Temperature accurate control device used for integrated cavity spectrum technology isotope analysis

A spectroscopic technology and precise control technology, applied in the field of gas isotope analysis of integrating cavity spectroscopy technology, can solve the problems affecting accuracy, stability and zero drift, to ensure the accuracy and stability of temperature control, wide application range, high sensitivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

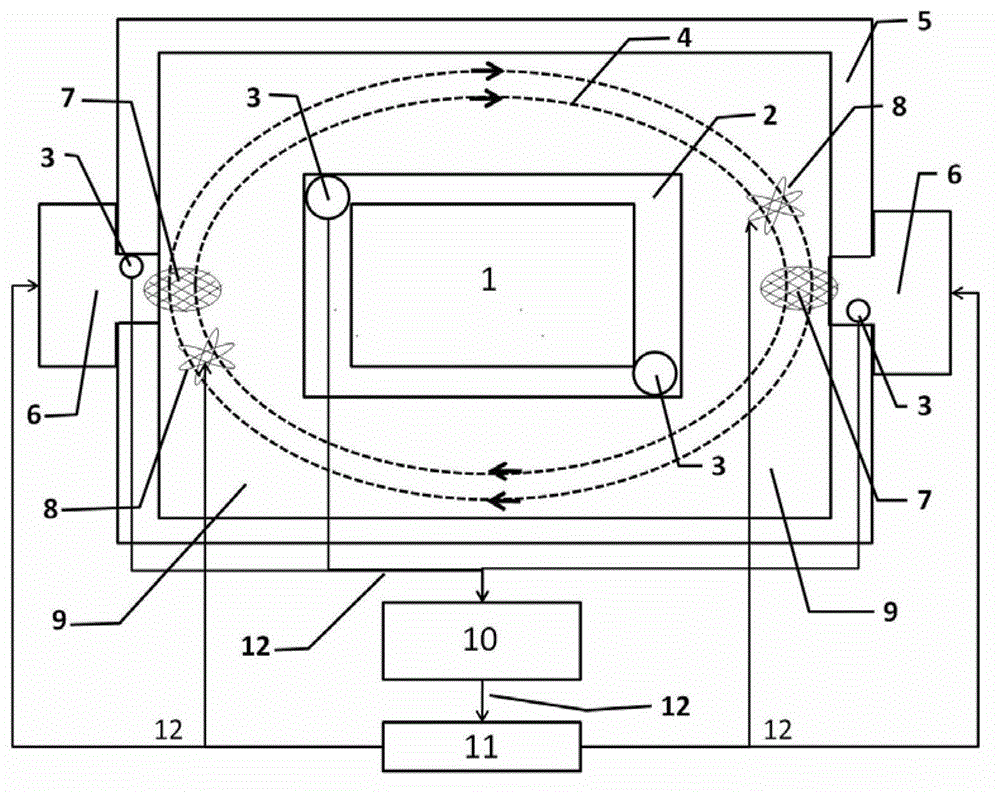

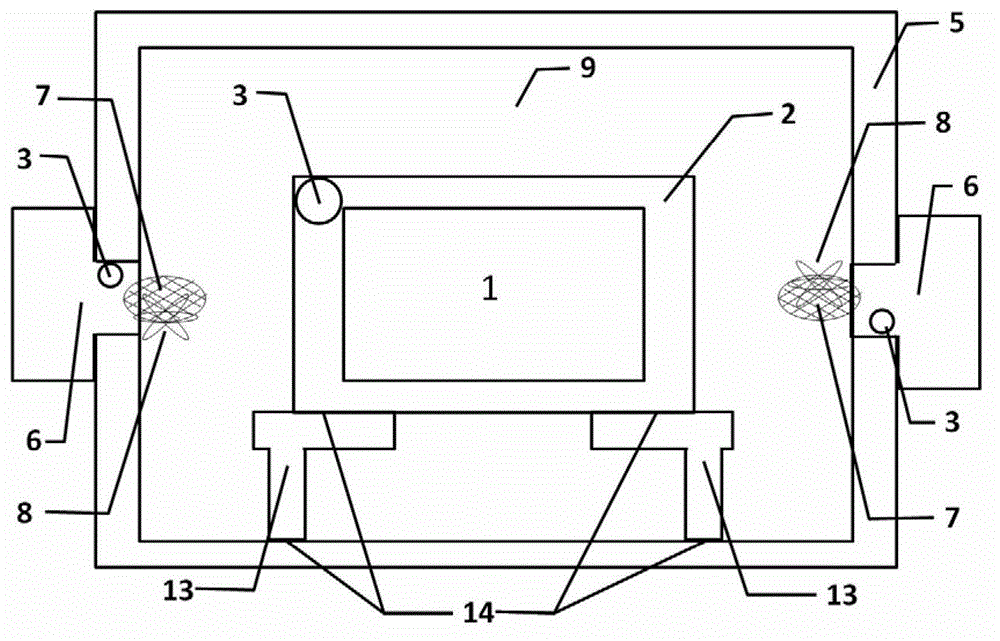

[0024] Such as figure 1 , figure 2 , image 3As shown, the device of the present invention includes two parts: one is the optical path system 1; the other is the secondary sealing system for precise temperature control; the secondary sealing system for precisely