Patents

Literature

85results about How to "To achieve synchronous operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

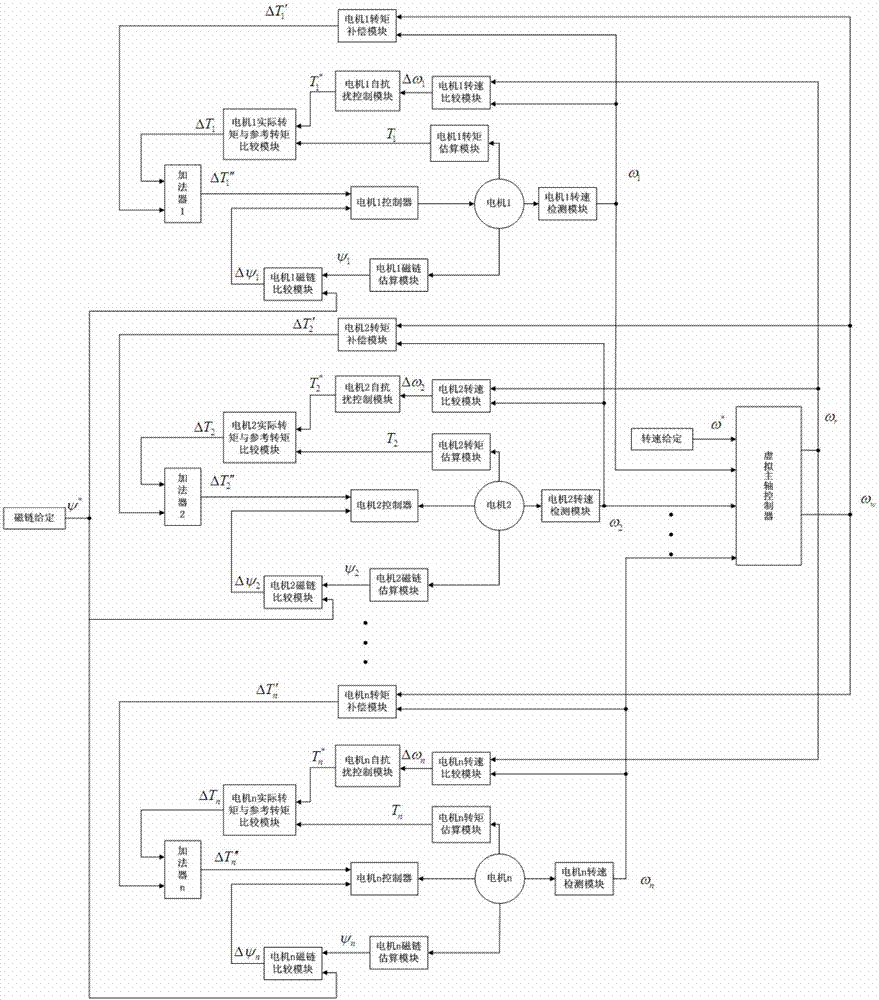

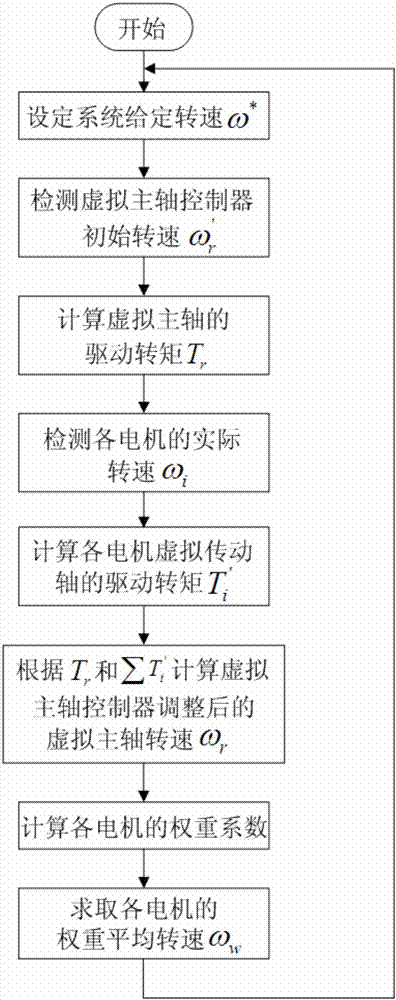

Rotational speed synchronous control device and control method of multi-switch reluctance motor

ActiveCN107070315ATo achieve synchronous operationAccurate trackingAC motor controlVector control systemsMotor speedSynchronous control

The invention discloses a rotational speed synchronous control method of a multi-switch reluctance motor. The rotational speed synchronous control method comprises the following steps of calculating a rotational speed of a virtual main shaft, taking the rotational speed as a given rotational speed of each motor; calculating weight average rotational speed of each motor, and taking the weight average rotational speed as a reference rotational speed of each motor torque compensation module; calculating a reference torque of each motor, and comparing the reference torque with an actual torque of the motor to obtain corresponding torque deviation; calculating a corresponding compensation torque of each motor, and adding the corresponding compensation torque to the torque deviation to obtain torque regulation quantity of each motor; comparing actual flux of the motor with given flux of a system to obtain flux deviation; controlling the motor according to the torque regulation quantity and the flux deviation so that accurate tracking on the given rotational speed of the system by the actual rotational speed of each motor can be achieved and the purpose of synchronous running at various motor rotational speeds is achieved. The invention also discloses a rotational speed synchronous control device of the multi-switch reluctance motor.

Owner:HUNAN UNIV OF SCI & TECH

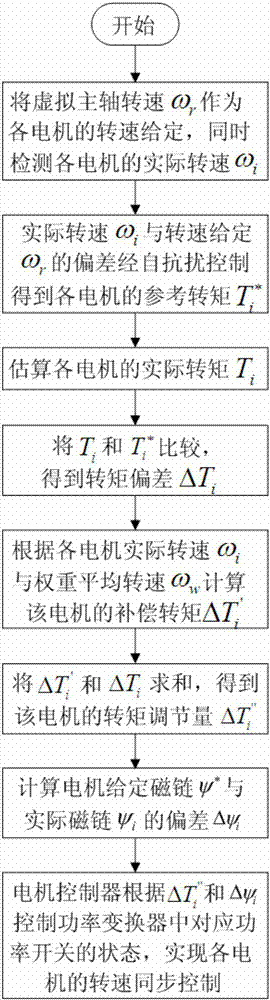

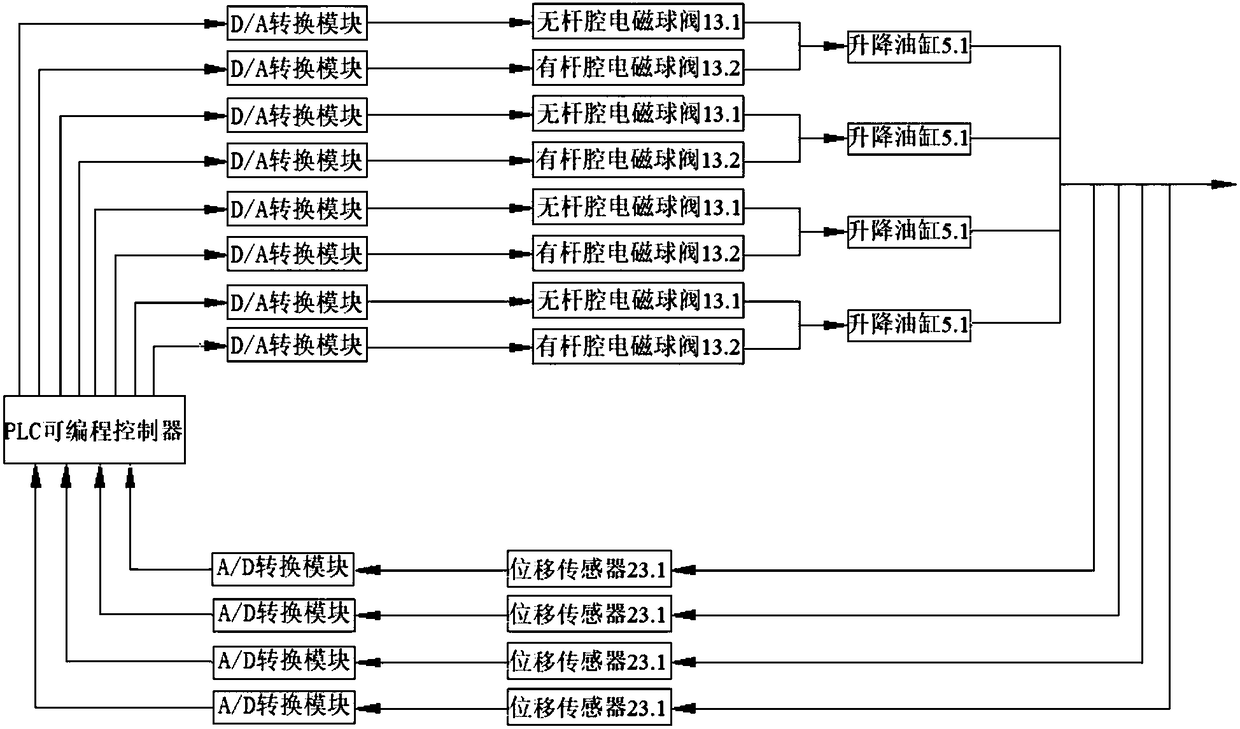

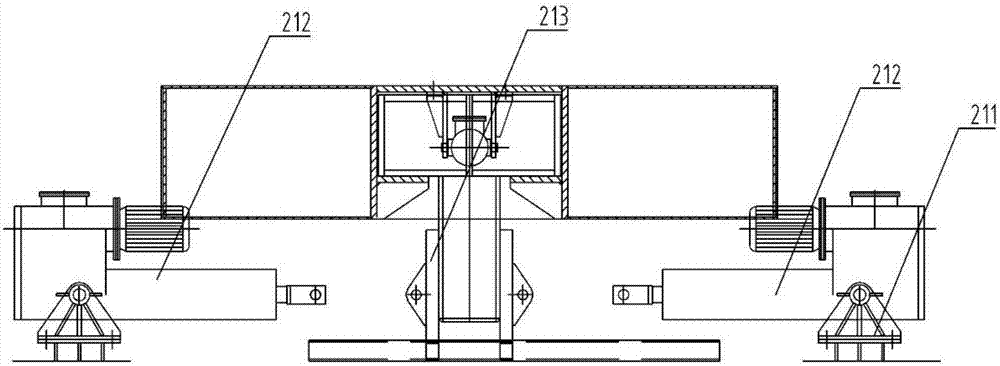

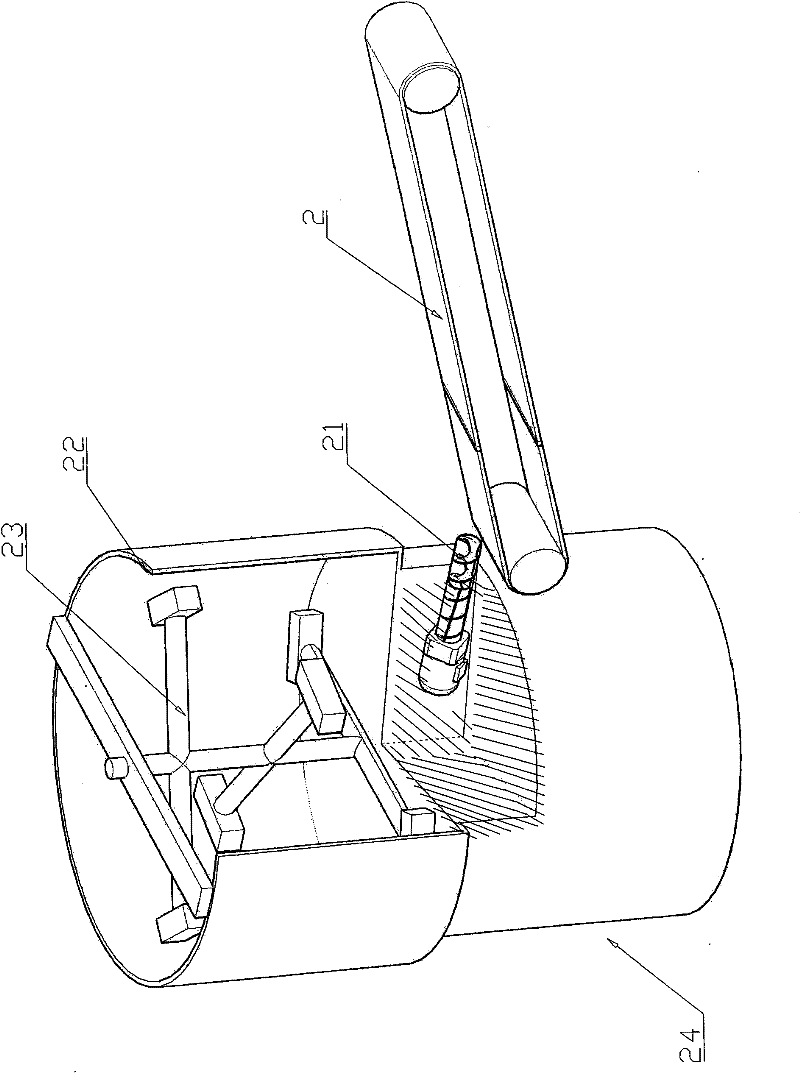

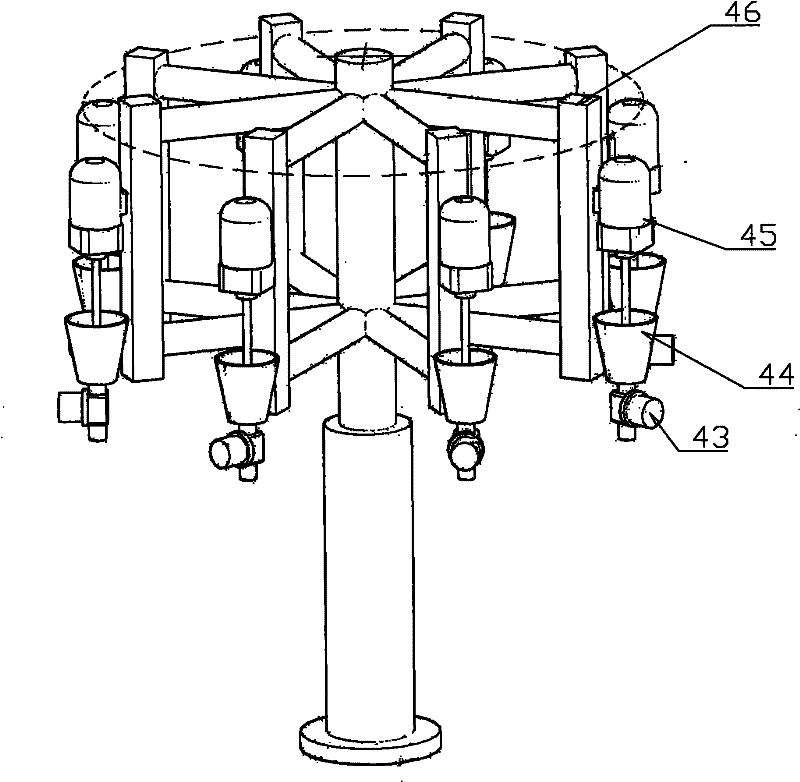

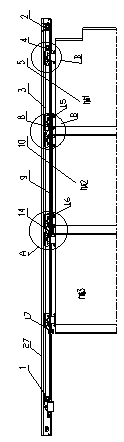

Plug type ocean lifting platform synchronous hydraulic system and control method thereof

PendingCN108194435ATo achieve synchronous operationImprove securityServomotor componentsServomotorsHydraulic cylinderControl valves

The invention discloses a plug type ocean lifting platform synchronous hydraulic system and a control method thereof. The hydraulic system comprises a first oil inlet pipeline, a second oil inlet pipeline, an oil return pipeline and an oil discharge pipeline and four oil inlet control devices for controlling corresponding lifting oil cylinders to ascend and descend; each oil inlet control device comprises a rod cavity oil inlet assembly for supplying oil to a rod cavity of the corresponding lifting oil cylinder and a rodless cavity oil inlet assembly for supplying oil to a rodless cavity of the corresponding oil cylinder; the hydraulic cylinder further comprises an upper plug control valve assembly and a lower plug control valve assembly. By adopting a parallel pipeline of rodless cavity electromagnetic ball valves and rodless cavity throttling valves of the rodless cavity oil inlet assemblies, synchronous operation of the lifting oil cylinders is achieved by detecting the stretchabledisplacement difference between the lifting oil cylinders and turning on or off the rodless cavity electromagnetic ball valves at the right moment.

Owner:DALIAN HUARUI HEAVY IND GRP CO LTD

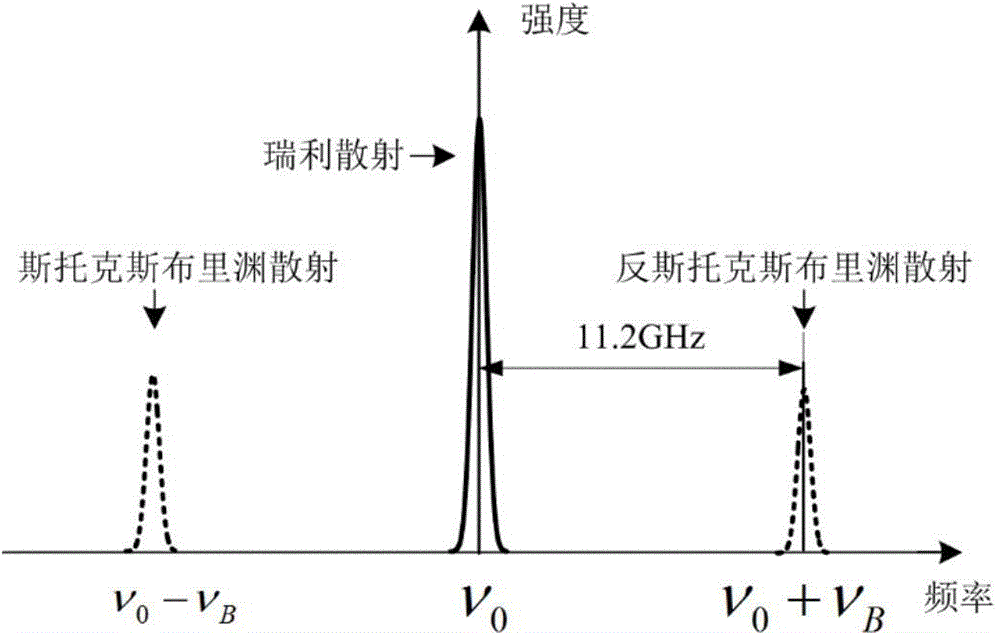

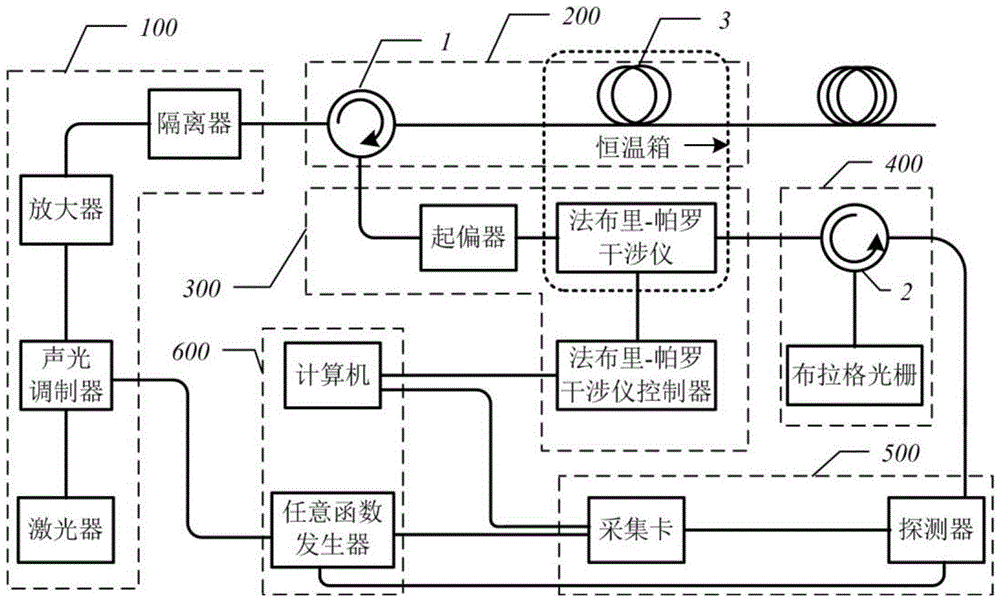

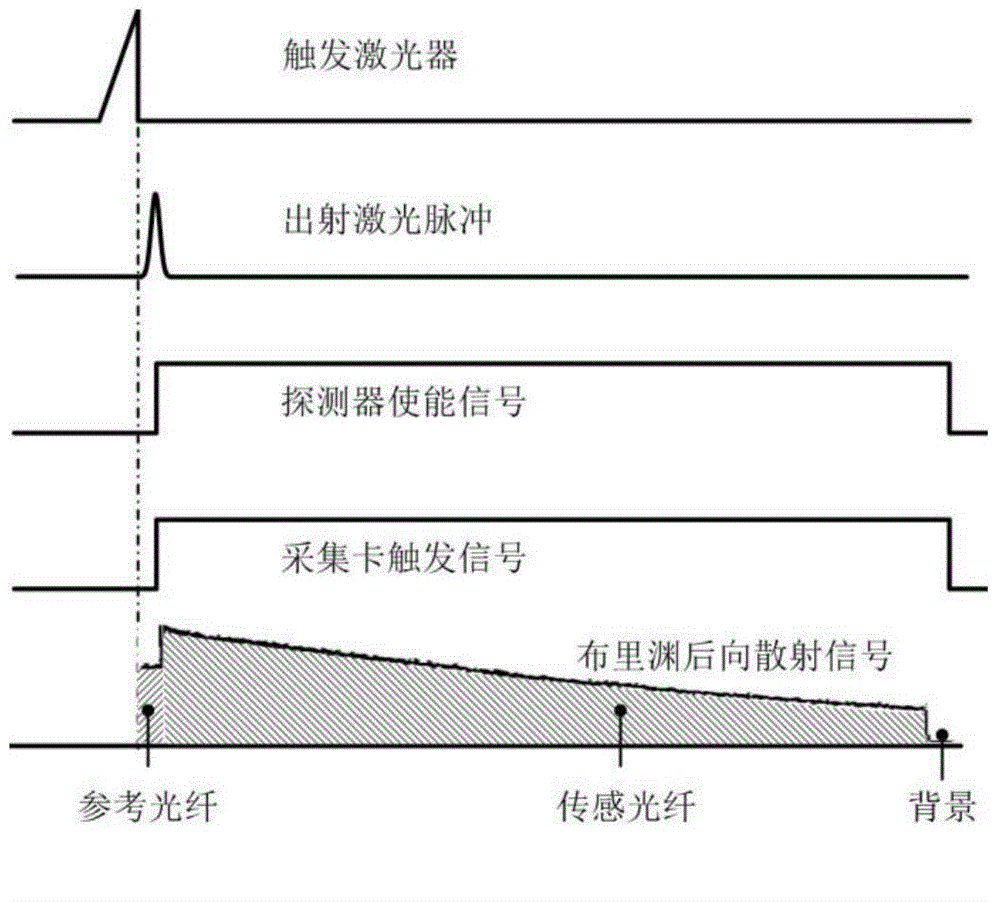

Optical fiber temperature and strain sensing device and method based on high spectral resolution technology

ActiveCN104677421AAddress cross-sensitivity issuesImprove stabilityMeasurement devicesGratingCarrier signal

The invention discloses an optical fiber temperature and strain sensing device based on a high spectral resolution technology. The optical fiber temperature and strain sensing device comprises an optical transmitting system, an optical fiber sensing system, a high spectral resolution scanning system, an optical filtering system, a data acquisition system and a control system. The invention further discloses an optical fiber temperature and strain sensing method based on a high spectral resolution technology. According to the invention, temperature and strain carriers based on optical fiber brillouin scattering are used for the distributed sensing of temperature and strain; a narrowband reflective tunable Bragg grating is used for filtering out optical fiber brillouin back scattering, a cavity length-tunable Fabry-Perot interferometer is used for the full spectrum scanning of optical fiber brillouin scattering spectrum, a single photon technology is used for detecting a back brillouin scattering signal in the optical fiber; the invention has the advantages that the structure is simple, s the stability is high, compared with coherent detection, the signal detection and processing difficulty and complexity are reduced, and the detection distance resolution and accuracy are improved.

