Gas distributor for ash agglomerating fluidized-bed gasification furnace

A gas distributor and gasifier technology, applied in the direction of granular/powdered fuel gasification, etc., can solve the problems that the shell is difficult to meet the long-term operation, the material requirements of the central tube are high, and the outer wall of the central tube is worn, etc., to achieve Conducive to large-scale production, lower temperature resistance requirements, and longer service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

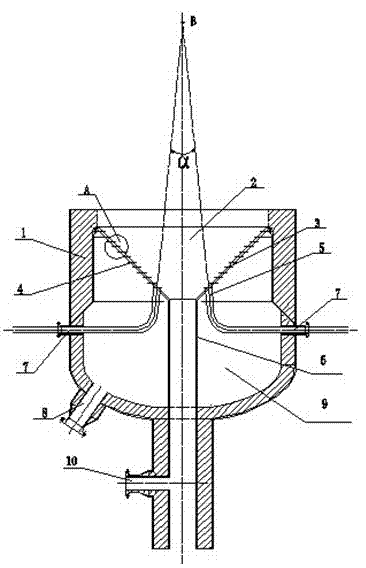

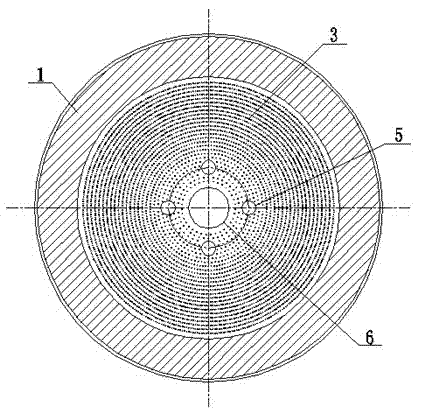

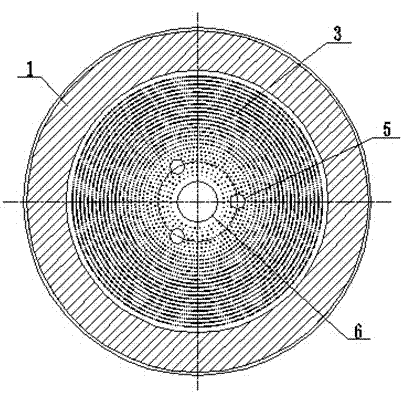

[0039] see figure 1 , figure 2 , Embodiment 1 of the present invention is a specific implementation mode provided with four distributed injection pipes 5, such as figure 1 and figure 2 As shown, the structure of the gas distributor includes gasifier shell 1, dense phase zone 2, conical distribution plate 3, distribution plate fluidization hole 4, distributed injection pipe 5, slag discharge pipe 6, injection pipe inlet Gas pipe 7, air chamber inlet pipe 8, air chamber 9 and slag discharge pipe inlet pipe 10. The conical distribution plate 3 is sealed and fixed on the casing 1 of the gasifier, see Figure 6 , the conical distribution plate 3 is provided with several axial fluidization holes 4 in the horizontal direction, the opening ratio of the fluidization holes 4 is 0.4-0.65%, and the diameter of the fluidization holes 4 is 1-3mm. The above-me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com