Preparation method and application of hollow structure Co3O4/CeO2 nanoparticle loaded nitrogen doped carbon nanofiber material

A technology of nanofibers and hollow structures, which is applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve the problems of complex synthesis paths and difficult uniform loading of catalysts, and achieve broad application prospects and improve catalytic performance. Reaction rate, the effect of more active sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

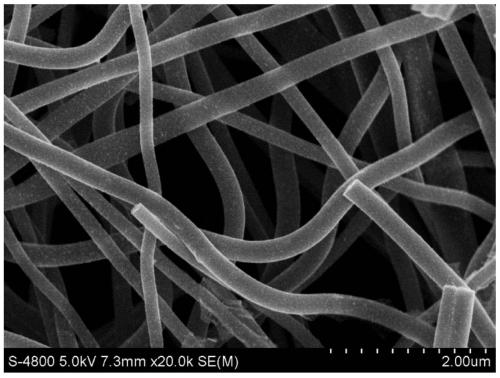

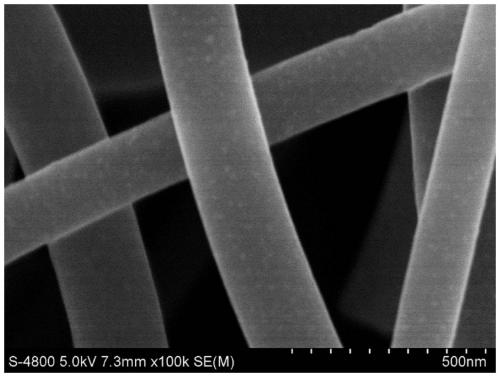

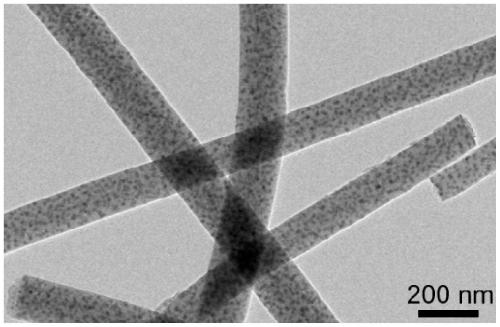

[0044] A nitrogen-doped carbon nanofiber loaded hollow structure of Co 3 o 4 / CeO 2 The preparation method of composite material, comprises the following steps:

[0045] 1)Co 2+ / C 3+ / PVP mixed sol preparation: weigh 1.0g PVP with 6ml DMF and 6ml C 2 h 5 OH solution was mixed, and 1.0mmol of Co(NO 3 ) 2 ·6H 2 O with 0.5mmol Ce(NO 3 ) 3 ·6H 2 O solid metal nitrate; after mechanical stirring at room temperature for 12h, make it evenly mixed, you can get red Co 2+ / C 3+ / PVP sol;

[0046] 2) Electrospinning method to prepare nitrogen-doped carbon nanofibers loaded with hollow structure Co 3 o 4 / CeO 2 Composite material: the red Co obtained in step 1) 2+ / C 3+ / PVP sol, processed by electrospinning technology, the spinning temperature is controlled at 25°C, and the injection speed is 1.0mL·h -1 , Voltage 22KV, the solid carbon fiber film material obtained, firstly undergoes pre-oxidation treatment in the air at 200°C for 3h, and then in N 2 Under the atmosphe...

Embodiment 2

[0049] A nitrogen-doped carbon nanofiber loaded hollow structure of Co 3 o 4 / CeO 2 The preparation method of composite material, comprises the following steps:

[0050] 1)Co 2+ / C 3+ / PVP mixed sol preparation: weigh 1.0g PVP with 6ml DMF and 6ml C 2 h 5 OH solution was mixed, and 1.0mmol of Co(NO 3 ) 2 ·6H 2 O with 0.25mmol Ce(NO 3 ) 3 ·6H 2 O solid metal nitrate; after mechanical stirring at room temperature for 12h, make it evenly mixed, you can get red Co 2+ / C 3+ / PVP sol;

[0051] 2) Nitrogen-doped carbon nanocomposites loaded with hollow structures of Co prepared by electrospinning 3 o 4 / CeO 2 Composite material: the red Co obtained in step 1) 2+ / C 3+ / PVP sol, processed by electrospinning technology, the spinning temperature is controlled at 25°C, and the injection speed is 1.0mL·h -1 , Voltage 22KV, the solid carbon fiber film material obtained, firstly undergoes pre-oxidation treatment in the air at 200°C for 3h, and then in N 2 Under the atmos...

Embodiment 3

[0053] A nitrogen-doped carbon nanofiber loaded hollow structure of Co 3 o 4 / CeO 2The preparation method of composite material, comprises the following steps:

[0054] 1)Co 2+ / C 3+ / PVP mixed sol preparation: weigh 1.0g PVP with 6ml DMF and 6ml C 2 h 5 OH solution was mixed, and 1.0mmol of Co(NO 3 ) 2 ·6H 2 O with 0.75mmol Ce(NO 3 ) 3 ·6H 2 O solid metal nitrate; after mechanical stirring at room temperature for 12h, make it evenly mixed, you can get red Co 2+ / C 3+ / PVP sol;

[0055] 2) Nitrogen-doped carbon nanocomposites loaded with hollow structures of Co prepared by electrospinning 3 o 4 / CeO 2 Composite material: the red Co obtained in step 1) 2+ / C 3+ / PVP sol, processed by electrospinning technology, the spinning temperature is controlled at 25°C, and the injection speed is 1.0mL·h -1 , Voltage 22KV, the solid carbon fiber film material obtained, firstly undergoes pre-oxidation treatment in the air at 200°C for 3h, and then in N 2 Under the atmosp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com