Porous silicon dioxide microspheres as well as preparation method and application thereof

A technology of porous silicon dioxide and silicon dioxide, applied in the direction of silicon dioxide, silicon oxide, chemical instruments and methods, etc., to achieve the effect of good reproducibility, simple process and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

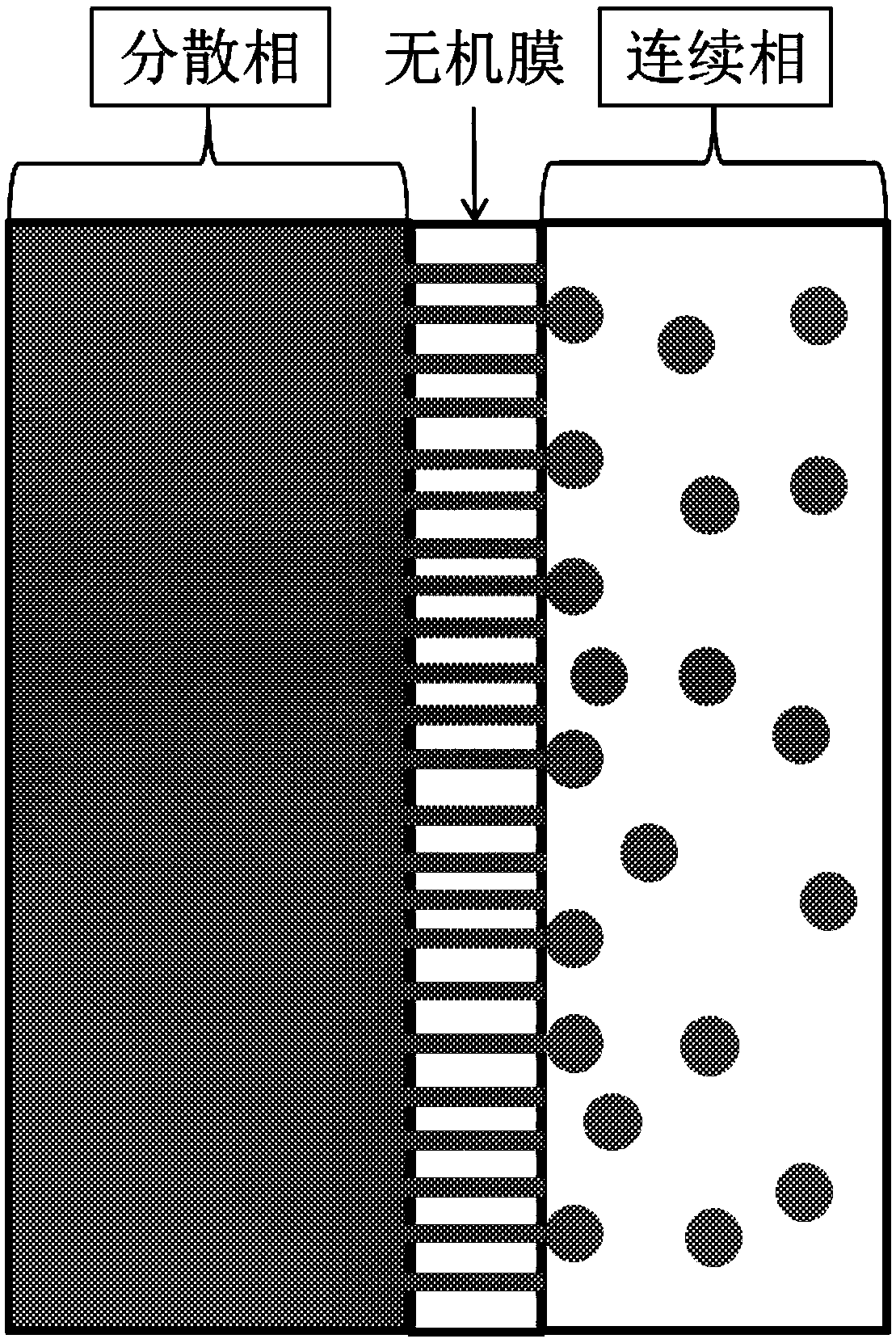

Method used

Image

Examples

Embodiment 1

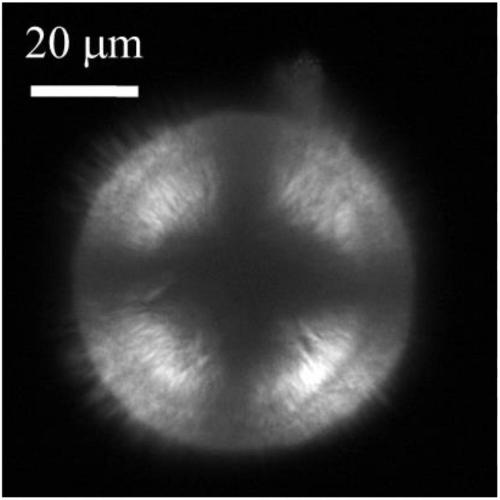

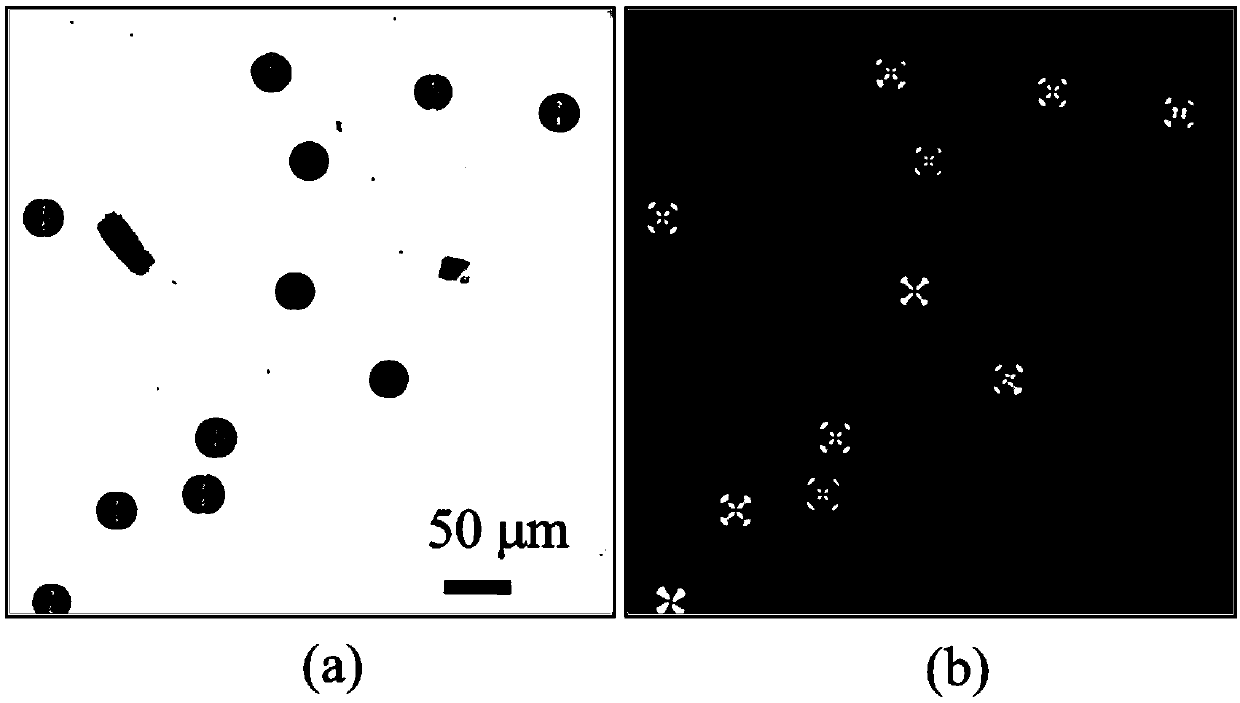

[0054] Preparation contains the liquid crystal mixture of 1.5g reactive liquid crystal RM257, 8.5g non-reactive liquid crystal 5CB, 0.1g photoinitiator DMPAP and 0.332g comonomer glycidyl methacrylate (the mass percent of reactive liquid crystal accounting for liquid crystal mixture is 14.4 %, the molar ratio of comonomer and reactive liquid crystal is about 1:1), it is made into polymer microspheres according to the above steps, wherein the SPG film micropore diameter is 10 microns, the continuous phase is water, and the liquid crystal conformation changes The molar concentration of SDS in water is 2mM. Such as image 3 As shown, the average particle size of the polymer microspheres in ethanol is 27 μm ( image 3 (a)), and shows a ray-type optical anisotropy (Maltese black cross) ( image 3 (b)). Keeping other conditions unchanged, changing the amount of comonomer so that the molar ratio of the comonomer to the reactive liquid crystal is 2:1 and 1:2, functional polymer mic...

Embodiment 2

