Hot wall glass coated with inorganic resistance thick film and manufacturing method thereof and heating module

A wall glass and inorganic technology, applied in the direction of resistance manufacturing, resistors, ohmic resistance heating, etc., can solve the problems of glass decorative glaze layer oxidation and fading, adhesive layer aging and delamination, expensive products, etc., to solve the problem of easy cracking, The effect of reducing the expansion coefficient and reducing the cost of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

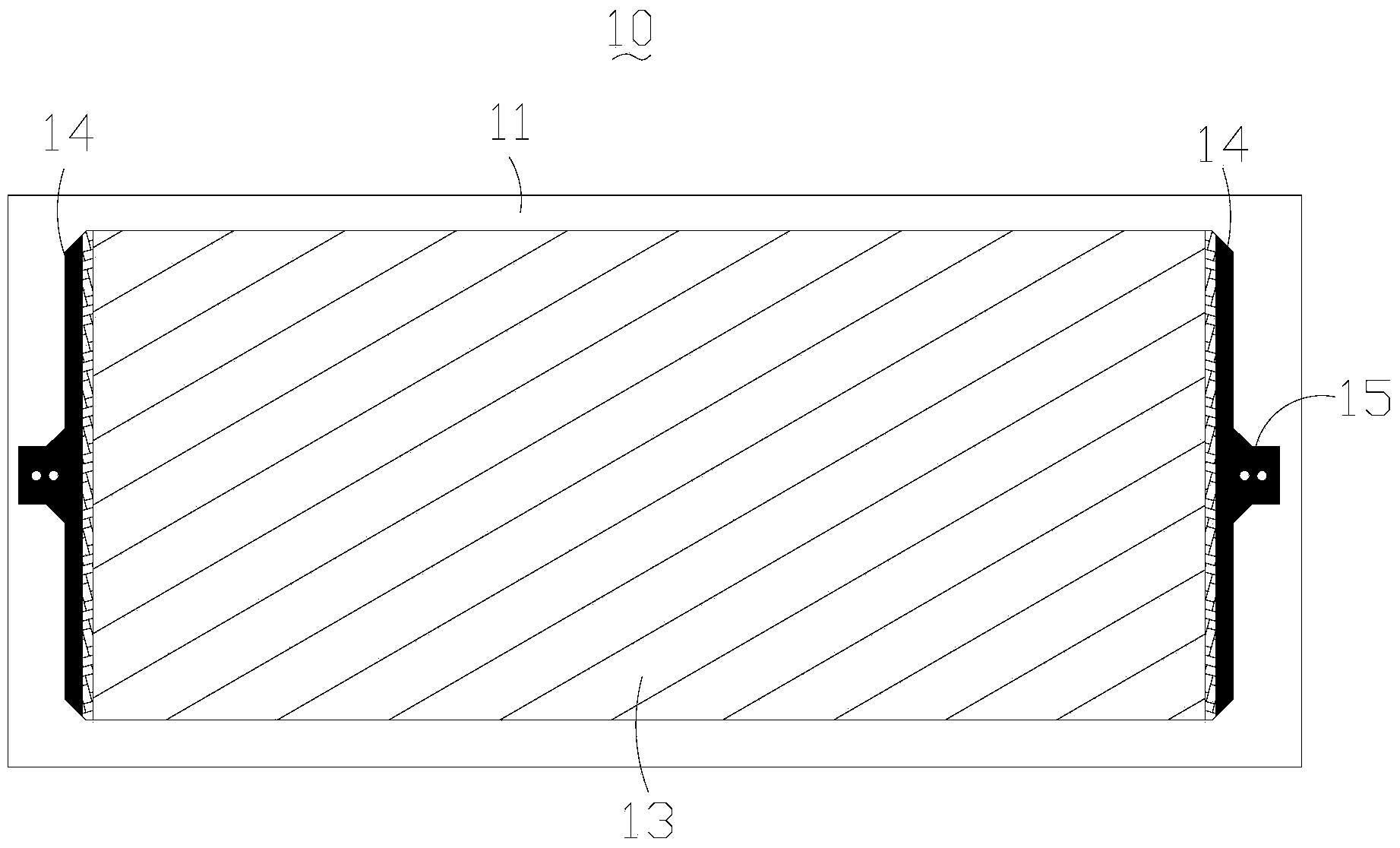

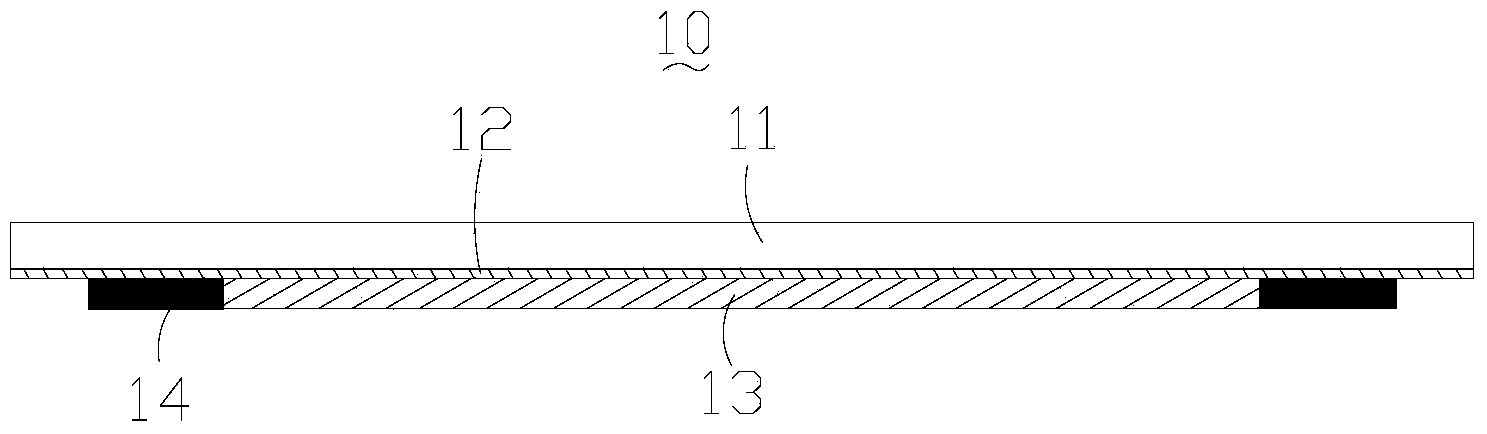

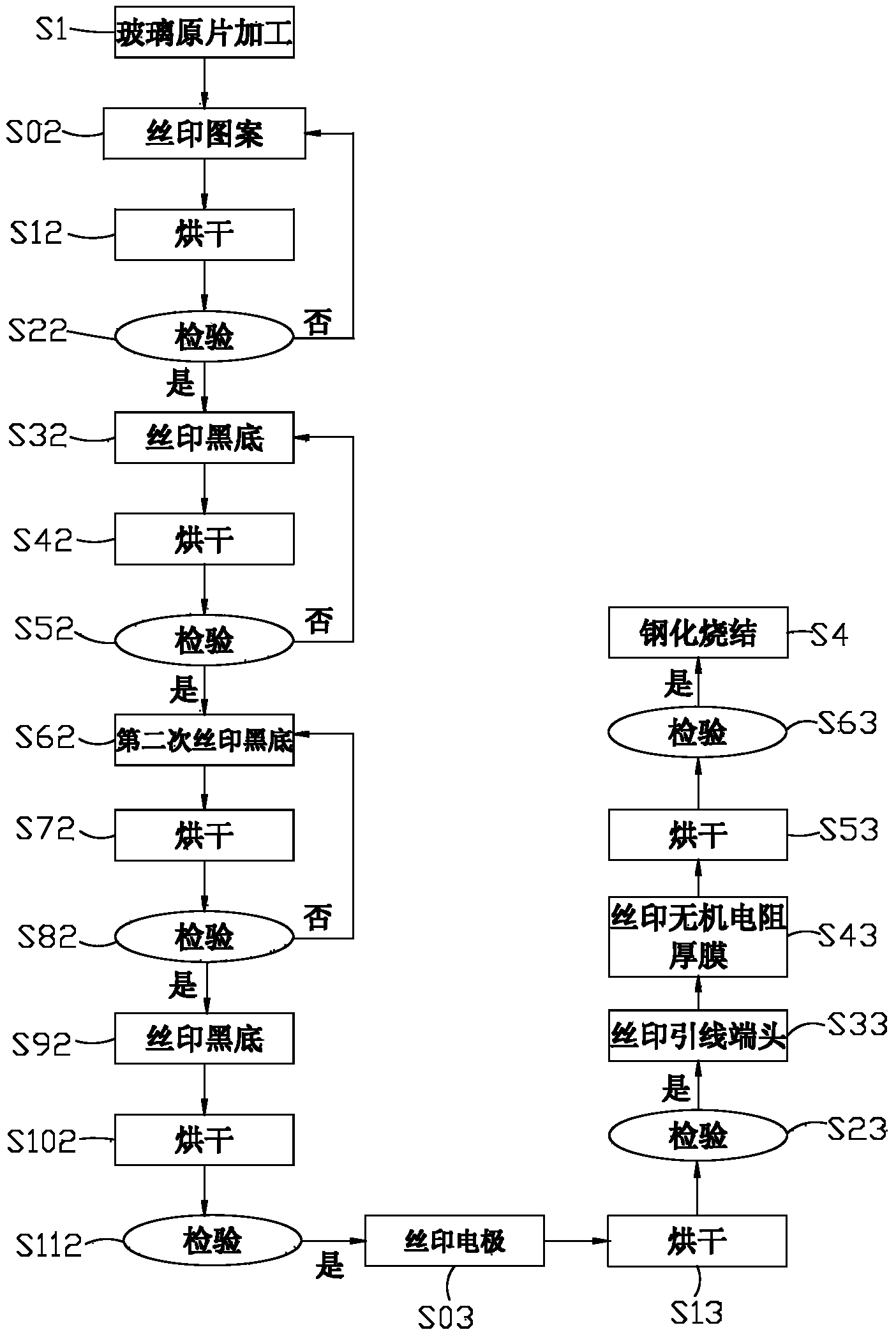

[0063] The embodiment of the present invention also provides a method for preparing the above-mentioned warm wall glass 10 coated with the inorganic resistance thick film 13, which includes the following steps:

[0064] S1) providing a glass substrate 11;