controlling the temperature includes: the optical path system 1 passes through the primary sealing casing 2 Carry out the first sealing, platinum resistance temperature sensor 3, gas laminar flow 4, secondary sealing shell 5, semiconductor refrigeration stack 6, mesh heat exchanger 7, fan 8, nitrogen 9 atmosphere, temperature controller 10, drive circuit Module 11 , cable 12 , rigid support 13 , shock absorbing foam 14 .

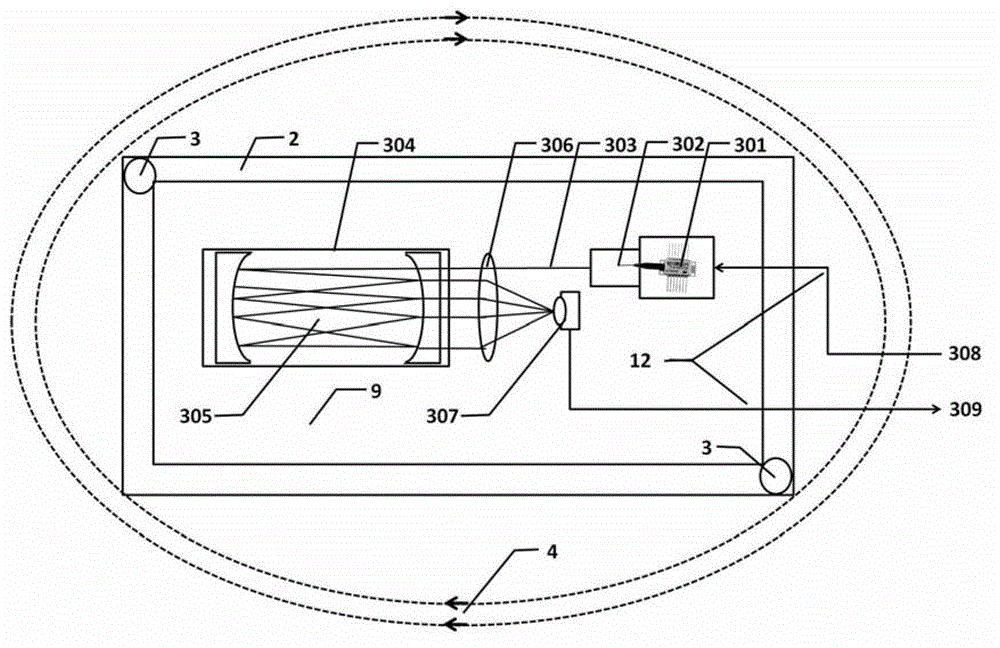

[0025] Optical path system 1 such as image 3 As shown, it mainly includes: a DFB laser 301 installed outside the primary sealed casing 2 and the secondary sealed casing 5, a beam converging collimating lens group 302, a collimated beam 303, an optical cavity 304, and the to-be-measured inside th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com