Energy regulation control method of dual-system screw type water chilling unit

A water chiller and energy regulation technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of high failure rate, low failure rate, high energy consumption, etc., achieve high energy efficiency ratio, reduce work energy consumption, extend The effect of unit life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0023] The invention is applied to a double-system screw type water cooling unit.

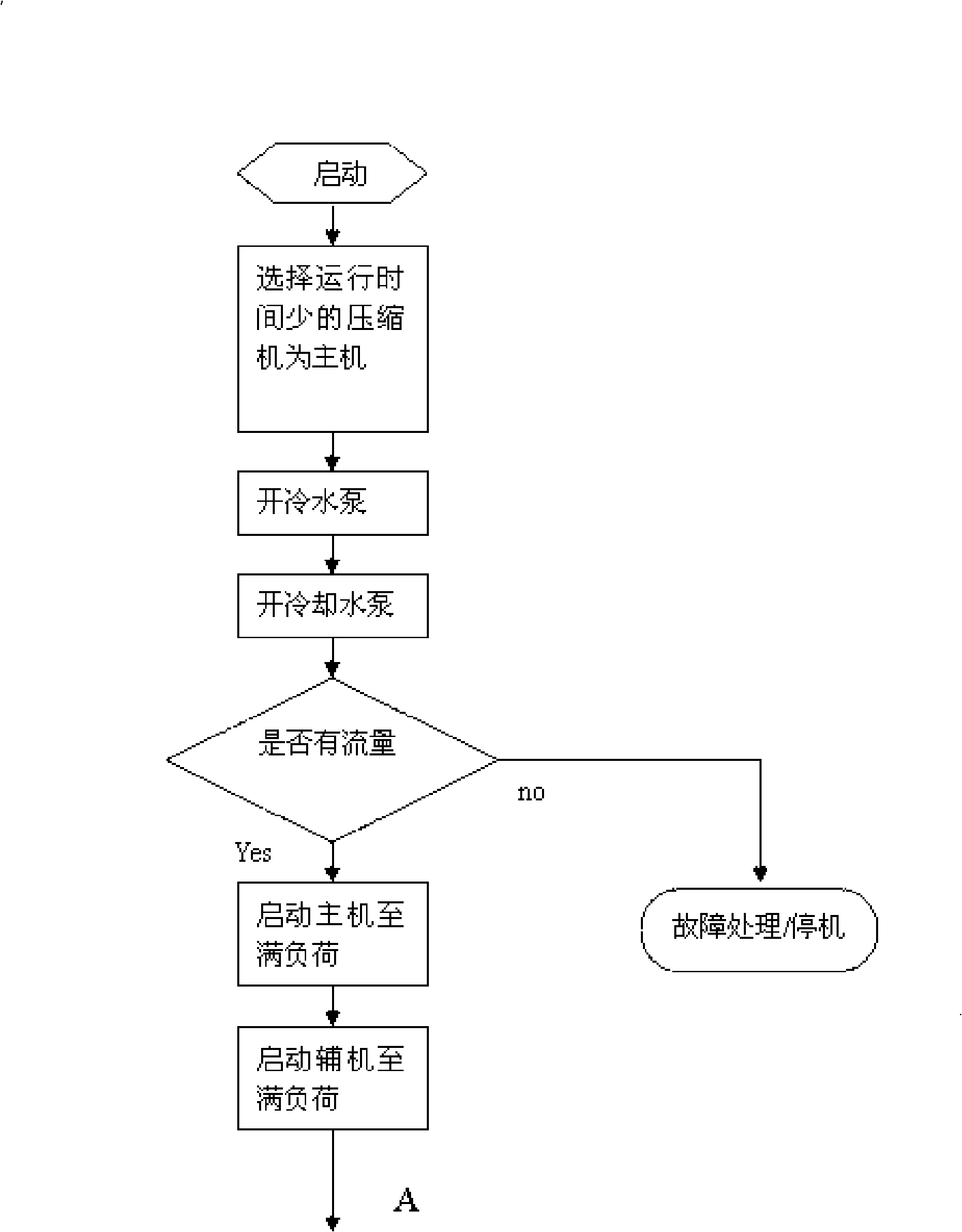

