CSTR temperature fault-tolerant control system based on double heat exchangers and method thereof

A fault-tolerant control, dual heat exchanger technology, applied in the direction of temperature control using electric mode, can solve the problems of poor dynamic performance, short residence time of heat transfer medium, low control accuracy, etc. Conducive to energy saving and consumption reduction, and the effect of improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

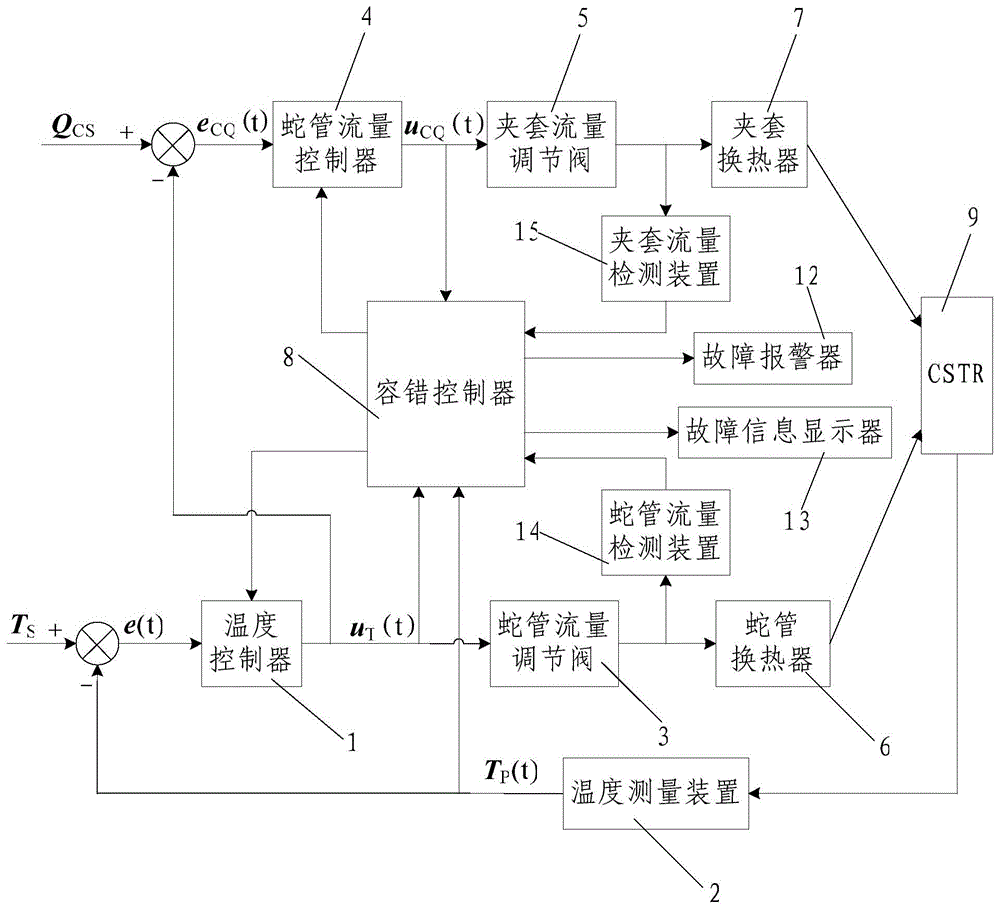

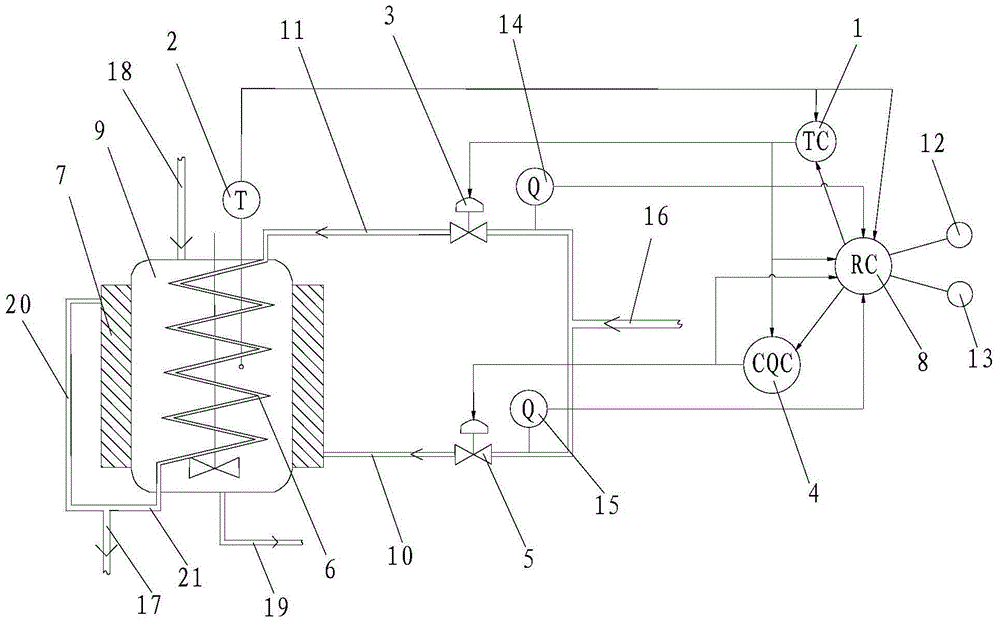

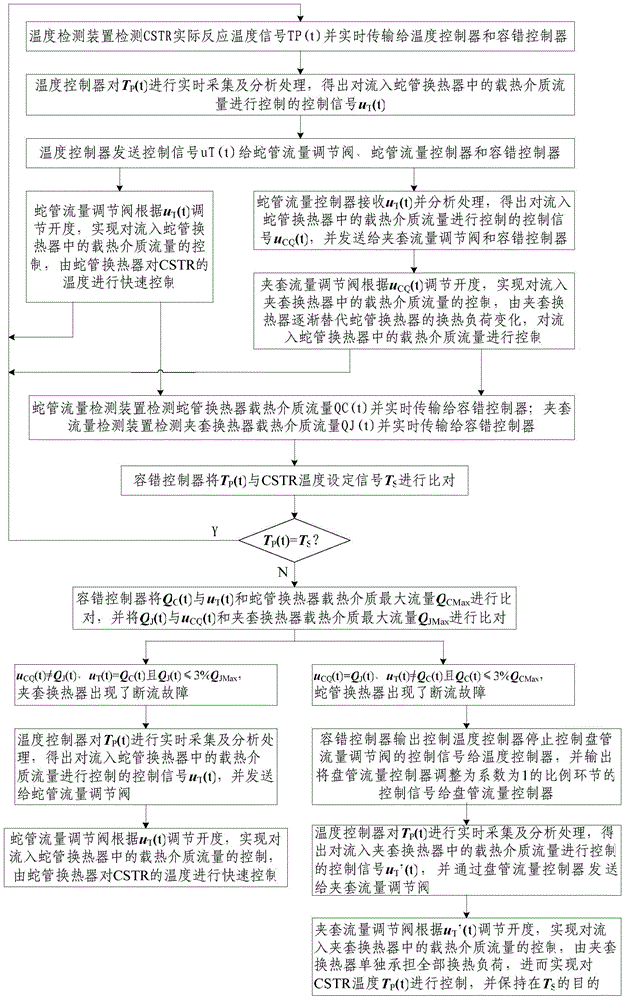

[0049] Such as figure 1 As shown, in the CSTR temperature fault-tolerant control system based on dual heat exchangers of the present invention, a coil heat exchanger 6 is provided inside the CSTR9, and a jacket heat exchanger 7 is provided outside the CSTR9. The heat-carrying medium inlet of the coil 6 is connected to a coiled heat-carrying medium input pipe 11, and the coiled heat-carrying medium input pipe 11 is provided with a device for adjusting the flow of the heat-carrying medium flowing into the coil heat exchanger 6. Coil flow regulating valve 3, the jacketed heat transfer medium inlet of the jacketed heat exchanger 7 is connected with a jacketed heat transfer medium input pipe 10, the jacketed heat transfer medium input pipe 10 is provided with a jacket for counterflow A jacketed flow regulating valve 5 for regulating the flow of the heat-carrying medium in the heat exchanger 7, and the CSTR temperature fault-tolerant control system includes a temperature controller 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com