Preparing method of silver-base metal acid-salt electrical-contact composite material

A technology of composite materials and acid salts, which is applied in the field of metallurgy to achieve the effects of lowering the use temperature, reducing plasticity deterioration, and improving contact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

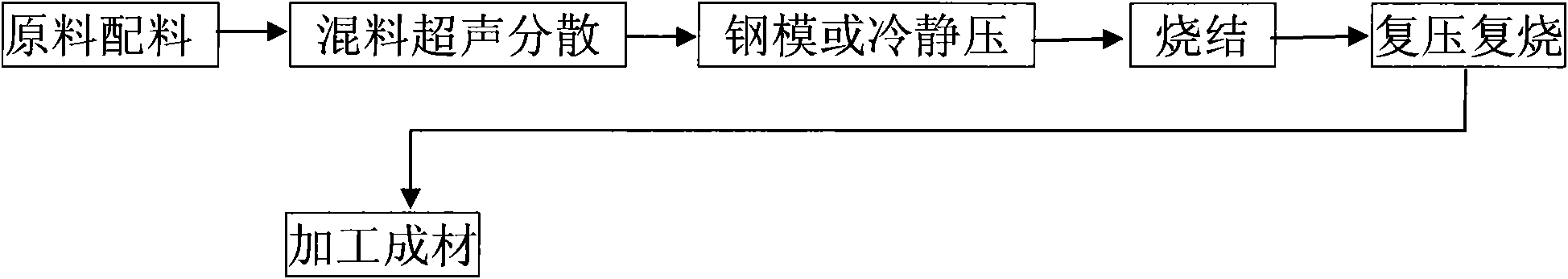

Method used

Image

Examples

Embodiment 1

[0038] By 12% silver stannate (Ag 2 SnO 3) powder (percentage by weight), 87% silver powder (percentage by weight), 1% tungsten powder (percentage by weight), put the powder into a mixer and mix it; with a power of 1KW, a frequency of 20KHz ultrasonic vibration powder for 10 minutes , to make it homogeneous. Two-way pressing in a steel mold forms a biscuit, and the forming pressure of the biscuit is 600MPa; the biscuit is sintered at 750°C for 4 hours to become an ingot; It is extruded into a wire rod at a temperature of 500°C, and finally cold-drawn into a wire (silk) material.

Embodiment 2

[0040] By 15% silver copper oxide (Ag 2 CuO 3 and AgCuO 2 ) powder (percentage by weight), 80% silver powder (percentage by weight), 4.5% silver-tin alloy powder (percentage by weight), 0.5% molybdenum powder (percentage by weight), the powder is put into a mixer and mixed; 3KW, frequency 25KHz ultrasonic vibration powder for 30 minutes to make it homogeneous. Two-way pressing in a steel mold forms a biscuit, and the forming pressure of the biscuit is 650MPa; the biscuit is sintered at 750°C for 4 hours to become an ingot; It is extruded into a wire rod at a temperature of 550°C, and finally cold-drawn into a wire (silk) material.

Embodiment 3

[0042] By 15% copper stannate (CuSnO 3 ) powder (percentage by weight), 84% silver powder (percentage by weight), 0.5% tungsten powder (percentage by weight), 0.5% molybdenum powder (percentage by weight), the powder is put into the mixer and mixed; power is 1KW , Ultrasonic vibration powder with a frequency of 20KHz for 25 minutes to homogenize it. Two-way pressing in a steel mold forms a biscuit, and the forming pressure of the green body is 600MPa; the green body is sintered at 700°C for 4 hours to become an ingot; the ingot is repressed at a pressure of 600MPa, refired at 650°C for 8 hours, and then It is extruded into a wire rod at a temperature of 500°C, and finally cold-drawn into a wire (silk) material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com