Wet-type electrostatic precipitator for waste gas treatment and using method thereof

A wet electrostatic precipitator and waste gas treatment technology, applied in electrode structure, electrostatic separation, external electrostatic separator, etc., can solve the problems of tailing and low interception efficiency of bag filter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

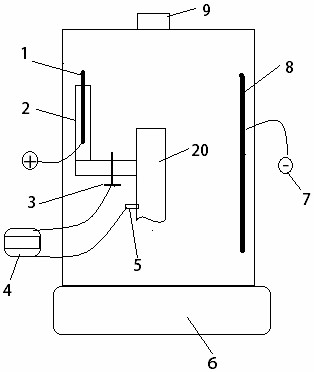

[0019] Such as figure 1 The wet electrostatic precipitator for waste gas treatment shown has acid and alkali corrosion-resistant metal discharge electrodes, dust collection electrodes, high-voltage discharge circuits, waste gas main pipes, purified gas outlets, and dust collection chambers; it also has waste gas branches, which pass through The control valve is connected to the side wall of the exhaust gas main pipe, part of the metal discharge electrode is sleeved in the exhaust gas branch circuit, and its discharge end is exposed outside the exhaust gas branch circuit.

[0020] A sensor capable of measuring the pH value of the exhaust gas is installed on the exhaust gas main pipe, the sensor is connected to the controller through the signal line, and the controller is connected to the control valve through the control line; when the pH value of the exhaust gas in the exhaust gas main pipe is small or the pH value is large , the control valve opens.

[0021] The exhaust gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com