Circularly swirling coal powder burn device with various concentration coal powder pipe

A technology of thick and thin pulverized coal and burner, which is applied in the burner, burner for burning powder fuel, combustion method, etc., to achieve the effect of reducing the number of minor repairs, lowering the flame temperature level, and large fuel adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

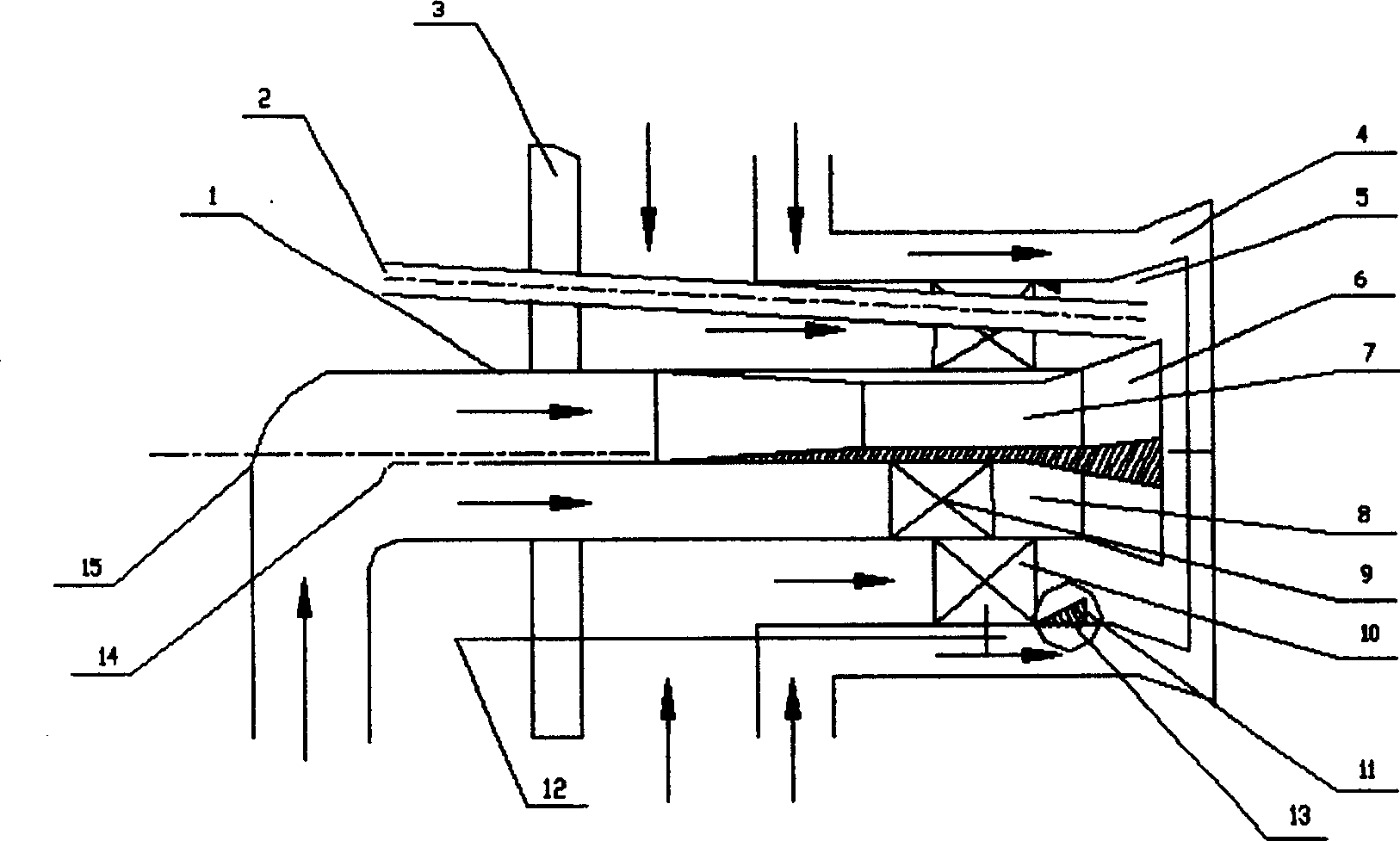

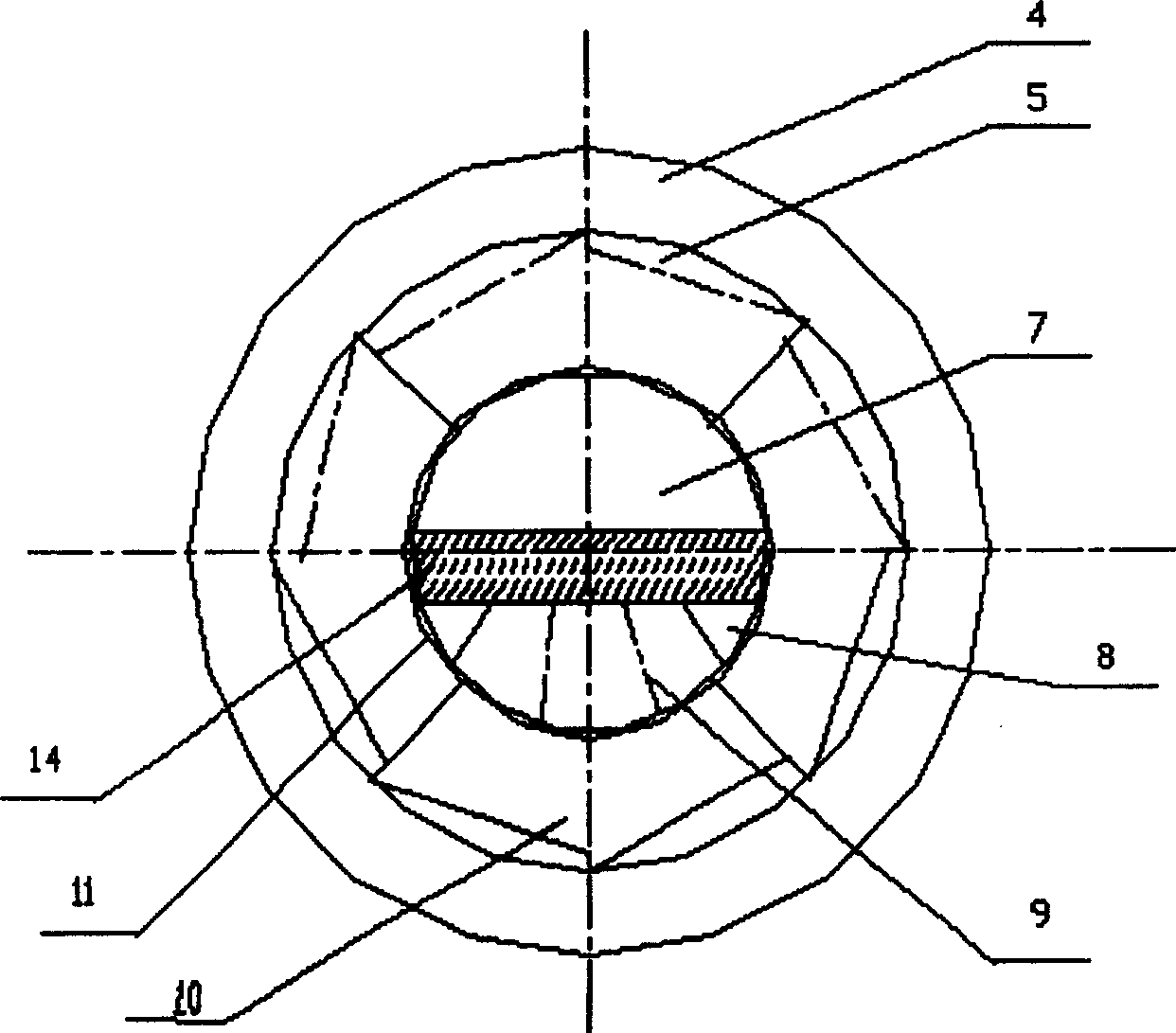

[0022] The structure, working principle and best embodiment of the present invention will be further described below in conjunction with the accompanying drawings.

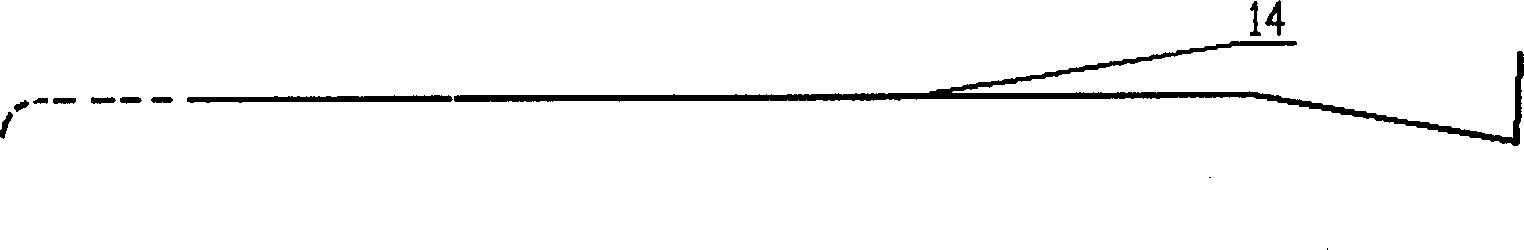

[0023] figure 1 , 2 It is a schematic diagram of the overall structure of the circular swirl rich-lean pulverized coal burner provided by the present invention. The burner contains a primary air pulverized coal pipe 1 with an elbow 15, a swirl inner secondary air pipe 5 and a direct current external secondary air pipe 4 that are arranged outside the primary air pulverized coal pipe in turn and are concentrically installed. The inner secondary air pipe 5 is arranged with an adjusting pull rod 12, an adjustable swirl blade 10 and an ignition oil gun 2; a separation partition 14 is arranged in the primary air pulverized coal pipe to divide the primary air pipe into upper and lower thick and thin pulverized coal pipes. The separation partition is composed of a straight plate and a sloping plate inclined downward, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com