Capacitance-resistance module and voltage divider including capacitance-resistance module

A voltage divider and resistance-capacitance technology, applied in the direction of voltage divider, etc., can solve the problem of high machining accuracy of resistance elements and capacitance elements, and achieve the effect of reducing the requirements of machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

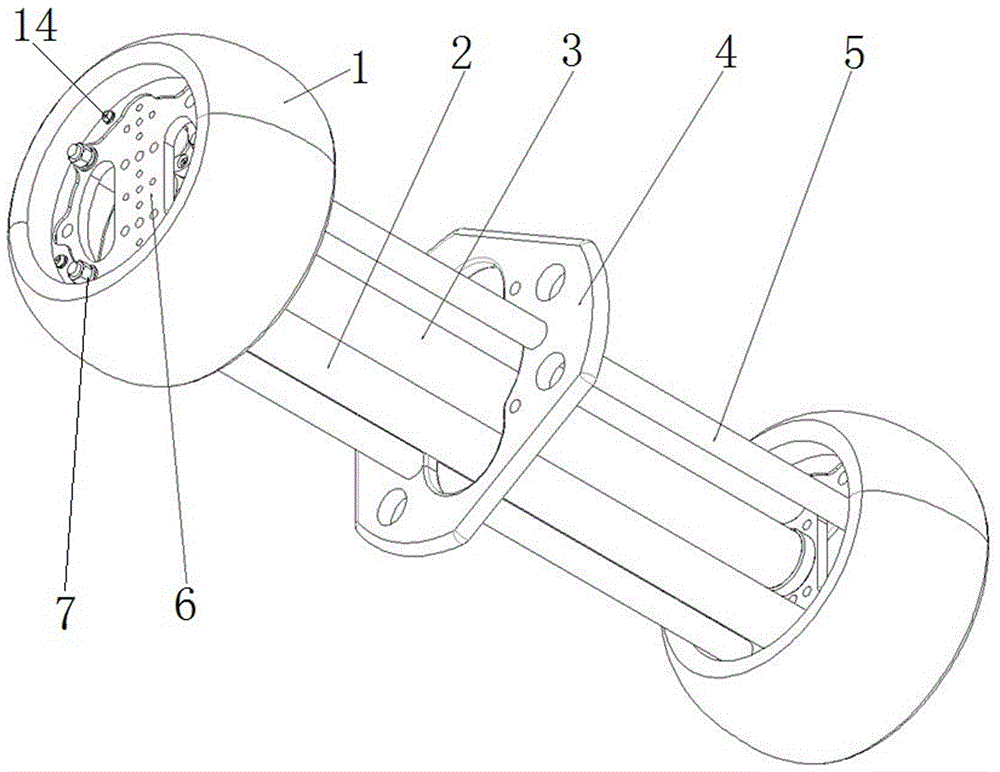

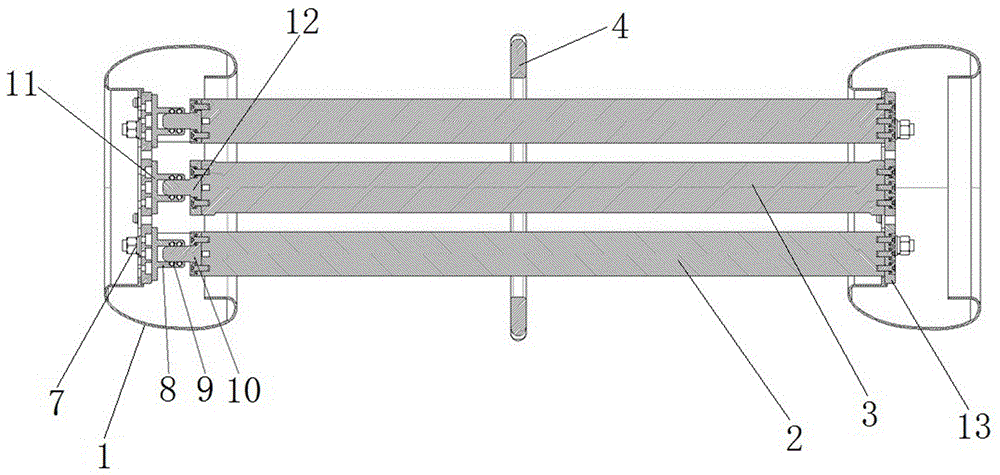

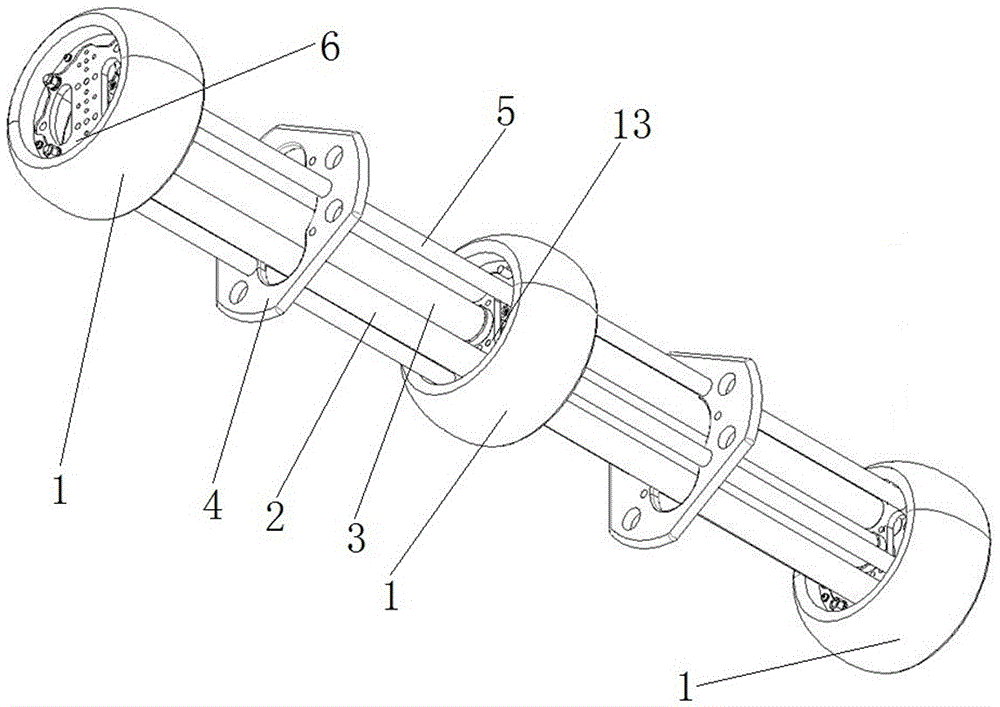

[0023] Specific embodiments of the resistance-capacitance module of the present invention, such as Figure 1 to Figure 3 As shown, 1 is the voltage equalizing ring, 2 is the resistance element, 3 is the capacitance element, 4 is the support plate, 5 is the insulating support rod, 6 is the first mounting plate, 7 is the nut, and 8 is the first spring finger fixing 9 is the spring contact finger, 10 is the first spring contact finger matching part, 11 is the second spring contact finger fixing part, 12 is the second spring contact finger matching part, 13 is the second mounting plate, and 14 is a screw.

[0024] Figure 1 is a resistance-capacitance module structure including two conductors, including two mounting plates, that is, the first mounting plate 6 and the second mounting plate 13, and a The capacitive element 3, the two resistive elements 2 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com