Owner:INST OF ADVANCED TECH UNIV OF SCI & TECH OF CHINA

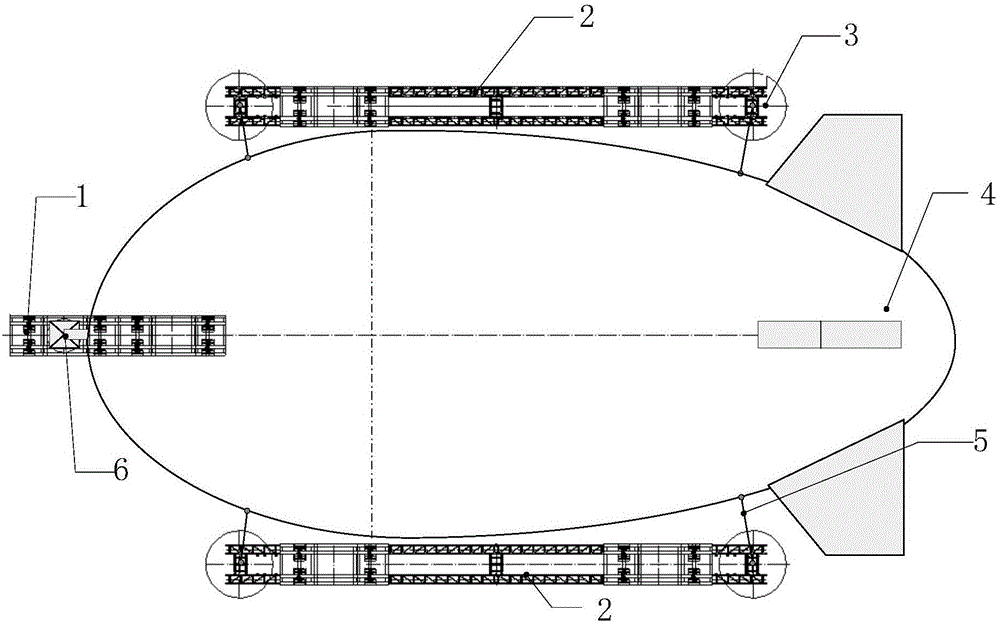

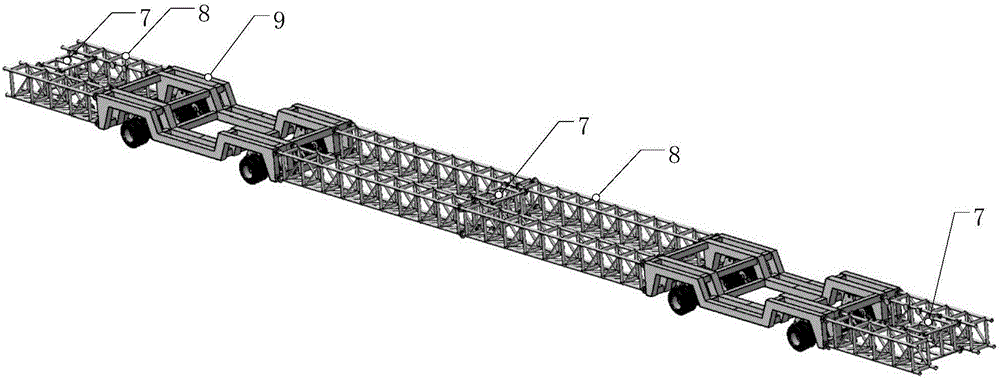

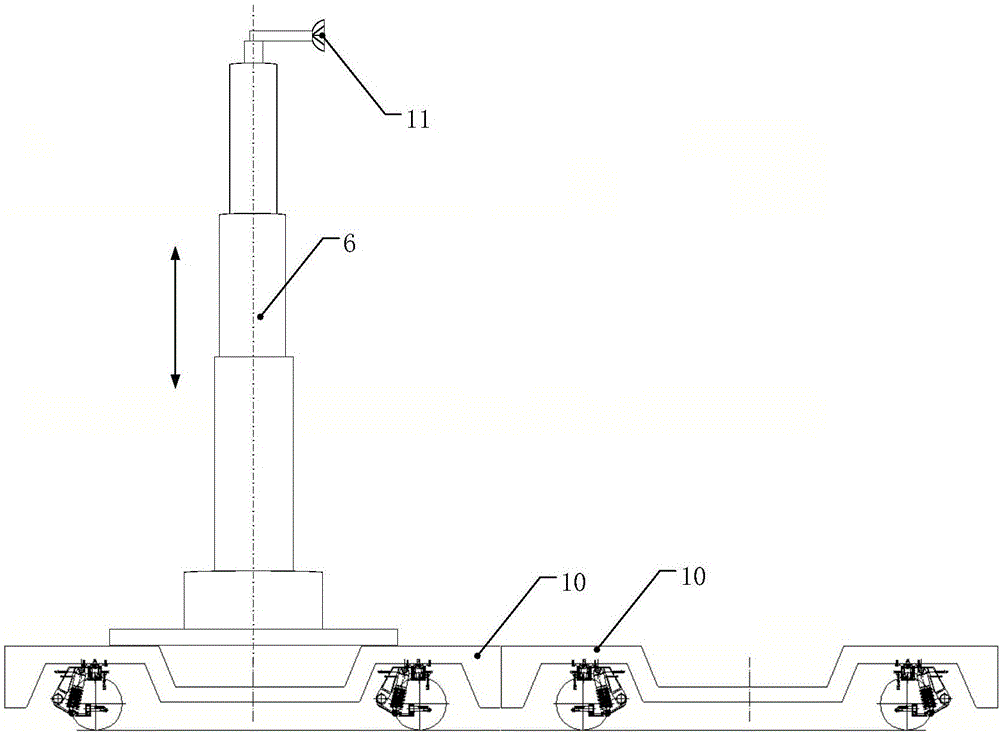

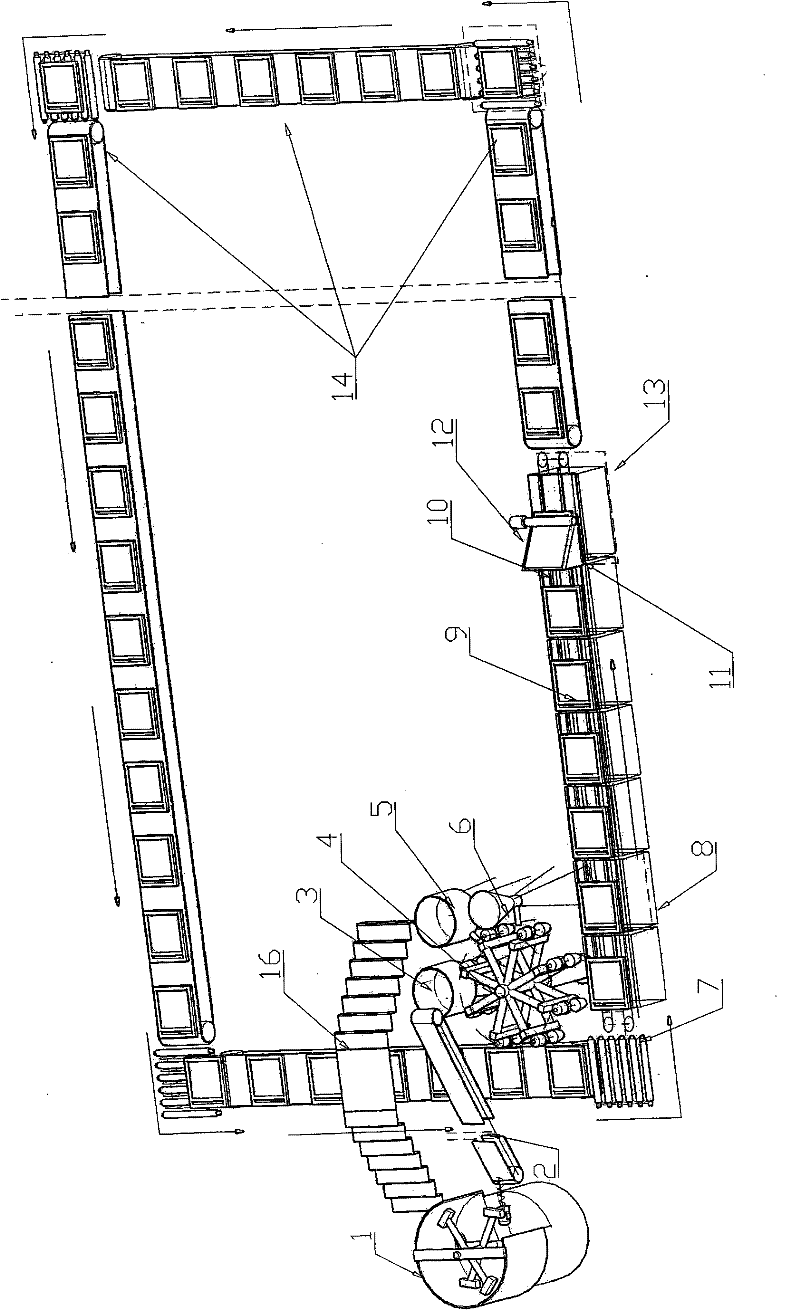

Discrete modular large airship transshipment and flying system and method

ActiveCN106275485AStrong scalabilityEasy to transportAnchoring installationsSynchronous controlWind field

The invention discloses a discrete modular large airship transshipment and flying system and method. The discrete modular large airship transshipment and flying system comprises a transshipment and flying platform and a synchronous control system. The transshipment and flying platform comprises a pulling vehicle set and two transshipment vehicle sets, and the pulling vehicle set and the two transshipment vehicle sets are independent of one another. The pulling vehicle set ties the head of an airship through pulling of a pulling tower. The two transshipment vehicle sets are arranged on the two sides of the airship correspondingly, and the two sides of the airship are fixed through mooring ropes. The pulling vehicle set and the transshipment vehicle sets are all of modular structures, and all modules can be modularly combined as needed through installation connectors. The synchronous control system controls the transshipment and flying platform to pull the airship to move and adjusts the movement direction of the transshipment and flying platform according to the change of a wind field. The discrete modular large airship transshipment and flying system and method are suitable for transshipment, mooring and flying tasks of large near space airships. The discrete modular large airship transshipment and flying system is convenient to operate, high in environment adaptability and especially suitable for transshipment and flying occasions of large airships.

Owner:NO 63655 TROOPS OF THE CHINESE PEOPLES LIBERATION ARMY

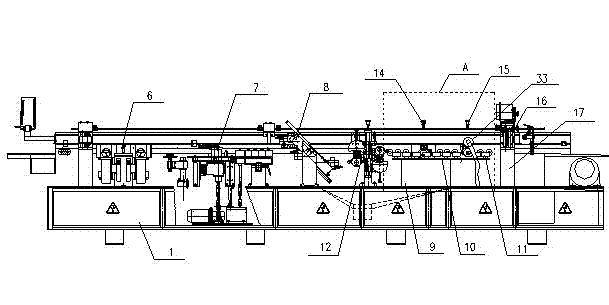

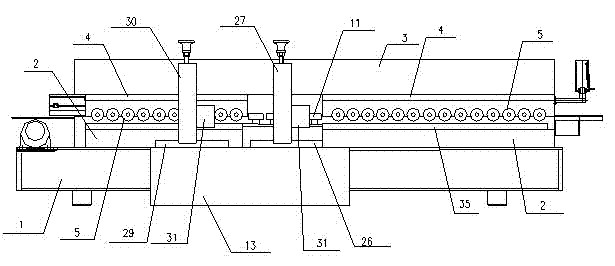

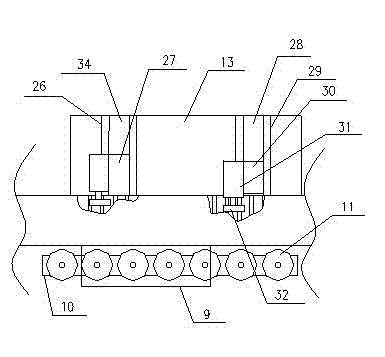

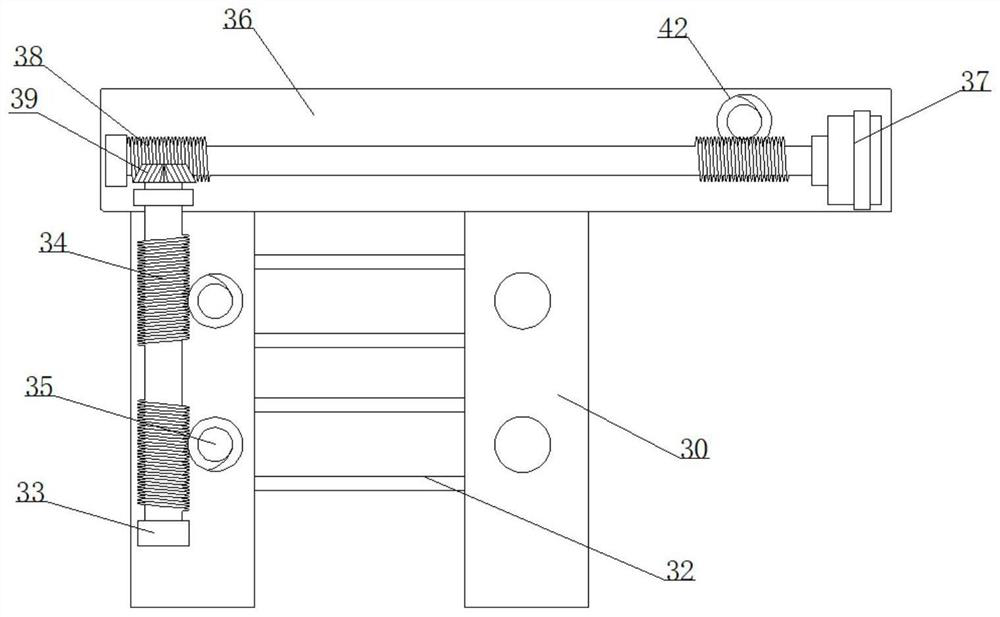

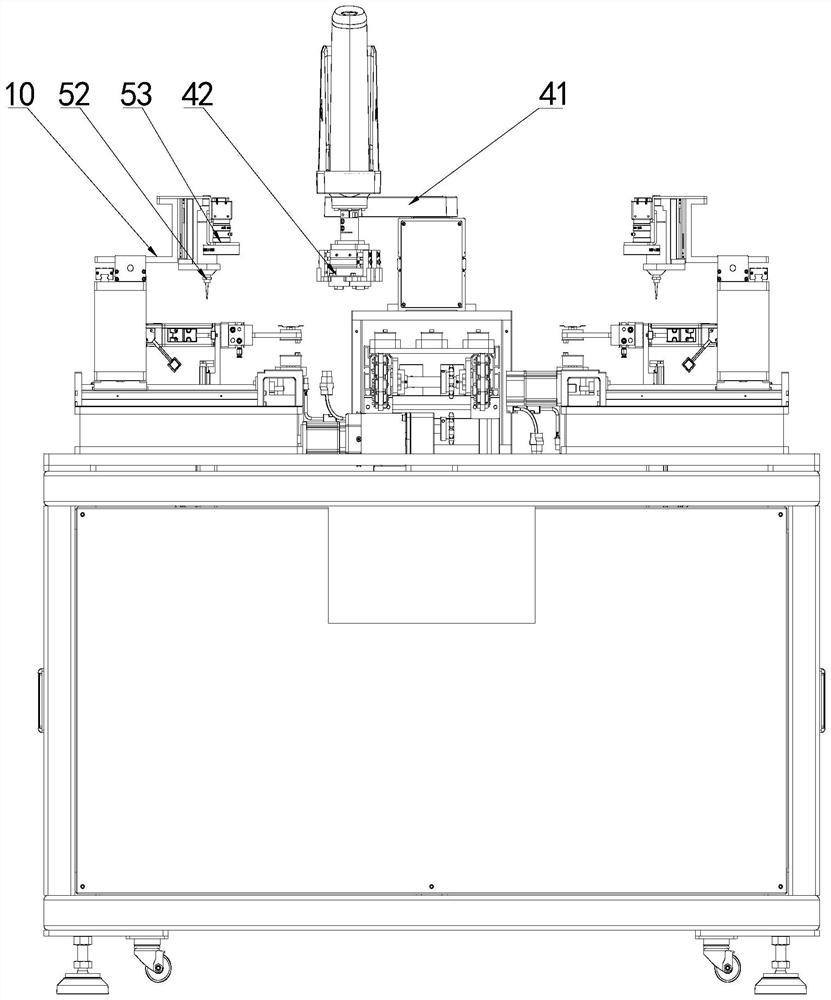

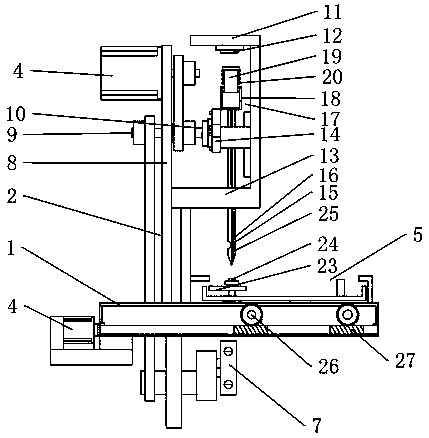

Dual-trimming door pocket edge banding machine

ActiveCN102189589AImprove work efficiencyReduce deformationMulti-purpose machinesWood mortising machinesEngineeringFuselage

The invention discloses a dual-trimming door pocket edge banding machine which comprises a machine body, wherein two first supporting platforms that are arranged left and right are connected to the upper surface of the machine body, a conveying belt group is arranged on each first supporting platform, the upper parts of the two first supporting platforms are provided with a supporting frame, the supporting frame is internally provided with two first brackets arranged left and right, a pressure wheel set is connected to each first bracket, and the two pressure wheel sets respectively correspond to one conveying belt group; the part of the machine body, which is positioned at the rear part of the supporting frame, is sequentially provided with a pre-milling device, a gluing and facing device and a belt-cutting device from left to right; the two conveying belt groups are connected through a coupling device, a fixing plate is connected to the upper surface of the coupling device, and a plurality of pulleys arranged left and right are arranged on the fixing plate; and the part of the machine body, positioned between the belt-cutting device and one end of the fixing plate, is provided with a first trimming device, the rear part of the machine body is provided with a second supporting platform for supporting a second trimming device and a slotting device. The invention has the advantages of improving working efficiency and reducing labor intensity.

Owner:江苏盐城苏凌机械有限公司

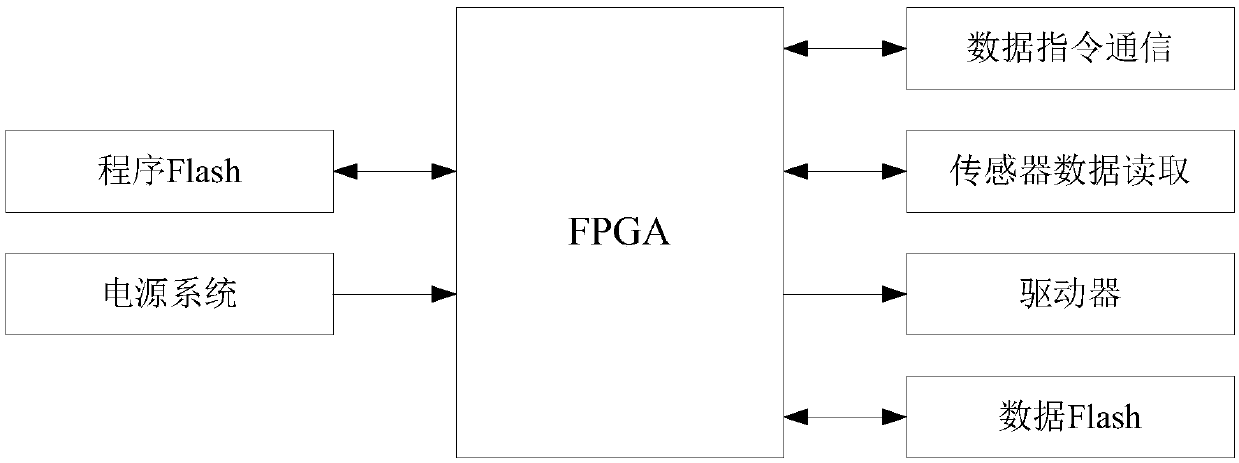

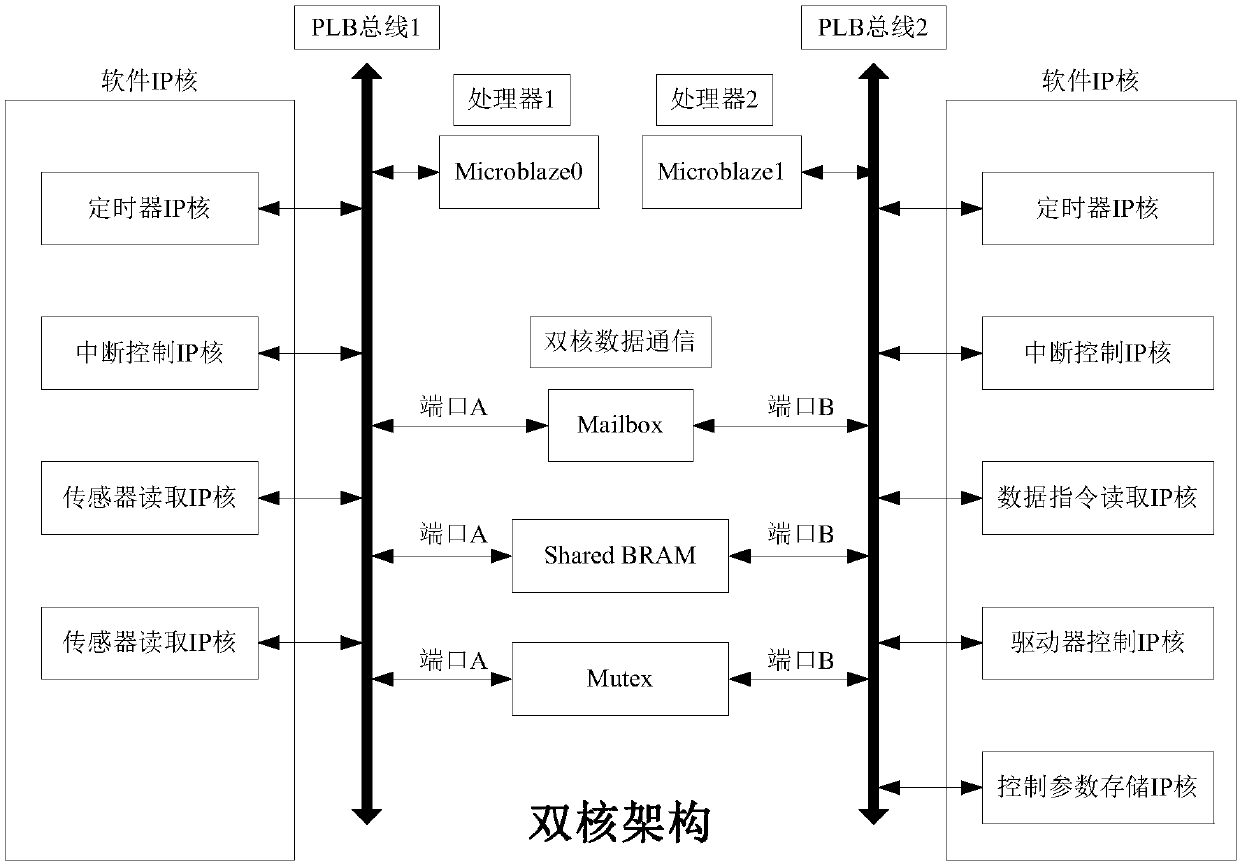

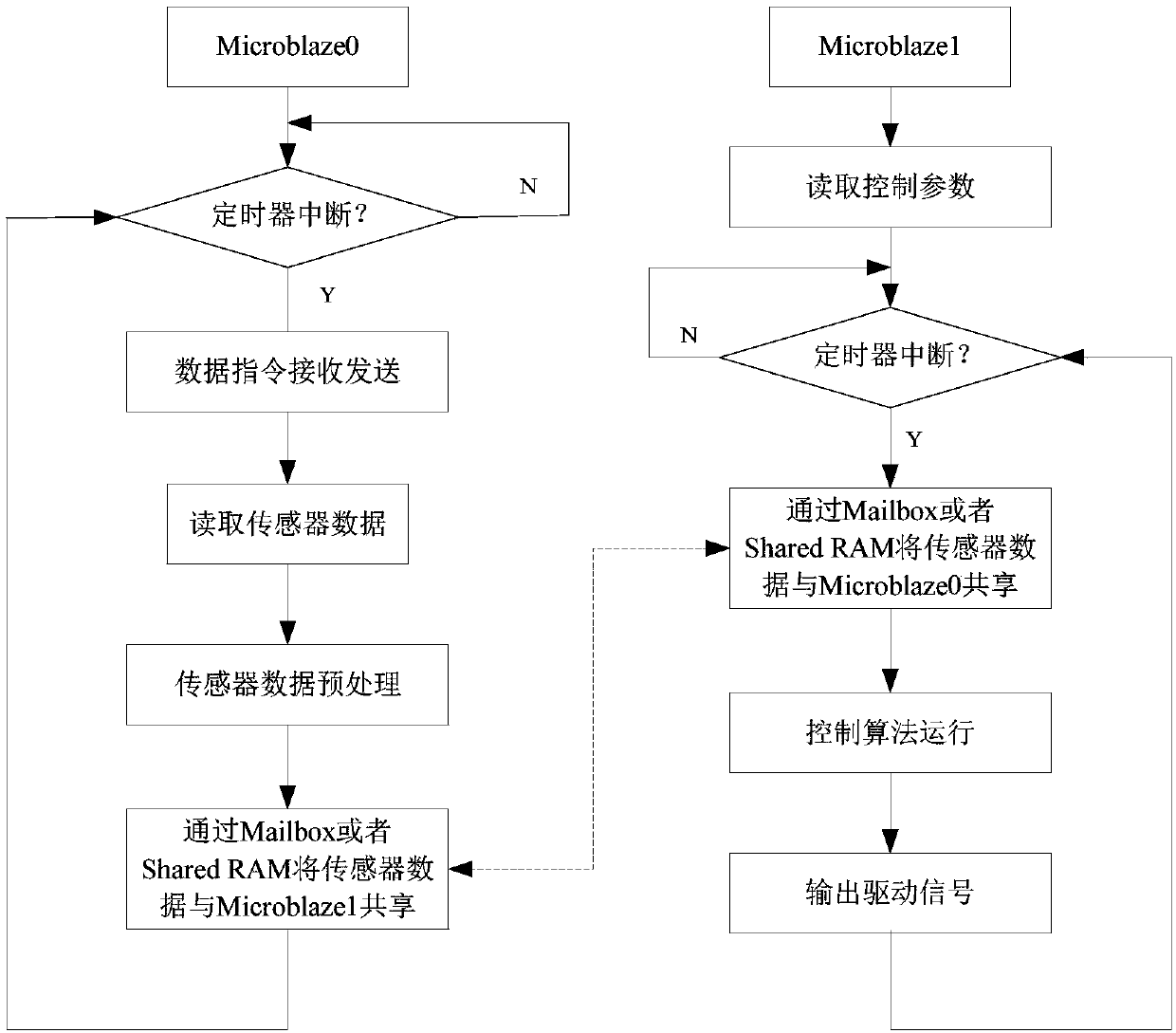

SOPC-based embedded dual-core servo controller and designed method thereof

ActiveCN107942797AImprove real-time performanceImplement cost designProgramme controlComputer controlCommunication unitSoft core processor

