Method and device for preparing octafluoropropane through electrolysis

An octafluoropropane and electrolytic cell technology, which is used in electrolytic components, electrolytic processes, electrolytic organic production, etc., can solve the problems of easy carbon chain breakage and low yield of octafluoropropane, and achieve stable control and easy control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

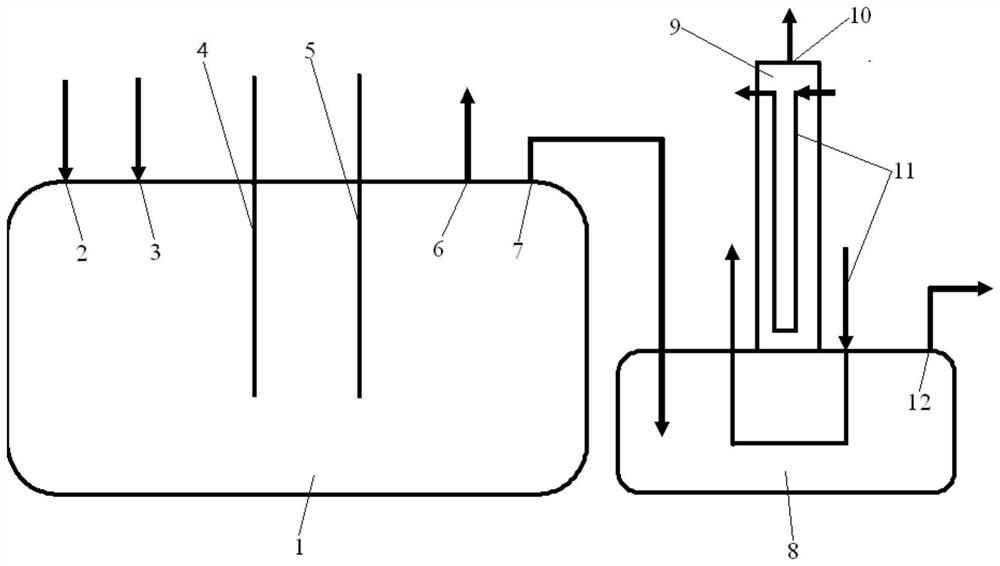

[0058] An electrolytic method of preparing octafluoropropane, the method steps:

[0059] At (1) 10 ℃, the HF KF and mixed to obtain a molten salt electrolyte.

[0060] (2) the electrolyte into the electrolytic cell, electricity is released water, electrolytic gas venting. Specifically, the first controls the electrolysis voltage is 3V, the electrolytic current trend was observed, when the current drops to zero in a stepwise manner stepwise voltage increase, enhance 0.5V each, until the voltage increased to 5V, the current drops to zero, the electrical lift the water over. In the electrolytic cell the anode and cathode is a porous nickel plate and a pitch of 5mm.

[0061] After completion (3) are electrically released water, the feedstock into the electrolytic cell, the electrolysis voltage is controlled 7V, an electrolysis temperature of -10 deg.] C, when it is detected electrolysis products containing octafluoropropane, electrolysis product was collected to give a crude octafluor...

Embodiment 2

[0067] An electrolytic method of preparing octafluoropropane, the method steps:

[0068] At (1) 10 ℃, the HF and CsF were mixed to obtain a molten salt electrolyte.

[0069] (2) the electrolyte into the electrolytic cell, electricity is released water, electrolytic gas venting. Specifically, the first controls the electrolysis voltage is 3V, the electrolytic current trend was observed, when the current drops to zero in a stepwise manner stepwise voltage increase, enhance 0.5V each, until the voltage increased to 5V, the current drops to zero, the electrical lift the water over. In the electrolytic cell a nickel anode and the cathode is a porous tube and a pitch of 5mm.

[0070] After completion (3) are electrically released water, the feedstock into the electrolytic cell, the electrolysis voltage was 6.5V control, an electrolysis temperature of 20 ℃, when detecting the electrolysis product contains octafluoropropane, electrolysis product was collected to give a crude octafluoropro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com