Wide-temperature range, high-magnetic permeability and low-distortion soft magnetic ferrite

A technology of soft ferrite and high magnetic permeability, applied in the direction of magnetic properties of inorganic materials, can solve problems such as poor practicability, unfavorable design and use of pulse transformers, and increased primary windings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

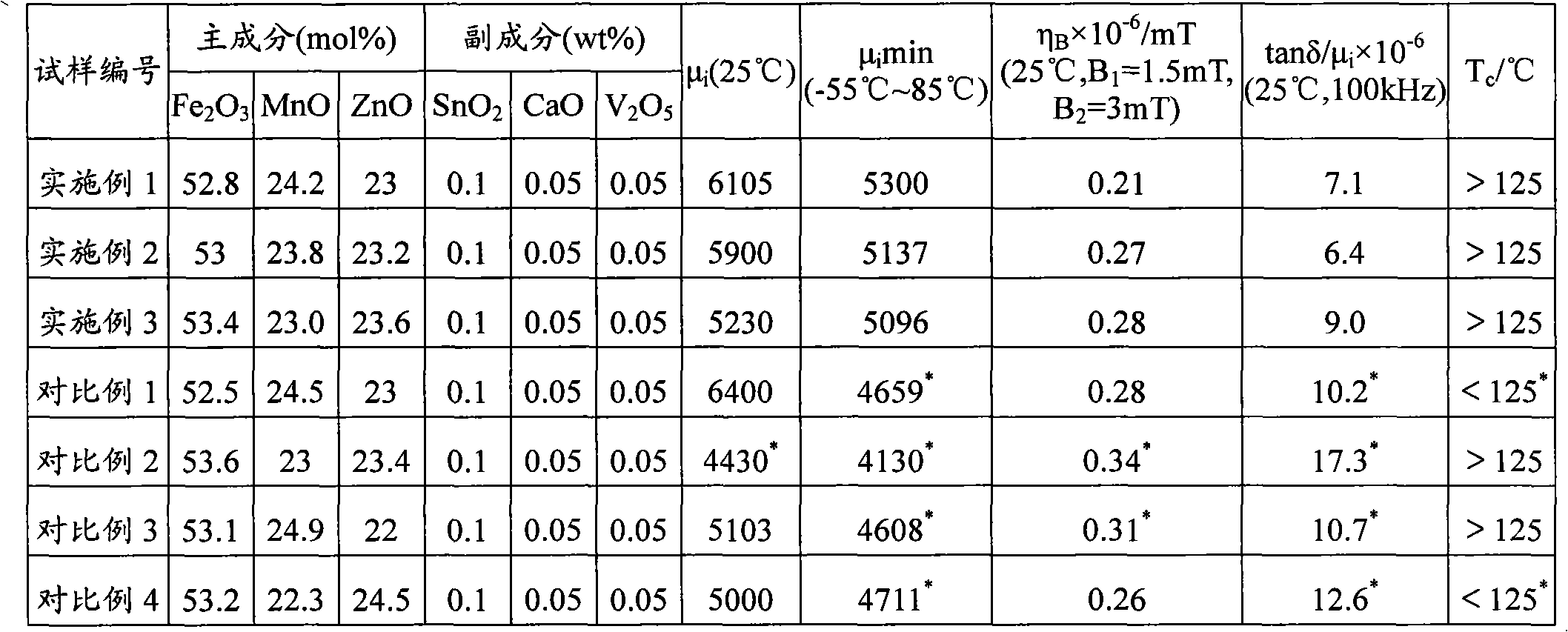

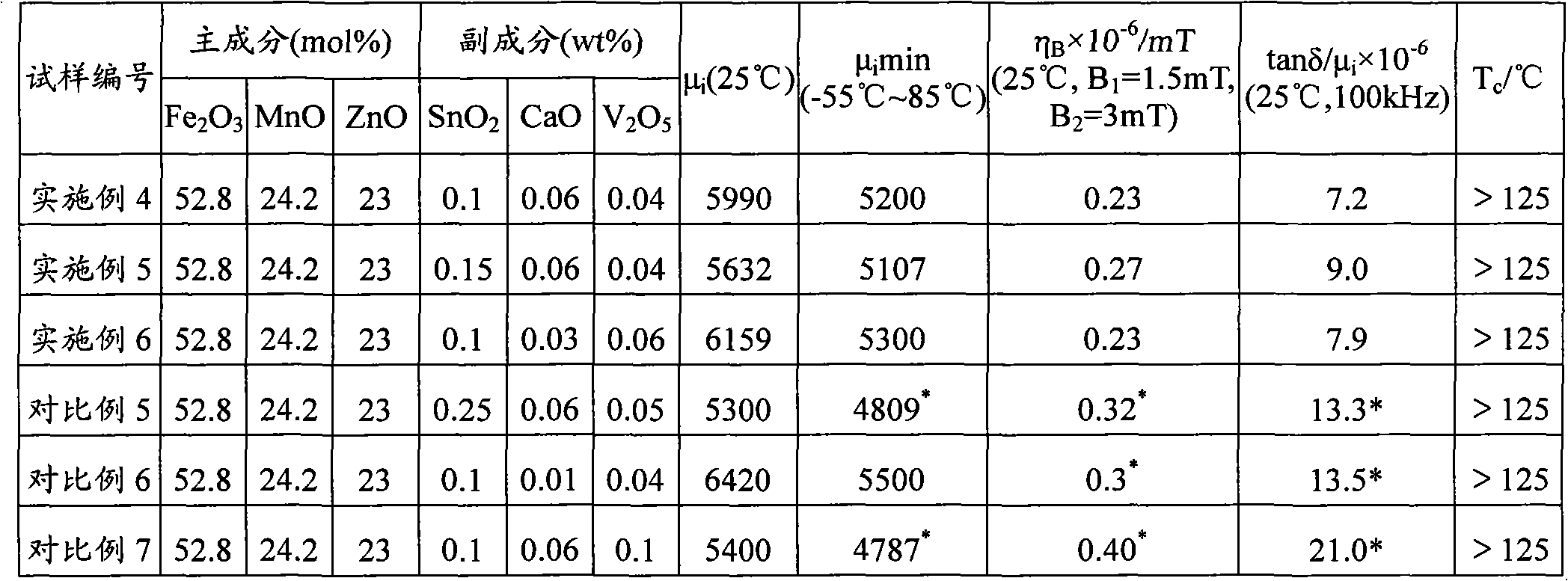

Embodiment 1

[0013] Weigh 52.8mol% Fe 2 o 3 , 24.2 mol% of MnO and 23 mol% of ZnO. After the above-mentioned main components are mixed and dried, they are pre-fired at 900°C to 1000°C. Subsequent additions are added to the calcined material for pulverization, and the particle size of the slurry after pulverization is controlled at 1.0 to 1.7 μm; relative to the total amount of the main components, the content of the subcomponents in terms of their respective oxides by weight (wt% ) are respectively: SnO 2 : 0.1, CaO: 0.05, V 2 o 5 : 0.05. Then pulverize, add a small amount of binder PVA into the mixture, and make 80-450 μm particles through a spray dryer, and then, the particles are pressed into a ring blank by a mold. The annular blank is sintered at 1340° C. to 1360° C. for 3 to 5 hours, and the oxygen content in the heat preservation section is controlled at 3.5% to 5.0%. The obtained MnZn ferrite annular magnetic core product has a size of Φ18mm×Φ8mm×h5mm. The magnetic core pre...

Embodiment 2

[0015] Weigh 53mol% Fe 2 o 3 , 23.8mol% of MnO and 23.2mol% of ZnO, the auxiliary components and preparation process are the same as in Example 1. The performance test results are shown in Table 1.

Embodiment 3

[0017] Weigh 53.4mol% Fe 2 o 3 , 23mol% MnO and 23.6mol% ZnO, the auxiliary components and preparation process are the same as in Example 1. The performance test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com