The invention provides an SOPC-based embedded dual-core servo controller and a designed method thereof. The hardware architecture includes an FPGA, a power system, a program FLASH, a data FLASH, a driver, a data instruction communication unit, and a sensor data reading unit and the like, wherein the power system, the program FLASH, the data FLASH, the driver, the data instruction communication unit, and the sensor data reading unit and the like are in signal connection with the FPGA. The FPGAs is provided with two Microblaze soft-core processors to carry out dual-core parallel computing. A plurality of IP soft cores are signal connection by a PLB bus. All Microblaze soft-core processors carry out data exchange with all IP soft cores through PLB buses. The two Microblaze soft-core processors carry out dual-core data communication. According to functional requirements of the control system, the hardware architecture and interface type are determined; the software bottom architecture is determined; compiling is carried out by using an XPS tool; a top interface file is outputted; and top-level soft core controller design development is carried out at an SDK platform. Therefore, the co-processing ability of the controller is enhanced. The SOPC-based embedded dual-core servo controller has advantages of abundant resources, strong expandability, high reliability, low cost and simple design.

Owner:SHANGHAI RADIO EQUIP RES INST

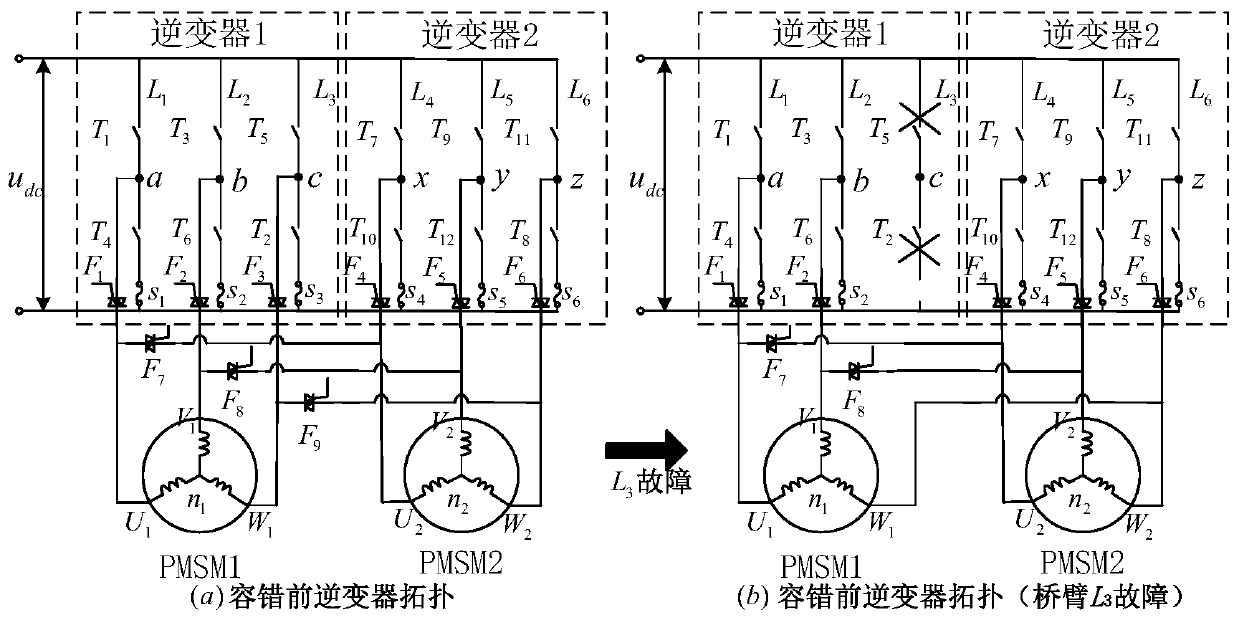

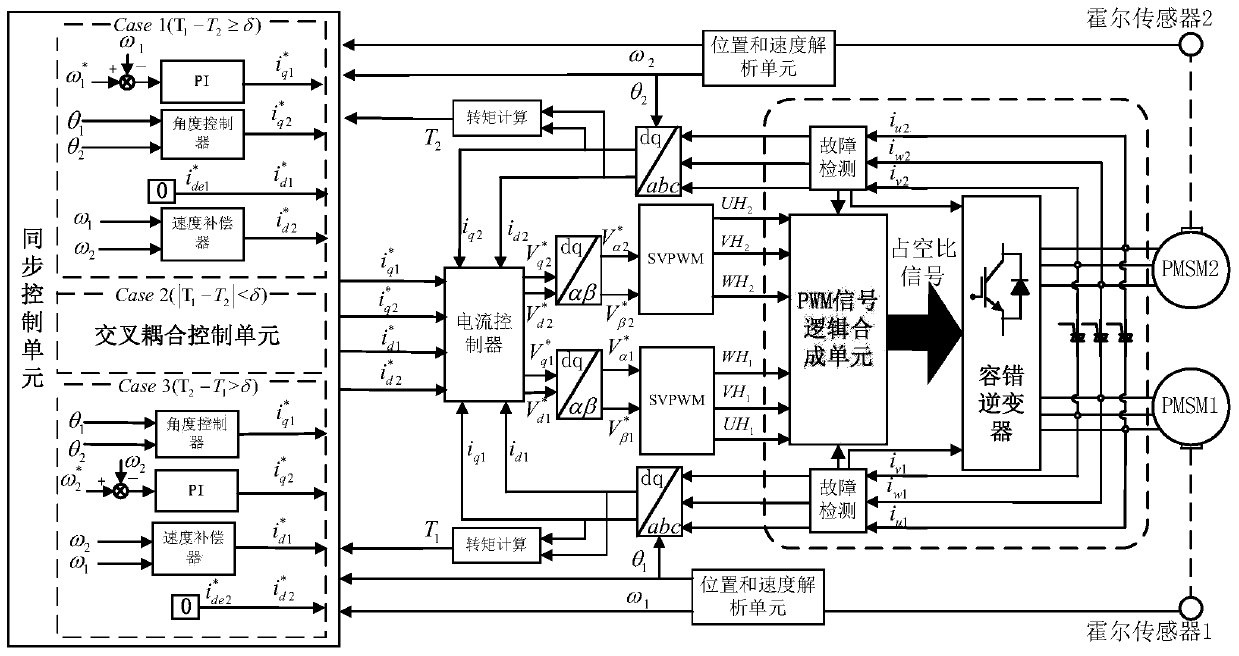

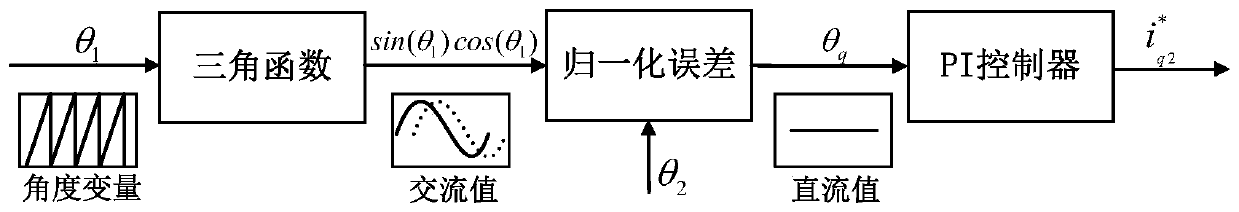

Fault-tolerant control method of dual-motor synchronous control system

ActiveCN111211711AImplement fault toleranceImprove reliabilityElectric motor controlVector control systemsPhase currentsReference current

The invention discloses a fault-tolerant control method of a dual-motor synchronous control system. A feedback rotating speed and a rotor position are input into a synchronous control unit, three-phase currents of double motors are converted through Park and Clark to obtain respective feedback quadrature-direct axis currents, corresponding torques are input into the synchronous control unit to becompared, and a corresponding angle and speed compensation strategies are determined; a quadrature-axis reference current and a direct-axis reference current are compared with the feedback quadrature-direct axis current of the double motors, and respective quadrature-direct axis reference voltages are calculated; Park inverse transformation is performed on the quadrature-direct axis reference voltage of the double motors to obtain two voltage components under a static coordinate system, and three duty ratio signals are obtained; and a fault bridge arm of the inverter is judged by detecting a three-phase current of the double motors, fault signals are sent to a fault-tolerant inverter and a PWM signal logic synthesis unit to complete reconstruction of a fault-tolerant topology and implementation of a fault-tolerant algorithm, and finally fault-tolerant control of the double permanent magnet synchronous motors is achieved. System reliability is high.

Owner:CHECC DATA CO LTD +1

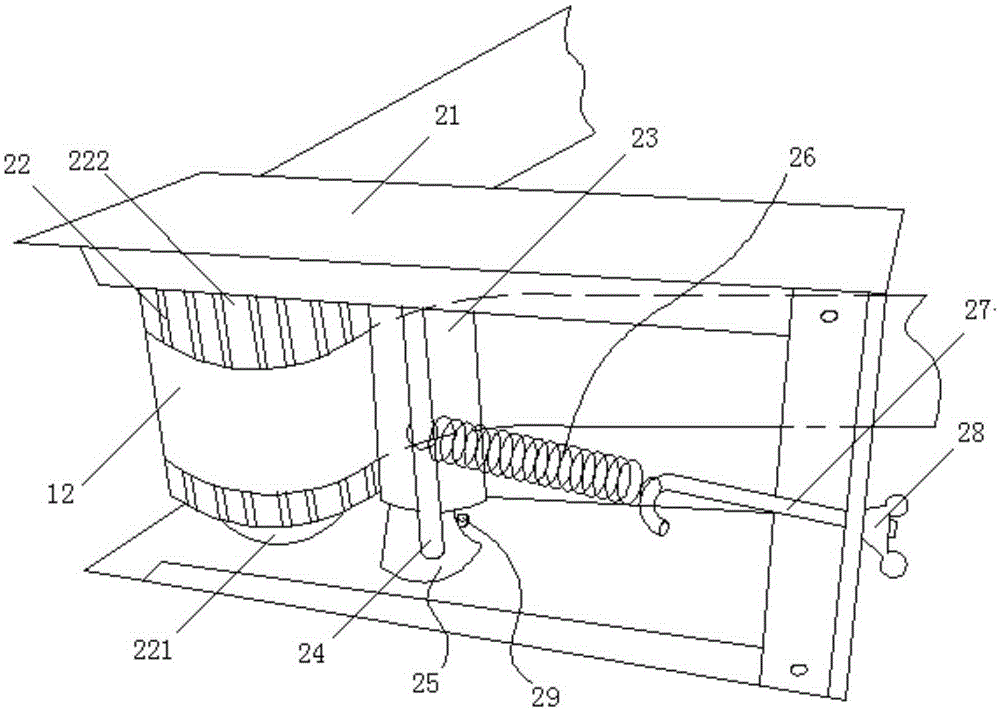

Continuous textile printing and dyeing device and textile printing and dyeing machine

InactiveCN112695477AReasonable structureTo achieve synchronous operationTextile treatment machine arrangementsTextile treatment carriersTextile printerMechanical engineering

The embodiment of the invention discloses a continuous textile printing and dyeing device and a textile printing and dyeing machine. The continuous textile printing and dyeing device comprises a base; a winding part is arranged on the base; the winding part comprises two first supporting plates, a winding motor, a winding rotating shaft, a rotating rod, two limiting pieces, two clamping blocks, a winding barrel, two second supporting plates, a driving shaft, a driving rotating roller, two cross grooves, two moving blocks, a driven rotating roller and two compression springs; and a drying part is arranged on the base. The invention further discloses the textile printing and dyeing machine, wherein the textile printing and dyeing machine is provided with the continuous textile printing and dyeing device. The continuous textile printing and dyeing device and the textile printing and dyeing machine are reasonable in structure, continuous operation can be achieved, the production speed is increased, the drying quality can be improved in work, products can be wound conveniently, and the work efficiency is improved.

