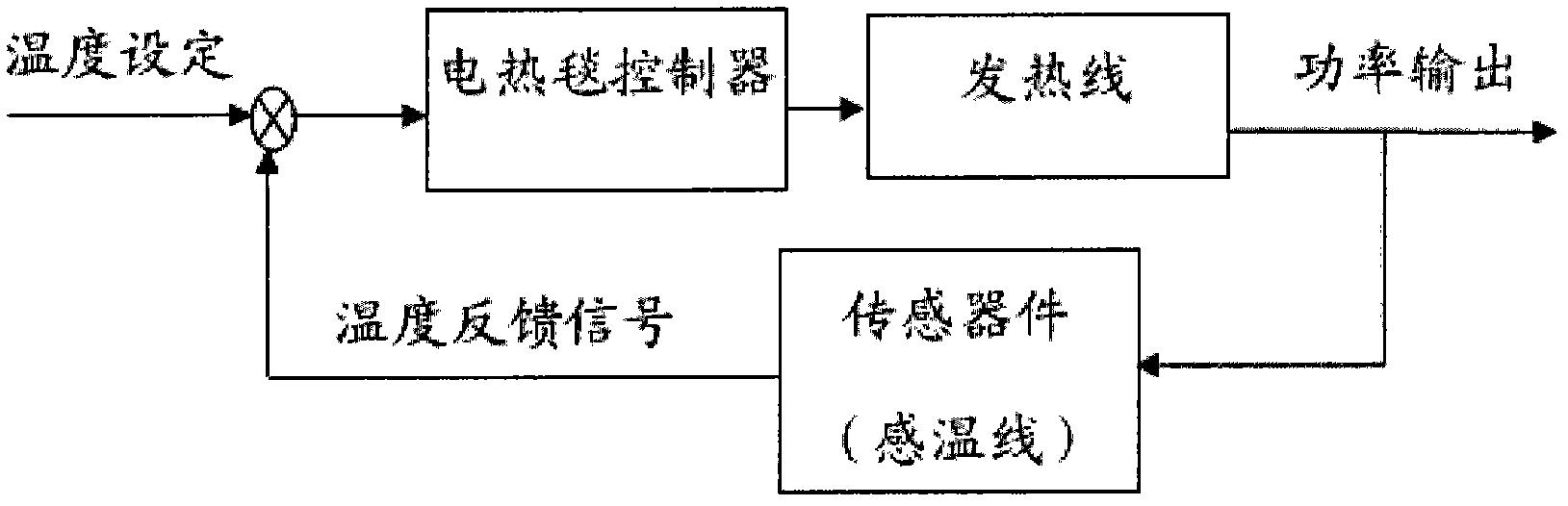

System and method for intelligently and automatically correcting temperature line of temperature control electric blanket

An automatic calibration and temperature-sensing line technology, which is applied to the parts of thermometers, sleeping blankets, thermometers, etc., can solve the problems of difficult to ensure the accuracy of calibration, hinder the popularization of products, and reduce production efficiency, so as to save labor costs and Production time, ensure temperature control accuracy and consistency, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

