Lotus leaf-based photothermal conversion material preparing method

A light-to-heat conversion material and light-to-heat conversion layer technology, which is applied in heat exchange materials, steam generation methods using solar energy, chemical instruments and methods, etc., to achieve the effects of low preparation cost, simple process and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

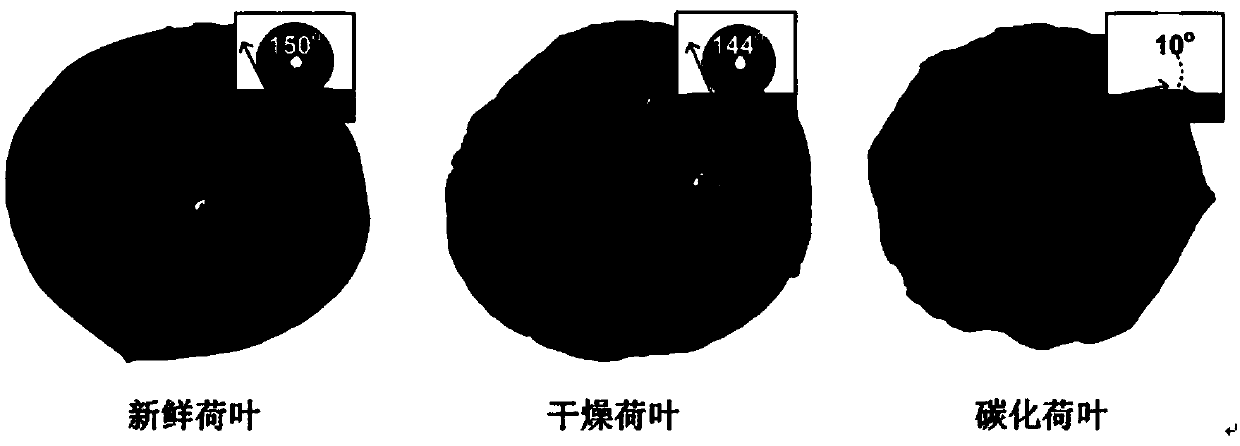

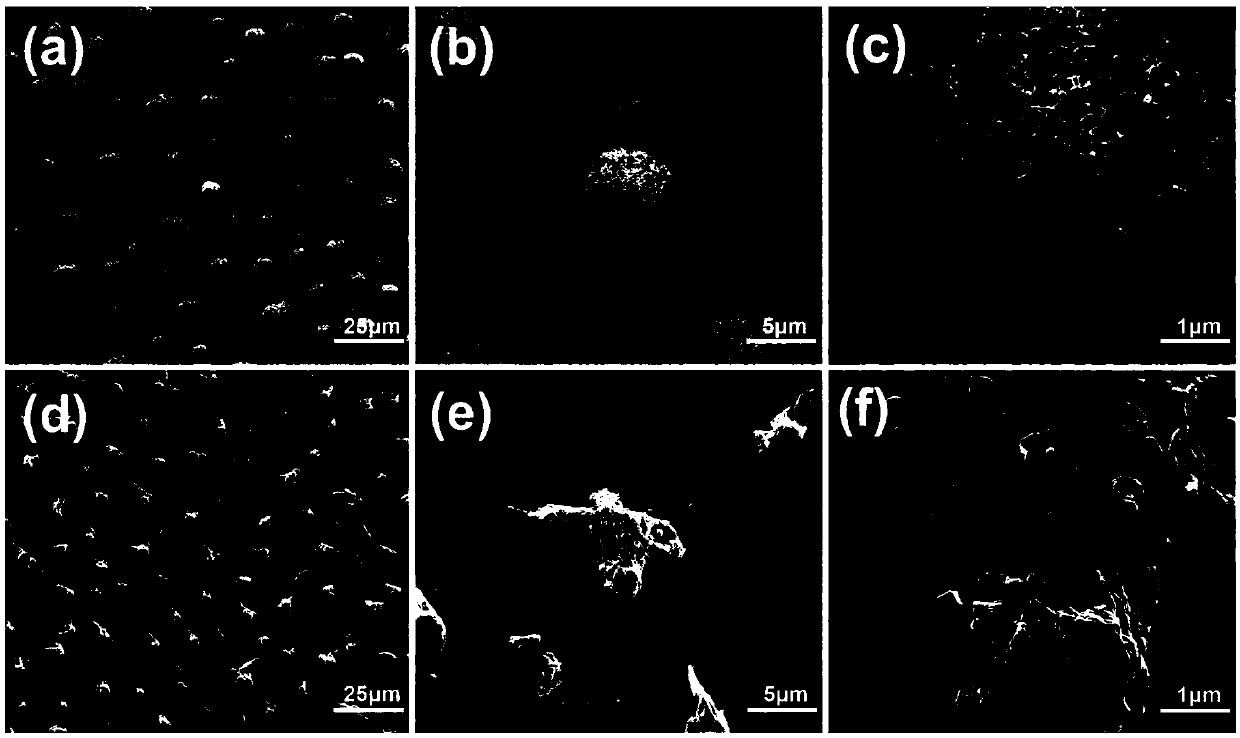

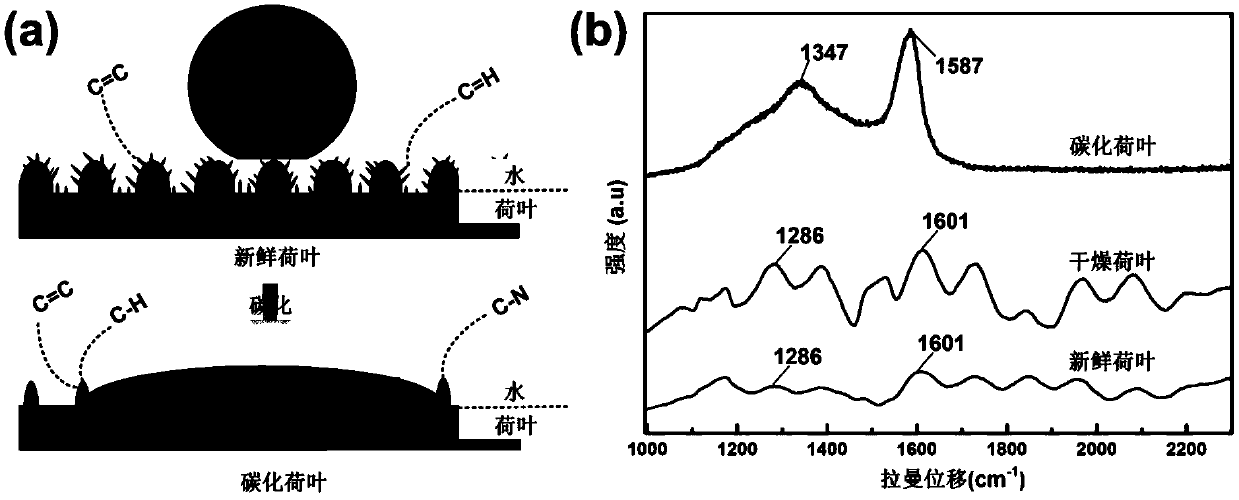

[0029] A method for preparing light-to-heat conversion materials based on lotus leaves, specifically comprising the following steps:

[0030] Step 1. Take a certain amount of fresh lotus leaves, and then place them in deionized water for ultrasonic cleaning. The time is 15 minutes, and the ultrasonic frequency is 50Hz. For use, the thickness of the selected lotus leaf is about 0.5mm, and the diameter is about 2.5cm;

[0031] Step 2. Put the lotus leaf leaves to be used in step 1 into the freezer of the refrigerator, and freeze at -18°C for 24 hours to obtain frozen sample A;

[0032] Step 3. Put the frozen sample A obtained in step 2 into a vacuum freeze-drying box, and dry it for 72 hours under the conditions of a vacuum degree of 8Pa and a temperature of -45°C to obtain a dried lotus leaf sample B;

[0033] Step 4. Place the sample B obtained in step 3 in a tube furnace, raise the temperature to 500°C at a heating rate of 2°C / min under a nitrogen atmosphere, and keep it at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com