Owner:史继林

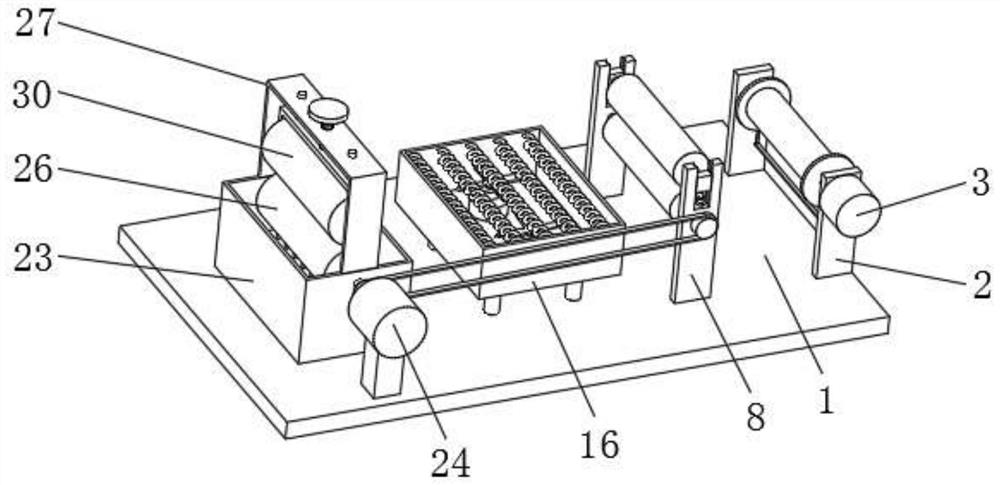

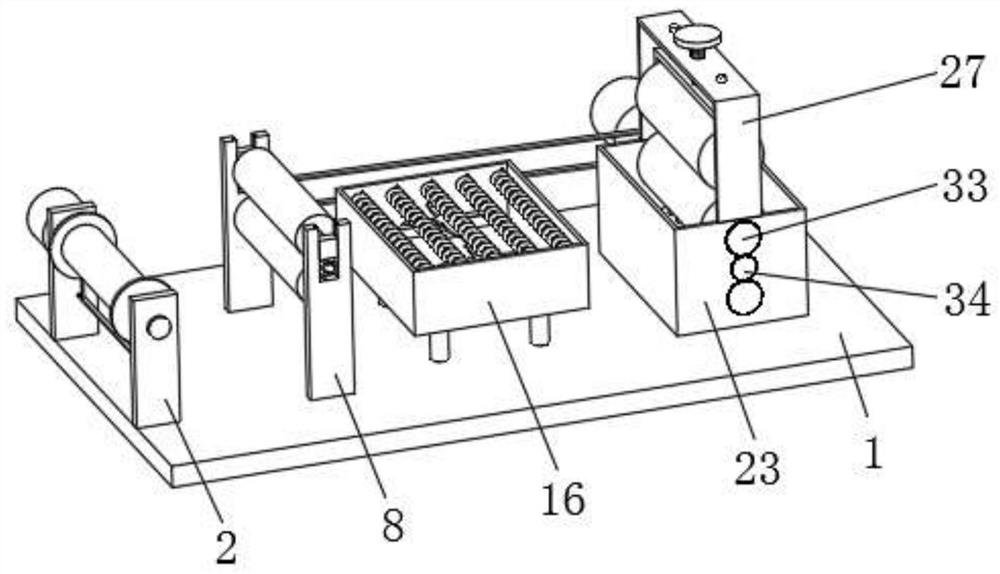

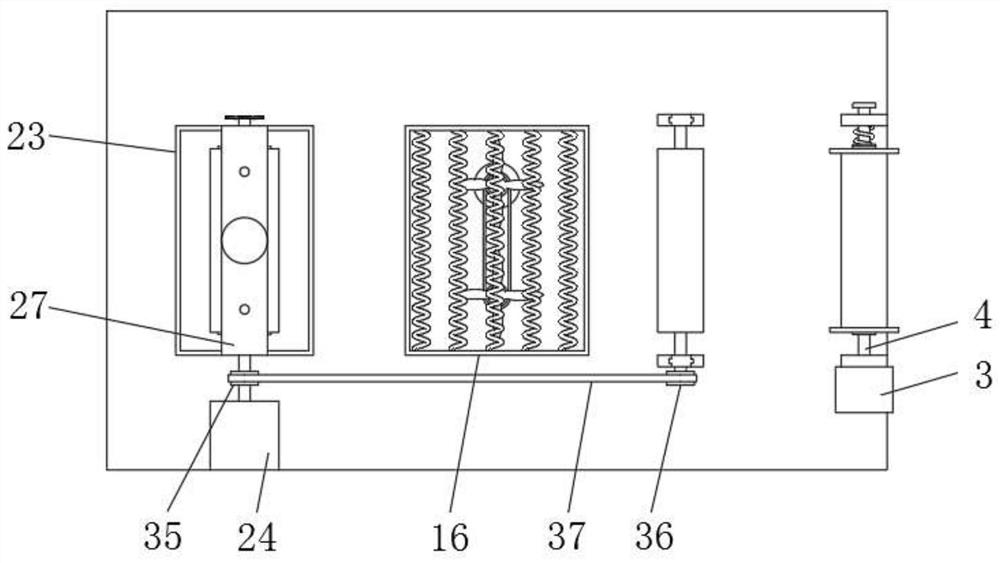

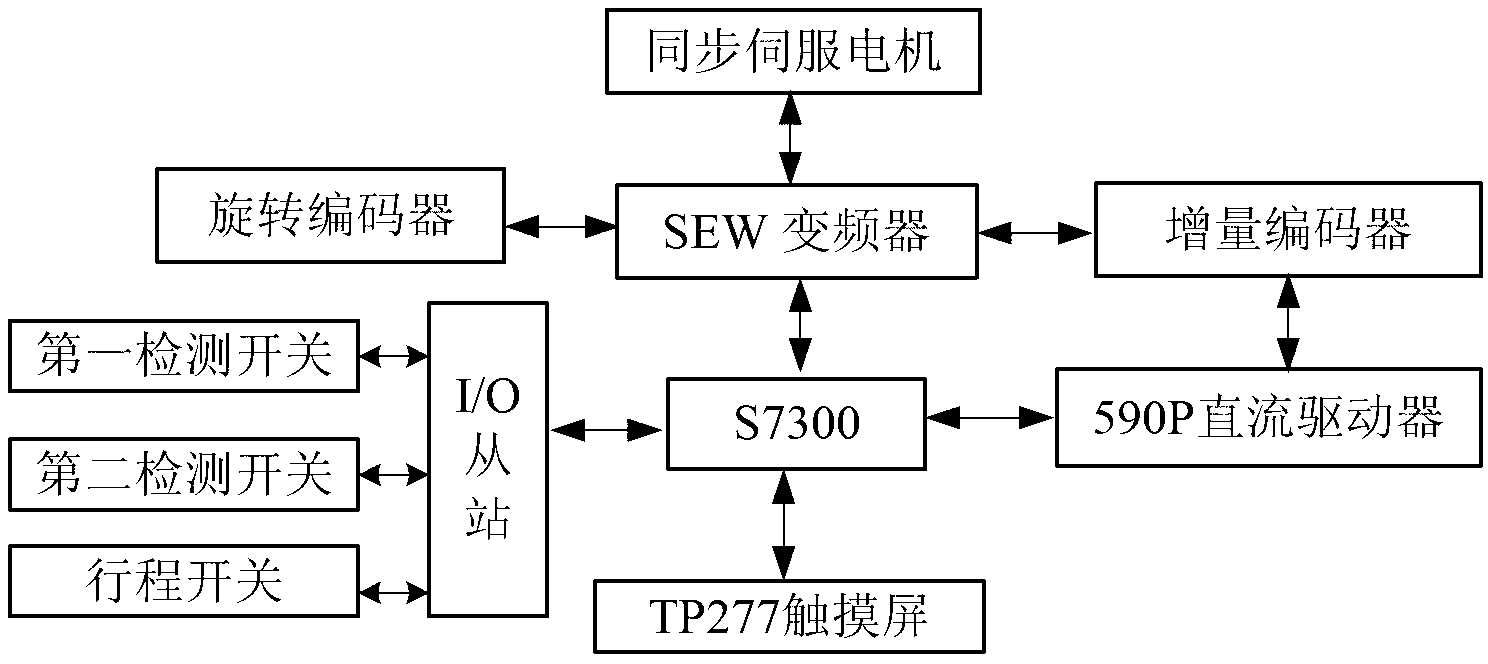

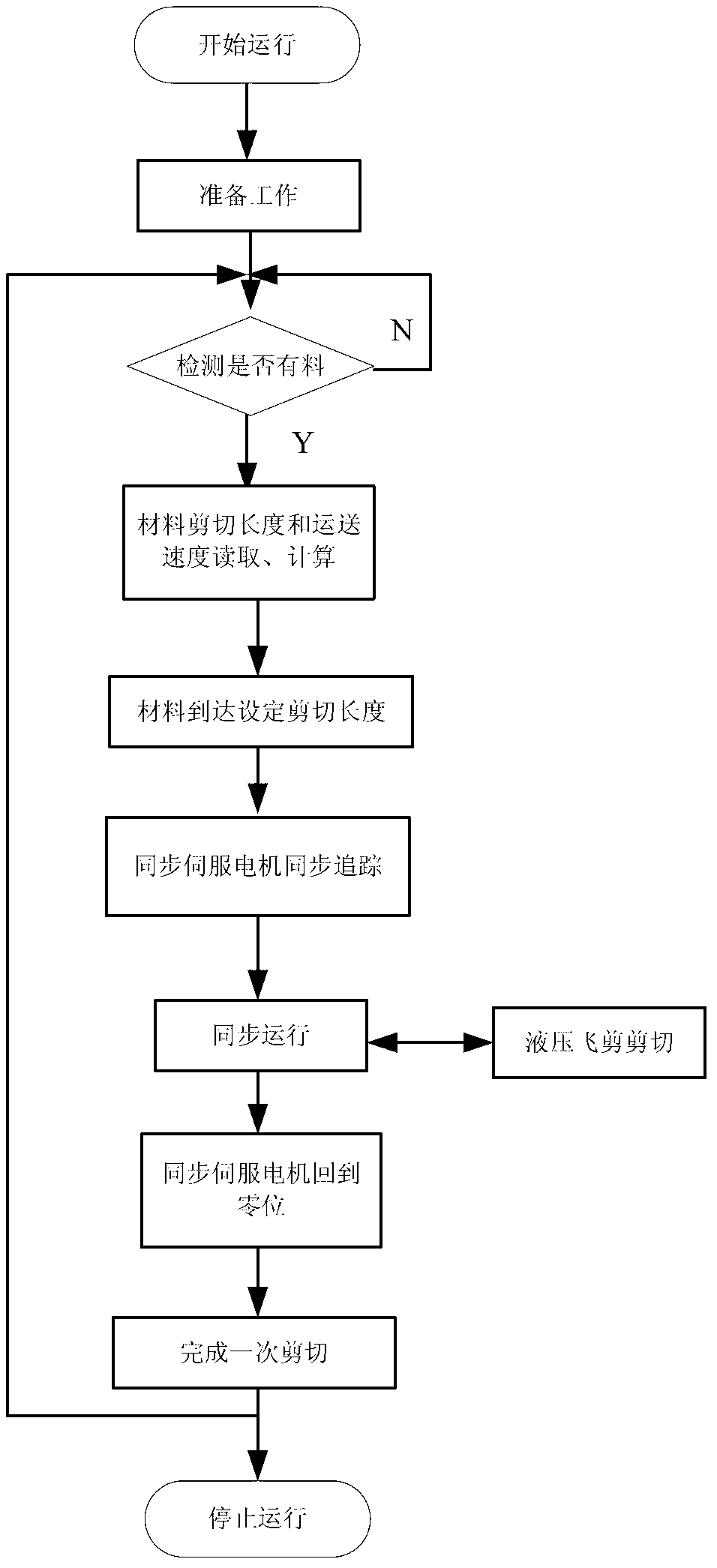

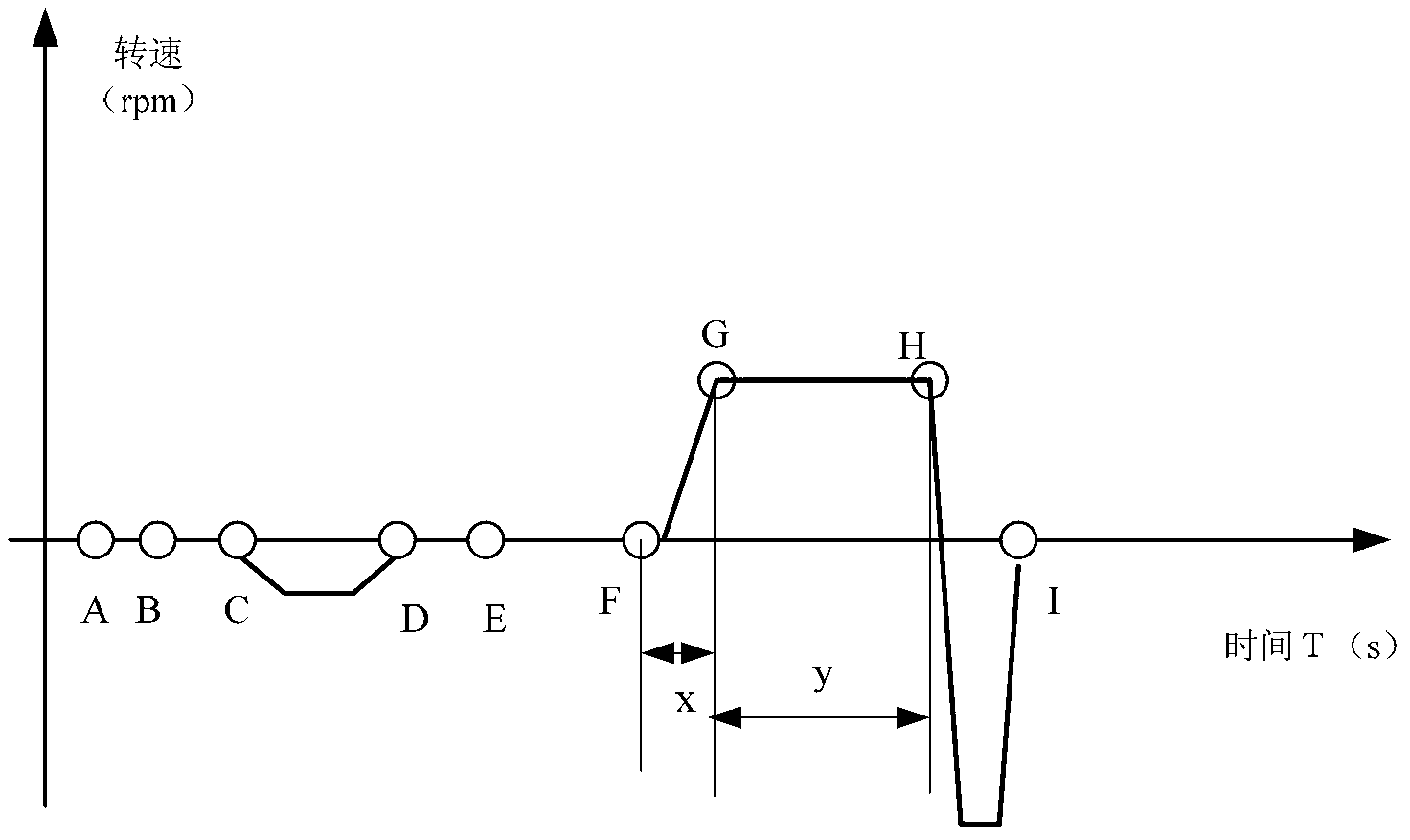

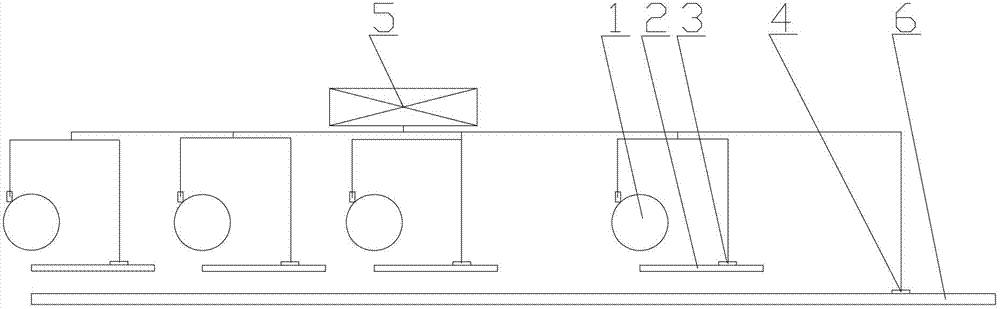

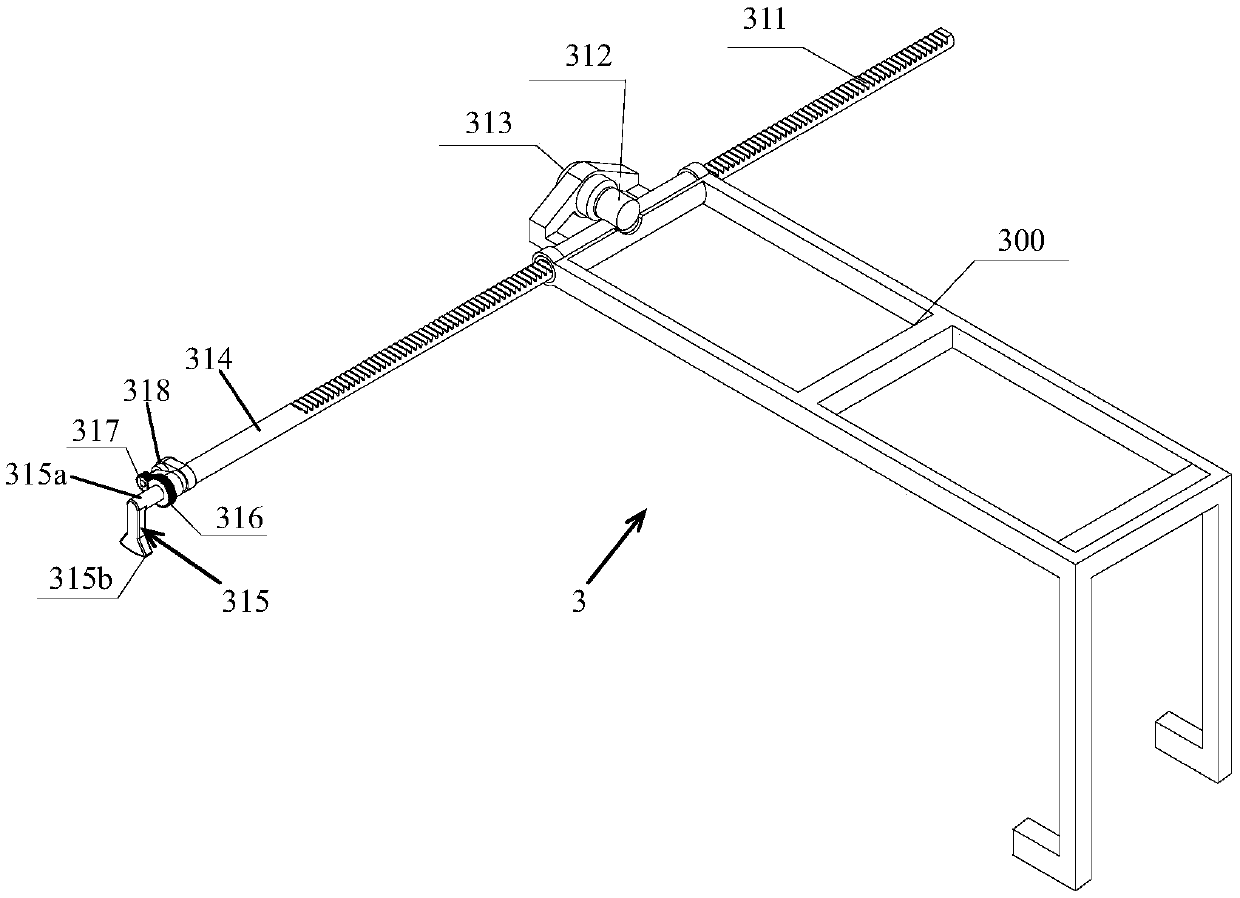

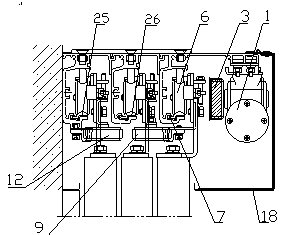

Flying shear control system and flying shear control method

InactiveCN103302349ATo achieve synchronous operationGuaranteed cutting qualityShearing control devicesFrequency changerControl layer

The invention discloses a flying shear control system and a flying shear control method. The flying shear control system is divided into a management layer, a control layer and an equipment layer, wherein the management layer comprises an upper computer; the control layer comprises a DCS (Distributed Control System) main station, an I / O (Input / Output) slave station and a frequency converter; the frequency converter, the I / O slave station and the upper computer are communicated with the DCS main station by DP (Data Processing) buses respectively; the equipment layer comprises a synchronous servo motor, a direct current motor, a pair of hydraulic flying shears and a first detection switch; the first detection switch is connected with the I / O slave station and mounted ahead the pair of hydraulic flying shears; a rotary encoder is arranged on a transmission shaft connected with the synchronous servo motor; an incremental encoder is arranged on a transmission shaft connected with the direct current motor; the synchronous servo motor and the rotary encoder are connected with the frequency converter, respectively; the direct current motor is connected with the DCS main station by a direct current driver; and the incremental encoder is connected with the frequency converter and the direct current driver respectively. The system and the method has the advantages of high shearing precision, strong working stability, high responsivity and the like.

Owner:GUANGZHOU MECHANICAL ENG RES INST

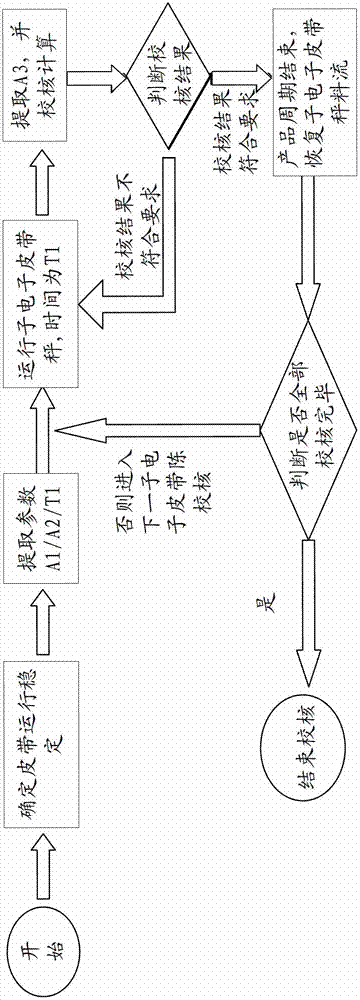

Checking method of subsidiary electronic belt scale

ActiveCN102818620ATo achieve synchronous operationWeighing apparatus testing/calibrationProduction lineNew materials

The invention discloses a checking method of a subsidiary electronic belt scale. The checking method comprises the following steps: step 1) recording a material flow A1 of a total electronic belt scale; step 2) adjusting the material flow of a subsidiary electronic belt scale, wherein the adjusting volume is A2; step 3) recording a new material flow A3 of the total electronic belt scale after the electronic belt scale works for a certain time period T1; step 4) substituting A1, A2 and A3 into a calculation formula as follow: checking parameter alpha=(A1-A3) / A2, and figuring out alpha; and step 5) comparing alpha with an error limit value B1, and obtaining the checking result. According to the checking method of the subsidiary electronic belt scale provided by the invention, the total electronic belt scale is adopted to check the subsidiary electronic belt scale; and in the whole checking process, the operation of automatic burdening production line is unnecessary to be stopped, the synchronous operation of production and checking is realized, and the scale is checked by the scale in the same standard, so that the checking precision is high.

Owner:LAIWU IRON & STEEL GRP

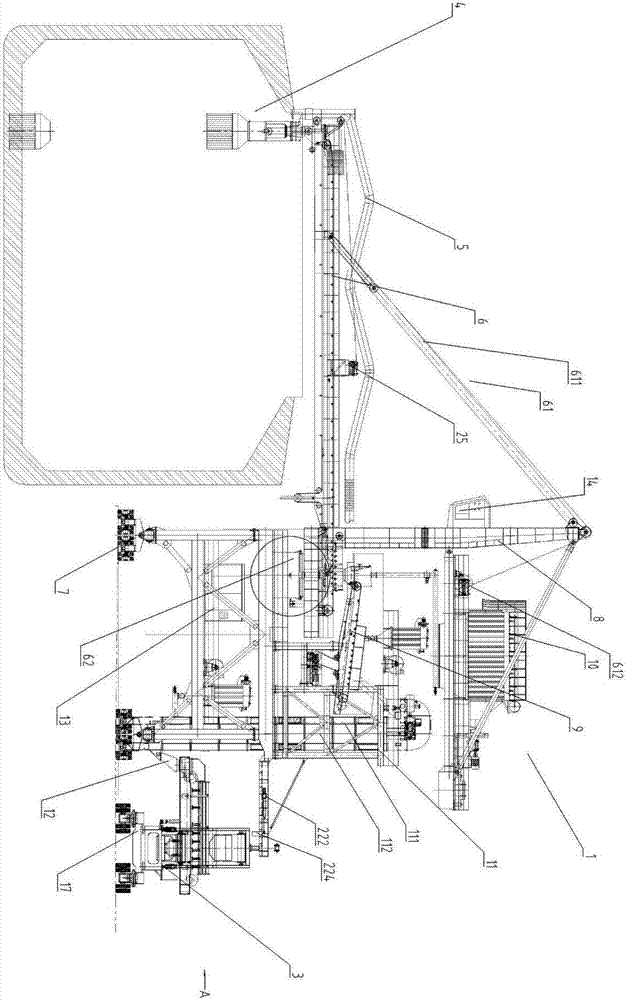

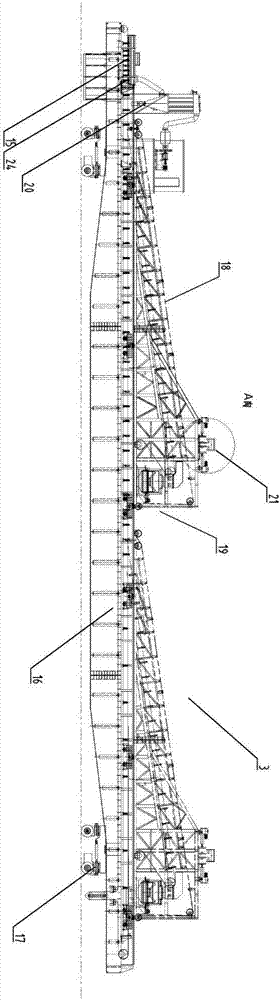

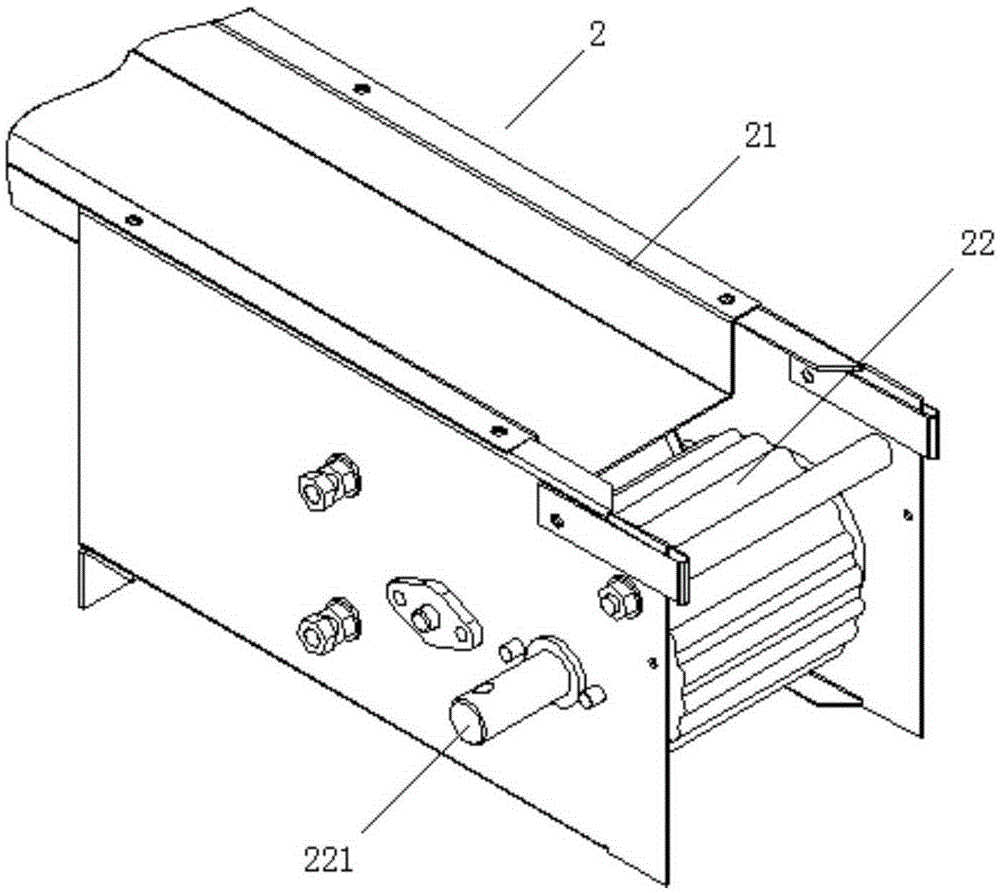

Tire type tail car conveying ship loader

InactiveCN106966195ATo achieve synchronous operationGuaranteed continuous feedingLoading/unloadingBogieEngineering

The invention provides a tire type tail car conveying ship loading machine, its tail car belt conveyor and mobile ship loading machine all adopt tire walking mechanism and are connected through an automatic docking system; Rack belt conveyors, intermediate transition belt conveyors, elevator systems and feeders. The ship loader provided by the present invention uses the tail car belt conveyor to feed the ship loader. When the ship loader moves, the tail car of the conveyor moves together, realizing the synchronous operation of the two sets of moving devices and ensuring continuous material supply; The automatic docking system is designed to connect the mobile ship loader and the tail car belt conveyor, and the twisted shaft is controlled by three sets of oil cylinders to realize fast docking and separation; when the ship loading operation is not in progress, the tail car belt conveyor and the mobile ship loader can be moved out Wharf, improve the operating capacity of the wharf; the hoist system can lift materials to a higher height in the narrow space of the wharf, meeting the loading needs of large ships; the system is equipped with dust-proof and dust-removing devices to achieve environmentally friendly shipping.

