Contaminated soil medium-temperature dry-screen weight reduction treatment system and application

A technology for polluted soil and treatment system, which is applied in the field of temperature and dry sieving reduction treatment system in polluted soil, can solve the problems of high energy consumption of high temperature sieving and poor economic efficiency of sieving reduction, avoid excessive temperature and reduce exhaust gas treatment. Difficulty, the effect of reducing gas treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

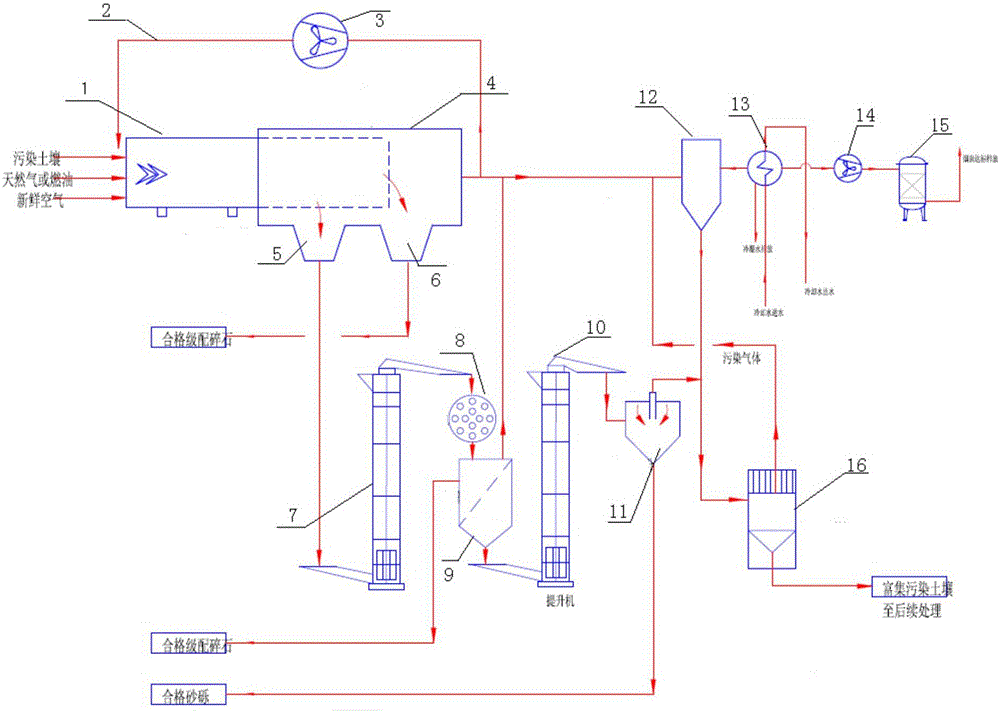

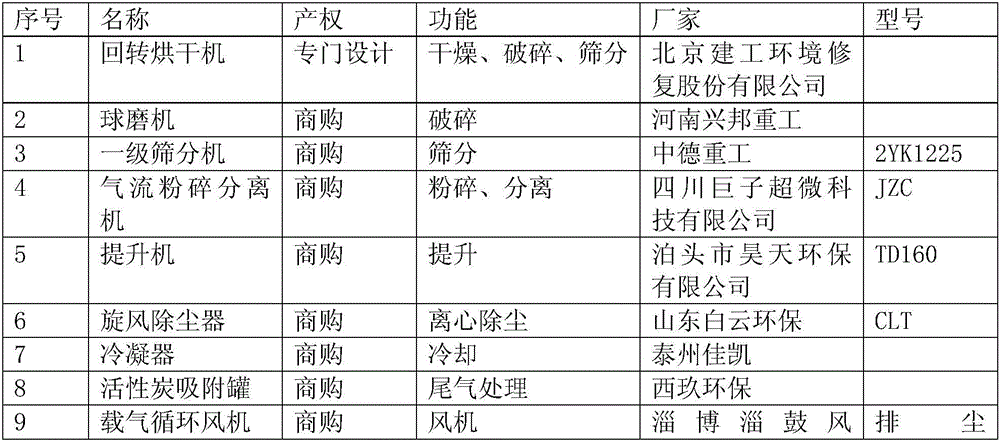

[0063] (1) Use the polluted soil medium temperature reduction treatment system of the present invention to process polluted soil

[0064] Contaminated soil and exhaust gas enter the rotary dryer, and fuel and fresh air pass through the combustion equipment to generate high-temperature flue gas. Under the action of the carrier gas circulation fan, the high-temperature flue gas contacts the polluted soil and undergoes circular heating. At the same time, the metal cylinder on the rotary dryer is turned over, so that the water in the polluted soil evaporates into the flue gas. After the water is reduced, the viscosity of the polluted soil drops significantly, and the soil particles are greatly broken. The diameter of the screen of the rotary dryer is 10mm. During the rotation of the rotary dryer, the soil less than 10mm enters the hopper through the mesh around the rotary dryer; while the qualified graded gravel larger than 10mm is discharged from the end outlet of the rotary dryer...

Embodiment 2

[0072] (1) Use the polluted soil medium temperature reduction treatment system of the present invention to process polluted soil

[0073] Contaminated soil and exhaust gas enter the rotary dryer, fuel and fresh air pass through the burner to generate high-temperature flue gas, and under the action of the carrier gas circulation fan, the high-temperature flue gas contacts the polluted soil and undergoes circular heating. At the same time, the metal cylinder on the rotary dryer is turned over, so that the water in the polluted soil evaporates into the flue gas. After the water is reduced, the viscosity of the polluted soil drops significantly, and the soil particles are greatly broken. The diameter of the screen of the rotary dryer is 20mm. During the rotation of the rotary dryer, the soil less than 20mm enters the hopper through the mesh around the rotary dryer; while the qualified graded gravel larger than 20mm is discharged from the end outlet of the rotary dryer. Complete pr...

Embodiment 3

[0080] (1) Use the polluted soil medium temperature reduction treatment system of the present invention to process polluted soil

[0081] Contaminated soil and exhaust gas enter the rotary dryer, fuel and fresh air pass through the burner to generate high-temperature flue gas, and under the action of the carrier gas circulation fan, the high-temperature flue gas contacts the polluted soil and undergoes circular heating. At the same time, the metal cylinder on the rotary dryer is turned over, so that the water in the polluted soil evaporates into the flue gas. After the water is reduced, the viscosity of the polluted soil drops significantly, and the soil particles are greatly broken. The diameter of the screen of the rotary dryer is 4mm. During the rotation of the rotary dryer, the soil less than 4mm enters the hopper through the mesh around the rotary dryer; while the qualified graded gravel larger than 4mm is discharged from the end outlet of the rotary dryer. Complete pre-c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com