Copper electroplating groove inlet section and outlet section water blocking buffer apparatus

A buffer device and electroplating copper technology, applied in the electrolysis process, electrolytic components, etc., can solve the problems of damage to the electroplating substrate, failure to ensure that the water retaining device transmission mechanism is synchronized, and there is no water retaining device, etc., to achieve the effect of ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

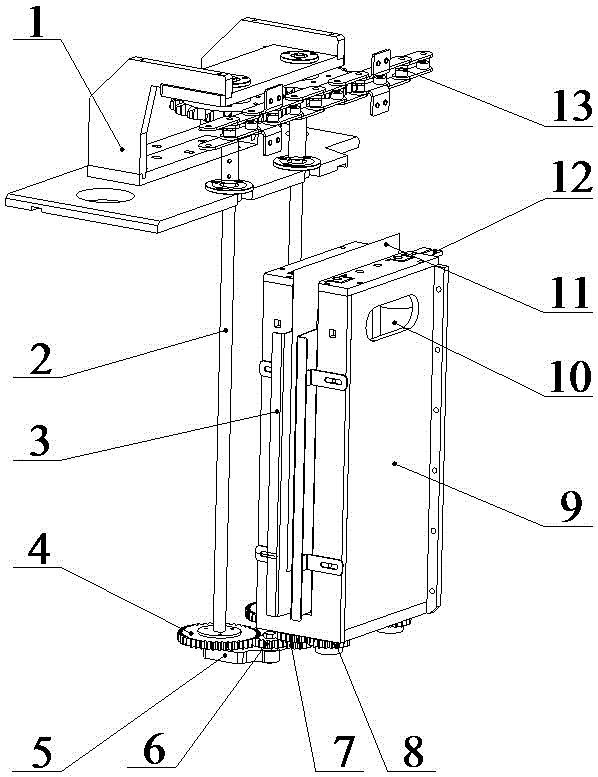

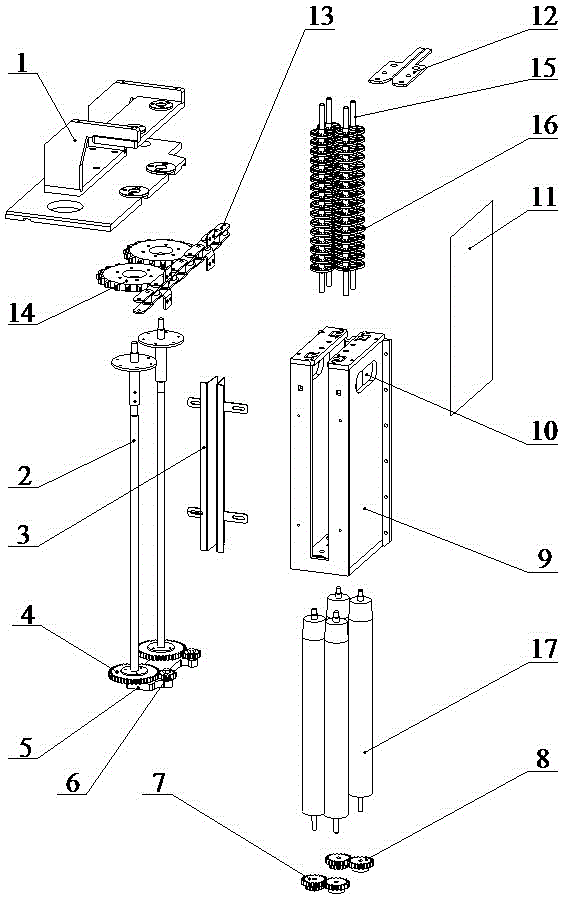

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0023] refer to figure 1 with figure 2 , a water retaining and buffering device for the import and export section of an electroplating copper tank, comprising a main transmission chain 13, a slave conveying device and a water retaining and buffering device, the slave conveying device comprising a fixed seat 1 on the slave transmission wheel, and a lower mount on the slave conveying wheel 5. From the transmission wheel shaft 2, the first from the transmission wheel 14, the second from the transmission wheel 4 and the third from the transmission wheel 6, the transmission wheel shaft 2 is arranged between the upper and lower fixed seats of the transmission wheel, and the first from the transmission wheel The transmission wheel 14 is rotatably connected to the upper end of the slave transmission wheel shaft 2, the second slave transmission wheel 4 is rotatably ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com