Transformer coil lifting beam

A technology of transformer coils and hanging beams, which is applied in the direction of load hanging components, transportation and packaging, etc. It can solve the problems of insufficient storage space, cost waste, and non-universal use of special iron pressure rings, so as to enhance versatility, reduce costs, and avoid The effect of partial discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

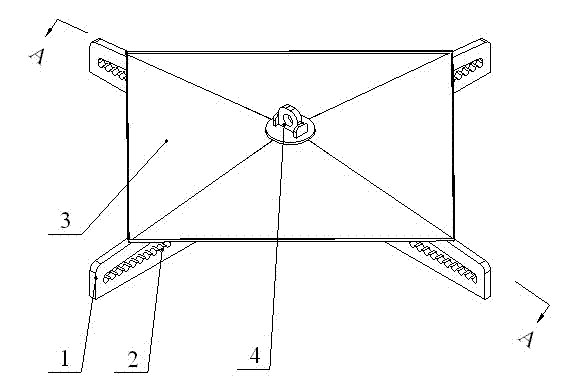

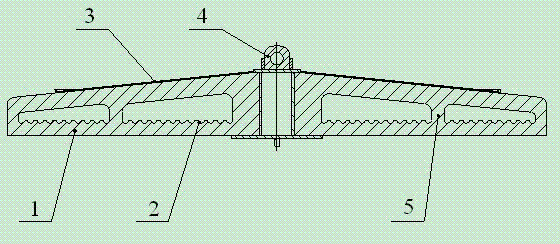

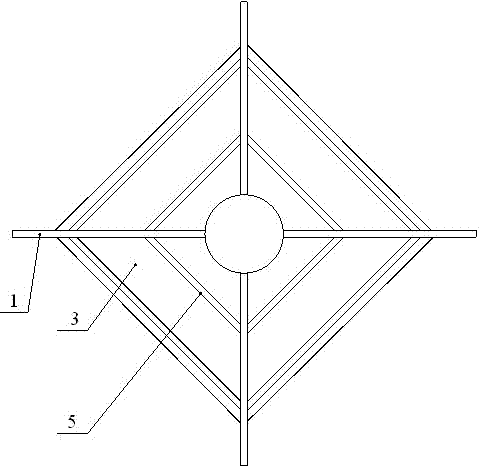

[0016] As shown in the figure, this embodiment includes four booms 1 perpendicular to each other, and the inner ends of the booms 1 are connected to each other. The middle parts of two adjacent booms 1 are connected to each other through a strengthening mechanism 5 . Each boom 1, strengthening mechanism 5 and hanging climb 4 can also adopt an integral structure. Each boom 1 is provided with two holes along its length, and the two holes are bounded by the strengthening mechanism 5 . The bottom edge of each hole is provided with a group of positioning grooves 2 along the length direction of the boom 1, so that the bottom edge forms a similar sawtooth shape.

[0017] A top cover 3 is arranged above the four booms 1 , and a suspension climber 4 is located above the top cover 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com