Owner:JIANGSU WANBAO MACHINERY

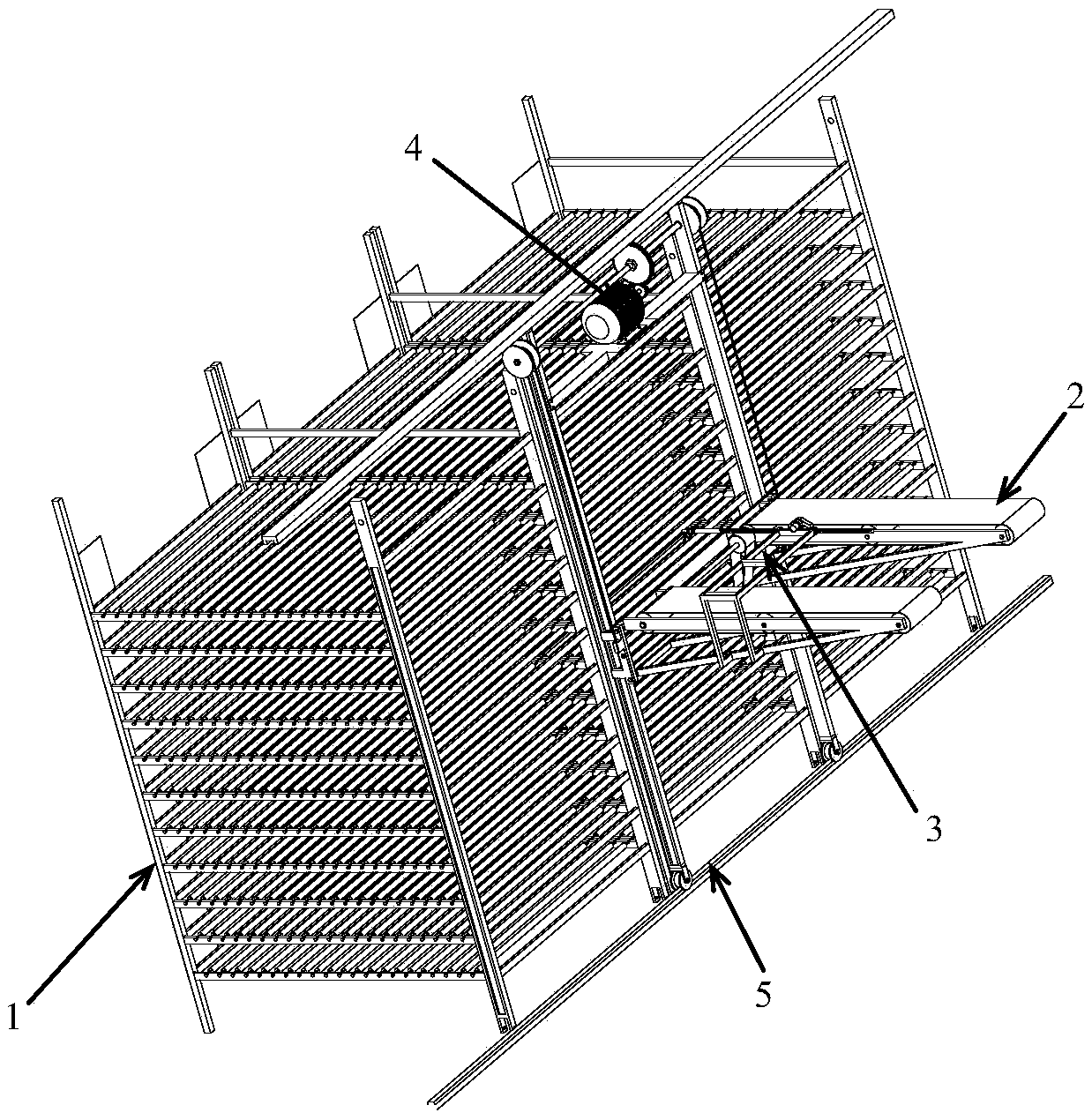

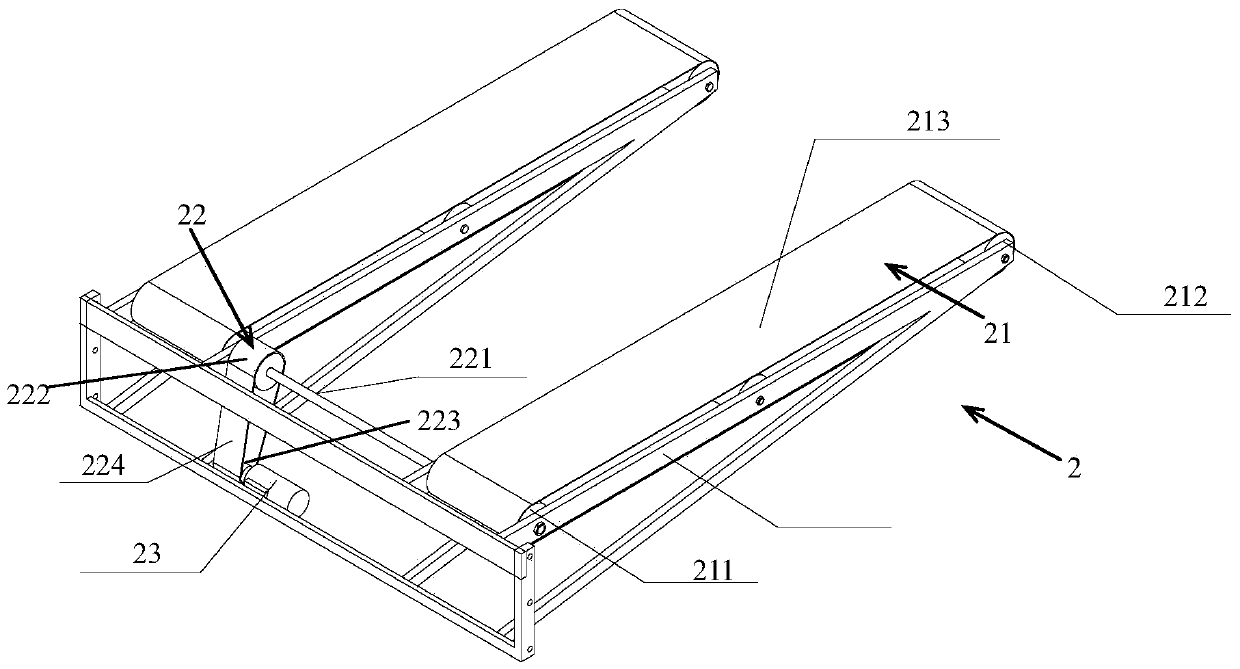

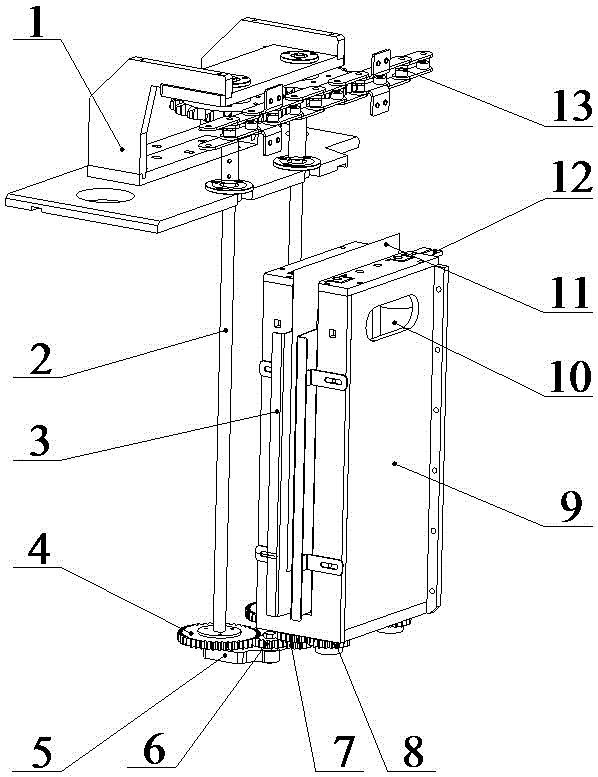

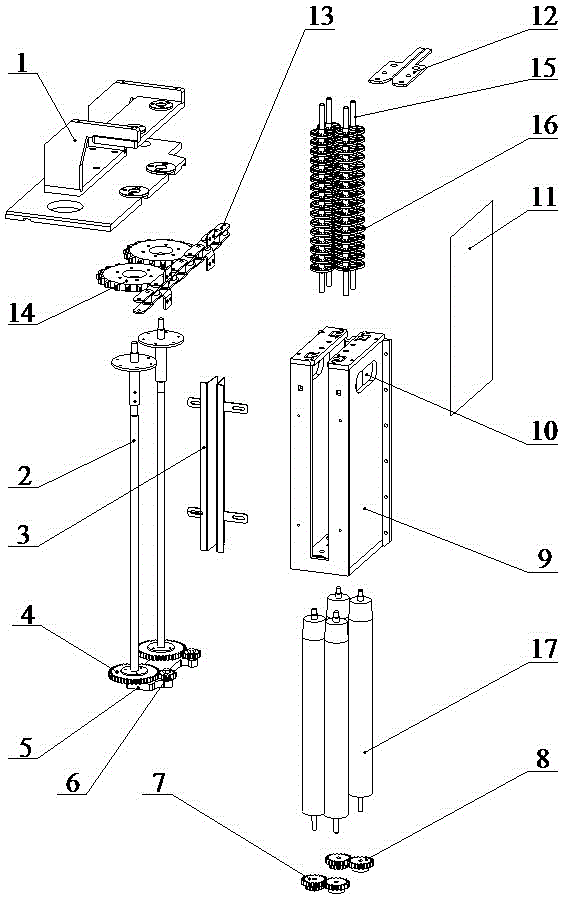

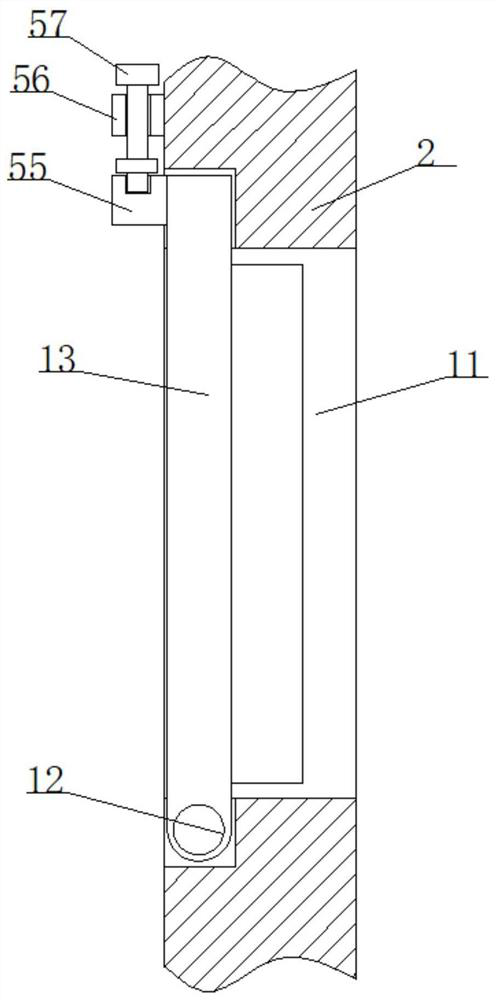

Battery storage and taking device

InactiveCN105501950ASimple structureEasy to operateConveyorsConveyor partsElectrical batteryEngineering

The invention discloses a battery storage and taking device which comprises a goods shelf storage mechanism used for containing batteries. A belt conveying and transporting mechanism is arranged at one side of the goods shelf storage mechanism and comprises at least one belt wheel set, and each belt wheel set comprises a horizontally-arranged supporting frame, a first belt wheel, a second belt wheel and a first belt, wherein the first belt wheel and the second belt wheel are mounted at the two ends of the supporting frame, and the first belt is wound around the first belt wheel and the second belt wheel. The first belt wheels are connected to first motors through first transmission units. A push unit is arranged above the belt conveying and transporting mechanism, and used for pushing the batteries in the direction close to or away from the first belts. According to the technical scheme, the battery storage and taking device is simple in structure, convenient to operate, capable of achieving automatic storage and taking of the batteries and high in automation degree.

Owner:GUIZHOU HENGJIN TECH CO LTD

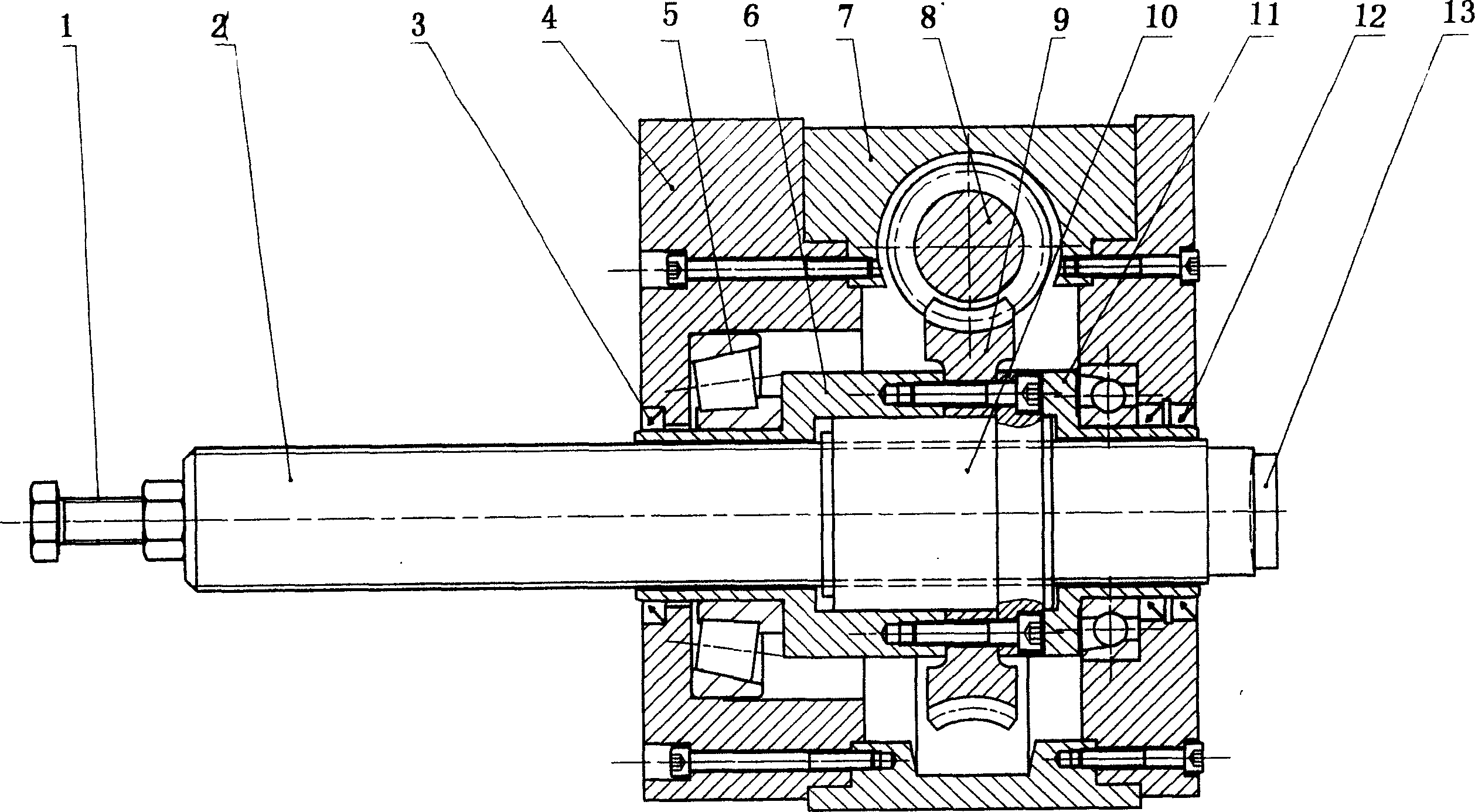

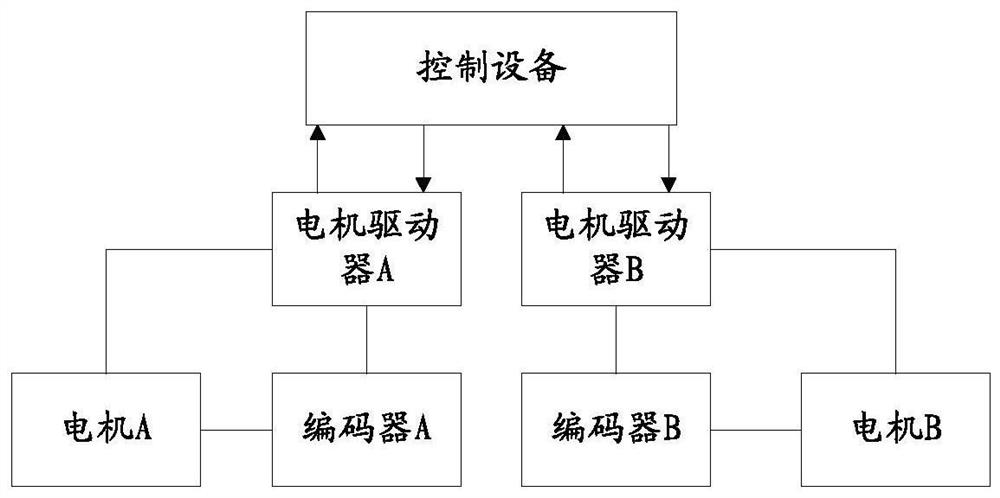

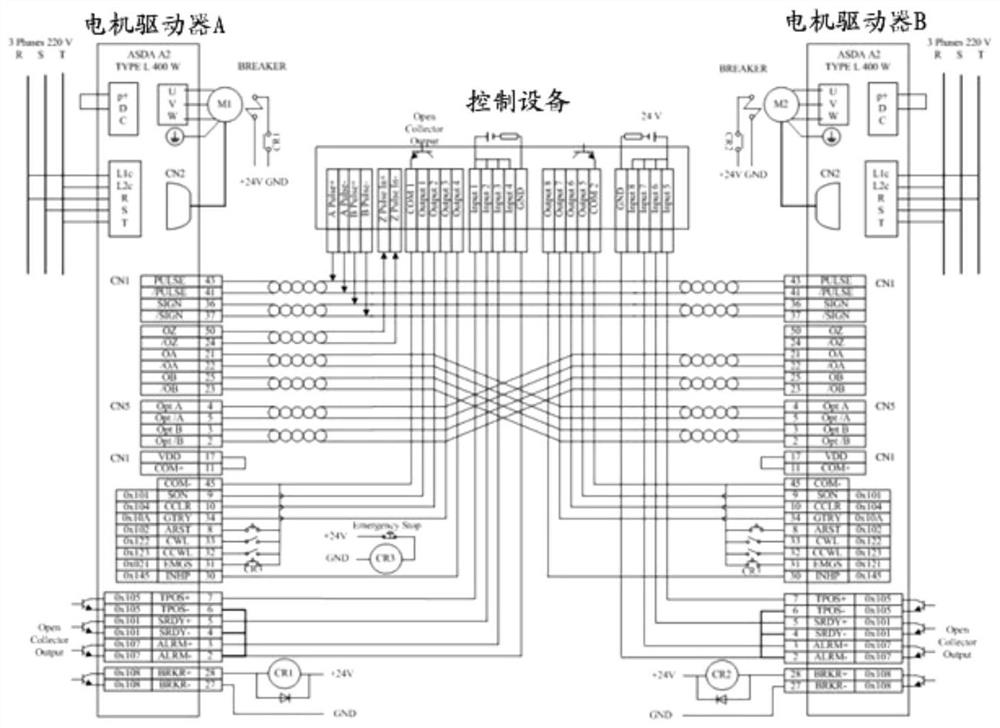

Servo motor driven digital control plate bending machine

The servo motor driven digitally controlled plate bending machine belongs to the field of digitally controlled machine tool. The plate bending machine consists of computerized digital control system, right and left servo motor drivers, right and left motors, right and left coders, right and left grating rules, right and left worm gear transmission pairs, nut, ball lead screw, block and frame connected together. The present invention s high efficiency, low power consumption and environment friendship.

Owner:吉素琴

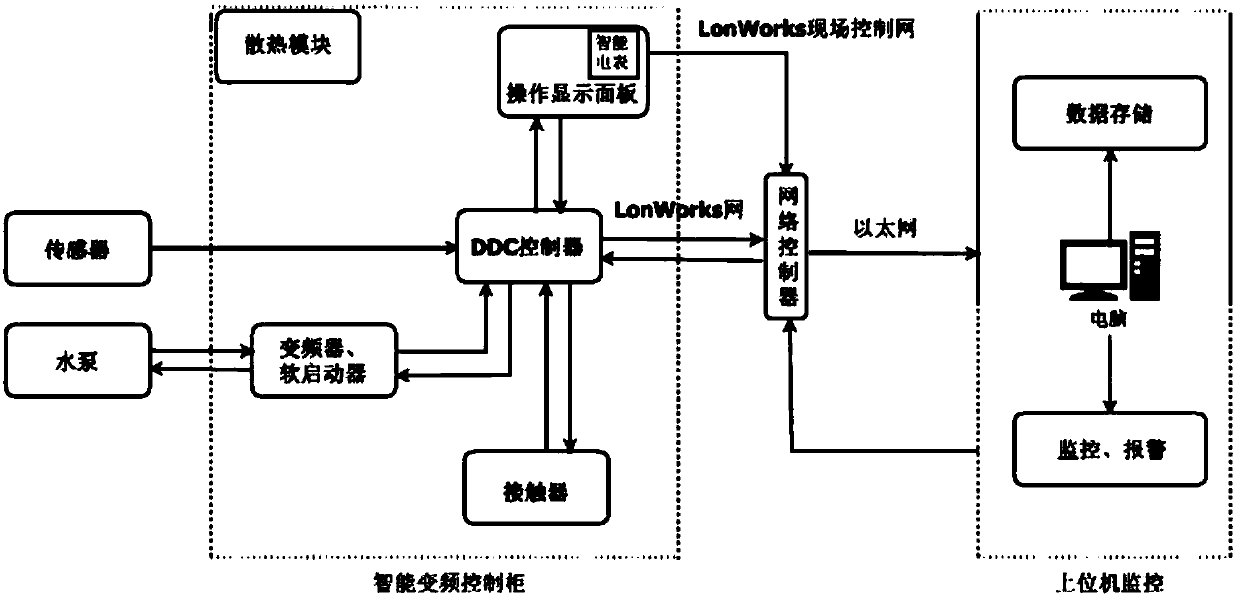

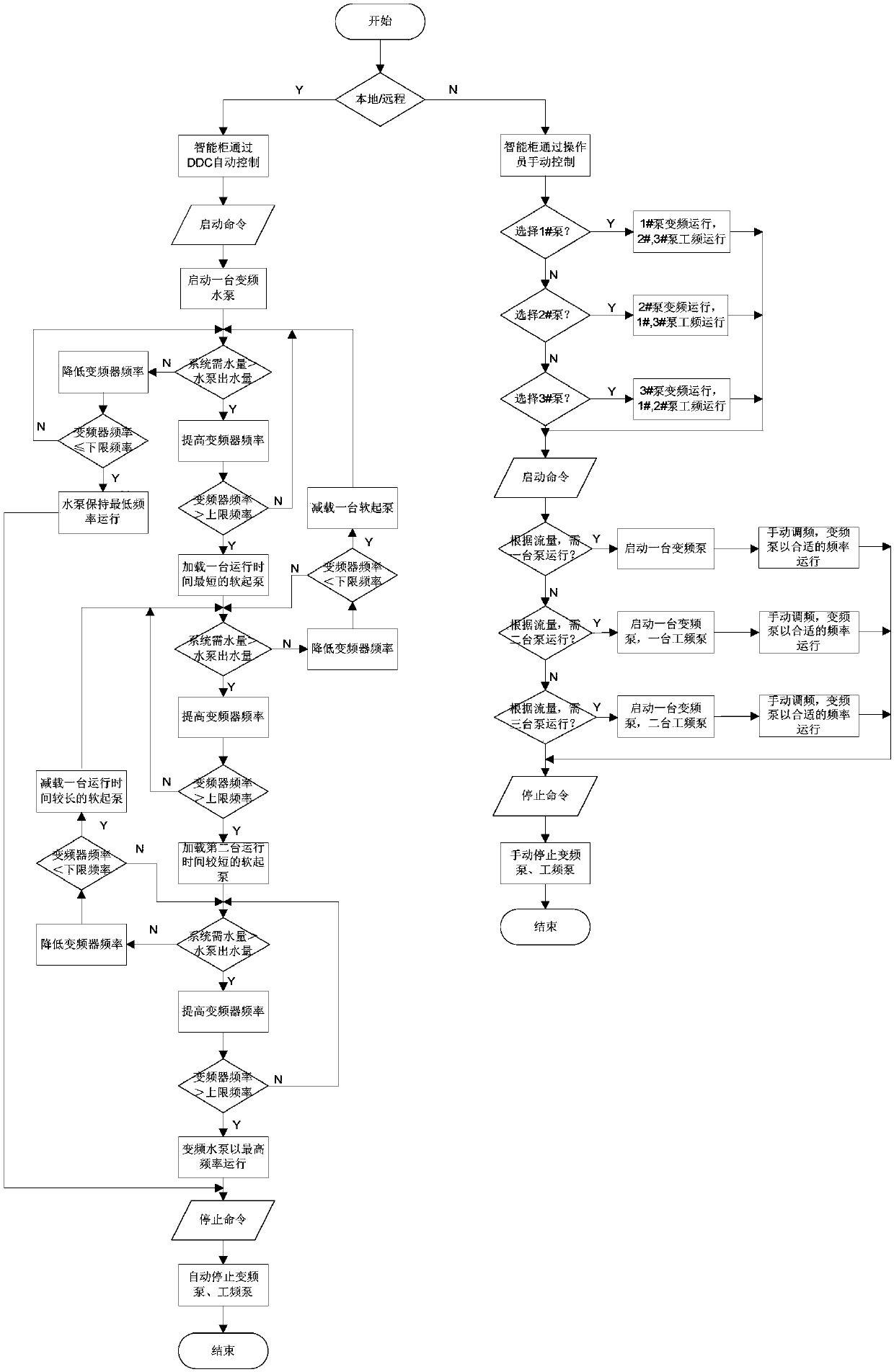

Intelligent frequency conversion control cabinet and control method thereof

InactiveCN108180602ASystem control stabilityGuaranteed safe operationMechanical apparatusSpace heating and ventilation safety systemsContactorAutomatic control

The invention discloses an intelligent frequency conversion control cabinet comprising a control cabinet body, and a DDC, a frequency converter, a soft starter, a contactor, an operation display panel, an intelligent electric meter and a thermal module which are installed in the control cabinet body; the operation display panel is provided with manual start-stop buttons, and variable frequency / power frequency and local / remote selector knobs; the DDC is controlled through these buttons and knobs so that the contactor, the frequency converter and the soft starter are controlled, and the DDC is connected to all on-site sensors through sensor interfaces; meanwhile, the DDC is further connected to a network controller through a cable, so that the operating data of the intelligent frequency conversion control cabinet is uploaded to a remote upper computer, and the system operation can be monitored conveniently and remotely. The intelligent frequency conversion control cabinet disclosed by the invention has the functions of energy efficiency monitoring, automatic control, energy-saving control and regulation, and energy use safety monitoring and alarm.

