Electromagnetic heating roll temperature control method and system thereof

A technology of electromagnetic heating roller and temperature control system, which is applied in the direction of auxiliary controller with auxiliary heating device, temperature control by electric method, etc., to achieve the effect of improving production efficiency and product qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

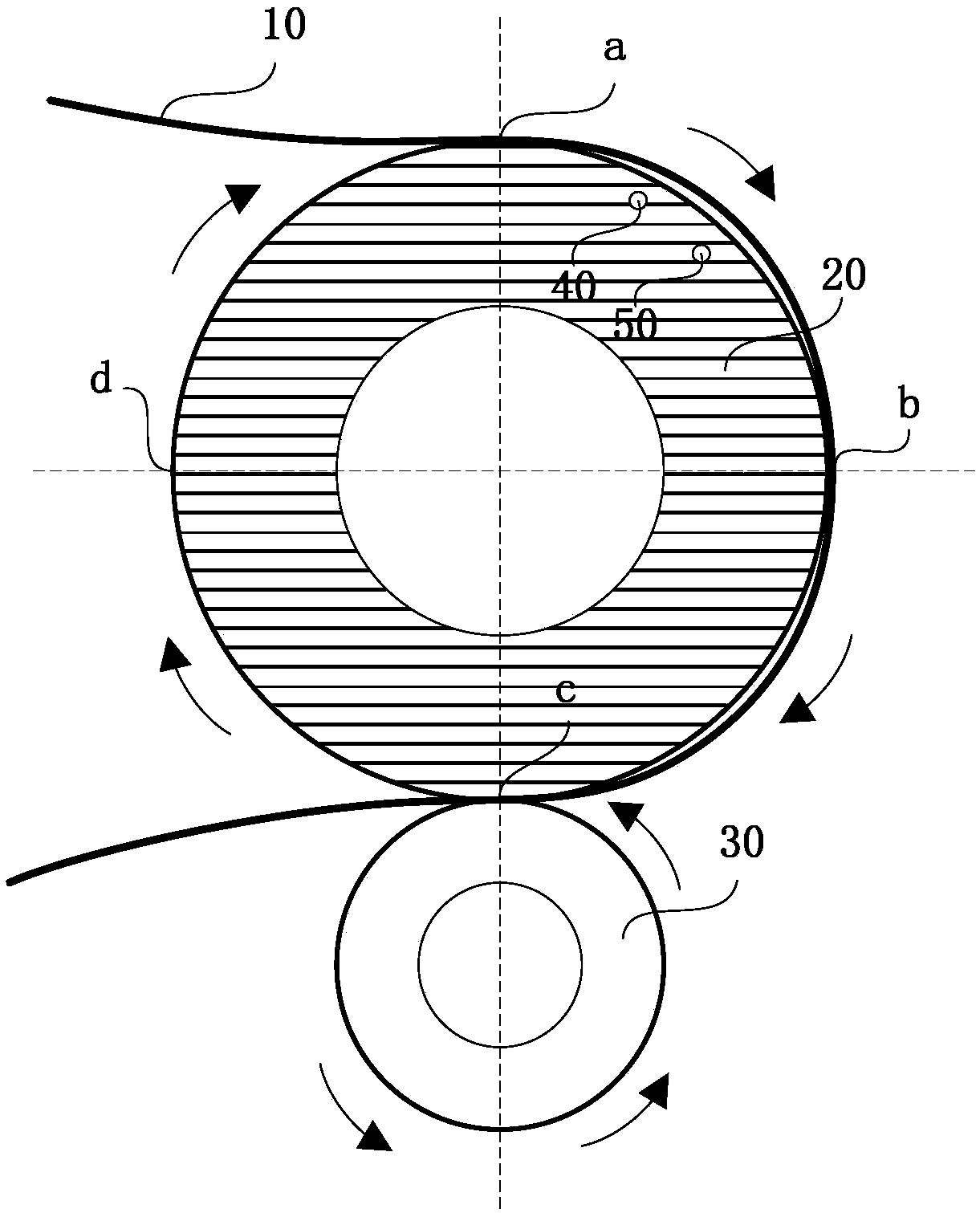

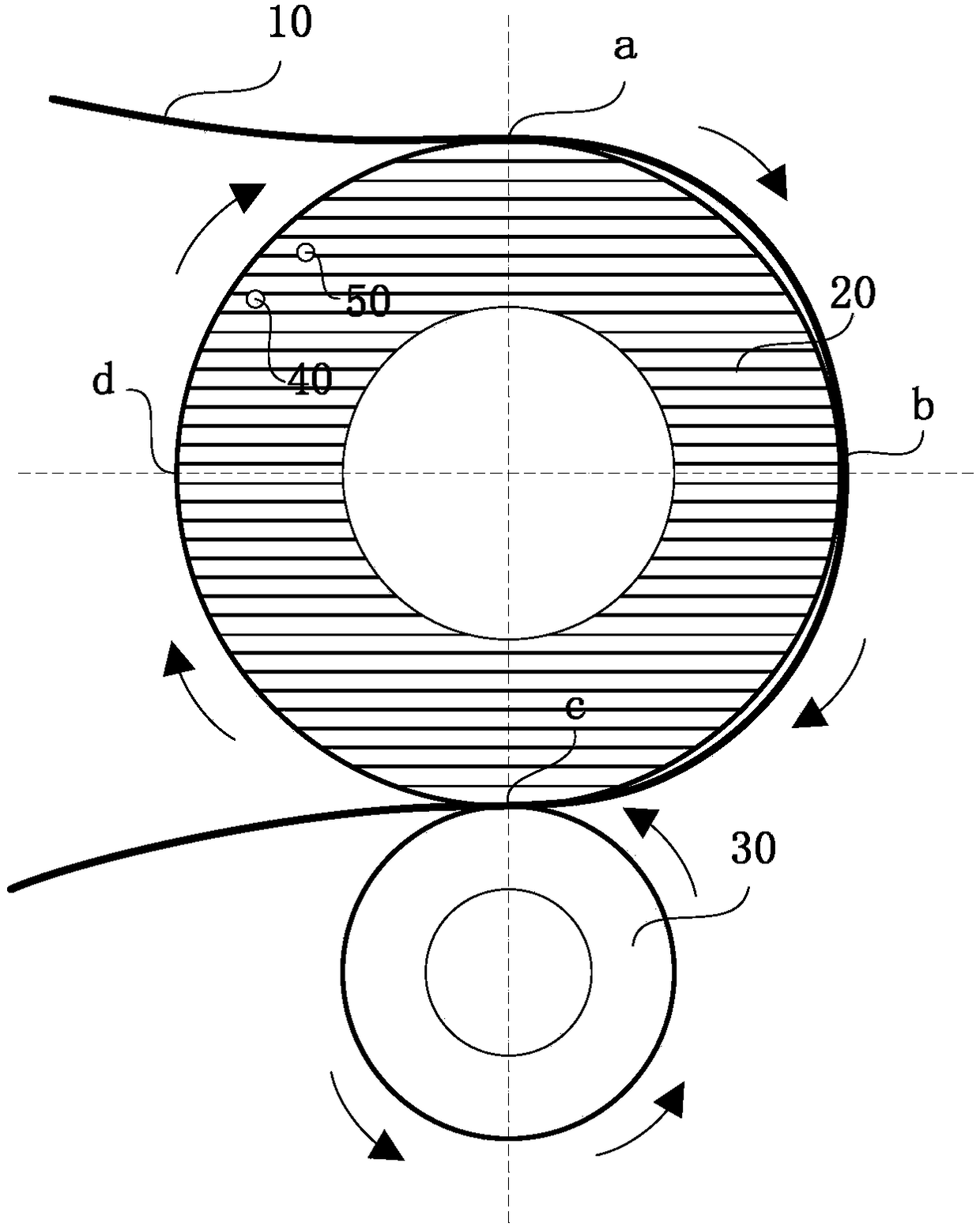

[0069] Example embodiments will now be described more fully with reference to the accompanying drawings. Example embodiments may, however, be embodied in many forms and should not be construed as limited to the embodiments set forth herein; rather, these embodiments are provided so that this