Special three-hole and double-thread punching and threading all-in-one machine for archives room

A technology of archives and all-in-one machine, applied in binding and other directions, can solve the problems of broken needles, complicated procedures, affecting the quality of binding, and achieve the effect of one-time improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

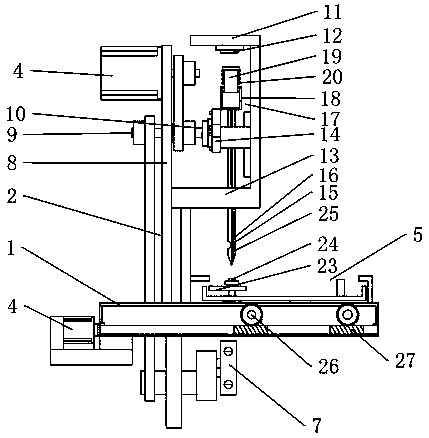

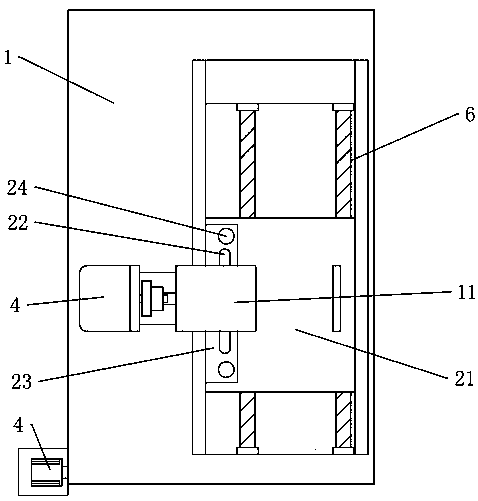

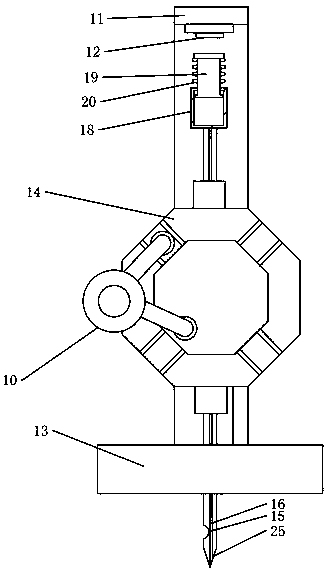

[0025] In the present invention, for the convenience of description, refer to figure 1 with figure 2 as shown, figure 1 The up and down direction is the up and down reciprocating direction of punching mechanism 3, figure 1 The left and right direction is the left and right direction of the column 2, figure 2 The up and down direction of the movable positioning splint 5 is the forward and backward reciprocating direction; refer to Figure 1-3 As shown, the three-hole double-wire punching and threading all-in-one machine for archives includes a frame 1, on which a column 2 is arranged, and the column 2 includes a base and two parallel poles 8 fixedly installed on the base. , the drive device is installed on the pole 8 on the left side of the base, the mounting seat 11 is installed on the pole 8 on the right side of the base, and the push-type reset switch 12 is installed on the lower part of the mounting seat 11, and the two poles 8 are inserted between The transmission ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com