Owner:江苏联宏智慧能源股份有限公司

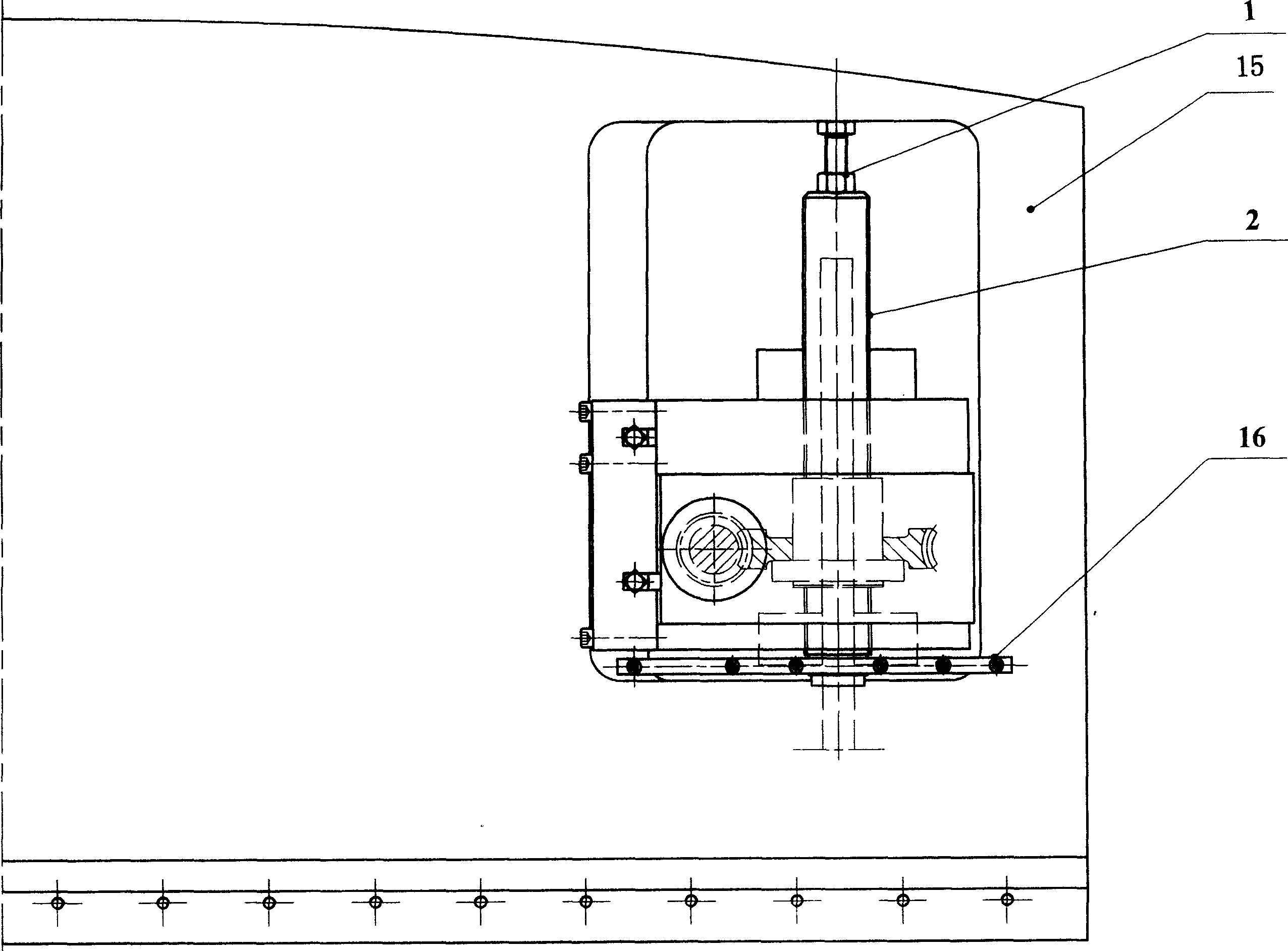

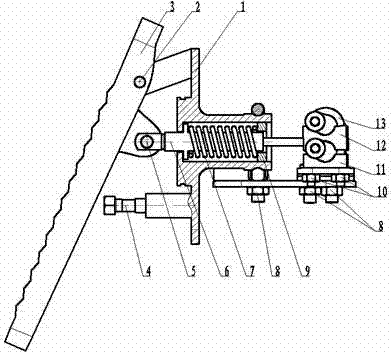

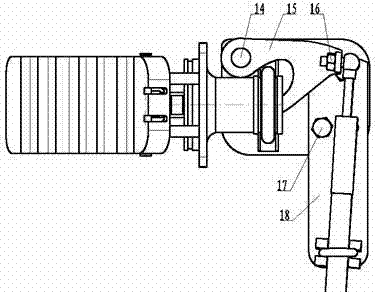

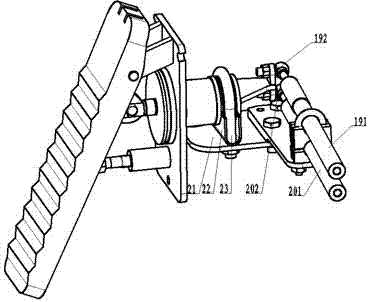

Double-motor mechanical synchronization accelerator pedal assembly

InactiveCN104747297ATo achieve synchronous operationImprove efficiencyEngine controllersMachines/enginesReturn functionDevice form

The invention discloses a double-motor mechanical synchronization accelerator pedal assembly which comprises a pedal fixing base (1), an anti-sliding pedal (3), a limiting bolt (4), a mandrel (6), two pulling wires with the same extending length and a connecting device formed by a stirring piece (15) and a rotating fixing plate (21). According to the structure, the fact that two engines share the same accelerator pedal is achieved, synchronization operation is achieved, efficiency is improved, and manpower is saved. In addition, assembly is provided with a rotating fixing device of the pulling wires, connecting wire multi-angle detaching and mounting are achieved, and price is very low. Meanwhile, a return spring (7) is arranged, so that the mandrel (6) and the return spring (7) are matched with each other, accordingly, an automatic returning function is achieved, and the service life of the accelerator pedal is prolonged.

Owner:LAIZHOU YATONG HEAVY EQUIP

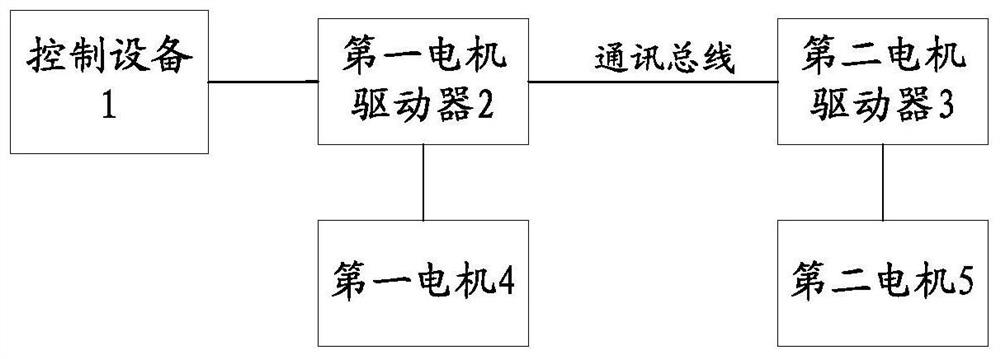

Gantry synchronous control method, motor driver and motor control system

InactiveCN111835235AAchieve interactionReduce interactionMultiple dynamo-electric motors speed regulationSynchronous controlControl system

The invention discloses a gantry synchronous control method, a motor driver and a motor control system. A first motor driver and a second motor driver of the motor control system are connected througha communication bus; the first motor driver acquires first position information of a first motor driven and controlled by the first motor driver; the second motor driver obtains second position information of a second motor driven and controlled by the second motor driver and sends the second position information to the first motor driver through the communication bus; the first motor driver obtains a position difference according to the obtained first position information and second position information; and gantry position compensation control is carried out according to the position difference. Compared with an existing gantry control mode, position information interaction between the first motor driver and the second motor driver is directly realized through the communication bus, thedisturbance resisting capacity is higher, the position information can be not transmitted to control equipment, and gantry control can be realized on the first motor driver, so that the data interaction is reduced, and the wiring complexity and the use and maintenance cost of the system are reduced.

Owner:SHENZHEN LEADSHINE INTELLIGENT CONTROL CO LTD +1

Egg collection line system of coop

The invention relates to an egg collection line system of a coop. The egg collection line system comprises a stacked coop frame body. An egg collection belt cleaning device and an egg collection belt transmission device are arranged on the two sides of the stacked coop frame body. An egg collection line conveying chain device is arranged at one end of the stacked coop frame body. A conveying chain and a transmission roller are arranged on the egg collection line conveying chain device. An egg collection line counter weight hammer fixing frame device is arranged at the tail end of the egg collection line conveying chain device. The egg collection line system has the advantages that dust on an egg conveying belt is removed through friction between an egg belt and an egg belt brush, and the cleanness degree of the egg belt is improved; the problem that the egg belt is excessively tensioned is solved by regulating the gap between a belt pressing roller and the egg belt roller through a butterfly nut, and the egg belt can not slip; arc turning is achieved through cooperation of hook bodies and hanging rods of the conveying chain, eggs can be stably conveyed, and installation and detachment are convenient; the chain can be in the tensioned state through a counter weight hammer, the effect of regulating the length of the chain can be achieved, the phenomenon that eggs are stuck can not happen, and egg breakage caused by the tension degree of the chain can not happen.

Owner:HENAN JINFENG POULTRY EQUIP

Copper electroplating groove inlet section and outlet section water blocking buffer apparatus

ActiveCN106637361ATo achieve synchronous operationGuaranteed qualityElectrolysis componentsWater flowEngineering

The present invention relates to the technical field of electroplating equipment, more particularly to a copper electroplating groove inlet section and outlet section water blocking buffer apparatus, which comprises a main conveying chain, a sub-conveying device and a water blocking buffer device, wherein the sub-conveying device comprises a sub-conveying wheel upper fixation seat, a sub-conveying wheel lower fixation seat, a sub-conveying wheel shaft, a first sub-conveying wheel, a second sub-conveying wheel and a third sub-conveying wheel, the sub-conveying wheel shaft is arranged between the sub-conveying wheel upper fixation seat and the sub-conveying wheel lower fixation seat, the first sub-conveying wheel is rotatably connected to the upper end of the sub-conveying wheel shaft, and the second sub-conveying wheel is rotatably connected to the lower end of the sub-conveying wheel shaft. According to the present invention, with the copper electroplating groove inlet section and outlet section water blocking buffer apparatus, it is ensured that the liquid level in the copper groove is maintained at a certain height, such that the liquid in the copper groove maintains the stable and low water flow pressure and the water flow rate, and the phenomenon that the liquid impact causes the plate snapping and the wrinkling of the electroplating substrate cannot be generated when the electroplating substrate enters the copper electroplating groove inlet section and outlet section water blocking buffer apparatus so as to ensure the product quality.

