Ladle brick cup hot repairing material and preparation method thereof

A technology of hot repairing and ladle seat, applied in the field of steel-making ladle refractory materials, can solve the problems of low service life, easy corrosion and damage of ventilation seat and nozzle seat bricks, etc. The effect of inconsistent material life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The present invention also provides a method for preparing the above-mentioned hot-state repair material for ladle seat bricks, comprising the following steps:

[0048] Weigh each raw material according to the weight ratio, stir and mix evenly.

[0049] Wherein, in the preparation method of the above-mentioned hot-state repair material for ladle seat bricks, the stirring time is ≥5 minutes.

[0050] The repairing material of the present invention is repaired in a water-combined manner. When in use, 4-5% of water needs to be added to satisfy self-flow. It is added through a catheter, which is similar to the way some steel plants add drainage sand, and is similar to the current organic dry method. Compared with the combination, it can reduce the smoke generated by the combustion of its organic binder, which is more friendly to the environment. After the mending material of the present invention is repaired, the moisture is heated and evaporated, and the water vapor forms p...

Embodiment 1

[0059] Embodiment 1 prepares the ladle seat brick thermal repair material of the present invention

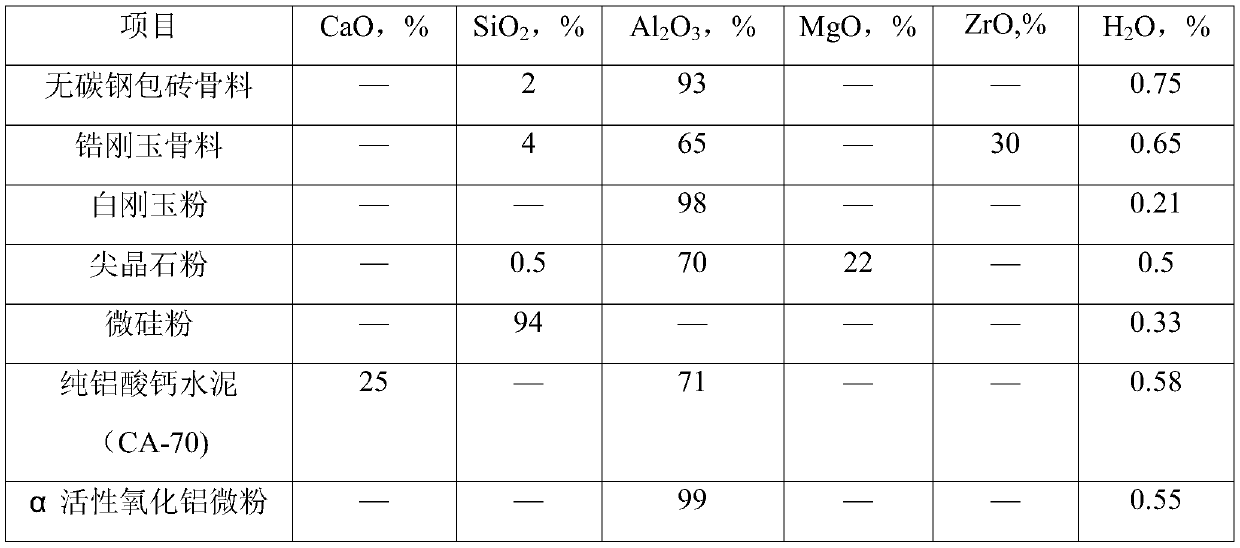

[0060] The raw materials of the repair material are shown in Table 3 below:

[0061] Table 3 raw material formula 1

[0062]

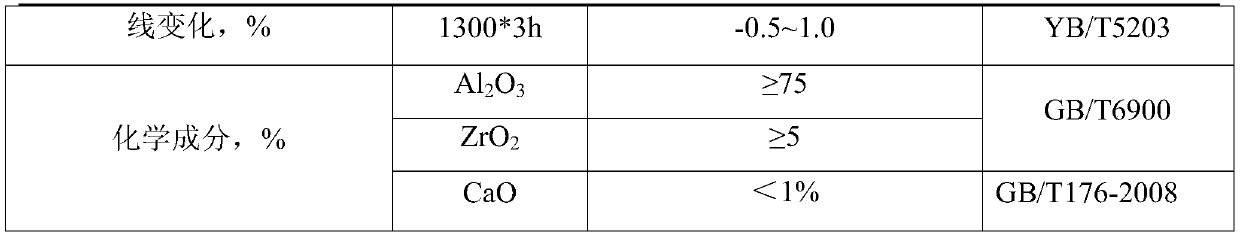

[0063] After batching, stirring and packaging, the hot-state repair material for ladle block bricks was sampled and tested according to the sampling procedures, and the physical and chemical test results are shown in Table 4:

[0064] Table 4 Example 1 Physical and chemical detection indicators of hot repair of ladle seat bricks

[0065] project Test results% Al 2 o 3 ,%

86.07 CaO, % 0.5 ZrO2,% 6.6 Bulk density (110℃×24h), g / cm 3

3.07 Flexural strength (1000℃×3h), MPa 7.24 Flexural strength (1550℃×3h), MPa 10.13 Linear change rate (1550℃×3h), % -0.2

[0066] Embodiment 1 sent 5 tons of ladle seat brick thermal repair material to the hot repair operation area, and collected data from...

Embodiment 2

[0070] Embodiment 2 prepares the ladle seat brick hot-state repair material of the present invention

[0071] The raw materials of the repair material are shown in Table 6 below:

[0072] Table 6 Implementation Recipe 2

[0073]

[0074]

[0075] After batching, mixing and packaging, the hot-state repair material for ladle block bricks was sampled and tested according to the sampling procedures, and the physical and chemical test results are shown in Table 7:

[0076] Table 7 Physical and chemical detection indicators of hot repair of ladle block brick in Example 2

[0077] project Test results% Al 2 o 3 ,%

85.74 CaO, % 0.5 ZrO2,% 6.3 Bulk density (110℃×24h), g / cm 3

2.95 Flexural strength (1000℃×3h), MPa 7.11 Flexural strength (1550℃×3h), MPa 9.5 Linear change rate (1550℃×3h), % 0.2

[0078] Embodiment 2 sent 5 tons of ladle block brick hot repair material to the hot repair operation area, collected dat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com