Supported bimetallic catalyst for CO catalytic oxidation through visible light at room temperature

A bimetallic catalyst, catalytic oxidation technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as low utilization efficiency of visible light, and achieve good light Catalytic performance, broadening the application range, reducing the effect of temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Au-Ag / TiO 2 Catalyst preparation

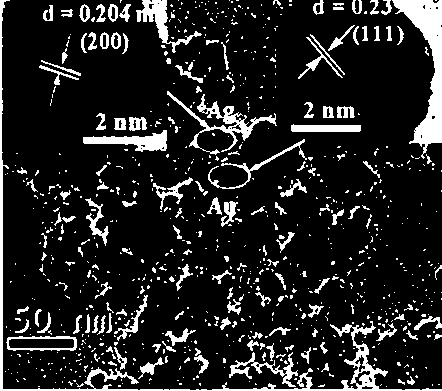

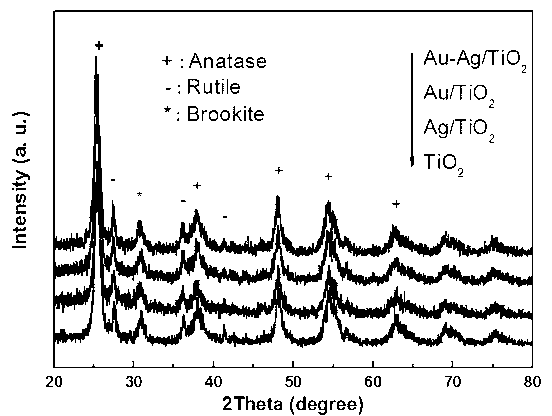

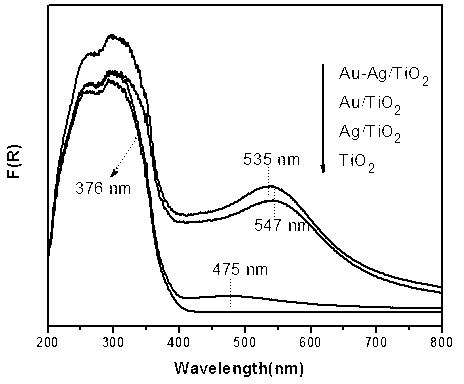

[0020] Weigh 1.0 g TiO 2 (particle size of 60-80 mesh) was placed in a beaker, and 0.5 mL of AgNO with a concentration of 0.01 mol / L was added 3 Solution, 1~5h, 60~80°C drying, the drying material with a concentration of 0.01mol / L NaBH 4 Solution (ice-water bath) reduction, deionized water washing, vacuum drying at 30~50°C after removing excess ions, to obtain Ag-containing intermediates, namely Ag / TiO 2 . Prepared Ag / TiO 2 The intermediate was placed in 0.5mL with a concentration of 0.01 mol / L HAuCl 4 solution, at the same time use 0.1mol / L NaOH solution to adjust the pH of the suspension to about 9~11, soak for 2~6h, and dry at 60~80℃; 4 Solution (ice-water bath) reduction, deionized water washing to remove excess ions to obtain a supported bimetallic catalyst containing Ag and Au, namely: Au-Ag / TiO 2 . The contents of Au and Ag in the catalyst are about 0.1 wt % and 0.05 wt %, respectively, and the molar ratio is 1:1.

[00...

Embodiment 2

[0026] Catalyst Performance Evaluation

[0027] The performance evaluation of the catalytic oxidation of CO by the catalyst prepared in Example 1 was carried out in a self-designed fixed-bed miniature continuous flow device at normal temperature and pressure with a circulating condensing system. The catalyst is packed in a square reaction tube (20*20*1mm 3 ), the catalyst dosage is 400 mg, the catalyst particle size is 0.2-0.3 mm (60-80 mesh), and the O in the reaction gas 2The contents of CO and CO are fixed at 0.3v%, He gas is used as the balance supplementary gas, and the reaction gas flow rate is about 100 mL / min. The reaction temperature is regulated by a circulating condensation system, which is about 20.5°C. Agilent 4890D gas chromatograph was used to regularly analyze CO and O in the atmosphere 2 and CO 2 concentration, TCD is the detector, TDX-01 is packed into the column, and the CO conversion rate is calculated by taking the result of the reaction for 2 hours. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com