AGV

A car body and telescopic device technology, applied in the field of AGV vehicles, can solve the problems of dangerous long-term use, dangerous long-term use of discharge and sparking, and easy failures, etc., and achieve the effect of reducing processing steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

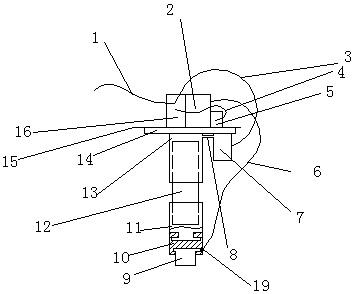

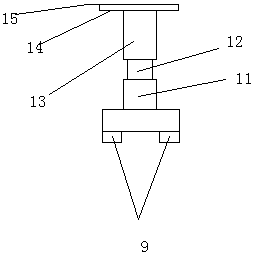

[0024] The specific embodiment 1 of AGV car of the present invention, as figure 1 As shown, a controller 16, a storage battery 2 and a voltage measuring device 5 are arranged side by side on the upper side of the vehicle body floor 15, and it is convenient for the user to observe and control the controller 16 on the vehicle body floor 15. The storage battery 2 and the voltage measuring device 5 are arranged side by side in order to facilitate wiring connection. The air pump is an air motor 7. The lower side of the vehicle body floor 15 is fixed with an air motor 7 and a pneumatic cylinder 13 through a fixed module 14. The air motor 7 and the air cylinder 13 are connected through a gas pipe 8. The cylinder 13 is provided with a cylinder shaft 12, the lower end of the cylinder shaft 12 is connected to the cylinder 11, the lower end of the cylinder 11 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com