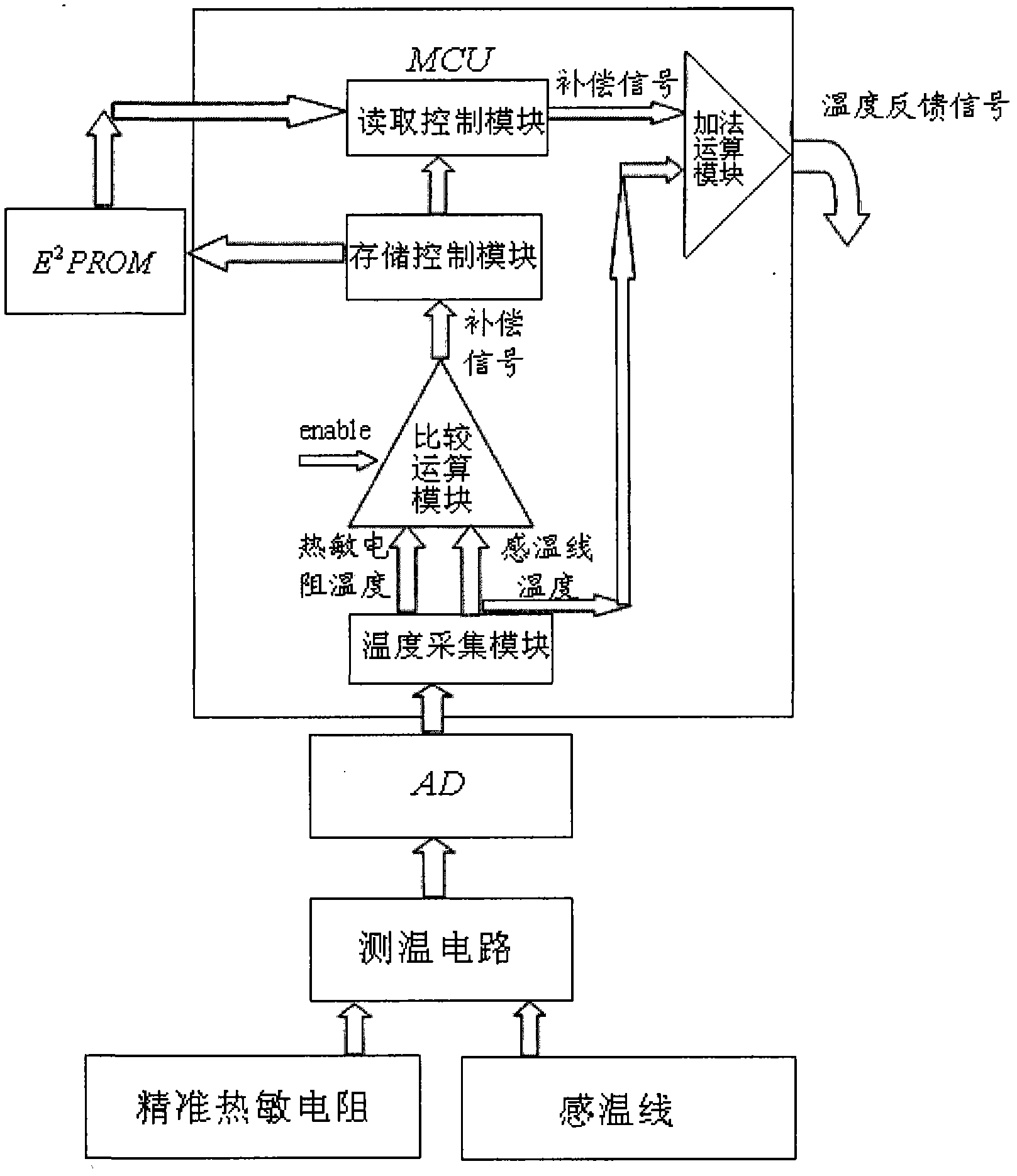

[0034] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

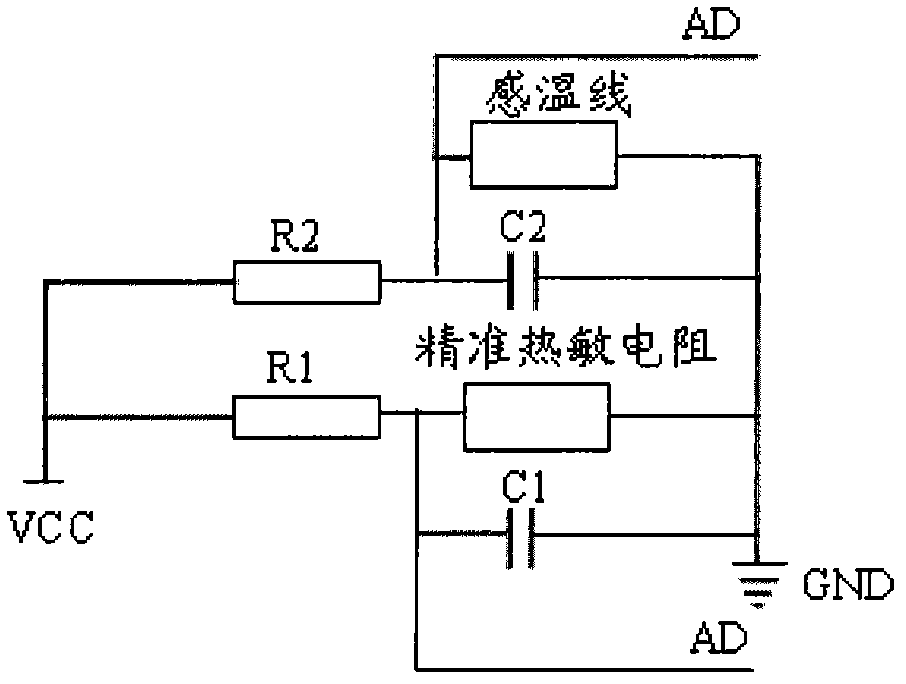

[0035] like figure 2 Shown is the structural block diagram of the intelligent automatic correction system of the temperature-control electric blanket temperature-sensing line of the present invention. It can be seen from the figure that the whole correction system consists of MCU, E 2 Composed of PROM, AD, temperature measuring circuit, temperature sensing line, and precise thermistor, among which the MCU software is the core of control, and the temperature sensing line is the temperature sensing device to be corrected, and its error is as high as 30°C. AD is the analog / digital converter , can convert the analog signal into a digital signal that can be recognized by the MCU, and is responsible for converting the voltage signal at both ends of the precise thermistor and the temperature sensing line into a temperature digital signal in the intell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com