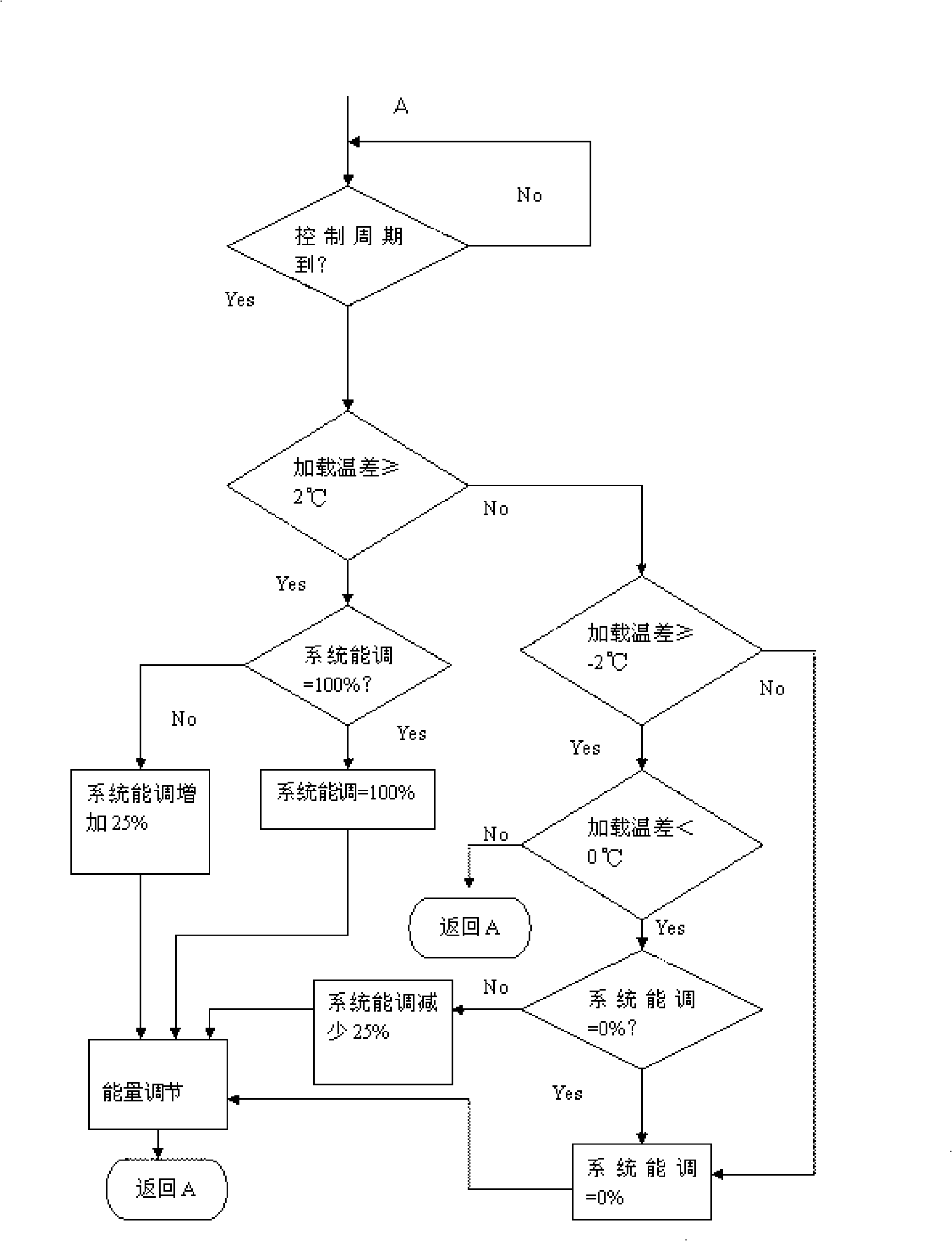

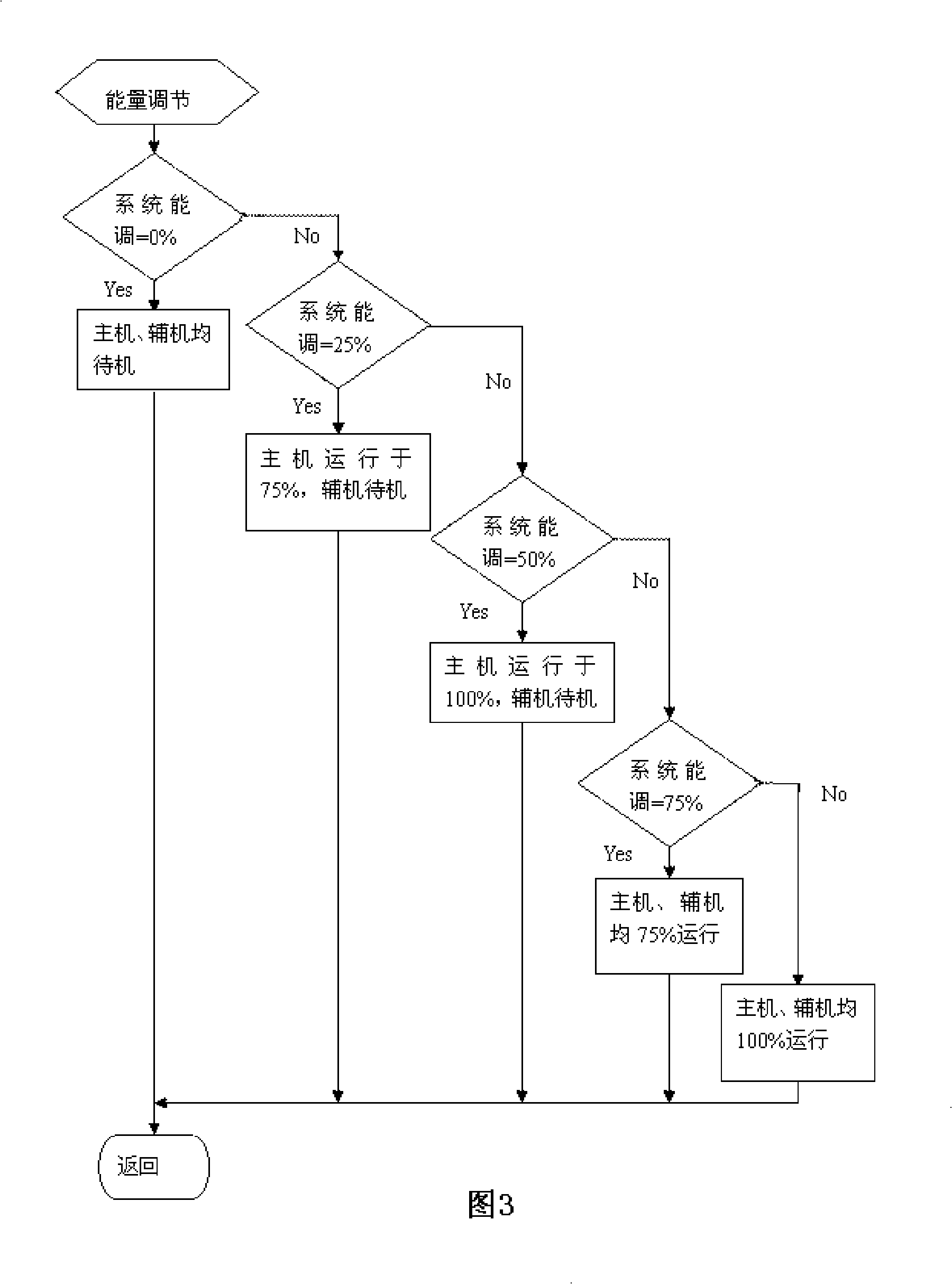

[0024] When the unit starts, select the screw compressor with less running time as the host, or when the two running times are equal, the screw compressor No. 1 is defaulted as the host; turn on the chilled water pump and chilled water pump at the same time or before or immediately after this , Check whether the two pumps have flow, if there is no flow, turn to fault processing and stop, if yes, start the main engine to full load and then start the auxiliary engine to full load, the start-up phase control ends and immediately enters the operation control phase. In this phase, according to The control cycle set by the system, at the end of each control cycle, calculate the difference between the measured temperature and the set temperature, that is, the load temperature difference, and determine the energy demand of the unit according to the load temperature difference. The system is divided into 0%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com