Multi-stage tubular electrolysis device for preparing octafluoropropane and preparation method

An electrolysis device, octafluoropropane technology, applied in electrolysis components, electrolysis process, electrolysis organic production and other directions, can solve the problems of difficult Cl atoms, increase the difficulty of design and processing of electrolyzers, low conversion rate, etc. The effect of solving design and processing difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

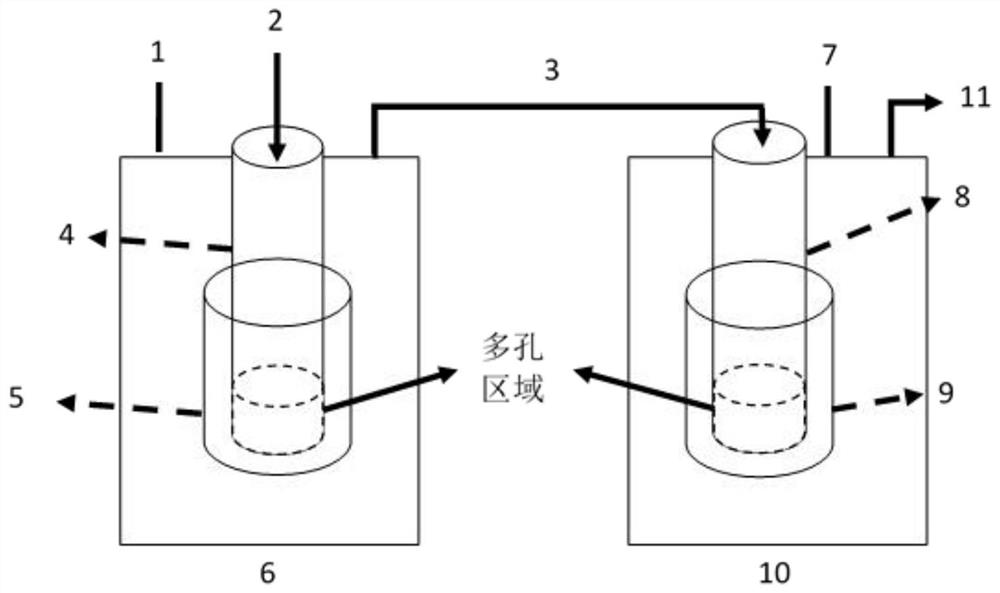

Embodiment example 1

[0040] The number of experimental electrolytic cells is 5, the design current is 200A; HF and KF are mixed into an electrolyte at 0°C, and the KF content is 10%; the anode is a local porous nickel tube, the cathode is a nickel tube, the distance is 4mm, and the gas raw material is propane or propylene. After the electrolysis of water is completed, the gas raw material enters the area between the anode and the cathode through the local porous nickel tube for electrolysis. The intake rate of a single anode is 1200L / h, the electrolysis voltage is 6.8V, the electrolysis current fluctuates between 130A and 150A, and the gas outlet is electrolyzed Gas crude product, exclude H 2 After concentration, the yield of octafluoropropane is over 46%, carbon tetrafluoride and hexafluoroethane are below 30%, and there is no abnormality in continuous operation for 120 days.

Embodiment example 2

[0042] The number of experimental electrolytic cells is 6, the design current is 200A; HF and KF are mixed into an electrolyte at 0°C, and the KF content is 10%; the anode is a local porous nickel tube, the cathode is a nickel tube, the distance is 4mm, and the gas raw material is Heptafluoropropane. After the electrolysis of water is completed, the gas raw material enters the area between the anode and the cathode through the local porous nickel tube for electrolysis. The intake rate of a single anode is 1000L / h, the electrolysis voltage is 6.5V, the electrolysis current fluctuates between 110A and 140A, and the gas outlet is electrolyzed Gas crude product, exclude H 2 After concentration, the yield of octafluoropropane is over 57%, carbon tetrafluoride and hexafluoroethane are below 25%, and there is no abnormality in continuous operation for 120 days.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com