disclosure will be thorough and complete, and will fully convey the concept of example embodiments to those skilled in the art. The same reference numerals denote the same or similar structures in the drawings, and thus their repeated descriptions will be omitted.

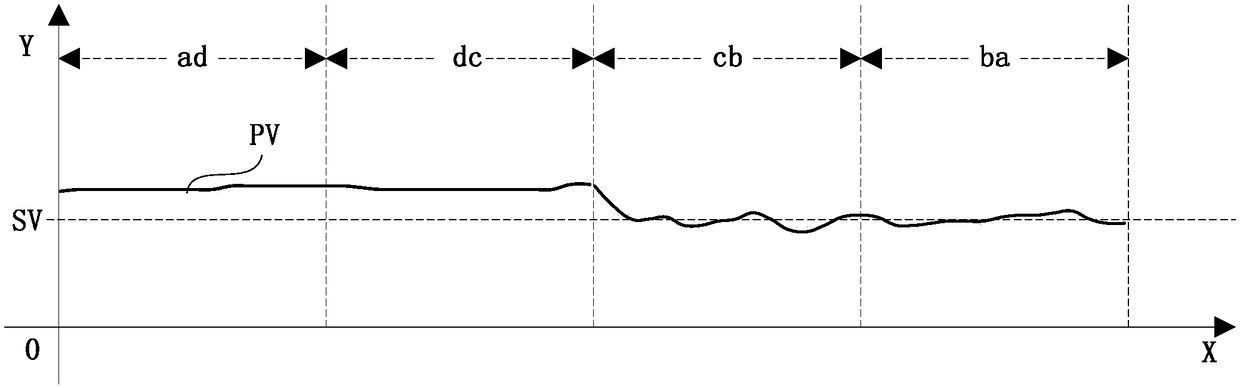

[0070] Figure 5 It is a flowchart of the electromagnetic heating roller temperature control method of the present invention. Such as Figure 5 As shown, the electromagnetic heating roller temperature control method of the present invention comprises the following steps:

[0071] S100. At least three temperature measuring units distributed on the circumference of the roller body detect the temperature data of the surface of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com