LiNbO3/SiO2/diamond multilayer piezoelectric film and preparation method thereof

A diamond and piezoelectric film technology, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, circuits, etc., can solve the temperature stability of multi-layer film structure SAW devices Sexuality has not been improved, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

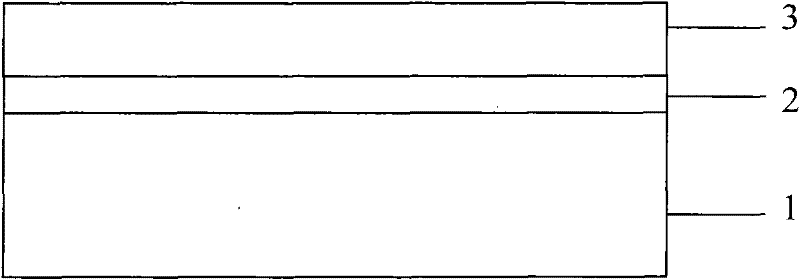

[0010] 1. Put the diamond substrate (which can be cleaned before use) into the vacuum chamber of the pulsed laser deposition equipment, and evacuate to 10 -3 Pa, heat the substrate to 300°C, use silicon (Si) as the target, the distance between the target and the diamond substrate is 4.5cm, feed 99.99% high-purity oxygen, and the oxygen pressure is 15Pa. Amorphous SiO deposited on the bottom 2 Buffer layer, amorphous SiO 2 The thickness of the buffer layer is 0.13μm;

[0011] 2. Amorphous SiO will be deposited 2 The diamond substrate of the buffer layer was heated up to 680°C, 99.99% high-purity oxygen was introduced during the deposition process, the oxygen pressure was kept at 60Pa, and the laser frequency was 3Hz. LiNbO 3 As the target, the distance between the target and the diamond substrate is 4cm, and the single pulse energy density is 3.5J / cm 2 laser on amorphous SiO 2 Deposit LiNbO with a thickness of 0.45 μm on the buffer layer 3 Piezoelectric film layer;

[00...

Embodiment 2

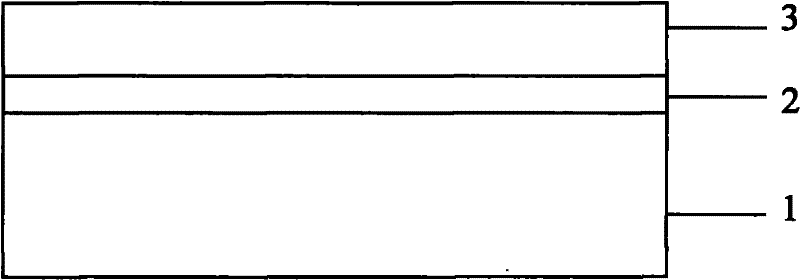

[0014] 1. Put the diamond substrate (which can be cleaned before use) into the vacuum chamber of the pulsed laser deposition equipment, and evacuate to 10 -3 Pa, heat the diamond substrate to 350°C, use silicon as the target, and conduct SiO in a 99.99% high-purity oxygen atmosphere at 15Pa 2 Deposition, the distance between the target and the substrate is 5.7cm, and the pulsed laser is used to deposit amorphous SiO with a thickness of 0.3μm on the diamond substrate. 2 The buffer layer;

[0015] 2. Amorphous SiO will be deposited 2 The diamond substrate of the buffer layer was heated up to 640°C, 99.99% high-purity oxygen was introduced during the deposition process, the oxygen pressure was kept at 40Pa, and the laser frequency was 3Hz. LiNbO 3 As a target, the distance between the target and the diamond substrate is 4.5cm, and the single pulse energy density is 4J / cm 2 laser on amorphous SiO 2 Deposit LiNbO with a thickness of 0.6 μm on the buffer layer 3 Piezoelectric f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com