Owner:KUN SHAN KORBE PRECISION EQUIP CO LTD

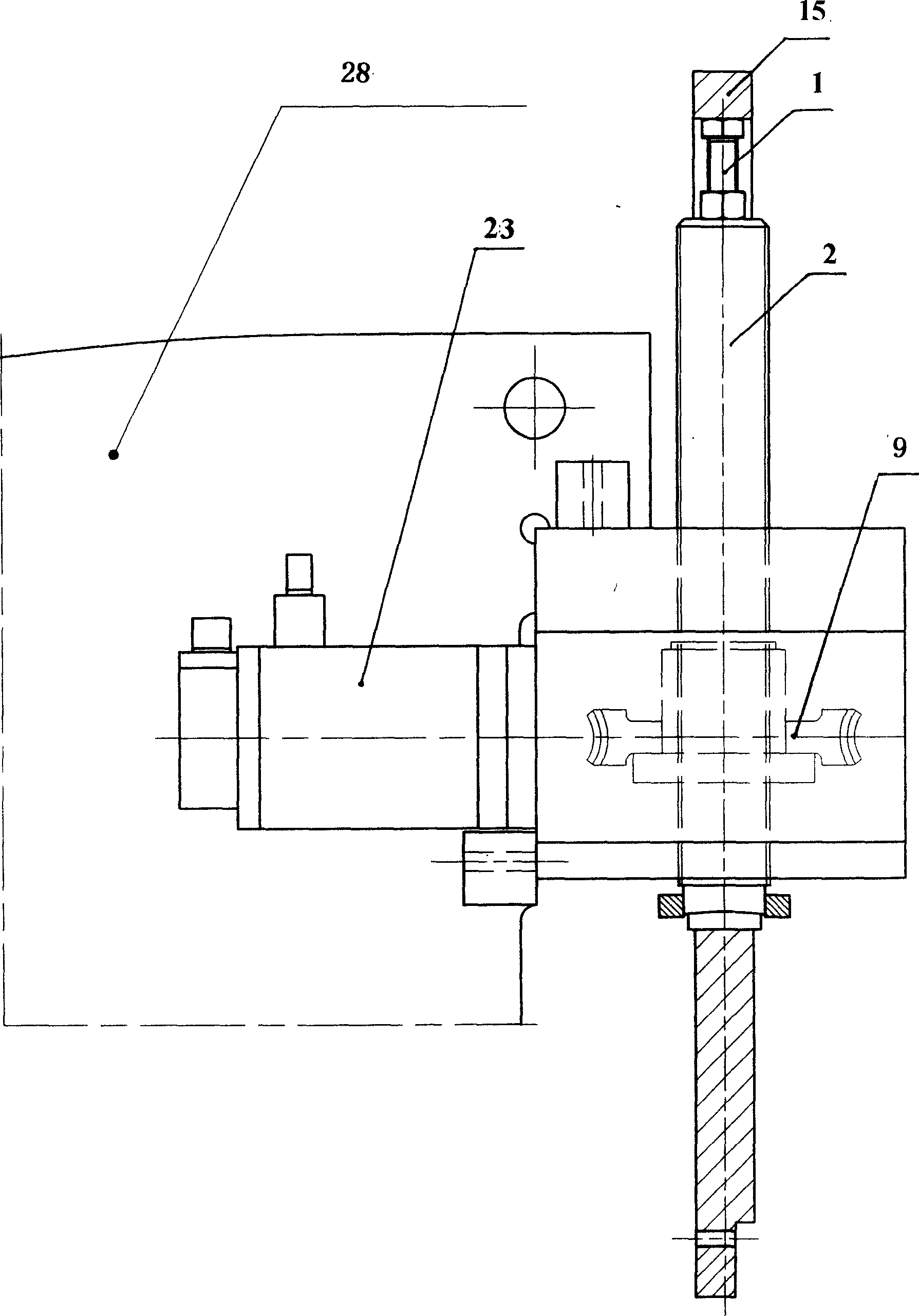

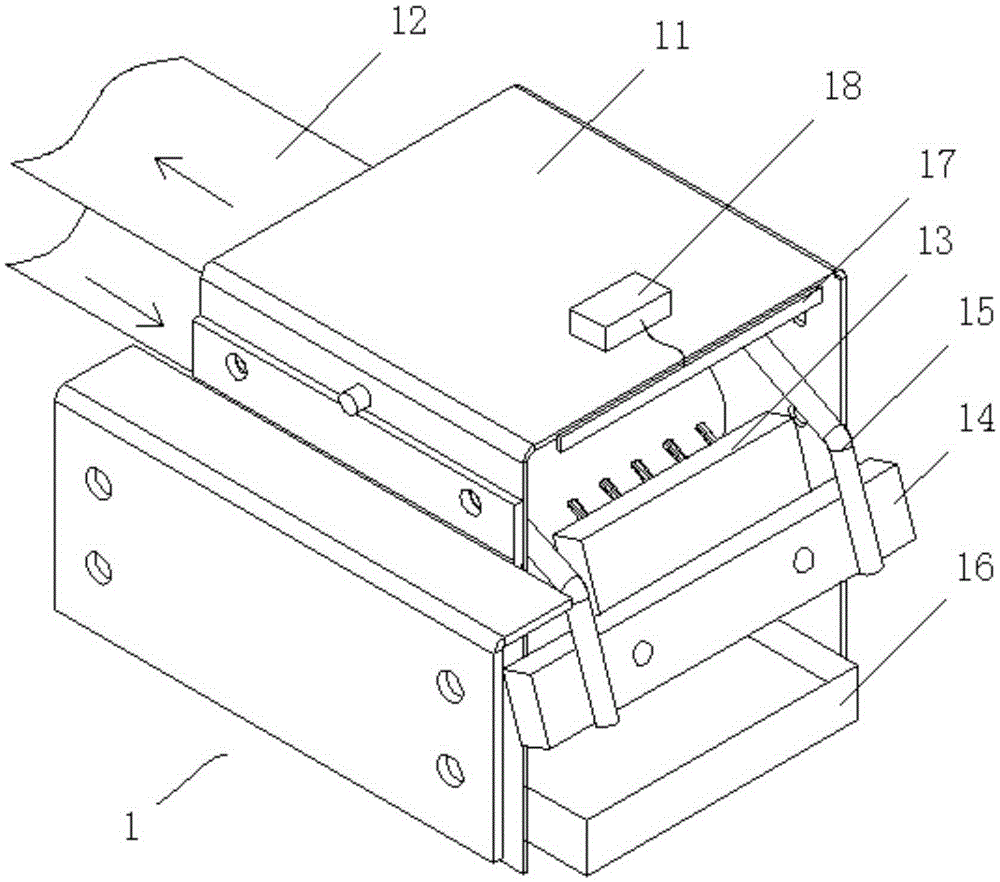

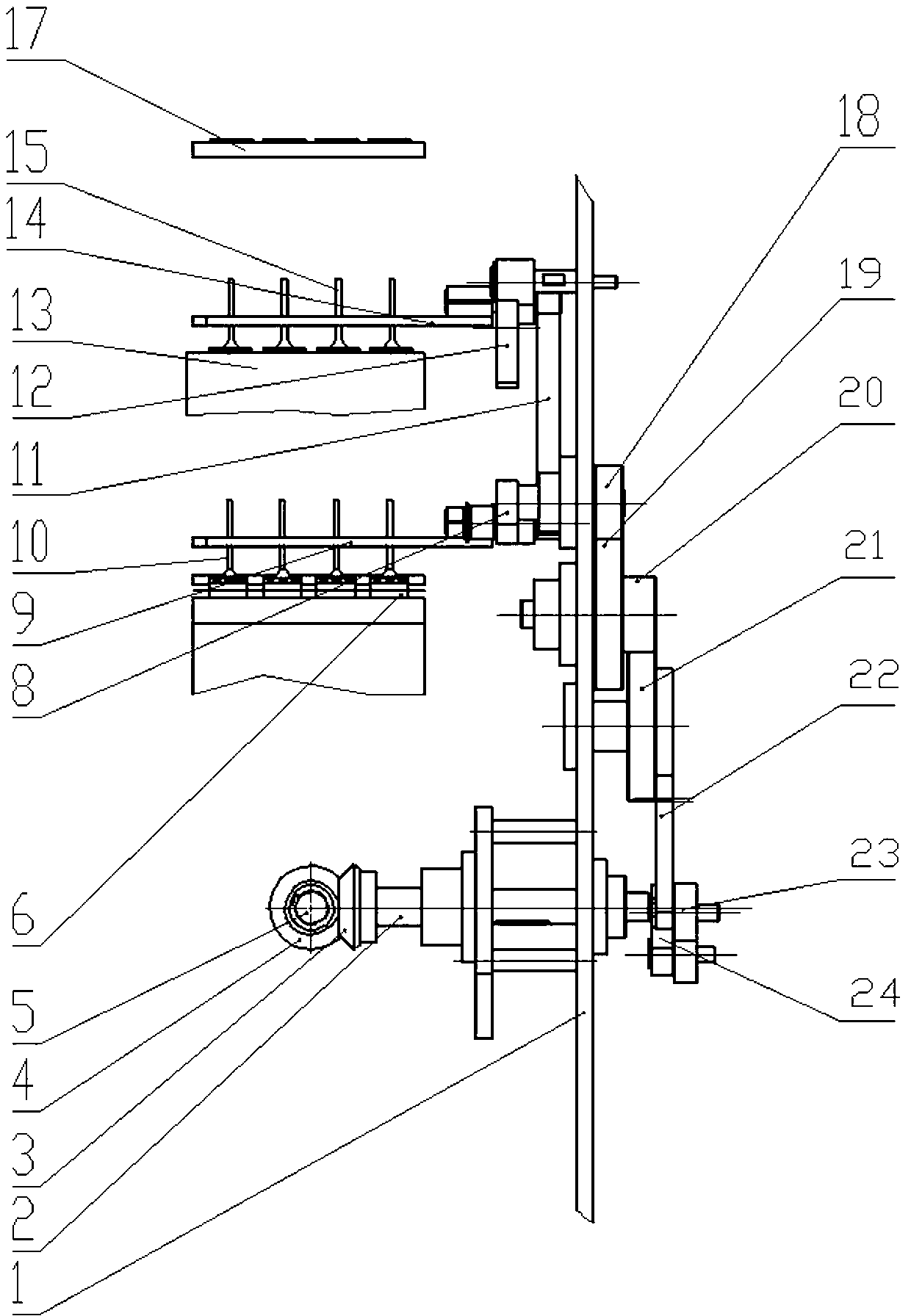

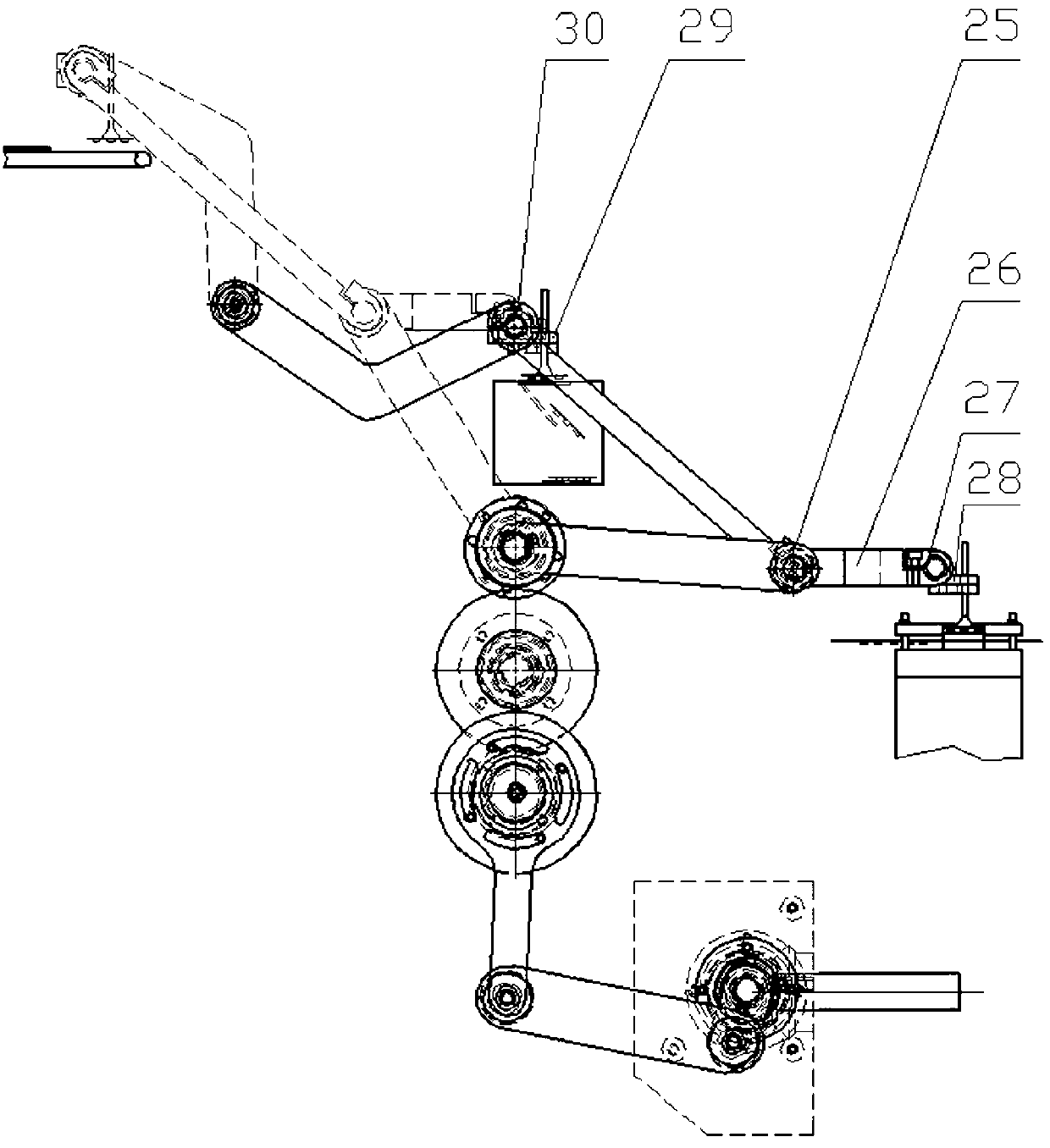

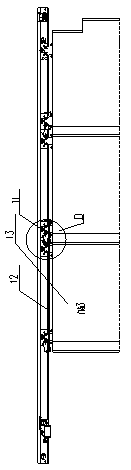

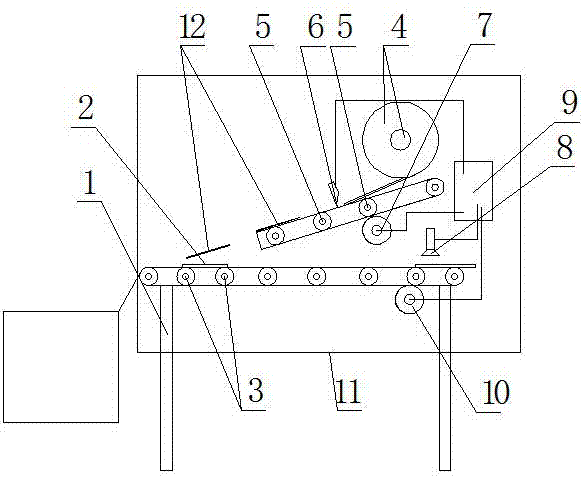

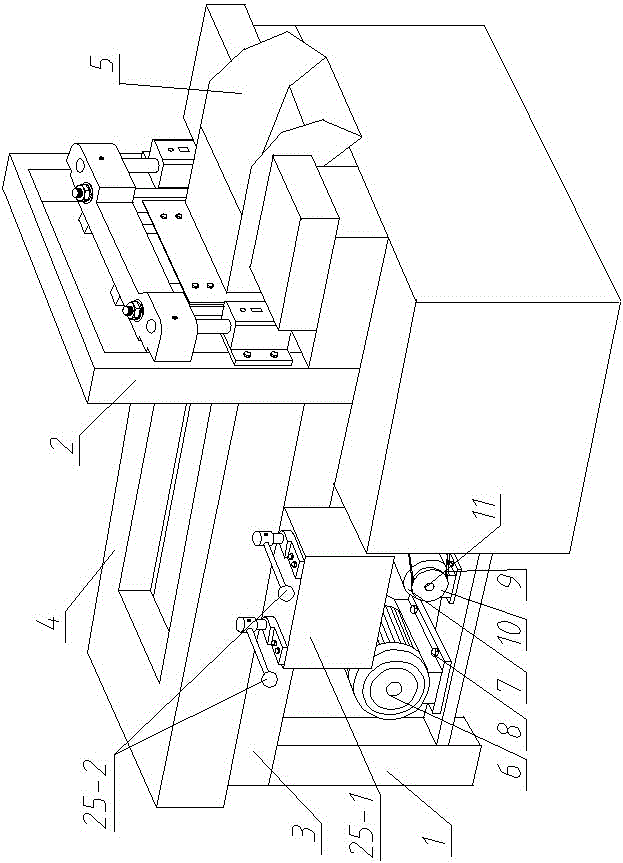

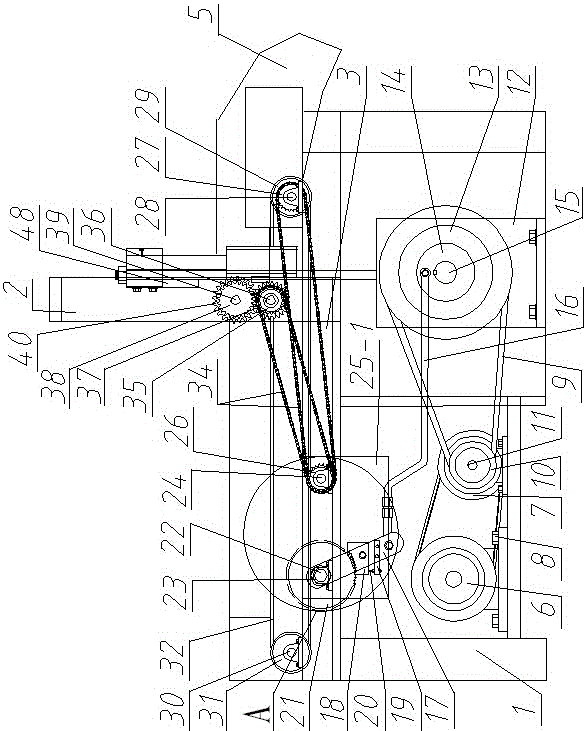

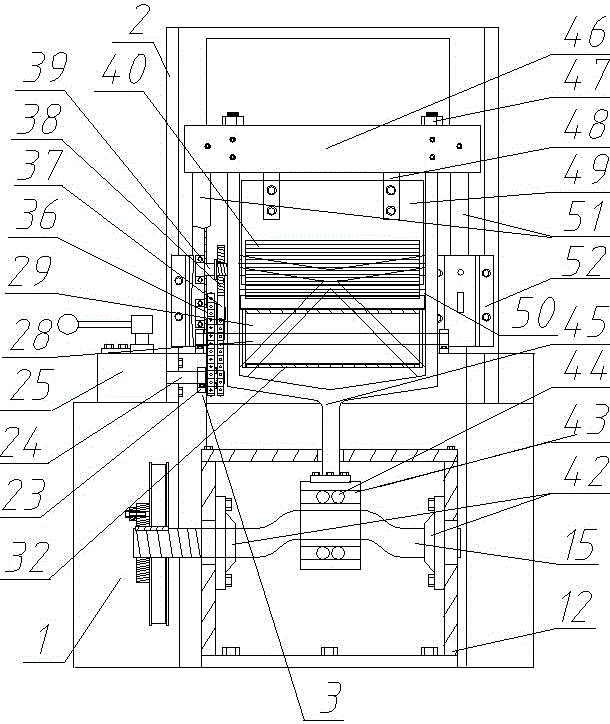

Waste removing and plate conveying mechanism of bubble cap boxing machine

ActiveCN103010532ATo achieve synchronous operationPackaging automatic controlEngineeringMechanical engineering

The invention discloses a waste removing and plate conveying mechanism of a bubble cap boxing machine. The mechanism is characterized by comprising a gateway (1) and a transmission main shaft (5), wherein the gateway (1) is connected with a driving swing arm (8) and a driven swing arm (12); the driving swing arm (8) is in transmission connection with the transmission main shaft (5), and is provided with a first absorption device (10); the driven swing arm (12) is hinged with the driving swing arm (8) through a connection rod (11); and a second absorption device (15) is arranged on the driven swing arm (12). As a result, medicine plates can be directly absorbed by the first absorption device and conveyed to a waste removing station after a bubble cap machine is cut off, and at the same time, the second absorption device absorbs the qualified medicine plates and conveys the same to a machine connection conveying belt; and this process is implemented in cycles to achieve the synchronous operation of cutting and conveying of the medicine plates and waste removal.

Owner:上海江南制药机械有限公司

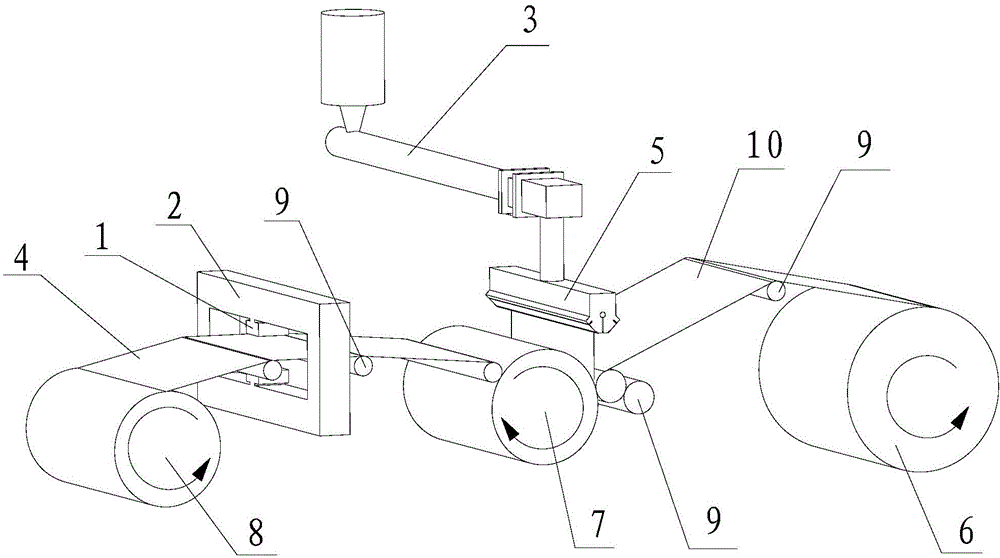

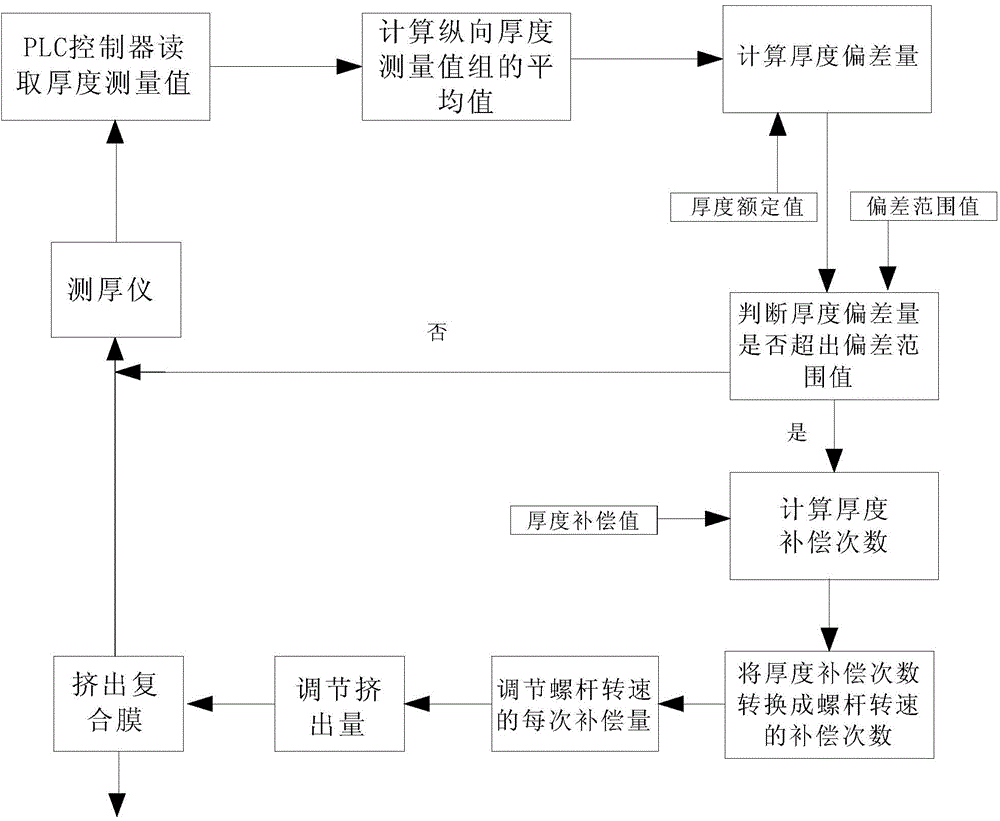

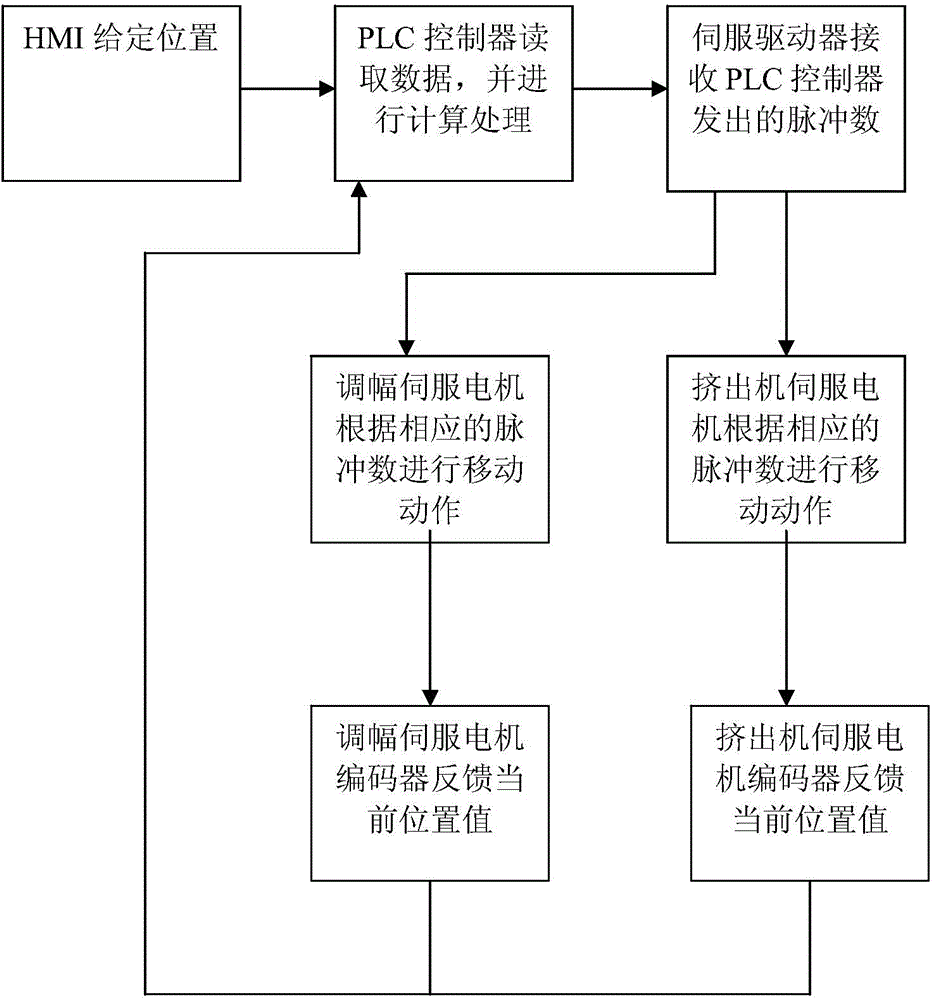

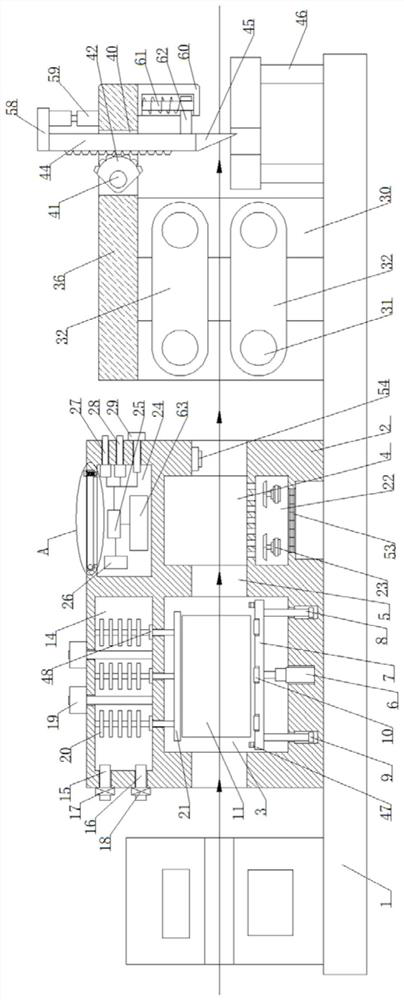

Device and method for controlling flatness of full-width composite material

ActiveCN104859121AImprove product qualityImprove surface uniformityComposite filmProgrammable logic controller

The invention discloses a device and a method for controlling the flatness of a full-width composite material. The device for controlling the flatness of the full-width composite material comprises a thickness gauge, a probe mounting rack, an extruder, a flatness adjusting mechanism, a PLC (programmable logic controller) and a thin film conveying mechanism, wherein a probe of the thickness gauge is arranged on the surface of extrusion composite films through the probe mounting rack; the flatness adjusting mechanism is arranged on the extruder; the flatness adjusting mechanism, the thickness gauge and the extruder are electrically connected with the PLC respectively; the extrusion composite films are conveyed by the thin film conveying mechanism; a die head of the extruder is arranged above the thin film conveying mechanism. The method for controlling the flatness of the full-width composite material comprises the step as follows: thickness uniformity adjustment of a horizontal cross section of each extrusion composite film, thickness uniformity adjustment of a longitudinal cross section of each extrusion composite film and surface flatness adjustment of the stacked extrusion composite films are performed integrally. According to the device and the method, integrated control of the thickness uniformity adjustment of the horizontal cross section of each extrusion composite film, the thickness uniformity adjustment of the longitudinal cross section of each extrusion composite film and the surface flatness adjustment of the stacked extrusion composite films can be realized, and the product quality is effectively improved.

Owner:HUILONG PLASTICS MACHINERY

High-viscosity epoxy resin composite material pultrusion equipment for fibers

The invention discloses a high-viscosity epoxy resin composite material pultrusion equipment for fibers, comprising a mounting base, a preheating mechanism, a heating curing mechanism, a traction mechanism and a cutting mechanism. The preheating mechanism, the heating curing mechanism, the traction mechanism and the cutting mechanism are all fixedly connected with the top of the mounting base; the heating curing mechanism comprises a curing box; a heating cavity is formed in the end, close to the preheating mechanism, of the curing box; a cooling cavity is formed in the end, away from the heating cavity, of the curing box; the heating cavity communicates with the cooling cavity through a through opening; a telescopic air cylinder is fixedly connected to the inner bottom of the heating cavity; the output end of the telescopic air cylinder is fixedly connected with a mounting plate; and the bottom of the mounting plate is fixedly connected with a plurality of sliding rods. Through the arrangement of the mounting adjusting mechanism, a mold in the heating curing mechanism can be replaced and maintained, and meanwhile, through the arrangement of the synchronous transmission mechanism, the traction mechanism and the cutting mechanism can work synchronously, so that the use effect of the pultrusion equipment is improved.

Owner:广东华彩复合材料有限公司

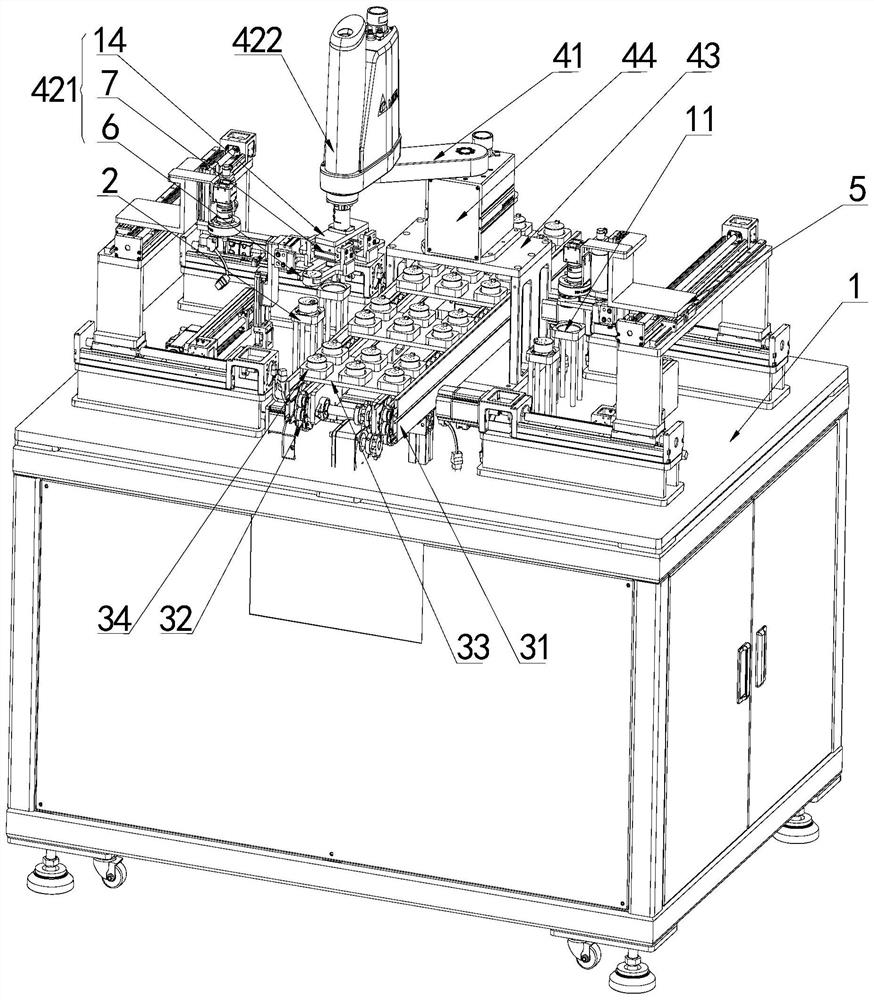

Die bonder and semiconductor device packaging method thereof

ActiveCN111916370APrevent movementAvoid mutual interferenceSolid-state devicesSemiconductor/solid-state device manufacturingImaging processingDevice material

The invention discloses a die bonder. The die bonder comprises a workbench; wherein a placing table, a conveying device for conveying a semiconductor device to be dispensed, a clamping device for transferring the semiconductor device to be dispensed between the placing table and the conveying device, and a dispensing device are arranged on the workbench; the dispensing device comprises a rack capable of getting close to and away from the containing table in a reciprocating mode, a dispensing head arranged on the rack and a detection device used for detecting the dispensing quality of the semiconductor device. The detection device comprises a camera and a processing module in communication connection with the camera; the processing module comprises an image processing unit, an abnormal point recognition unit and a poor dispensing analysis unit. The die bonder is high in automation degree and dispensing precision, and the finished product rate of products is increased. The invention further discloses a semiconductor device packaging method, high-hardness packaging colloid packaging is carried out on the device after high-viscosity gel is dispensed on the device through the die bonder, the packaged device has both reliability and protection performance, and the packaging method is simple and good in compatibility.

