S2, warp knitting: use FDY polyester as the upper yarn and DTY polyester as the base yarn to weave a three-layer gray fabric, with DTY layers on both sides and FDY layer in the middle;

[0057] S3, cloth cutting: cut the gray cloth from the middle to obtain two semi-finished fabrics;

[0058] S4, pre-shaping: transfer the semi-finished fabric in the tunnel furnace, the heating temperature of the tunnel furnace is 220°C;

[0059] S5, modification by immersion:

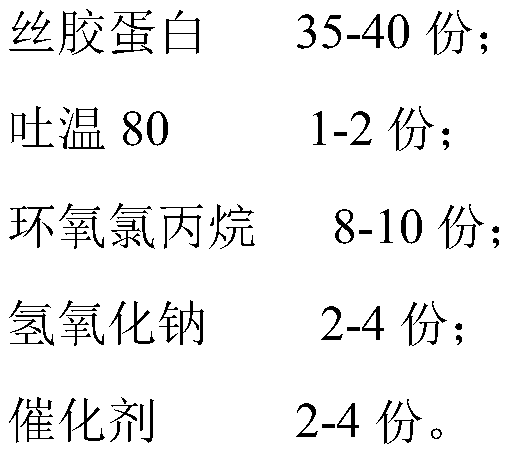

[0060] S5.1 Put the pre-shaped fabric into a dye vat without dye, add pretreatment agent, soak at 80°C for 60 minutes, and dry after two dips and two rollings;

[0061] S5.2, put the pretreated fabric into a dye vat without dye, add a modifying agent, soak for 50 minutes at 90°C, adjust the pH to neutral, and then dry ...

Embodiment 2

[0070] The difference with embodiment 1 is:

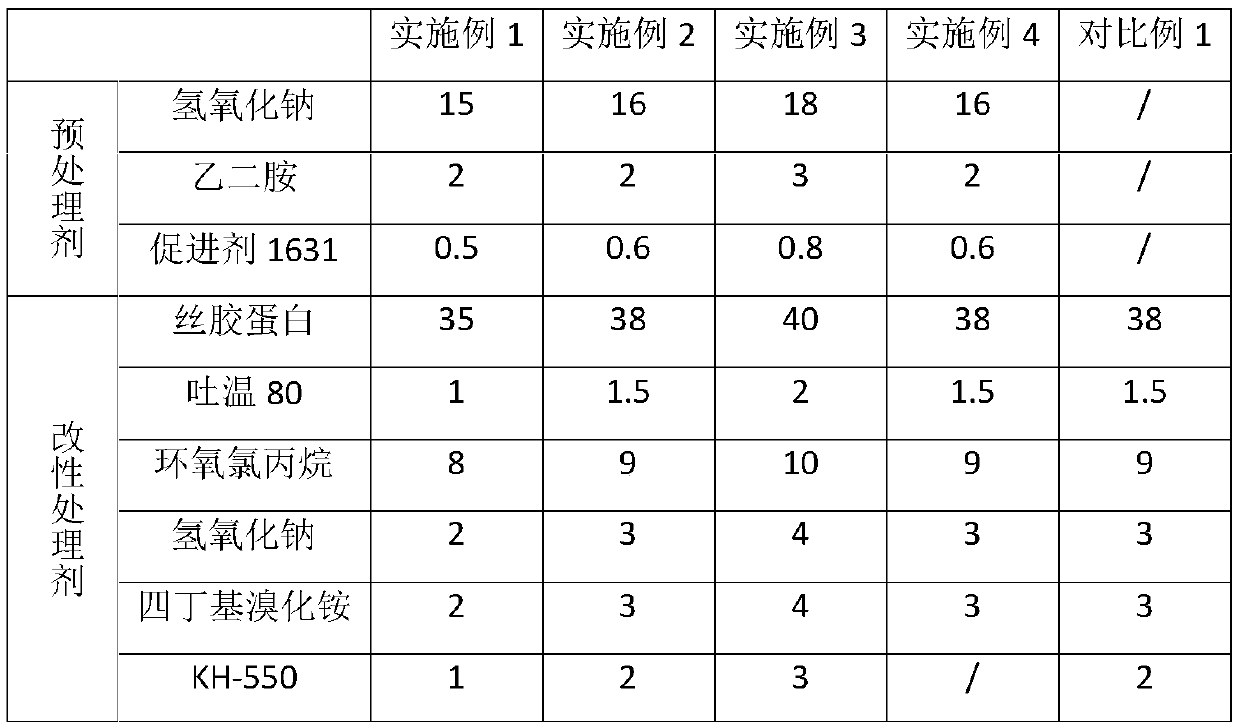

[0071] In parts by weight, per 100 parts of water, the raw material components of the pretreatment agent are shown in Table 1.

[0072] In parts by weight, per 100 parts of water, the raw material components of the modified treatment agent are shown in Table 1.

Embodiment 3

[0074] The difference with embodiment 1 is:

[0075] In parts by weight, per 100 parts of water, the raw material components of the pretreatment agent are shown in Table 1.

[0076] In parts by weight, per 100 parts of water, the raw material components of the modified treatment agent are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com