Method for simplifying rectification process for preparing ethanol through hydrogenation of acetic acid

A technology for producing ethanol and ethyl acetate, which is applied in chemical instruments and methods, organic chemistry, preparation of hydroxyl compounds, etc., can solve the problems of insufficient downstream application and excess capacity of downstream acetic acid, and achieve the effect of saving equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

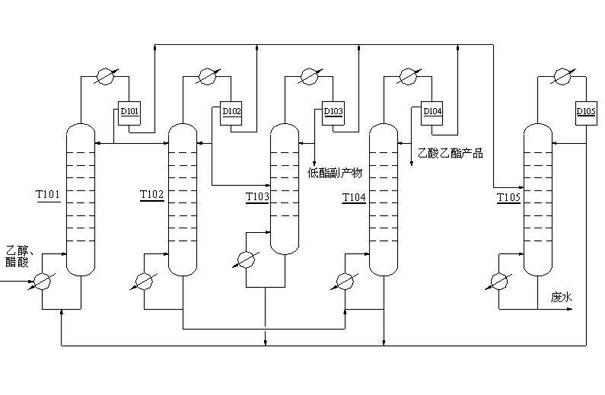

[0033] Embodiment 1: (instructions attached figure 1 )

[0034] In the production process of ethyl acetate, the raw materials ethanol and acetic acid are added from the tower tank of the esterification tower, and the reaction is carried out under the catalysis of sulfuric acid circulating in the tower tank. The reaction products are ethyl acetate, water, and a small amount of low-ester and unreacted by-products. The finished small amount of ethanol and acetic acid are distilled from the top of the tower, and after condensation, they are stratified in the reflux tank of the esterification tower. The water phase is extracted and processed in the waste water recovery tower. Thin tower.

[0035] The oil phase material extracted from the top of the esterification tower is fed from the top of the enrichment tower, and after being separated by rectification, the crude ethyl acetate product from the bottom of the tower, which has removed low-ester, ethanol and most of the water, ente...

Embodiment 2

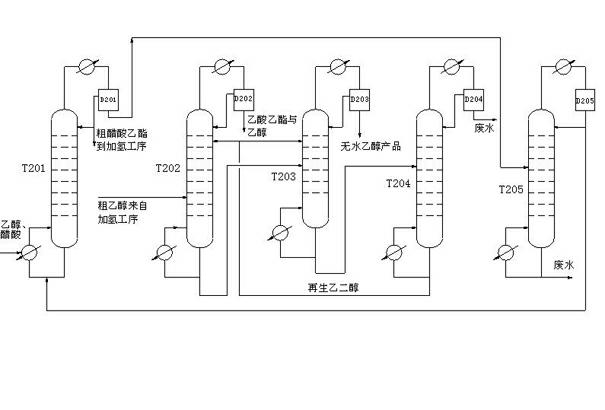

[0039] Embodiment 2: (instructions attached figure 2 )

[0040] In the production process of ethanol, the raw material ethanol and acetic acid are added from the tower tank of the esterification tower, and the reaction is carried out under the catalysis of sulfuric acid circulating in the tower tank. The reaction products are ethyl acetate, water, a small amount of low-ester and unreacted by-products A small amount of ethanol and acetic acid are evaporated from the top of the tower, and after condensation, they are stratified in the reflux tank of the esterification tower. The water phase is extracted and processed in the waste water recovery tower. The oil phase is partially refluxed to the top of the esterification tower, and ethyl acetate is partially extracted. In the gasification tower of the hydrogenation section, the oil phase produced is a crude product of ethyl acetate, of which the content of ethyl acetate is 90.0%-92.0% (mass percentage).

[0041]The oil phase mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com