Ammonia gas absorption device for tert-butyl alcohol reduced pressure recovery tower and ammonia gas absorption method

A technology of decompression recovery tower and absorption device, applied in separation methods, chemical instruments and methods, climate sustainability, etc., can solve environmental pollution, reduce rectification process, waste of ammonia gas raw materials, etc., to reduce pollution, The effect of meeting separation requirements and reducing investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings. The following description is only for those skilled in the art to better understand the present invention, but does not limit the present invention in any way.

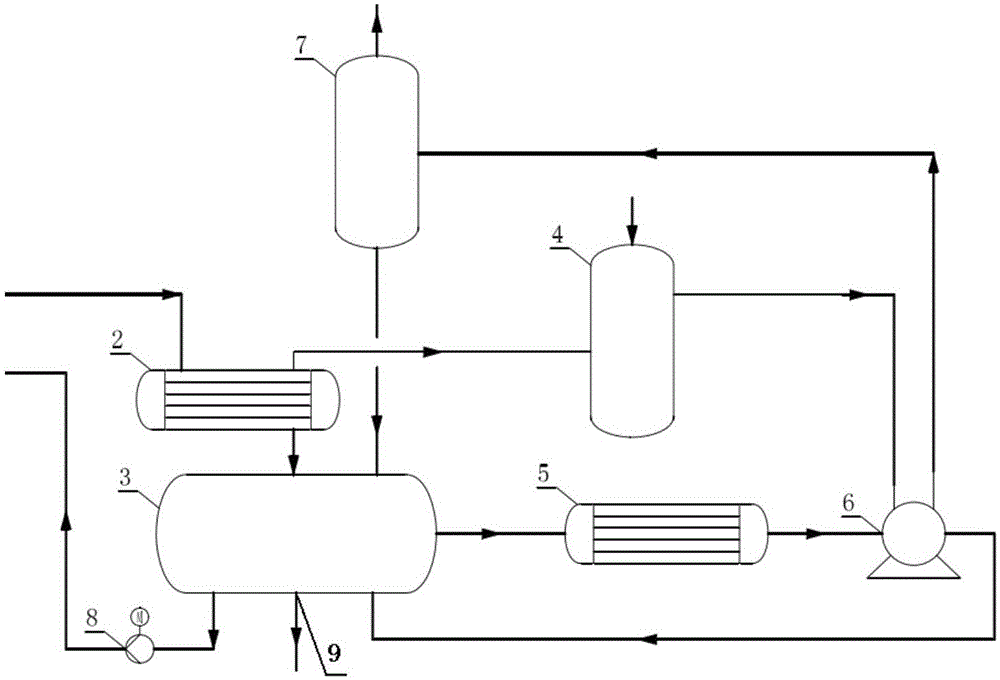

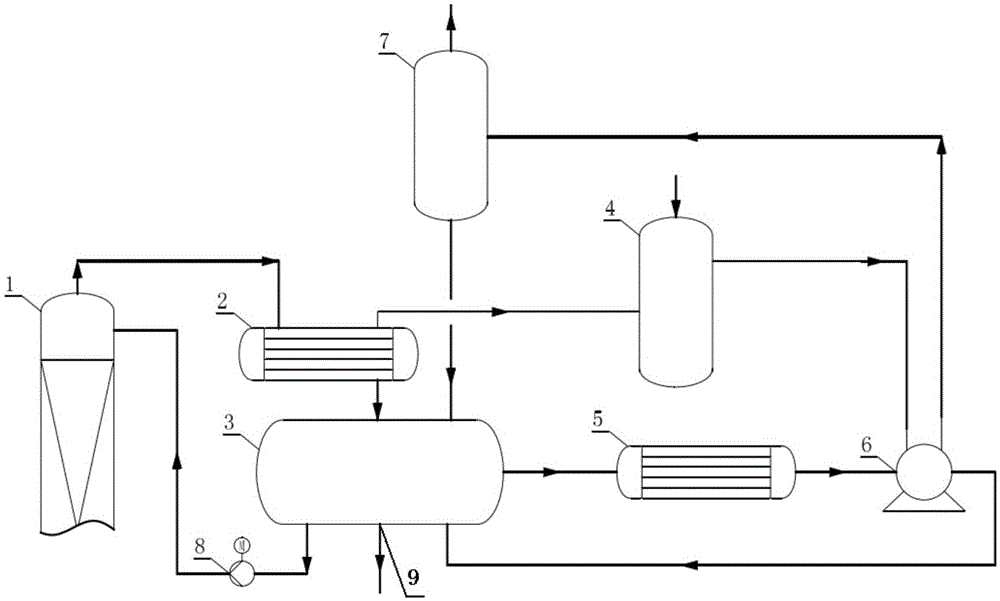

[0020] A kind of ammonia absorption device of tert-butanol decompression recovery tower (see figure 1 ), comprising primary cooler 2, storage tank 3, vacuum surge tank 4, cryocooler 5, liquid ring vacuum pump 6, gas-liquid separator 7 and reflux pump 8, the pipeline connected to the top of the tert-butanol decompression tower and The primary cooler 2, the storage tank 3, and the reflux pump 8 are connected to the return pipe of the tert-butanol decompression tower; the non-condensable gas outlet of the primary cooler 2 is connected with the vacuum buffer tank 4, the liquid ring vacuum pump 6, the gas-liquid After the separator 7 is connected, it is connected to the storage tank 3; the storage tank 3 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com