Temperature measurement optical fiber adaption module and transformer with temperature measurement optical fiber adaption module

A temperature-measuring optical fiber and transformer technology, which is applied in the field of temperature-measuring optical fiber transfer modules and transformers with temperature-measuring optical fiber transfer modules, can solve the optical loss of three-section optical fiber structure, cannot be used repeatedly, and low coupling efficiency problem, achieve the effect of improving bidirectional optical coupling efficiency, improving signal strength and stability, and good sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

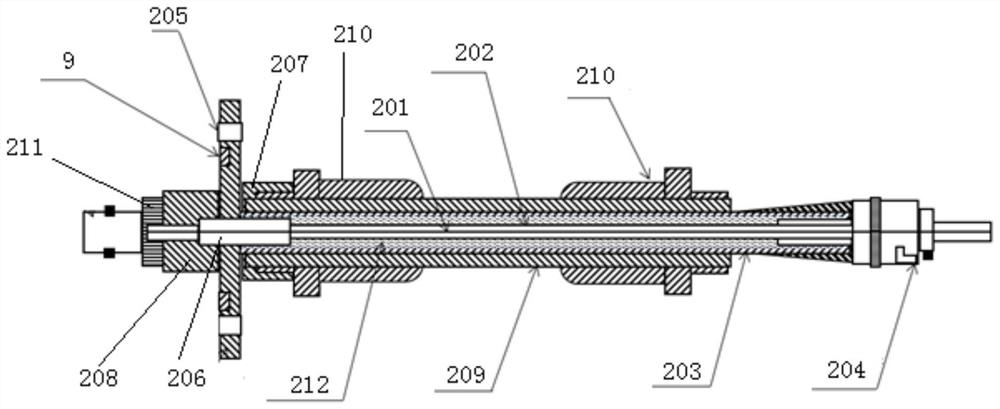

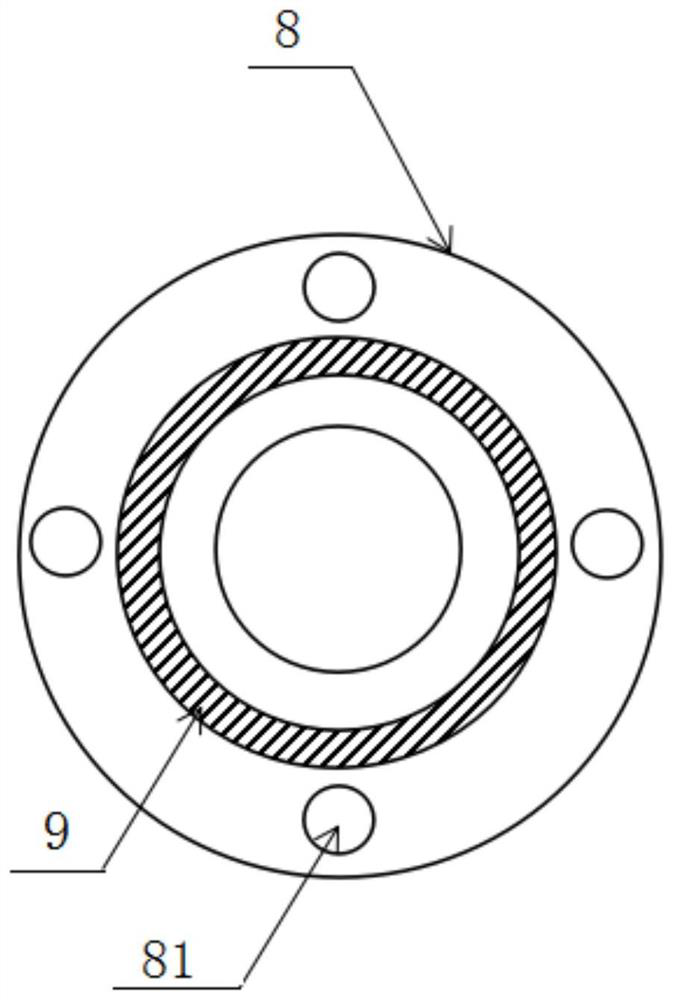

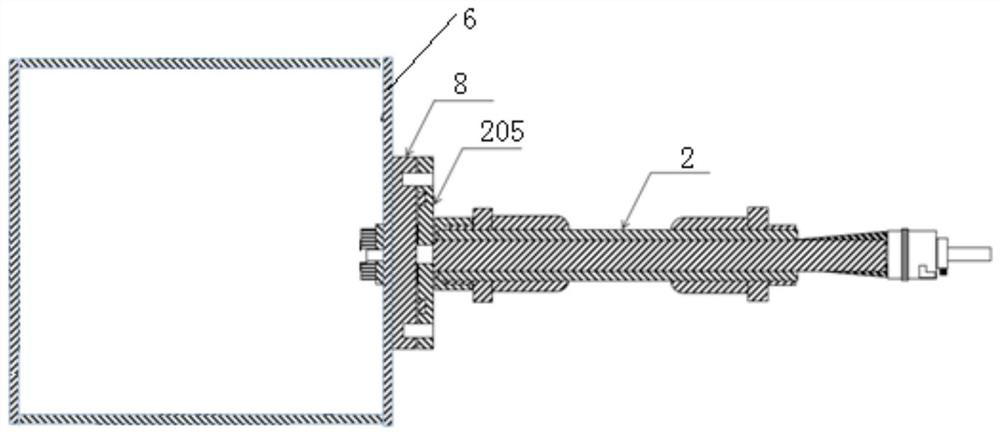

[0071] The difference from Embodiment 1 is that: Figure 4 As shown, the temperature measuring probe 1 is set in the transformer body 6; Figure 5 As shown, the temperature measuring probe 1 includes a temperature measuring optical fiber 11, a first optical fiber inner sheath 12, a first optical fiber outer sheath 13, a sheath pressure ring 14 and a first optical fiber connector 15; the first optical fiber outer sheath 13 is set on On the first optical fiber inner sheath 12, one end of the first optical fiber outer sheath 13 is set in the first optical fiber joint 15 through the sheath pressure ring 14; one end of the temperature measuring optical fiber 11 is bonded with a fluorescent material 16, and the other end passes through The first optical fiber connector 15 is docked with the adapter optical fiber 201, Figure 4 Among them, A is the docking point.

[0072] In this embodiment, the temperature-measuring optical fiber 11 is made of quartz fiber material, the detection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com