Three-stage temperature control cooling water tank

A temperature-controlled cooling and water tank technology, applied in the field of control, can solve problems such as noisy environment, limited experimental conditions, and narrow operating space, and achieve the effects of saving space, ensuring temperature control efficiency, temperature control accuracy, and precise temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

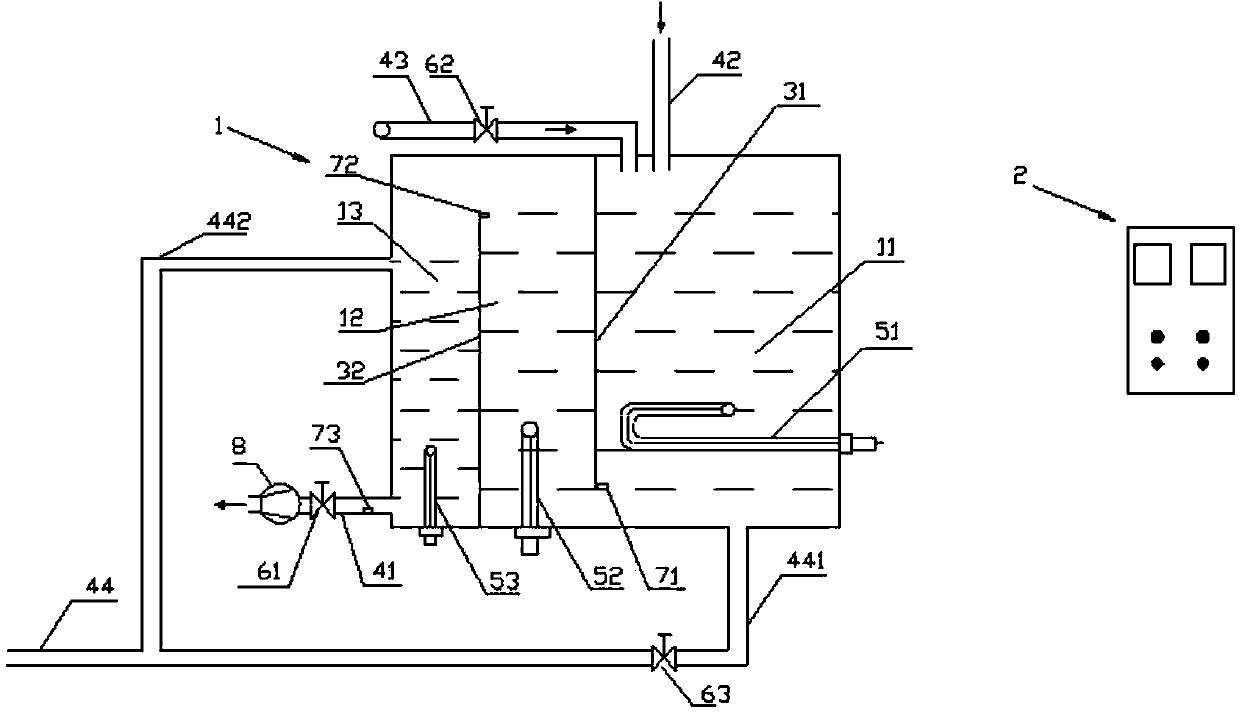

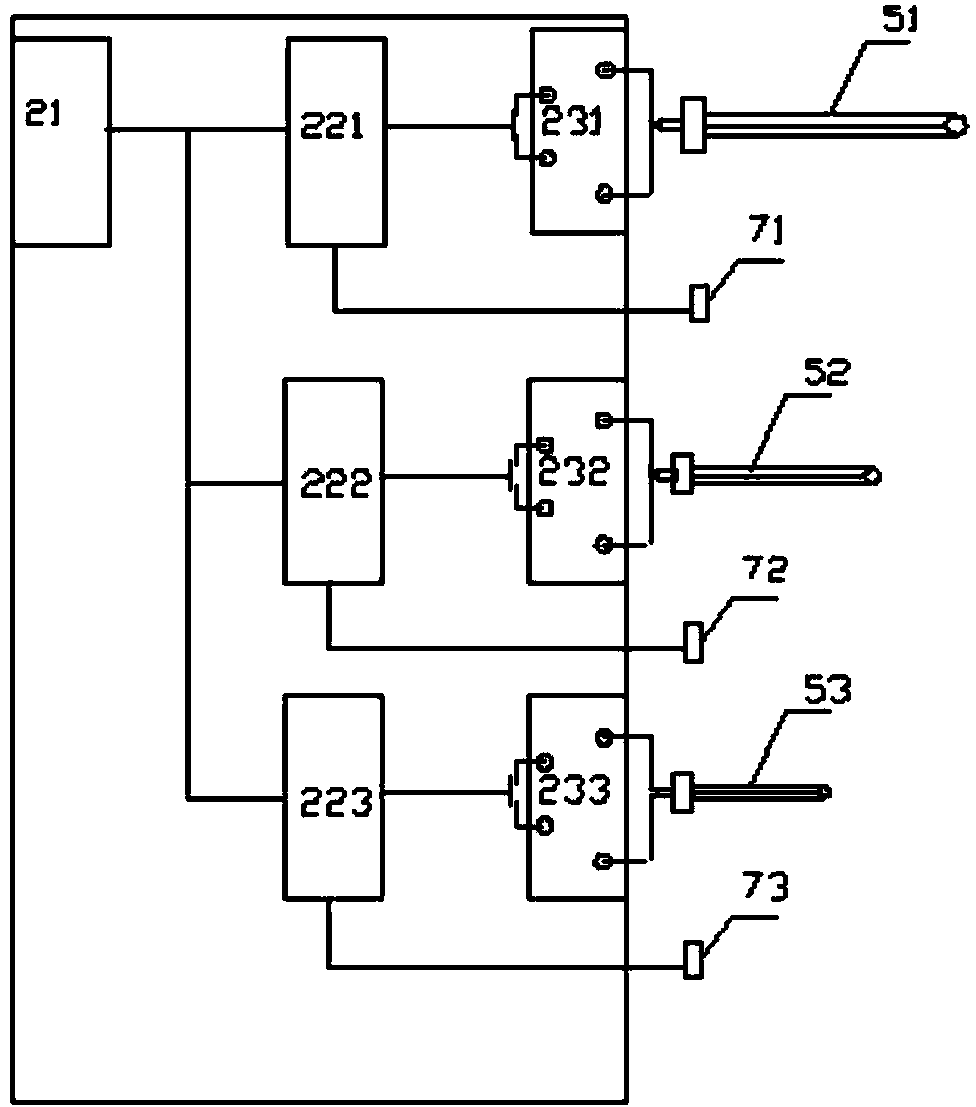

[0024] Such as figure 2 As shown, a three-stage temperature-controlled cooling water tank provided in this embodiment includes a box body 1 containing cooling water, and a first partition plate 31 and a second partition plate 32 are vertically arranged in the box body 1 to separate the box body into The first box body 11, the second box body 12 and the third box body 13, the first heating device 51 is installed in the first box body 11, the discharge pipe 441 is installed at the bottom, and the return water pipe 42 and the water supply pipe 43 are installed at the top , the second heating device 52 is installed in the second box body 12, the third heating device 53 is installed in the third box body 13, the overflow pipe 442 is installed on the upper part of the side wall of the third box body 13, and the water supply pipeline is installed on the lower part 41. Both the discharge pipe 441 and the overflow pipe 442 are connected to the drain pipe 44, the bottom of the first bo...

Embodiment 2

[0030] A three-stage temperature-controlled cooling water tank, including a box body 1 containing cooling water, a first partition 31 and a second partition 32 are vertically arranged in the box body 1 to separate the box body into a first box body 11, a second box body Box 12 and the third box 13, the first heating device 51 is installed in the first box 11, the discharge pipe 441 is installed at the bottom, the return water pipe 42 and the water supply pipe 43 are installed at the top, and the second box 12 is installed There is a second heating device 52, a third heating device 53 is installed in the third box body 13, an overflow pipe 442 is installed on the top of the side wall of the third box body 13, and a water supply pipe 41, a discharge pipe 441 and an overflow pipe 41 are installed on the bottom. The flow pipes 442 are all connected to the drain pipe 44 , the bottom of the first box 11 communicates with the second box 12 , and the second box 12 communicates with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com