Small cutter head structure of quasi-rectangular shield and construction method of small cutter head structure

A technology of rectangular shield and small cutterhead, which is used in earth-moving drilling, mining equipment, tunnels, etc., can solve the problem that the small cutterhead is prone to failure and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

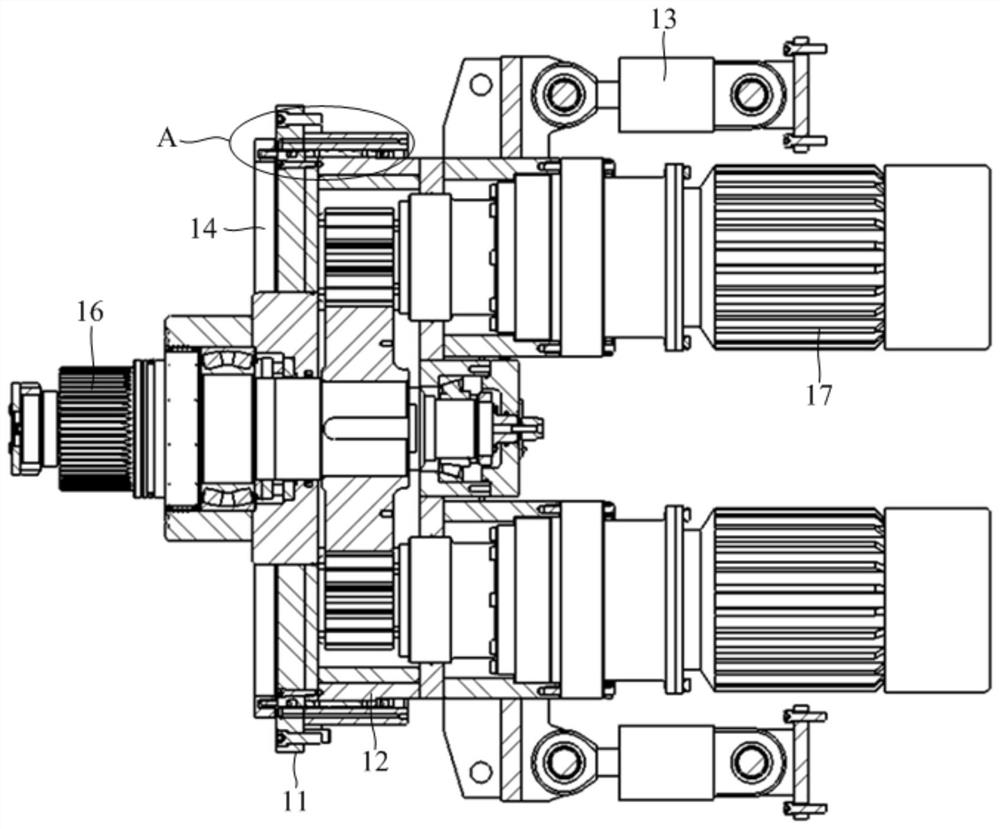

[0056] The motor 17 drives the rotating shaft 16 to rotate, thereby driving the cutter head to rotate. During the cutting process, if the axial force is too large, the telescopic piece 13 is controlled to shrink, thereby driving the housing 12 to move along the fixed sleeve 11 away from the cutting surface, and the cutter is moved away from the cutting surface. The disc also moves away from the cutting face;

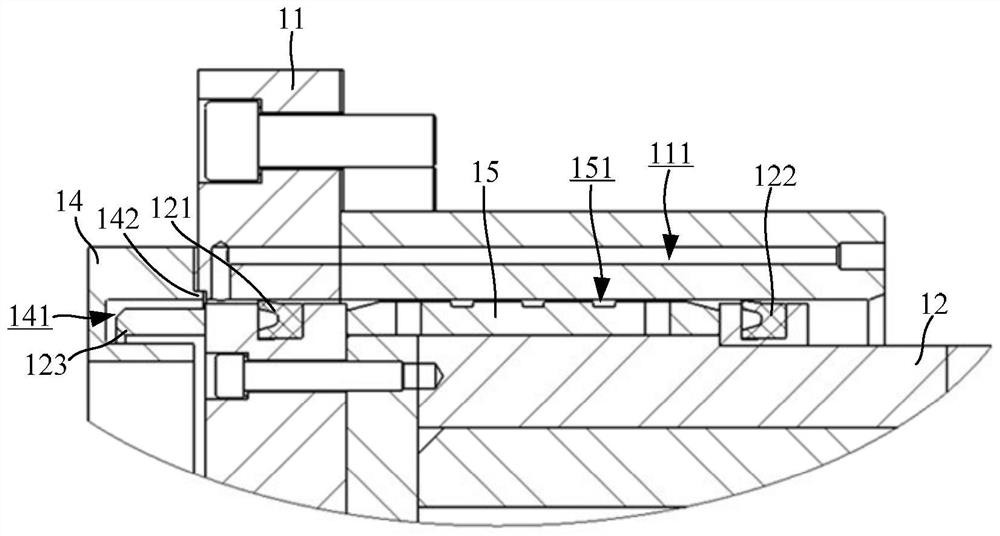

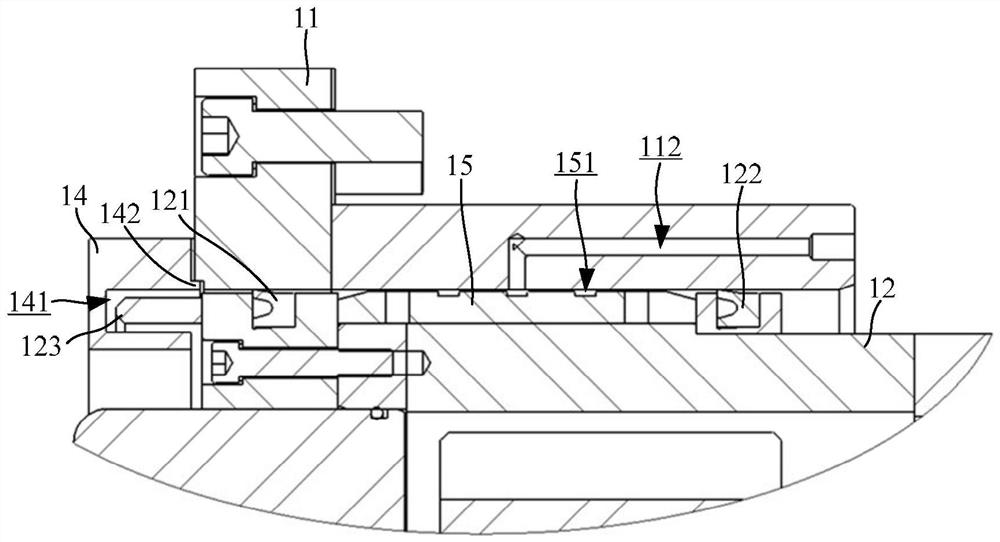

[0057] At this time, the clamping block 123 moves along the clamping slot 141, and the clamping block 123 can block the external sand and gravel from entering the housing 12, and since the overlapping length of the clamping block 123 and the clamping slot 141 is greater than the expansion and contraction amount of the telescopic piece 13, there is always some The clamping block 123 is located in the clamping slot 141, which can prevent sand and gravel from entering the housing 12;

[0058] HBW grease can be injected into the position between the sealing plate 14 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com