[0065] S2) printing the inorganic decorative glaze layer 12 on the glass substrate 11 and drying;

[0066] S3) On the inorganic decorative glaze layer 12 of the glass substrate 11, print the electrode 14, the lead terminal 15 and the inorganic resistance thick film 13 sequentially, and make the lead terminal 15 and the electrode 14 Electrically connected, the inorganic resistive thick film 13 is electrically connected to the electrode 14;

[0067] S4) Tempering and sintering the glass substrate 11 printed with the electrodes 14 , the lead terminals 15 , the inorganic resistor thick film 13 and the inorganic decorative glaze layer 12 .

[0068] The glass substrate 11 in step S1) is formed by processing a glass original she...

Embodiment 1

[0092] Take a rectangular glass substrate 11 with a length of 600 mm, a width of 200 mm and a thickness of 5 mm printed with an inorganic decorative glaze layer 12;

[0093] Then with silver conductive paste on the surface of the two short sides of the rectangular substrate 11 printed with the inorganic decorative glaze layer 12 respectively coated with a length of 170mm, an electrode 14 of wide 10mm, and then as figure 1 Coat the lead terminal 15 as shown, and then provide the following recipe ingredients:

[0094]

[0095] Stir the 6 ingredients in the above formula except graphite powder evenly, melt the mixture at 1200°C for 60 minutes, cool the obtained mixture block and crush it, and then use a ball mill for 48 hours to make the particle size less than 350 mesh powder, then add graphite powder thereinto to obtain the first mixture; then add 120g-150g of liquid organic carrier composed of 95% by weight terpineol and 5% by weight ethyl cellulose to prepare a uniform slu...

Embodiment 2

[0098] In Example 2, except that the glass substrate 11 was replaced by a mica base plate, the experiment was carried out according to the conditions of Example 1, and basically the same results as Example 1 were obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com