Constant temperature bath based on mixing cold and hot liquid to control temperature

A liquid mixing and constant temperature tank technology, applied in the field of constant temperature tank, can solve the problems of uneven temperature, uneven speed distribution in the working area, and the uniformity of the temperature field needs to be improved, so as to increase the horizontal stirring force, which is conducive to the overall temperature control, The effect of avoiding the influence of cold and heat sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

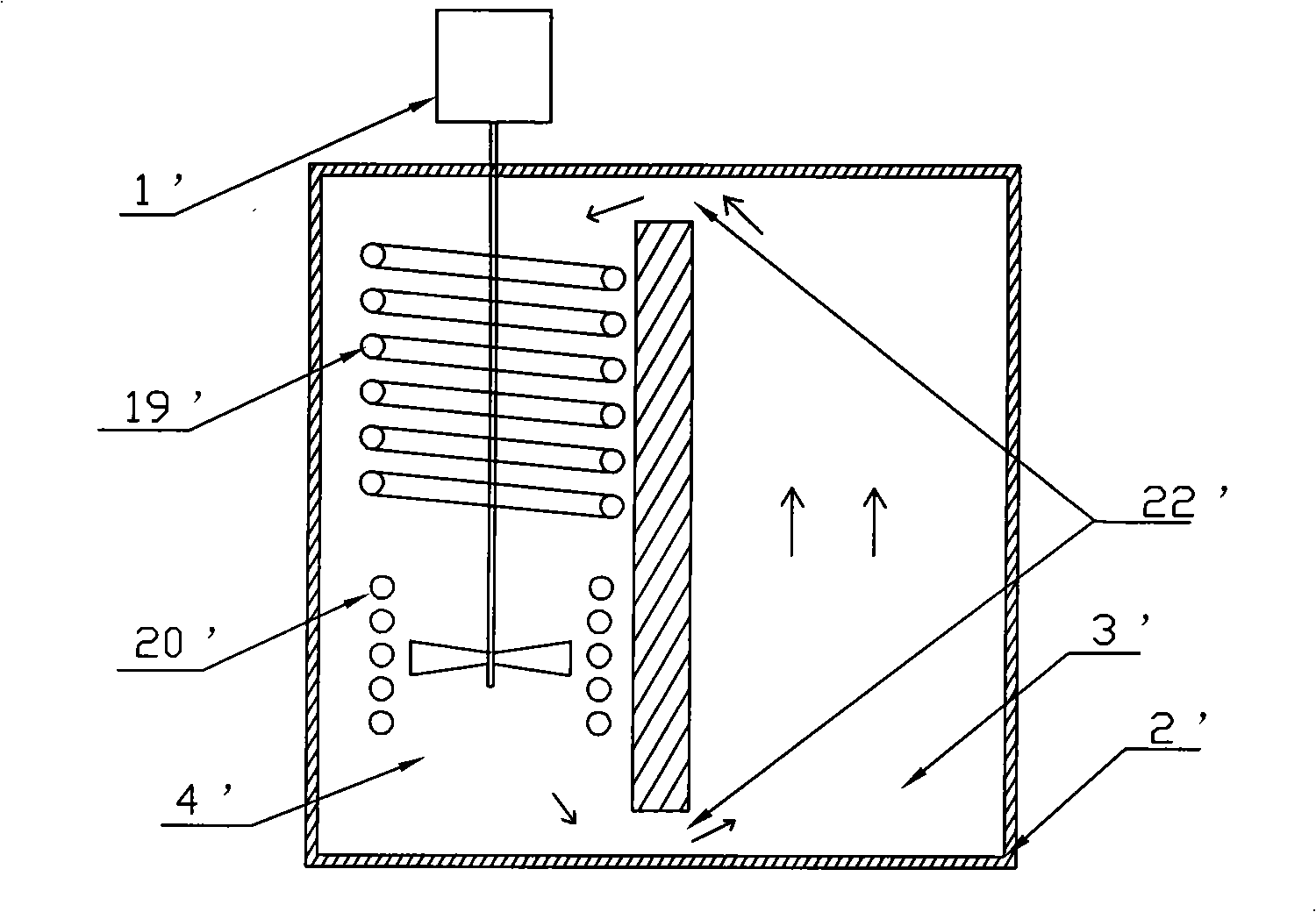

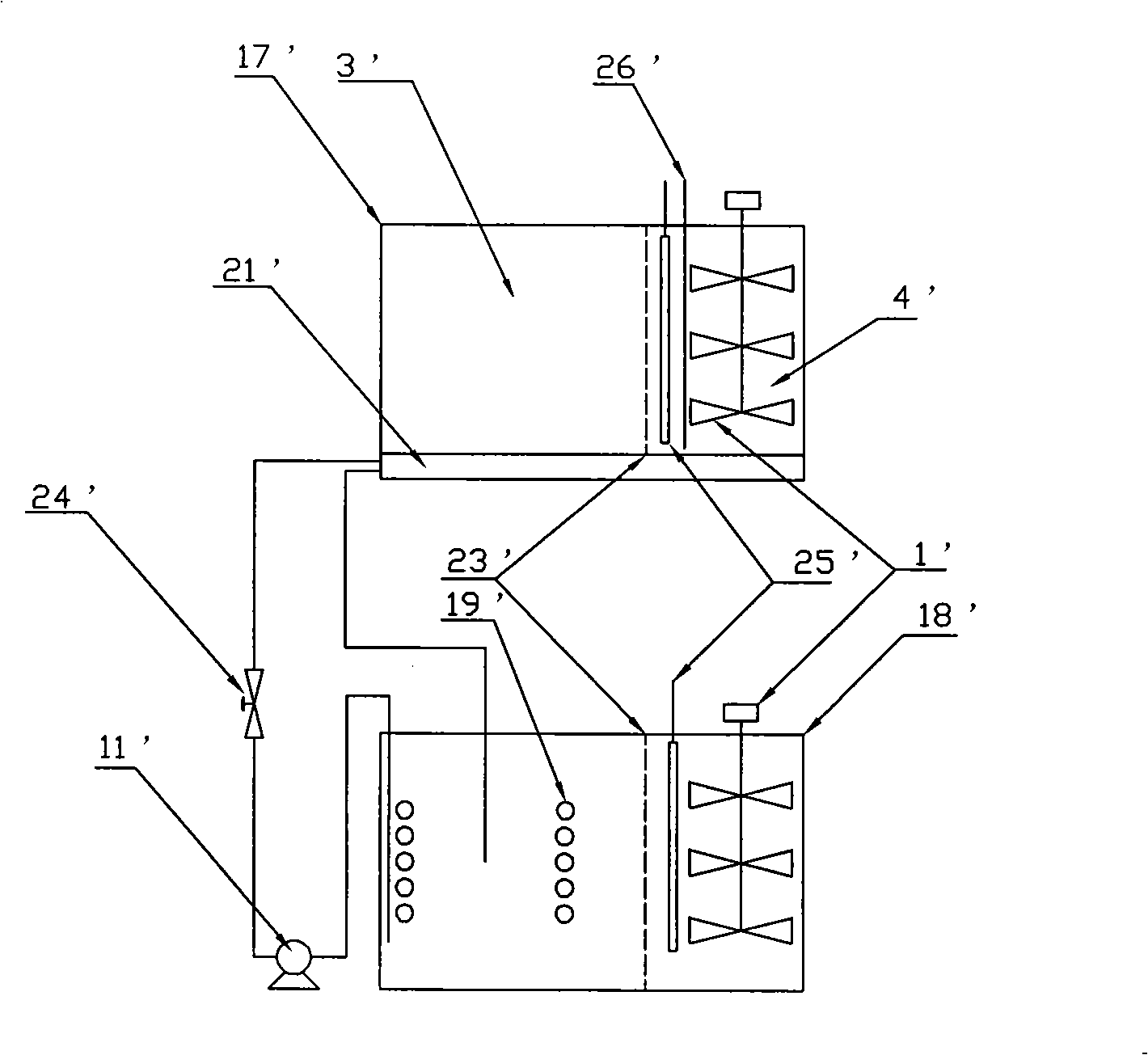

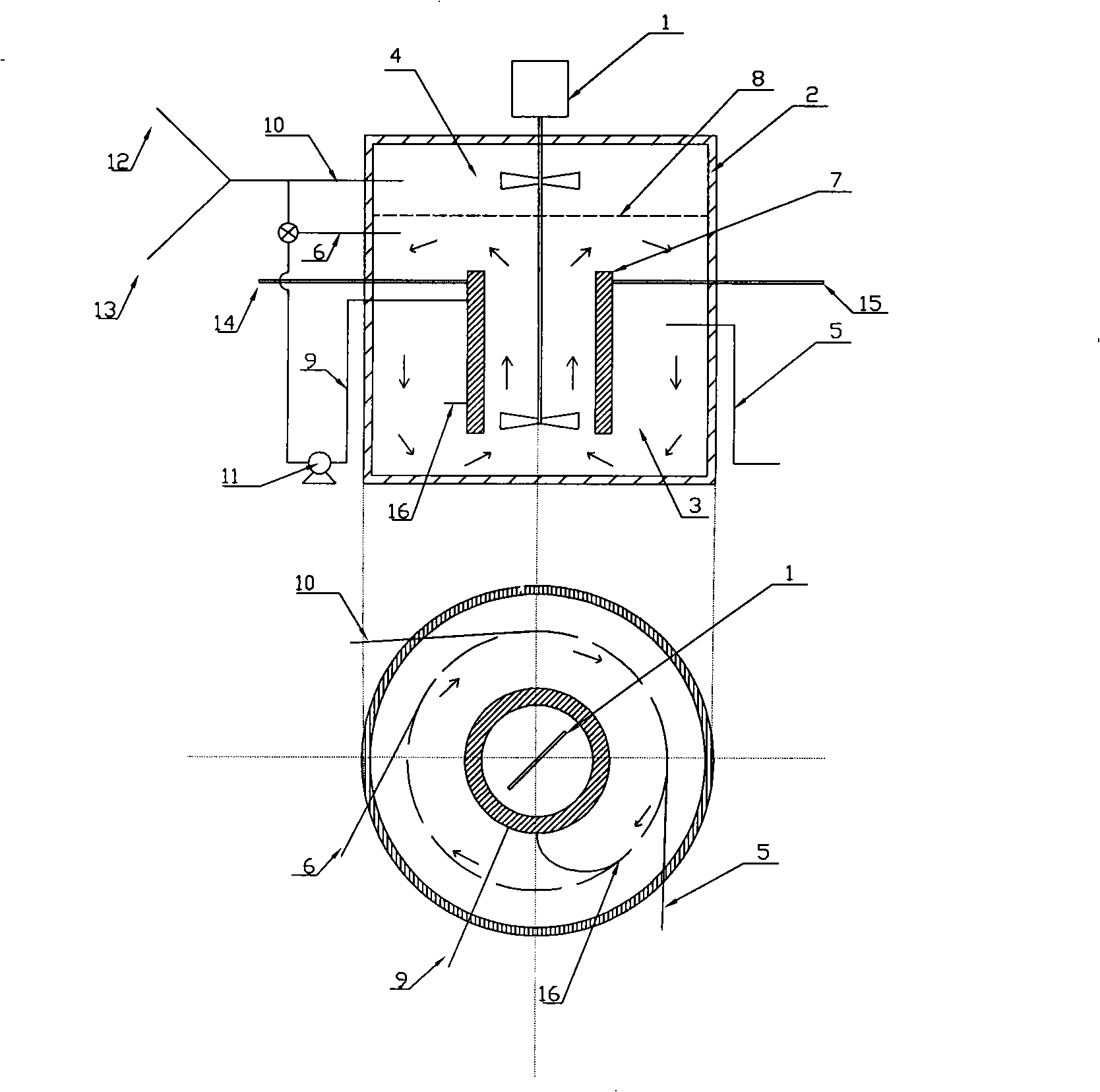

[0048] see image 3As shown, the present invention is a thermostatic bath based on mixing hot and cold liquids for temperature control. The main body of the thermostatic bath, that is, the thermostatic bath body, is made of a metal material with high thermal conductivity and has a certain thickness to balance the temperature of the liquid; The constant temperature tank is divided into a working area 3 and a temperature regulating area 4, separated by a metal partition 8 with holes in the middle, which can reduce the temperature impact of the temperature regulating area 4 on the working area 3. Stirrer 1 is provided with stirring paddles in both the temperature adjustment zone and the work zone. The temperature control zone implements horizontal stirring, and the work zone implements vertical stirring. The heat exchanger 7 in the work zone is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com