Method for improving efficiency of large-scale steam turbine power generation system

A technology for power generation systems and steam turbines, applied in steam engine installations, machines/engines, mechanical equipment, etc., and can solve problems such as untested practices, impossible cooperation from user units, and difficulty in carrying out adjustment tests.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] The embodiment of the invention provides a method for improving the efficiency of a large steam turbine power generation system.

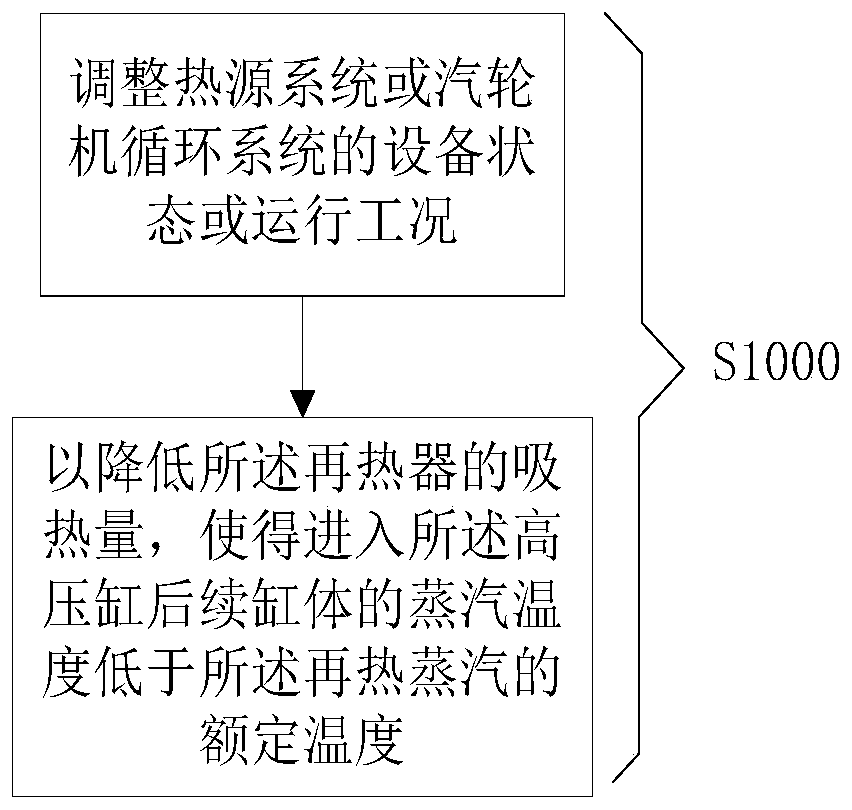

[0060] see figure 1 , figure 1 It is a schematic flowchart of a method for improving the efficiency of a large steam turbine power generation system provided by Embodiment 1 of the present invention.

[0061] Such as figure 1 As shown, a method for improving the efficiency of a large-scale steam turbine power generation system, the steam turbine power generation system includes: a heat source system, a steam turbine circulation system, and a cold end system, wherein the steam turbine circulation system includes: a main steam system, a steam turbine cylinder system, A reheat steam system and a shaft-sealed steam system, wherein the reheat steam system includes a reheater, the steam turbine block system includes a high-pressure cylinder, and the method includes:

[0062] S1000: Adjust the equipment status or operating conditions of the heat...

Embodiment 2

[0064] The embodiment of the invention provides a method for improving the efficiency of a large steam turbine power generation system.

