Temperature control system for unfreezing and heat preservation of biological product liquid medicine

A technology of temperature control system and biological products, applied in the direction of temperature control, control/regulation system, non-electric variable control, etc., can solve the problems of biological products inactivation, inaccurate temperature control, high cost, etc., to ensure temperature control accuracy, The effect of improving the temperature response speed and speeding up the temperature change speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

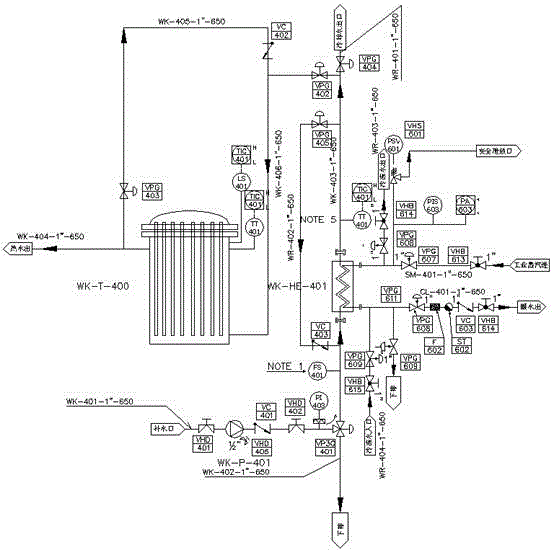

[0028] When we let the temperature control system start to work, first start the water bath heating module, use industrial steam for heating, first manually open the sanitary ball valve VBH613, the industrial steam pneumatic angle valve VPG607 automatically adjusts the opening according to the set temperature, and then the industrial steam passes through the industrial The steam pneumatic angle valve VPG607, reaches the plate heat exchanger WK-HE-401, conducts heat exchange through the plate heat exchanger WK-HE-401, heats the hot water to the set temperature, and is heated by the plate heat exchanger WK-HE- The hot water in 401 absorbs the superheated industrial steam to liquefy, then flows out from the plate heat exchanger WK-HE-401 to the chilled water pneumatic angle valve VPG611, and then passes through the condensed water pneumatic angle valve VPG608 and is filtered by the filter F602, and then sequentially The outflow from the temperature control system is through steam ...

Embodiment 2

[0032] When the temperature is close to the design temperature, the electric heating module is used, and the cooling water flows into the pneumatic valve through the pneumatic angle valve three VPG402 to the pipeline WK-406-”-650 before the heating tank, and then flows into the heating tank WK-T-400, and the heated tank The hot water heated by WK-T-400 can flow out from the hot water output pipeline WK-404-”-650 of the heating tank, and can also flow through the pneumatic angle valve four VPG403 and then through the hot water return pipeline WK-405-” -650 returns to the pipeline WK-406-"-650 from the pneumatic valve to the front of the heating tank. By controlling the number of switches and heating time of the heating tube in the heating tank WK-T-400, the temperature rise accuracy can be effectively controlled, reaching ± 0.1 degree design accuracy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com