Owner:佛山市顺德区蚬华多媒体制品有限公司

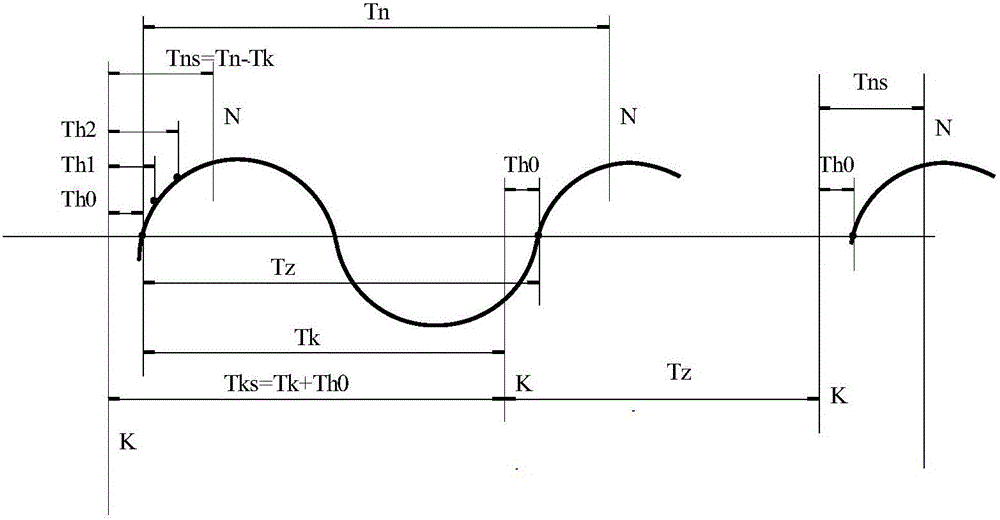

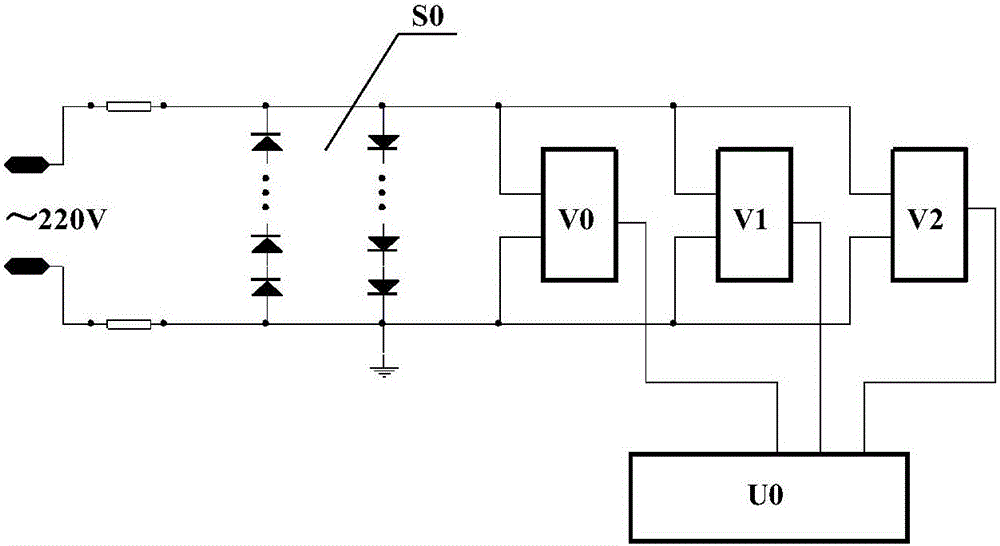

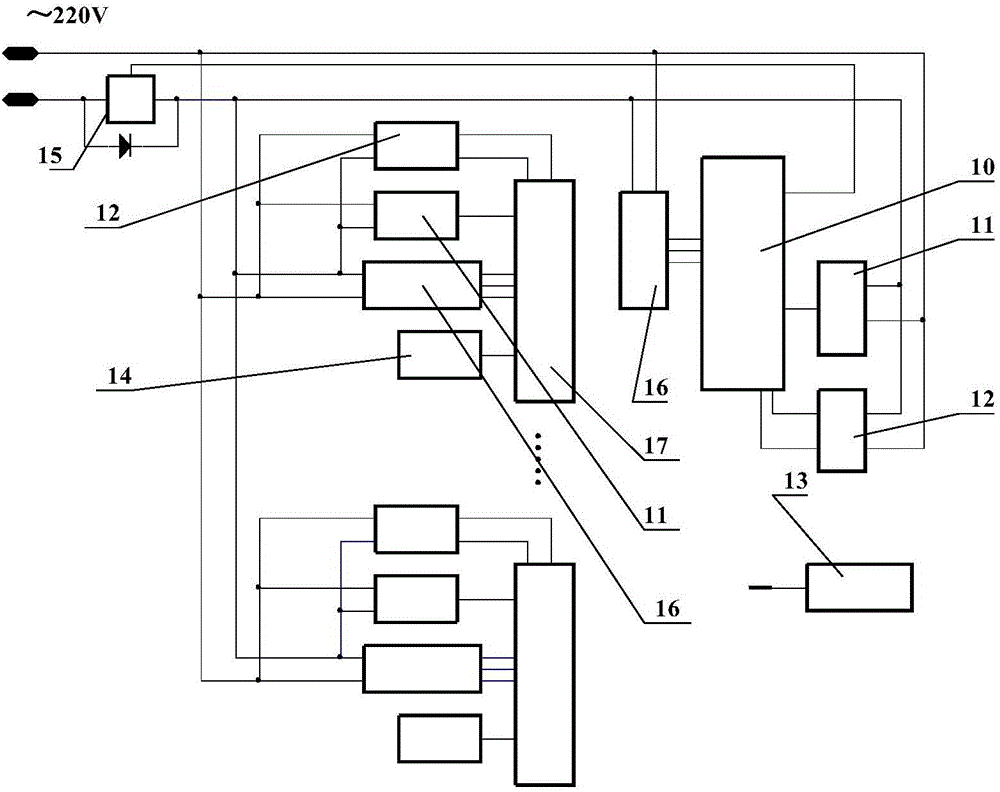

Household light intelligent control system

ActiveCN105848370ATo achieve synchronous operationElectrical apparatusElectroluminescent light sourcesOperation modeMaster controller

The invention relates to a household light intelligent control system comprising multiple decorative lighting controllers and a master controller. The AC power supply of each decorative lighting controller is connected in parallel on an original socket or load controlled by a switch so that decorative lighting control is realized. The master controller and each decorative lighting controller are provided with a cyclic wave discrimination circuit which is used for generating synchronization time of the system and maintaining consistency of system action. The master controller is also provided with an infrared receiving circuit. The decorative lighting operation mode is controlled and changed by a remote control emitter.

Owner:FARUI NEW TECH JIANGXI CO LTD

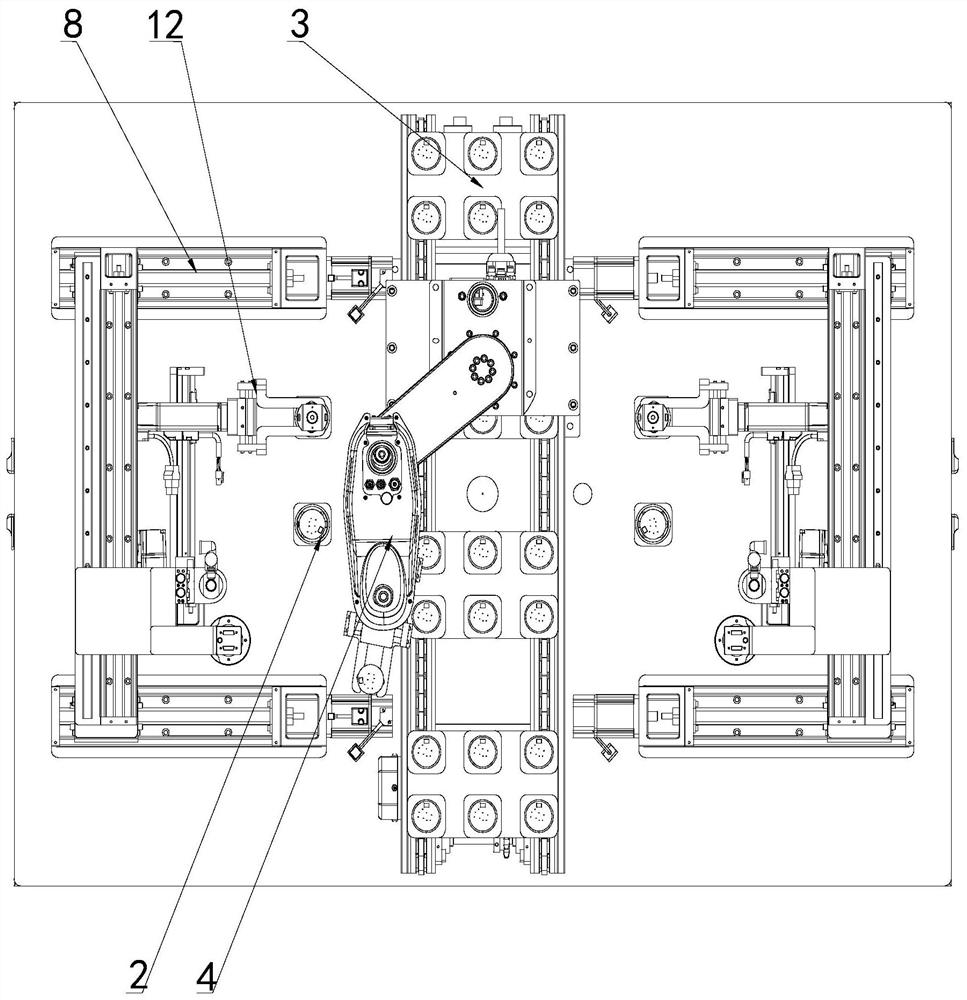

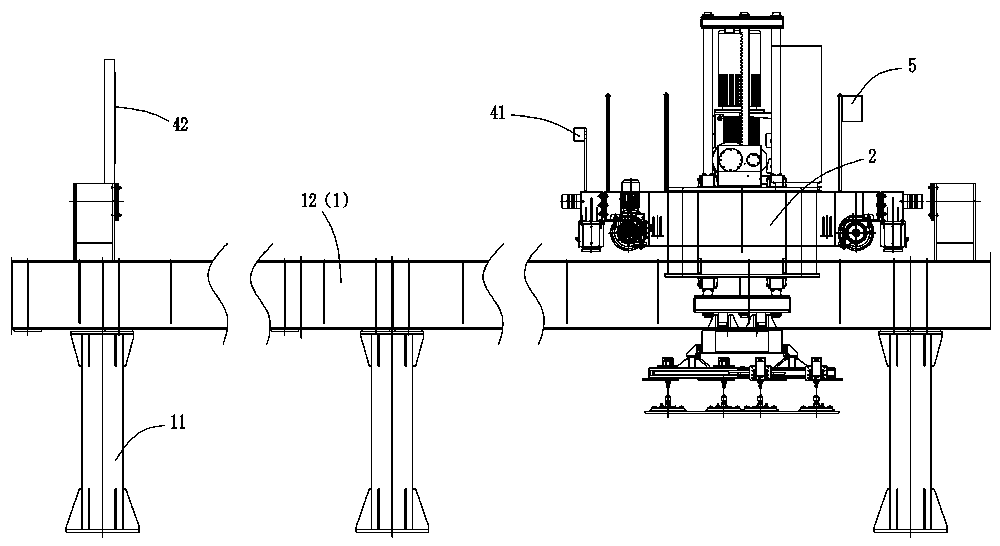

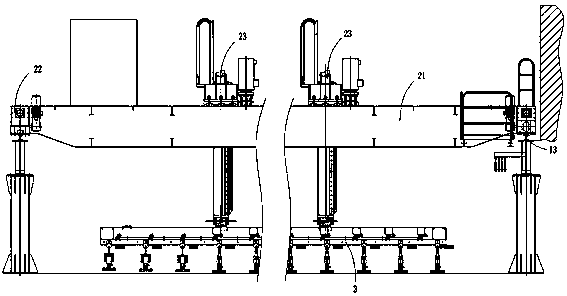

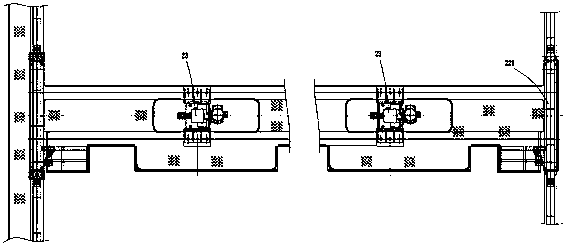

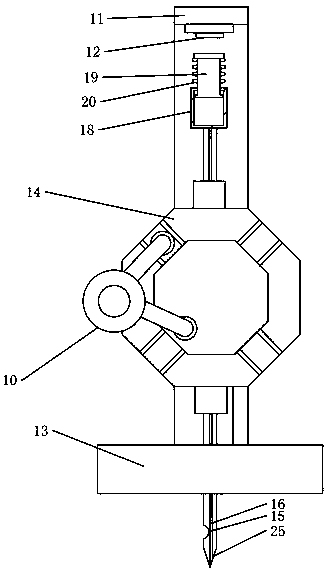

High-precision heavy-load carrying operation device

PendingCN110872056APrecise positioningTo achieve synchronous operationTravelling gearLaser rangingControl system

The invention relates to the technical field of carrying work, and discloses a high-precision heavy-load carrying operation device. The high-precision heavy-load carrying operation device comprises aframe part, a moving part, a clamp part and an electric control system, the frame part comprises stand columns arranged on the two sides of the moving part; a girder is arranged between every two adjacent stand column, a rail is laid on the girder, the moving part comprises a bridge frame spanning between the two side rails, the bridge frame is driven by a first walking mechanism to walk along therail; the moving part further comprises a lifting mechanism arranged on the bridge frame to move vertically, and the clamp part is connected to the lifting mechanism; one end of the moving part is provided with a laser ranging sensor, the frame part is provided with a laser reflecting plate corresponding to the laser ranging sensor at the end position of the rail, and the first walking mechanism,the lifting mechanism and the laser ranging sensor are all in signal connection with the electrical control system. The overall framework of the equipment is suitable for large-range material carrying, the operation area is wider, the walking distance is not limited, the maximum span is more than 20 m, the maximum load is more than or equal to 50 t, and the equipment carrying precision is smallerthan or equal to + / -5 mm.

Owner:湖南天桥嘉成智能科技有限公司

Full-automatic molding production line for decorative gypsum board

InactiveCN102241052ATo achieve synchronous operationSolve the technical problems of air bubble removalMixing operation control apparatusCeramic shaping apparatusProduction lineSlurry

The invention discloses a full-automatic molding production line for a decorative gypsum board. The full-automatic molding production line comprises a gypsum powder mixing stirrer, a gypsum powder belt conveyor, an automatic gypsum slurry stirrer, a slope type vibration platform, a double-frequency low-amplitude rolling molding platform, a linear conveying platform and a right-angle steering device which are arranged in sequence and integrally form a closed automatic production line. The full-automatic molding production line for the decorative gypsum board can be used for finishing the production of the decorative gypsum board without the participation of manual work. The temperature deflection and the water absorption of the produced gypsum board are greatly reduced.

Owner:平江县天元建材科技有限公司

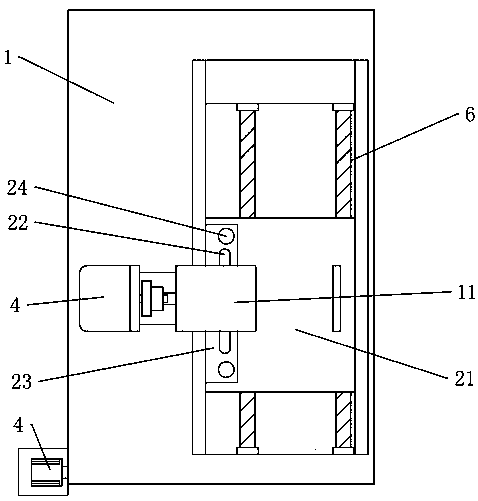

Special three-hole and double-thread punching and threading all-in-one machine for archives room

The invention discloses a special three-hole and double-thread punching and threading all-in-one machine for an archives room. The special three-hole and double-thread punching and threading all-in-one machine comprises a rack, and a stand column is arranged on the rack. A punching mechanism moving up and down is movably arranged on the stand column, and a driving device dynamically connected withthe punching mechanism is arranged on the stand column. A movable positioning clamping plate moving back and forth is correspondingly arranged at the lower part of the punching mechanism, and a powermechanism dynamically connected with the movable positioning clamping plate is arranged on a rack. A switch of the power mechanism is arranged at the upper part of the punching mechanism, and the switch is turned on along with the rising of the punching mechanism and is turned off along with the falling of the punching mechanism. A rotating shuttle forming a lock stitch with the punching mechanism is arranged at the lower part of the rack, and the rotating shuttle is dynamically connected with the driving device. The special three-hole and double-thread punching and threading all-in-one machine is convenient in use, reduces the difficulty of operation, and achieves the technical effects of realizing punching and threading at one time and improving the binding quality.

Owner:LINQU POWER SUPPLY CO OF STATE GRID SHANDONG ELECTRIC POWER CO +1

Extensible type protective door

InactiveCN103541638ATo achieve synchronous operationBig spaceRadiation protectionPower-operated mechanismOperating theatresStructural engineering

The invention discloses an extensible type protective door. The extensible type protective door comprises the protective door, a door beam, slide rails, a lower rail, a power mechanism and the like and is characterized in that the protective door is provided with two or more door leaves; the slide rails which are arranged on the door beam are corresponding to the door leaves; the number of the slide rails is more than two; the extensible type protective door is also provided with moving devices for the door leaves; a protective cover is arranged on the upper portion of the last door leaf. The extensible type protective door has the advantages of achieving synchronous operation of the three leaves due to the fact that three identical automatic door beams are organically combined together; leaving large room (more than 3500) for a device moving area when the protective door is completely opened due to the fact that the three door leaves are completely superposed; effectively satisfying an operating room requirement for cleansing when the protective door is completely closed due to the fact that reliable leakproofness of the protective door can completely isolate two adjacent space; effectively blocking harmful radiation of an X-ray radiated from a CT (Computed Tomography) to adjacent areas.

Owner:JINAN DAHUA YITE ENVIRONMENTAL PROTECTION ENG

Photosensitive material plate output device capable of laying protective paper synchronously

PendingCN107031932AIncrease productivityReduce labor intensityIndividual articlesArticle deliveryEngineeringPaper sheet

The invention relates to a photosensitive material plate output device and a photosensitive material plate output device capable of laying protective paper synchronously. The photosensitive material plate output device comprises a rack, wherein a first conveying device of horizontally arranged photosensitive material plate monomers is arranged under the rack; a paper coiling roller is arranged on the rack; a second conveying device of paper is arranged under the coiling roller; a paper cutting knife is arranged on the second conveying device; an output end of the second conveying device is arranged on the first conveying device; the transferring direction of the second conveying device is obliquely arranged and is close to the upper surface of the first conveying device; the second conveying device is provided with second power for driving the second conveying device to move; a probe is arranged on the first conveying device; the cutting knife and the second power are connected with a control device; and the first conveying device and the second conveying device are connected with the control device and are arranged in a box. The photosensitive material plate output device capable of laying protective paper synchronously has the advantages of high production efficiency and low labor intensity.

Owner:CHANGGE HUIDA PHOTOSENSITIVE MATERIAL

Full-automatic intermittent-conveying and cutting machine for traditional Chinese medicine

ActiveCN106671154ATo achieve synchronous operationGuaranteed service lifeMetal working apparatusEngineeringMechanical engineering

The invention relates to a full-automatic intermittent-conveying and cutting machine for traditional Chinese medicine. The full-automatic intermittent-conveying and cutting machine comprises a rack device, a cutting device and an intermittent conveying device. The intermittent conveying device and the cutting device are installed in the rack device. The rack device comprises a rack, a vertical frame, a cross girder, a feeding groove, a discharging groove, a motor, a speed regulating box, bolts, a belt, a first belt wheel and a pin, wherein the rack, the vertical frame, the cross girder, the feeding groove and the discharging groove are welded and fixed into a whole. The motor and the speed regulating box are fixed into the rack through the bolts, and connected through the belt. The first belt wheel is fixed to the speed regulating box through the pin. The intermittent conveying device comprises an intermittent rotating assembly, a conveying belt assembly and a roller conveying assembly. The full-automatic intermittent-conveying and cutting machine is reasonable in structural design, the cutting device and the intermittent conveying device are tightly coupled, and the traditional Chinese medicine is conveyed and cut synchronously. In cutting application, through intermittent conveying of the traditional Chinese medicine, the cutting thickness for the traditional Chinese medicine can be regulated by controlling the conveying speed.

Owner:桐君堂药业有限公司

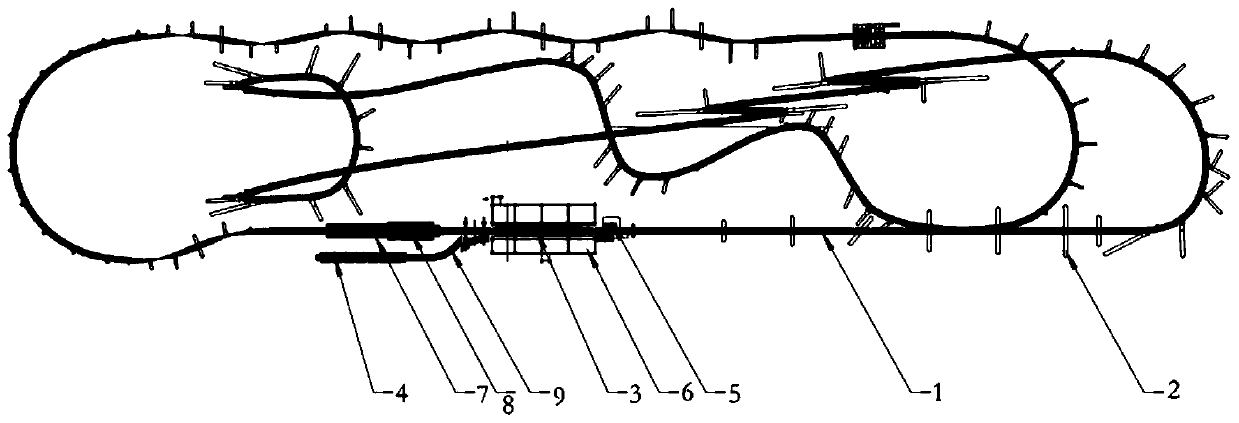

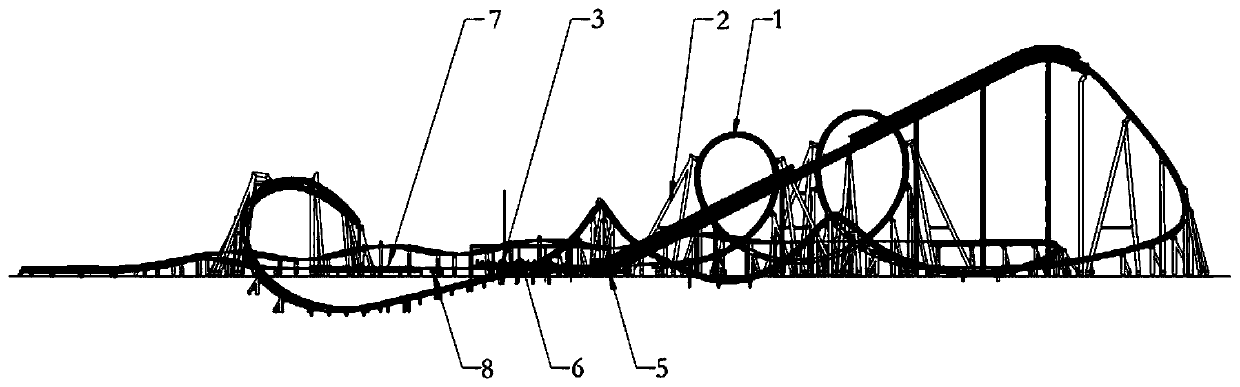

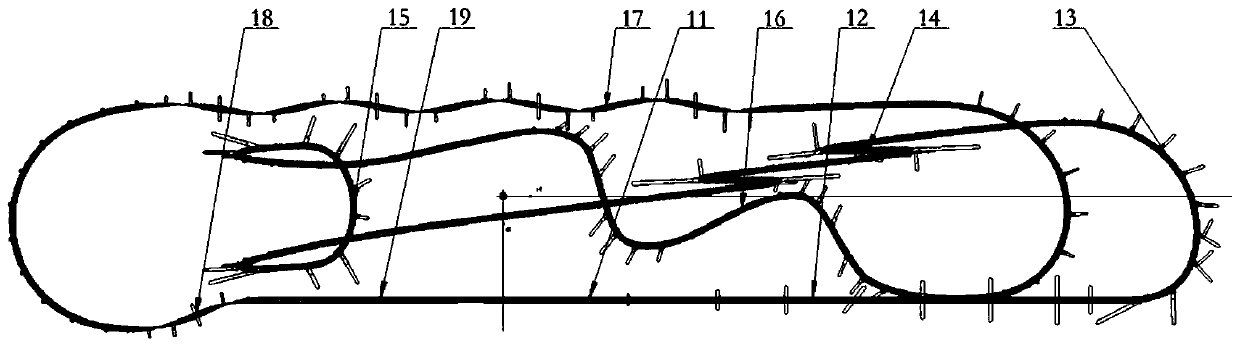

Tumbling type roller coaster device

ActiveCN109692481AIncrease profitTo achieve synchronous operationHelter-skeltersRoller coasterEngineering

The invention provides a tumbling type roller coaster device. The tumbling type roller coaster device comprises tracks, upright columns for supporting the tracks, a train running on the tracks, a traction device used for pulling the train to travel, a station allowing parking of the train and a driving device for driving, wherein the tracks comprise a continuous vertical ring track, a horse-shoe collar track and spiral tracks. The tracks comprise the continuous vertical ring track, the horse-shoe collar track, first spiral tracks, second spiral tracks and a third spiral track, by means of thecontinuous vertical ring track and the horse-shoe collar track, utilization of track space can be increased on the premise that the track rangeability is met, and the requirements for high change rateand fast train rate change can be met by track design through the tumbling form; correspondingly, a plurality of first spiral tracks and a plurality of second spiral tracks are distributed sequentially according to different helicity and different track lengths, so that the track change frequency can be further increased on the premise that the overall floor area of the track device is reduced.

Owner:北京中冶设备研究设计总院有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com