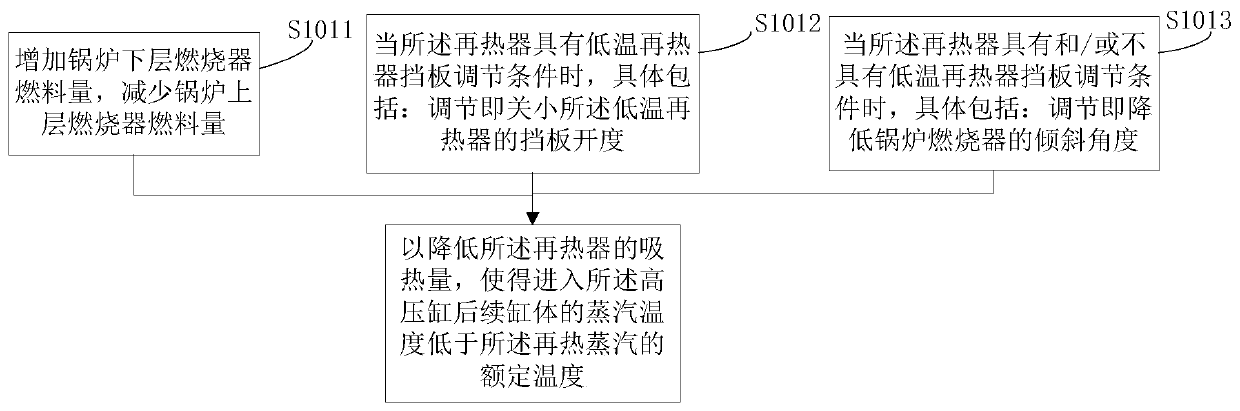

[0065] Such as figure 2 As shown, on the basis of Embodiment 1, for a traditional power plant, the method includes:

[0066] S1011: Adjust the fuel volume and output of the burners on the relevant floors, specifically: increase the fuel volume of the lower boiler burners and reduce the fuel volume of the upper boiler burners; or,

[0067] S1012: When the reheater has adjustment conditions for the baffle of the low-temperature reheater, it specifically includes: adjusting, that is, closing down the opening of the baffle of the low-temperature reheater; or,

[0068] S1013: When the reheater has and / or does not have adjustment conditions for low-temperature reheater baffles, it specifically includes: adjusting, that is, reducing the inclination angle of the boiler burner.

[0069] To reduce the heat absorption of the reheater, so that the te...

Embodiment 3

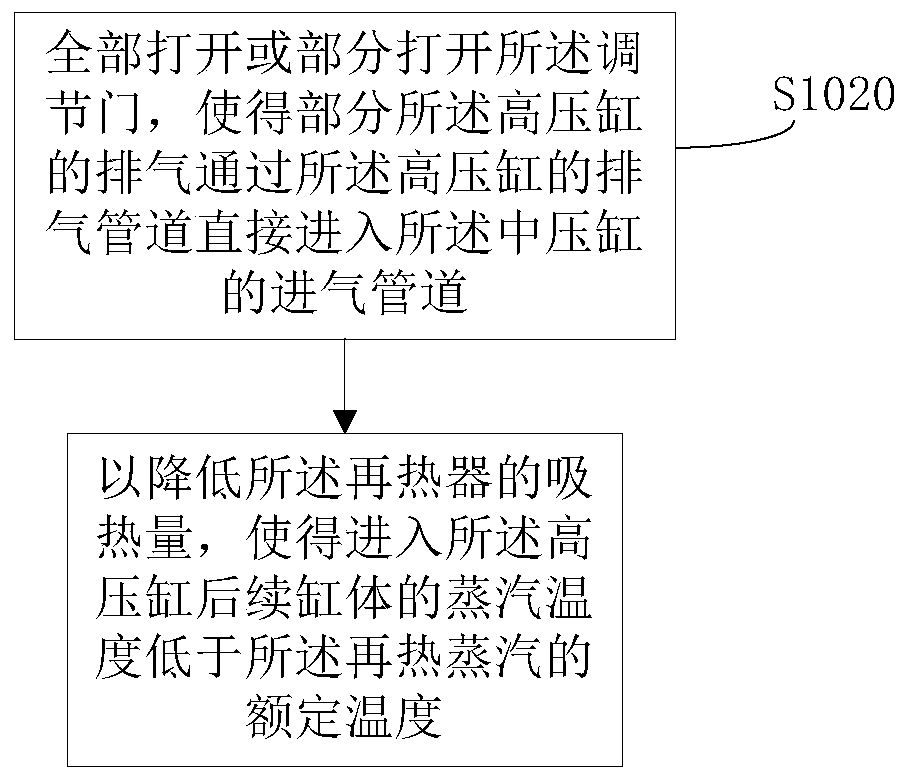

[0071] The embodiment of the invention provides a method for improving the efficiency of a large steam turbine power generation system.

[0072] Such as image 3 As shown, on the basis of Embodiment 1, for a traditional power plant, when the steam turbine block system also includes an intermediate pressure cylinder, a reheating pipe is set between the exhaust pipe of the high pressure cylinder and the intake pipe of the intermediate pressure cylinder. A steam bypass pipeline, and an adjustment door is set on the reheat steam bypass pipeline, the method includes:

[0073] S1020: Fully or partially open the regulating door, so that part of the exhaust gas of the high-pressure cylinder directly enters the intake pipe of the medium-pressure cylinder through the exhaust pipe of the high-pressure cylinder.

[0074] To reduce the heat absorption of the reheater, so that the temperature of the steam entering the subsequent cylinder of the high pressure cylinder is lower than the rate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com