Iron scrap and aluminum scrap separating and conveying device

A conveying device, iron-aluminum technology, used in magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problems of incomplete separation and different particle sizes of iron and aluminum scraps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

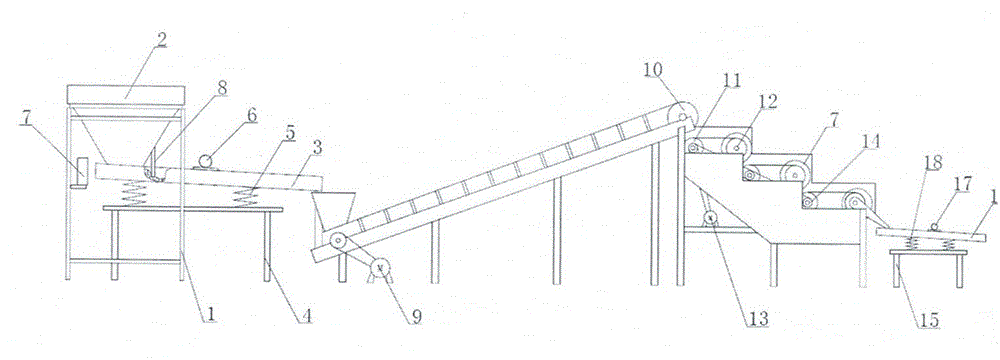

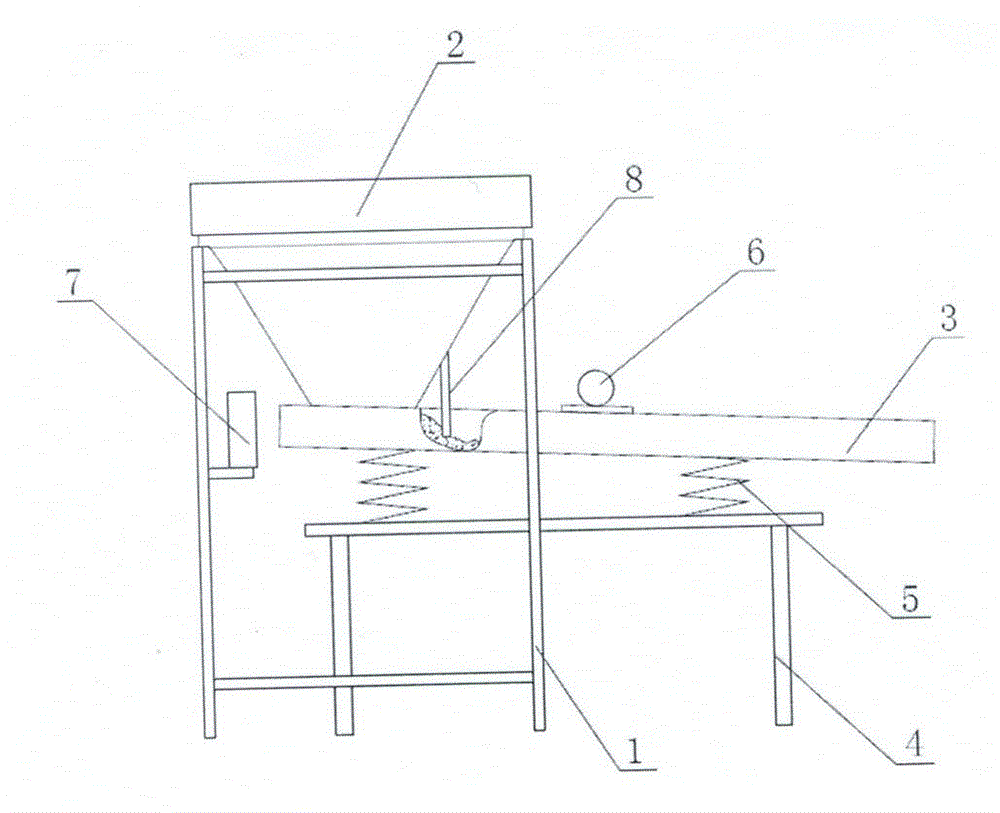

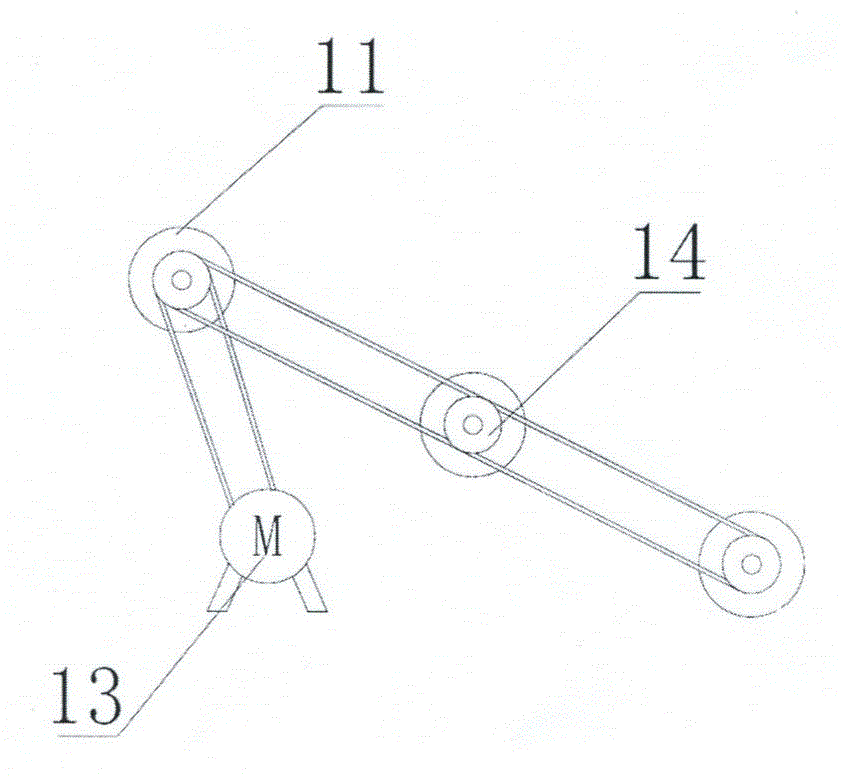

[0020] see Figure 1 ~ Figure 4 , a conveying device for separating iron and aluminum scraps according to the present invention, including a vibration separation mechanism, a lifting mechanism and a multi-stage separation mechanism, the vibration separation mechanism includes a frame 1, and a storage bucket 2 for iron and aluminum scraps fixed on the frame 1 1. A vibrating frame 3 and a vibrating frame base 4 are provided on the lower side of the iron and aluminum chip storage bucket 2, a vibrating spring 5 is arranged between the vibrating frame 3 and the vibrating frame base 4, and a vibrating motor 6 is arranged on the vibrating frame 3 , a powerful magnet 7 is arranged at the upper end of the frame 1 relative to the vibrating frame 3, and the lifting mechanism includes a transmission roller 10, a conveyor belt 1 and a liftin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com