[0060] Prepare liquid crystal mixtures containing 1g reactive liquid crystal RM257, 9g non-reactive liquid crystal 5CB, 0.221g comonomer glycidyl methacrylate and 0.1g photoinitiator DMPAP, and 2g reactive liquid crystal RM257, 8g non-reactive liquid crystal The liquid crystal mixture of 5CB, 0.443g comonomer glycidyl methacrylate and 0.1g photoinitiator DMPAP (wherein the mass percentage that reactive liquid crystal accounts for liquid crystal mixture is respectively 9.7% and 19%, comonomer and reactive liquid crystal The molar ratio is about 1:1). It was made into polymer microspheres according to the above steps, wherein the micropore diameter of the SPG membrane was 20 microns, the continuous phase was water, and the molar concentration of the liquid crystal conformation changing agent SDS in water was 2 mM.

[0061] Next, 0.5 g of the above-prepared polymer microspheres were dispersed in 20 mL of tetrahydrofuran, and 560 μL of ethylenediamine was added with stirring, and ...

Embodiment 3

[0066] Preparation contains the liquid crystal mixture of 1.5g reactive liquid crystal RM257, 8.5g non-reactive liquid crystal 5CB, 0.1g photoinitiator DMPAP and 0.332g comonomer glycidyl methacrylate (the mass percent of reactive liquid crystal accounting for liquid crystal mixture is 14.4 %, the molar ratio of comonomer and reactive liquid crystal is about 1:1), it is made into polymer microspheres according to the above steps, wherein the SPG membrane micropore diameter is 2.8 microns, the continuous phase is water, and the liquid crystal conformation changes The molar concentration of SDS in water is 2mM.

[0067] Next, 0.5 g of the above-prepared polymer microspheres were dispersed in 20 mL of tetrahydrofuran, 560 μL of ethylenediamine was added under stirring, and the mixture was refluxed at 80° C. for 24 hours. Filter, wash with ethanol and distilled water alternately for 3 times, and dry to obtain aminated polymer microspheres.

[0068] Finally, 0.5 g of aminated poly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com